Magnetic Properties and Microstructure of FeCoNi(CuAl)0.8Snx (0 ≤ x ≤ 0.10) High-Entropy Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. X-ray Diffraction

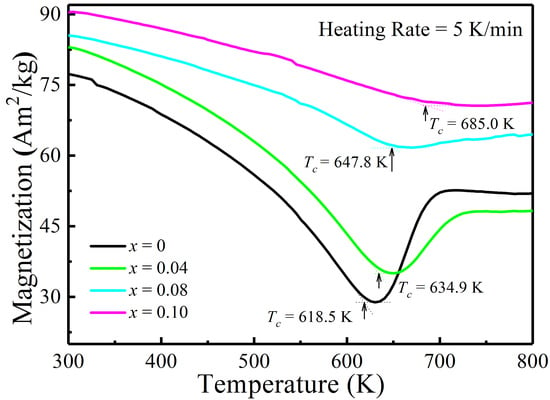

3.2. Magnetic Properties

3.3. Microstructure

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Murty, B.S.; Yeh, J.W.; Ranganathan, S. High-Entropy Alloys; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Wei, R.; Sun, H.; Chen, C.; Tao, J.; Li, F. Formation of soft magnetic high entropy amorphous alloys composites containing in situ solid solution phase. J. Magn. Magn. Mater. 2018, 449, 63–67. [Google Scholar] [CrossRef]

- Xu, J.; Axinte, E.; Zhao, Z.F.; Wang, Y. Effect of C and Ce addition on the microstructure and magnetic property of the mechanically alloyed FeSiBAlNi high entropy alloys. J. Magn. Magn. Mater. 2016, 414, 59–68. [Google Scholar] [CrossRef]

- Lin, C.M.; Juan, C.C.; Chang, C.H.; Tsai, C.W.; Yeh, J.W. Effect of Al addition on mechanical properties and microstructure of refractory AlxHfNbTaTiZr alloys. J. Alloys Compd. 2015, 624, 100–107. [Google Scholar] [CrossRef]

- Borkar, T.; Chaudhary, V.; Gwalani, B.; Choudhuri, D.; Mikler, C.V.; Soni, V.; Alam, T.V.; Ramanujan, R.; Banerjee, R. A combinatorial approach for assessing the magnetic properties of high entropy alloys: Role of Cr in AlCoxCr1−xFeNi. Adv. Eng. Mater. 2017, 19, 1700048. [Google Scholar] [CrossRef]

- Xu, X.D.; Liu, P.; Guo, S.; Hirata, A.; Fujita, T.; Nieh, T.G.; Liu, C.T.; Chen, M.W. Nanoscale phase separation in a fcc-based CoCrCuFeNiAl0.5 high-entropy alloy. Acta Mater. 2015, 84, 145–152. [Google Scholar] [CrossRef]

- Tsai, M.H.; Yuan, H.; Cheng, G.; Xu, W.; Tsai, K.Y.; Tsai, C.W.; Jian, W.W.; Juan, C.C.; Shen, W.J.; Chuang, M.H.; et al. Morphology, structure and composition of precipitates in Al0.3CoCrCu0.5FeNi high-entropy alloy. Intermetallics 2013, 32, 329–336. [Google Scholar] [CrossRef]

- Li, R.; Niu, P.; Yuan, T.; Cao, P.; Chen, C.; Zhou, K. Selective laser melting of an equiatomic CoCrFeMnNi high-entropy alloy: Processability, non-equilibrium microstructure and mechanical property. J. Alloys Compd. 2018, 746, 125–134. [Google Scholar] [CrossRef]

- Wang, W.R.; Wang, W.L.; Wang, S.C.; Tsai, Y.C.; Lai, C.H.; Yeh, J.W. Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 2012, 26, 44–51. [Google Scholar] [CrossRef]

- Chou, H.P.; Chang, Y.S.; Chen, S.K.; Yeh, J.W. Microstructure, thermophysical and electrical properties in AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys. Mater. Sci. Eng. B 2009, 163, 184–189. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Gao, M.M.C.; Yeh, J.W.; Liaw, P.K.; Zhang, Y. High-Entropy Alloys: Fundamentals and Applications, 1st ed.; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Lim, X.Z. Metal mixology stronger, tougher, stretchier: With a simple new recipe, metallurgists are creating a generation of alloys with remarkable properties. Nature 2016, 533, 306–307. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zuo, T.T.; Cheng, Y.Q.; Liaw, P.K. High-entropy alloys with high saturation magnetization, electrical resistivity, and malleability. Sci. Rep. 2013, 3, 1455. [Google Scholar] [CrossRef] [PubMed]

- Zaddach, A.J.; Niu, C.; Oni, A.A.; Fan, M.; LeBeau, J.M.; Irving, D.L.; Koch, C.C. Structure and magnetic properties of a multi-principal element Ni–Fe–Cr–Co–Zn–Mn alloy. Intermetallics 2016, 68, 107–112. [Google Scholar] [CrossRef] [Green Version]

- Cheng, H.; Liu, X.; Tang, Q.; Wang, W.; Yan, X.; Dai, P. Microstructure and mechanical properties of FeCoCrNiMnAlx high-entropy alloys prepared by mechanical alloying and hot-pressed sintering. J. Alloys Compd. 2019, 775, 742–751. [Google Scholar] [CrossRef]

- Alijani, F.; Reihanian, M.; Gheisari, K. Study on phase formation in magnetic FeCoNiMnV high entropy alloy produced by mechanical alloying. J. Alloys Compd. 2019, 773, 623–630. [Google Scholar] [CrossRef]

- Kilmametov, A.; Kulagin, R.; Mazilkin, A.; Seils, S.; Boll, T.; Heilmaier, M.; Hahn, H. High-pressure torsion driven mechanical alloying of CoCrFeMnNi high entropy alloy. Scripta Mater. 2019, 158, 29–33. [Google Scholar] [CrossRef]

- Gao, M.C.; Miracle, D.B.; Maurice, D.; Yan, X.; Zhang, Y.; Hawk, J.A. High-entropy functional materials. J. Mater. Res. 2018, 33, 3138–3155. [Google Scholar] [CrossRef]

- Li, P.P.; Wang, A.D.; Liu, C.T. Composition dependence of structure, physical and mechanical properties of FeCoNi(MnAl)x high entropy alloys. Intermetallics 2017, 87, 21–26. [Google Scholar] [CrossRef]

- Li, P.P.; Wang, A.D.; Liu, C.T. A ductile high entropy alloy with attractive magnetic properties. J. Alloys Compd. 2017, 694, 55–60. [Google Scholar] [CrossRef]

- Shang, C.; Axinte, E.; Ge, W.; Zhang, Z.; Wang, Y. High-entropy alloy coatings with excellent mechanical, corrosion resistance and magnetic properties prepared by mechanical alloying and hot pressing sintering. Surf. Interfaces 2017, 9, 36–43. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, H.; Tan, X.H.; Hou, X.L.; Wu, S.W.; Tan, G.S.; Yu, L.Y. The effects of phase constitution on magnetic and mechanical properties of FeCoNi(CuAl)x (x = 0−1.2) high-entropy alloys. J. Alloys Compd. 2017, 693, 1061–1067. [Google Scholar] [CrossRef]

- Li, Z.; Xu, H.; Gu, Y.; Pan, M.X.; Yu, L.Y.; Tan, X.H.; Hou, X.L. Correlation between the magnetic properties and phase constitution of FeCoNi(CuAl)0.8Gax(0 ≤ x ≤ 0.08) high-entropy alloys. J. Alloys Compd. 2018, 746, 285–291. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, J.B.; Zhang, C.; Li, J.C.; Jiang, Q. Microstructure and the properties of FeCoCuNiSnx high entropy alloys. Mater. Sci. Eng. A 2012, 548, 64–68. [Google Scholar] [CrossRef]

- Zuo, T.; Gao, M.C.; Ouyang, L.; Yang, X.; Cheng, Y.; Feng, R.; Chen, S.; Liaw, P.K.; Hawk, J.A.; Zhang, Y. Tailoring magnetic behavior of CoFeMnNiX (X = Al, Cr, Ga, and Sn) high entropy alloys by metal doping. Acta Mater. 2017, 130, 10–18. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Dean, J.A. Lange’s Handbook of Chemistry; McGraw-Hill Inc.: New York, NY, USA, 1999. [Google Scholar]

| x | I(110)BCC/I(111)FCC | aFCC (nm) | aBCC (nm) |

|---|---|---|---|

| 0 | 0.38 | 0.3588 | 0.2856 |

| 0.02 | 0.69 | 0.3634 | 0.2891 |

| 0.04 | 1.11 | 0.3642 | 0.2894 |

| 0.06 | 1.81 | 0.3614 | 0.2876 |

| 0.08 | 2.40 | 0.3612 | 0.2879 |

| 0.10 | 10.53 | 0.3616 | 0.2876 |

| x | Ms (Am2/kg) | Br (mT) | Hc (A/m) | Pu (J/m3) | μm | μi |

|---|---|---|---|---|---|---|

| 0 | 78.6 | 179.5 | 362.0 | 558.6 | 254.3 | 124.8 |

| 0.02 | 80.6 | 164.5 | 404.5 | 738.2 | 193.6 | 103.9 |

| 0.04 | 82.2 | 145.9 | 529.8 | 947.4 | 135.4 | 100.9 |

| 0.06 | 84.4 | 114.2 | 580.7 | 988.5 | 96.15 | 62.44 |

| 0.08 | 86.1 | 115.4 | 685.0 | 1275 | 87.69 | 65.55 |

| 0.10 | 88.8 | 119.5 | 1020 | 1848 | 60.86 | 50.94 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Wang, C.; Yu, L.; Gu, Y.; Pan, M.; Tan, X.; Xu, H. Magnetic Properties and Microstructure of FeCoNi(CuAl)0.8Snx (0 ≤ x ≤ 0.10) High-Entropy Alloys. Entropy 2018, 20, 872. https://0-doi-org.brum.beds.ac.uk/10.3390/e20110872

Li Z, Wang C, Yu L, Gu Y, Pan M, Tan X, Xu H. Magnetic Properties and Microstructure of FeCoNi(CuAl)0.8Snx (0 ≤ x ≤ 0.10) High-Entropy Alloys. Entropy. 2018; 20(11):872. https://0-doi-org.brum.beds.ac.uk/10.3390/e20110872

Chicago/Turabian StyleLi, Zhong, Chenxu Wang, Linye Yu, Yong Gu, Minxiang Pan, Xiaohua Tan, and Hui Xu. 2018. "Magnetic Properties and Microstructure of FeCoNi(CuAl)0.8Snx (0 ≤ x ≤ 0.10) High-Entropy Alloys" Entropy 20, no. 11: 872. https://0-doi-org.brum.beds.ac.uk/10.3390/e20110872