On the Evidence of Thermodynamic Self-Organization during Fatigue: A Review

Abstract

:1. Introduction

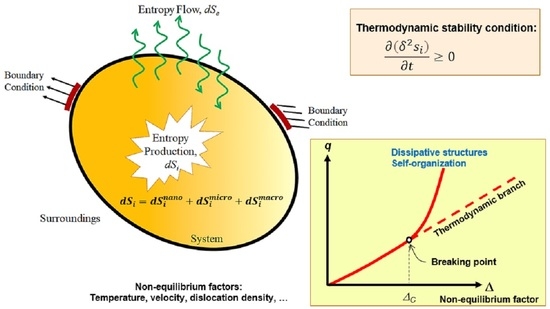

2. Theoretical Overview of Irreversible Thermodynamics and Entropy

2.1. Linear Non-Equilibrium Region; Near Equilibrium

2.2. Non-Linear Non-Equilibrium Region; Far from Equilibrium

3. Self-Organization Evidence during Fatigue

3.1. Self-Organization and PSBs Formation

3.2. Self-Organization and Stored Energy Concept

3.3. Self-Organization Evidence in Acoustic Signals and Thermography

3.3.1. Self-Heating and Thermography

3.3.2. Acoustic Emission

3.3.3. Self-Organization through External Elements during Fatigue

4. Discussion on the Stability of Self-Organized Structures

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Walgraef, D. Spatio-Temporal Pattern Formation: With Examples from Physics, Chemistry, and Materials Science; Springer Science & Business Media: New York, NY, USA, 2012. [Google Scholar]

- Kondepudi, D.; Prigogine, I. Modern Thermodynamics: From Heat Engines to Dissipative Structures, 2nd ed.; Wiley & Sons: Chichester, UK; Hoboken, NJ, USA, 2015. [Google Scholar]

- Ghoniem, N.; Walgraef, D. Instabilities and Self-Organization in Materials; Oxford University Press: Oxford, UK, 2008. [Google Scholar]

- Nicolis, G.; Prigogine, I. Self-Organization in Nonequilibrium Systems: From Dissipative Structures to Order through Fluctuations; John Wiley and Son: New York, NY, USA, 1977. [Google Scholar]

- Prigogine, I. Time, structure, and fluctuations. Science 1978, 201, 777–785. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Prigogine, I.; Stengers, I. Order Out of Chaos: Man’s New Dialogue with Nature; Verso Books: London, UK, 2018. [Google Scholar]

- Prigogine, I. Introduction to Thermodynamics of Irreversible Processes; Interscience Publishers: New York, NY, USA, 1961; Volume 7. [Google Scholar]

- Haken, H. Synergetics. Phys. Bull. 1977, 28, 412. [Google Scholar] [CrossRef]

- Bak, P.; Tang, C.; Wiesenfeld, K. Self-organized criticality: An explanation of 1/f noise. Phys. Rev. Lett. 1987, 59, 381. [Google Scholar] [CrossRef] [PubMed]

- Yates, F. What Is Self-Organization? Princeton University Press: Princeton, NJ, USA, 1983. [Google Scholar]

- Ghoniem, N.; Tong, S.-H.; Singh, B.; Sun, L. On dislocation interaction with radiation-induced defect clusters and plastic flow localization in fcc metals. Philos. Mag. A 2001, 81, 2743–2764. [Google Scholar] [CrossRef]

- Totten, G.E.; Fox-Rabinovich, G. Self-Organization during Friction: Advanced Surface-Engineered Materials and Systems Design; CRC Press: BocaRaton, FL, USA, 2006. [Google Scholar]

- Huo, W.; Fang, F.; Liu, X.; Tan, S.; Xie, Z.; Jiang, J. Fatigue resistance of nanotwinned high-entropy alloy films. Mater. Sci. Eng. A 2019, 739, 26–30. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Ritchie, R.O.; Meyers, M.A. Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog. Mater. Sci. 2019, 102, 296–345. [Google Scholar] [CrossRef]

- Pawlak, D.A.; Kolodziejak, K.; Turczynski, S.; Kisielewski, J.; Rożniatowski, K.; Diduszko, R.; Kaczkan, M.; Malinowski, M. Self-Organized, Rodlike, Micrometer-Scale Microstructure of Tb3Sc2Al3O12-TbScO3: Pr Eutectic. Chem. Mater. 2006, 18, 2450–2457. [Google Scholar] [CrossRef]

- Pawlak, D.A.; Turczynski, S.; Gajc, M.; Kolodziejak, K.; Diduszko, R.; Rozniatowski, K.; Smalc, J.; Vendik, I. How far are we from making metamaterials by self-organization? The microstructure of highly anisotropic particles with an SRR-like geometry. Adv. Funct. Mater. 2010, 20, 1116–1124. [Google Scholar] [CrossRef]

- Choudhury, A. Pattern-formation during self-organization in three-phase eutectic solidification. Trans. Indian Inst. Met. 2015, 68, 1137–1143. [Google Scholar] [CrossRef]

- Pawlak, D.; Lerondel, G.; Dmytruk, I.; Kagamitani, Y.; Durbin, S.; Royer, P.; Fukuda, T. Second order self-organized pattern of terbium-scandium-aluminum garnet and terbium-scandium perovskite eutectic. J. Appl. Phys. 2002, 91, 9731–9736. [Google Scholar] [CrossRef]

- Dennstedt, A.; Ratke, L.; Choudhury, A.; Nestler, B. New metallographic method for estimation of ordering and lattice parameter in ternary eutectic systems. Metallogr. Microstruct. Anal. 2013, 2, 140–147. [Google Scholar] [CrossRef] [Green Version]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Huang, E.-W.; Yu, D.; Yeh, J.-W.; Lee, C.; An, K.; Tu, S.-Y. A study of lattice elasticity from low entropy metals to medium and high entropy alloys. Scr. Mater. 2015, 101, 32–35. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Zhao, S.; Alotaibi, S.M.; Liu, Y.; Wang, B.; Meyers, M.A. Adiabatic shear localization in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2018, 151, 424–431. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Tang, Z.; Yuan, T.; Tsai, C.-W.; Yeh, J.-W.; Lundin, C.D.; Liaw, P.K. Fatigue behavior of a wrought Al0.5CoCrCuFeNi two-phase high-entropy alloy. Acta Mater. 2015, 99, 247–258. [Google Scholar] [CrossRef]

- Hemphill, M.A.; Yuan, T.; Wang, G.; Yeh, J.; Tsai, C.; Chuang, A.; Liaw, P. Fatigue behavior of Al0.5CoCrCuFeNi high entropy alloys. Acta Mater. 2012, 60, 5723–5734. [Google Scholar] [CrossRef]

- Klamecki, B.E. A thermodynamic model of friction. Wear 1980, 63, 113–120. [Google Scholar] [CrossRef]

- Klamecki, B.E. An entropy-based model of plastic deformation energy dissipation in sliding. Wear 1984, 96, 319–329. [Google Scholar] [CrossRef]

- Kostetsky, B. Structural-energetic adaptation of materials at friction. J. Frict. Wear 1985, 6, 201. [Google Scholar]

- Kostetskii, B. Evolution of structural and phase state and mechanism of self-organization in materials at external friction. J. Frict. Wear C/C Trenie I Iznos 1993, 14, 120. [Google Scholar]

- Bershadsky, L.; Iosebidze, D.; Kutelia, E. Tribosynthesis of graphite-diamond films and its employment for obtaining structurally adaptive coatings. Thin Solid Films 1991, 204, 275–283. [Google Scholar] [CrossRef]

- Bershadsky, L. On self-organizing and concept of tribosystem self-organizing. J. Frict. Wear 1992, 13, 101–114. [Google Scholar]

- Bushe, N.; Kopitko, V. Compatibility of Rubbing Surfaces; Science: Moscow, Russia, 1981. [Google Scholar]

- Gershman, I.; Bushe, N. Thermodynamic aspects of the existence of stable secondary structures on surfaces of sliding contacts at high current. J. Frict. Wear 1989, 10, 24–29. [Google Scholar]

- Gershman, I.S.; Bushe, N.A. Elements of thermodynamics and self-organization during friction. Mater. Eng. N. Y. 2007, 31, 13. [Google Scholar]

- Fox-Rabinovich, G.; Gershman, I.; Yamamoto, K.; Biksa, A.; Veldhuis, S.; Beake, B.; Kovalev, A. Self-organization during friction in complex surface engineered tribosystems. Entropy 2010, 12, 275–288. [Google Scholar] [CrossRef]

- Amiri, M.; Khonsari, M.M. On the thermodynamics of friction and wear—A review. Entropy 2010, 12, 1021–1049. [Google Scholar] [CrossRef] [Green Version]

- Mortazavi, V. Modeling of Instabilities and Self-organization at the Frictional Interface. Ph.D. Thesis, University of Wisconsin-Milwaukee, Milwaukee, WI, USA, 2014. [Google Scholar]

- Gershman, I.; Gershman, E.; Mironov, A.; Fox-Rabinovich, G.; Veldhuis, S. Application of the self-organization phenomenon in the development of wear resistant materials—A Review. Entropy 2016, 18, 385. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Amano, R.; Lucci, J.M.; Rohatgi, P.K. Physical chemistry of self-organization and self-healing in metals. Phys. Chem. Chem. Phys. 2009, 11, 9530–9536. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Bhushan, B. Thermodynamics of surface degradation, self-organization and self-healing for biomimetic surfaces. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2009, 367, 1607–1627. [Google Scholar] [CrossRef] [PubMed]

- Fox-Rabinovich, G.; Kovalev, A.; Shuster, L.S.; Bokiy, Y.F.; Dosbayeva, G.; Wainstein, D.; Mishina, V. Characteristic features of alloying HSS-based deformed compound powder materials with consideration for tool self-organization at cutting: 1. Characteristic features of wear in HSS-based deformed compound powder materials at cutting. Wear 1997, 206, 214–220. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Kovalev, A.; Shuster, L.S.; Bokiy, Y.F.; Dosbayeva, G.; Wainstein, D.; Mishina, V. On characteristics features of alloying HSS-based deformed compound powder materials with consideration for tool self-organization at cutting 2. Cutting tool friction control due to the alloying of the HSS-based deformed compound powder material. Wear 1998, 214, 279–286. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Veldhuis, S.; Kovalev, A.; Wainstein, D.; Gershman, I.; Korshunov, S.; Shuster, L.; Endrino, J. Features of self-organization in ion modified nanocrystalline plasma vapor deposited AlTiN coatings under severe tribological conditions. J. Appl. Phys. 2007, 102, 074305. [Google Scholar] [CrossRef]

- Kovalev, A.; Wainstein, D.; Fox-Rabinovich, G.; Veldhuis, S.; Yamamoto, K. Features of self-organization in nanostructuring PVD coatings on a base of polyvalent metal nitrides under severe tribological conditions. Surf. Interface Anal. Int. J. Devot. Dev. Appl. Tech. Anal. Surf. Interfaces Thin Films 2008, 40, 881–884. [Google Scholar] [CrossRef]

- Gershman, J.; Bushe, N. Thin films and self-organization during friction under the current collection conditions. Surf. Coat. Technol. 2004, 186, 405–411. [Google Scholar] [CrossRef]

- Klimontovich, Y.L. Introduction to the Physics of Open Systems; Yanus: Moscow, Russia, 2002. [Google Scholar]

- Fox-Rabinovich, G.; Yamamoto, K.; Beake, B.; Kovalev, A.; Aguirre, M.; Veldhuis, S.; Dosbaeva, G.; Wainstein, D.; Biksa, A.; Rashkovskiy, A. Emergent behavior of nano-multilayered coatings during dry high-speed machining of hardened tool steels. Surf. Coat. Technol. 2010, 204, 3425–3435. [Google Scholar] [CrossRef]

- Gershman, I.; Mironov, A.; Veldhuis, S.; Gershman, E.I.; Podrabinnik, P.; Kuznetsova, E. Influence of the Nonequilibrium Material State on Wear Resistance. Lubricants 2019, 7, 53. [Google Scholar] [CrossRef] [Green Version]

- Yurov, V.; Kubich, V. Some questions of self-organization tribological systems containing thin layers of grease. Eurasian Phys. Tech. J. 2015, 12, 23–27. [Google Scholar]

- Nosonovsky, M. Self-organization at the frictional interface for green tribology. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 4755–4774. [Google Scholar] [CrossRef]

- Gershman, J.; Bushe, N.; Mironov, A. Self-organizing at friction and development of wearproof materials. In Proceedings of the World Tribology Congress III, Washington, DC, USA, 12–16 September 2005; pp. 137–138. [Google Scholar]

- Ren, F.; Arshad, S.; Bellon, P.; Averback, R.S.; Pouryazdan, M.; Hahn, H. Sliding wear-induced chemical nanolayering in Cu–Ag, and its implications for high wear resistance. Acta Mater. 2014, 72, 148–158. [Google Scholar] [CrossRef]

- Ren, F.; Bellon, P.; Averback, R.S. Nanoscale self-organization reaction in Cu–Ag alloys subjected to dry sliding and its impact on wear resistance. Tribol. Int. 2016, 100, 420–429. [Google Scholar] [CrossRef] [Green Version]

- Frost, F.; Ziberi, B.; Schindler, A.; Rauschenbach, B. Surface engineering with ion beams: From self-organized nanostructures to ultra-smooth surfaces. Appl. Phys. A 2008, 91, 551–559. [Google Scholar] [CrossRef]

- Bhushan, B.; Jung, Y.C.; Koch, K. Micro-, nano-and hierarchical structures for superhydrophobicity, self-cleaning and low adhesion. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2009, 367, 1631–1672. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Weatherly, G.; Dodonov, A.; Kovalev, A.; Shuster, L.; Veldhuis, S.; Dosbaeva, G.; Wainstein, D.; Migranov, M. Nano-crystalline filtered arc deposited (FAD) TiAlN PVD coatings for high-speed machining applications. Surf. Coat. Technol. 2004, 177, 800–811. [Google Scholar] [CrossRef]

- Cai, W.; Bellon, P. Microstructural self-organization triggered by twin boundaries during dry sliding wear. Acta Mater. 2012, 60, 6673–6684. [Google Scholar] [CrossRef]

- Pan, S.; Zhao, C.; Wei, P.; Ren, F. Sliding wear of CoCrNi medium-entropy alloy at elevated temperatures: Wear mechanism transition and subsurface microstructure evolution. Wear 2019, 440, 203108. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Mortazavi, V. Friction-Induced Vibrations and Self-Organization: Mechanics and Non-Equilibrium Thermodynamics of Sliding Contact; CRC Press: BocaRaton, FL, USA, 2013. [Google Scholar]

- Yamaguchi, D.; Yuasa, T.; Sone, T.; Tominaga, T.; Noda, Y.; Koizumi, S.; Hashimoto, T. Hierarchically self-organized dissipative structures of filler particles in poly (styrene-ran-butadiene) rubbers. Macromolecules 2017, 50, 7739–7759. [Google Scholar] [CrossRef]

- Hashimoto, T.; Amino, N.; Nishitsuji, S.; Takenaka, M. Hierarchically self-organized filler particles in polymers: Cascade evolution of dissipative structures to ordered structures. Polym. J. 2019, 51, 109–130. [Google Scholar] [CrossRef]

- Koga, T.; Hashimoto, T.; Takenaka, M.; Aizawa, K.; Amino, N.; Nakamura, M.; Yamaguchi, D.; Koizumi, S. New insight into hierarchical structures of carbon black dispersed in polymer matrices: A combined small-angle scattering study. Macromolecules 2008, 41, 453–464. [Google Scholar] [CrossRef]

- Hashimoto, T. Combined small-angle scattering analysis of hierarchically self-assembled soft matters: Unique “Sponge-Like” gel structure as an example of dissipative patterns formed in open non-equilibrium systems. Chin. J. Phys. 2012, 50, 171–192. [Google Scholar]

- Zhao, Y.; Saijo, K.; Takenaka, M.; Koizumi, S.; Hashimoto, T. Order-disorder transition of nanocomposites: Pd nanoparticles in polystyrene-block-polyisoprene microdomain templates. Macromolecules 2009, 42, 5272–5277. [Google Scholar] [CrossRef]

- Zhao, Y.; Saijo, K.; Hashimoto, T. Order-disorder transition of nanocomposites: Polystyrene-block-poly (methyl methacrylate) with palladium nanoparticles. Macromolecules 2013, 46, 957–970. [Google Scholar] [CrossRef]

- Wang, C.; Hashimoto, T. Self-organization in electrospun polymer solutions: From dissipative structures to ordered fiber structures through fluctuations. Macromolecules 2018, 51, 4502–4515. [Google Scholar] [CrossRef]

- Hashimoto, T.; Murase, H. Cascading time evolution of dissipative structures leading to unique crystalline textures. IUCrJ 2015, 2, 59–73. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Murase, H.; Jinnai, H.; Toriyama, T.; Hashimoto, T. Cascade self-organization of shish kebabs in fibers spun from polymer solutions: Crystalline fibrils bridging neighboring kebabs discovered by transmission electron microtomography. Macromolecules 2019, 52, 575–591. [Google Scholar] [CrossRef]

- Nakouzi, E.; Steinbock, O. Self-organization in precipitation reactions far from the equilibrium. Sci. Adv. 2016, 2, e1601144. [Google Scholar] [CrossRef] [Green Version]

- Ebeling, W.; Engel, A.; Feistel, R. Physik der Evolutionsprozesse; Akademie-Verlag: Berlin, Germany, 1990. [Google Scholar]

- Evans, J. Observations of a regular void array in high purity molybdenum irradiated with 2 MeV nitrogen ions. Nature 1971, 229, 403–404. [Google Scholar] [CrossRef]

- Jäger, W.; Ehrhart, P.; Schilling, W. Dislocation patterning under irradiation. In Solid State Phenomena; Trans Tech Publications Ltd.: Pfaffikon, Switzerland, 1988; pp. 279–294. [Google Scholar]

- Onsager, L. Reciprocal relations in irreversible processes. I. Phys. Rev. 1931, 37, 405. [Google Scholar] [CrossRef]

- Onsager, L. Reciprocal relations in irreversible processes. II. Phys. Rev. 1931, 38, 2265. [Google Scholar] [CrossRef] [Green Version]

- Amiri, M.; Droguett, E.L.; Iyyer, N.; Naderi, M. The second law of thermodynamics and degradation of materials. In Proceedings of the Safety and Reliability of Complex Engineered Systems, Zurich, Switzerland, 7–10 September 2015; pp. 7–10. [Google Scholar]

- Nosonovsky, M.; Esche, S. A paradox of decreasing entropy in multiscale Monte Carlo grain growth simulations. Entropy 2008, 10, 49–54. [Google Scholar] [CrossRef]

- Ostoja-Starzewski, M.; Malyarenko, A. Continuum mechanics beyond the second law of thermodynamics. Proc. R. Soc. A Math. Phys. Eng. Sci. 2014, 470, 20140531. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Sevick, E.M.; Mittag, E.; Searles, D.J.; Evans, D.J. Experimental demonstration of violations of the second law of thermodynamics for small systems and short time scales. Phys. Rev. Lett. 2002, 89, 050601. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Evans, D.J.; Cohen, E.G.; Morriss, G.P. Probability of second law violations in shearing steady states. Phys. Rev. Lett. 1993, 71, 2401. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Evans, D.J.; Searles, D.J. Equilibrium microstates which generate second law violating steady states. Phys. Rev. E 1994, 50, 1645. [Google Scholar] [CrossRef] [Green Version]

- Evans, D.J.; Searles, D.J. The fluctuation theorem. Adv. Phys. 2002, 51, 1529–1585. [Google Scholar] [CrossRef]

- Jarzynski, C. Equalities and inequalities: Irreversibility and the second law of thermodynamics at the nanoscale. Annu. Rev. Condens. Matter Phys. 2011, 2, 329–351. [Google Scholar] [CrossRef] [Green Version]

- Reid, J.C.; Brookes, S.J.; Evans, D.J.; Searles, D.J. The dissipation function: Its relationship to entropy production, theorems for nonequilibrium systems and observations on its extrema. In Beyond the Second Law; Springer: New York, NY, USA, 2014; pp. 31–47. [Google Scholar]

- Seifert, U. Stochastic thermodynamics, fluctuation theorems and molecular machines. Rep. Prog. Phys. 2012, 75, 126001. [Google Scholar] [CrossRef] [Green Version]

- Lebon, G.; Jou, D.; Casas-Vázquez, J. Understanding Non-Equilibrium Thermodynamics; Springer: Berlin/Heidelberg, Germany, 2008; Volume 295. [Google Scholar]

- Gyamati, I. Non-Equilibrium Thermodynamics. Field Theory and Variational Principkes; Springer: Berlin/Heidelberg, Germany, 1970. [Google Scholar]

- Kanth, V.K.; Bai, B.P.; Biswas, S. Wear mechanisms in a hypereutectic aluminium silicon alloy sliding against steel. Scr. Metall. Mater. 1990, 24, 267–271. [Google Scholar] [CrossRef]

- Glansdorff, P.; Prigogine, I. Thermodynamic Theory of Structure, Stability and Fluctuations; Wiley-Interscience: New York, NY, USA, 1971; Volume 306. [Google Scholar]

- Heylighen, F. The science of self-organization and adaptivity. Encycl. Life Support Syst. 2001, 5, 253–280. [Google Scholar]

- Klimontovich, Y.L. Is turbulent motion chaos or order? Is the hydrodynamic or the kinetic description of turbulent motion more natural? Phys. B Condens. Matter 1996, 228, 51–62. [Google Scholar] [CrossRef]

- Li, P.; Li, S.X.; Wang, Z.G.; Zhang, Z.F. Fundamental factors on formation mechanism of dislocation arrangements in cyclically deformed fcc single crystals. Prog. Mater. Sci. 2011, 56, 328–377. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Z.F. Physical origin of surface slip morphologies induced by regular self-organized dislocation patterns in fatigued copper single crystals. J. Appl. Phys. 2014, 115, 033504. [Google Scholar] [CrossRef]

- Meyers, M.A.; Nesterenko, V.F.; LaSalvia, J.C.; Xue, Q. Shear localization in dynamic deformation of materials: Microstructural evolution and self-organization. Mater. Sci. Eng. A 2001, 317, 204–225. [Google Scholar] [CrossRef]

- Trochidis, A.; Douka, E.; Polyzos, B. Formation and evolution of persistent slip bands in metals. J. Mech. Phys. Solids 2000, 48, 1761–1775. [Google Scholar] [CrossRef]

- Aifantis, E.C. On the dynamical origin of dislocation patterns. Mater. Sci. Eng. 1986, 81, 563–574. [Google Scholar] [CrossRef]

- Gregor, V.; Kratochvil, J. Self-organization approach to cyclic microplasticity: A model of a persistent slip band. Int. J. Plast. 1998, 14, 159–172. [Google Scholar] [CrossRef]

- Huang, E.W.; Barabash, R.I.; Clausen, B.; Liu, Y.-L.; Kai, J.-J.; Ice, G.E.; Woods, K.P.; Liaw, P.K. Fatigue-induced reversible/irreversible structural-transformations in a Ni-based superalloy. Int. J. Plast. 2010, 26, 1124–1137. [Google Scholar] [CrossRef]

- Kratochvıl, J. Self-organization model of localization of cyclic strain into PSBs and formation of dislocation wall structure. Mater. Sci. Eng. A 2001, 309, 331–335. [Google Scholar] [CrossRef]

- Kratochvil, J.; Saxlová, M. Dislocation pattern formation and strain hardening in solids. Phys. Scr. 1993, 1993, 399. [Google Scholar] [CrossRef]

- Kratochvíl, J.; Saxlová, M. On physical foundations of plasticity. Meccanica 1996, 31, 495–506. [Google Scholar] [CrossRef]

- Schiller, C.; Walgraef, D. Numerical simulation of persistent slip band formation. Acta Metall. 1988, 36, 563–574. [Google Scholar] [CrossRef]

- Walgraef, D.; Aifantis, E.C. Dislocation patterning in fatigued metals as a result of dynamical instabilities. J. Appl. Phys. 1985, 58, 688–691. [Google Scholar] [CrossRef]

- Mughrabi, H. The cyclic hardening and saturation behaviour of copper single crystals. Mater. Sci. Eng. 1978, 33, 207–223. [Google Scholar] [CrossRef]

- Winter, A.T. Nucleation of persistent slip bands in cyclically deformed copper crystals. Philos. Mag. A 1978, 37, 457–463. [Google Scholar] [CrossRef]

- Jin, N.Y. Formation of dislocation structures during cyclic deformation of FCC crystals—I. Formation of PSBs in crystals oriented for single-slip. Acta Metall. 1989, 37, 2055–2066. [Google Scholar] [CrossRef]

- Watt, D.P.; Embury, J.D.; Ham, R.K. The relation between surface and interior structures in low-amplitude fatigue. Philos. Mag. J. Theor. Exp. Appl. Phys. 1968, 17, 199–203. [Google Scholar] [CrossRef]

- Woods, P.J. An optical analysis of the dislocation structure in walls formed by fatigue. Philos. Mag. 1973, 28, 193–202. [Google Scholar] [CrossRef]

- Holzwarth, U.; Essmann, U. The evolution of persistent slip bands in copper single crystals. Appl. Phys. A 1993, 57, 131–141. [Google Scholar] [CrossRef]

- Dickson, J.I.; Boutin, J.; L’Espérance, G. An explanation of labyrinth walls in fatigued fcc metals. Acta Metall. 1986, 34, 1505–1514. [Google Scholar] [CrossRef]

- Laird, C.; Wang, Z.; Ma, B.T.; Chai, H.F. Low energy dislocation structures produced by cyclic softening. Mater. Sci. Eng. A 1989, 113, 245–257. [Google Scholar] [CrossRef]

- Lépinoux, J.; Kubin, L.P. Dislocation mechanisms and steady states in the cyclic deformation of facecentred cubic crystals. Philos. Mag. A 1986, 54, 631–649. [Google Scholar] [CrossRef]

- Mughrabi, H. Dislocations and Properties of Real Materials; Book No. 323; The Institute of Metals: London, UK, 1985; p. 244. [Google Scholar]

- Wang, R.; Mughrabi, H. Secondary cyclic hardening in fatigued copper monocrystals and polycrystals. Mater. Sci. Eng. 1984, 63, 147–163. [Google Scholar] [CrossRef]

- Li, P.; Li, S.X.; Wang, Z.G.; Zhang, Z.F. Unified factor controlling the dislocation evolution of fatigued face-centered cubic crystals. Acta Mater. 2017, 129, 98–111. [Google Scholar] [CrossRef]

- Glazov, M.V.; Laird, C. Size effects of dislocation patterning in fatigued metals. Acta Metall. Mater. 1995, 43, 2849–2857. [Google Scholar] [CrossRef]

- Winter, A.T. A model for the fatigue of copper at low plastic strain amplitudes. Philos. Mag. 1974, 30, 719–738. [Google Scholar] [CrossRef]

- Cheng, A.S.; Laird, C. Mechanisms of fatigue hardening in copper single crystals: The effects of strain amplitude and orientation. Mater. Sci. Eng. 1981, 51, 111–121. [Google Scholar] [CrossRef]

- Ananthakrishna, G. Current theoretical approaches to collective behavior of dislocations. Phys. Rep. 2007, 440, 113–259. [Google Scholar] [CrossRef]

- Gómez-García, D.; Devincre, B.; Kubin, L.P. Dislocation patterns and the similitude principle: 2.5 D mesoscale simulations. Phys. Rev. Lett. 2006, 96, 125503. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Z.F.; Li, X.W.; Li, S.X.; Wang, Z.G. Effect of orientation on the cyclic deformation behavior of silver single crystals: Comparison with the behavior of copper and nickel single crystals. Acta Mater. 2009, 57, 4845–4854. [Google Scholar] [CrossRef]

- Li, X.W.; Wang, Z.G.; Li, S.X. Influence of crystallographic orientation on cyclic strain-hardening behaviour of copper single crystals. Philos. Mag. Lett. 1999, 79, 869–875. [Google Scholar] [CrossRef]

- Li, X.W.; Wang, Z.G.; Li, S.X. Survey of plateau behaviour in the cyclic stress-strain curve of copper single crystals. Philos. Mag. Lett. 1999, 79, 715–719. [Google Scholar] [CrossRef]

- Li, P.; Li, S.X.; Wang, Z.G.; Zhang, Z.F. Formation mechanisms of cyclic saturation dislocation patterns in [0 0 1], [0 1 1] and [1¯ 1 1] copper single crystals. Acta Mater. 2010, 58, 3281–3294. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Z.F.; Li, S.X.; Wang, Z.G. Comparison of dislocation patterns in cyclically deformed fcc metals. Scr. Mater. 2008, 59, 730–733. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Z.F.; Li, S.X.; Wang, Z.G. Effect of orientations on cyclic deformation behavior of Ag and Cu single crystals: Cyclic stress-strain curve and slip morphology. Acta Mater. 2008, 56, 2212–2222. [Google Scholar] [CrossRef]

- Liu, R.; Zhang, Z.J.; Zhang, Z.F. The criteria for microstructure evolution of Cu and Cu-Al alloys induced by cyclic loading. Mater. Sci. Eng. A 2016, 666, 123–138. [Google Scholar] [CrossRef]

- Peralta, P.; Laird, C. Cyclic plasticity and dislocation structures. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Sauzay, M.; Kubin, L.P. Scaling laws for dislocation microstructures in monotonic and cyclic deformation of fcc metals. Prog. Mater. Sci. 2011, 56, 725–784. [Google Scholar] [CrossRef]

- Taylor, G.I.; Quinney, H. The latent energy remaining in a metal after cold working. Proc. R. Soc. Lond. Ser. A Contain. Pap. Math. Phys. Character 1934, 143, 307–326. [Google Scholar]

- Benzerga, A.A.; Brechet, Y.; Needleman, A.; Van der Giessen, E. The stored energy of cold work: Predictions from discrete dislocation plasticity. Acta Mater. 2005, 53, 4765–4779. [Google Scholar] [CrossRef] [Green Version]

- Chen, B.; Jiang, J.; Dunne, F.P.E. Is stored energy density the primary meso-scale mechanistic driver for fatigue crack nucleation? Int. J. Plast. 2018, 101, 213–229. [Google Scholar] [CrossRef]

- Seeger, A. Thermodynamics of open systems, self-organization, and crystal plasticity. In Strength of Metals and Alloys (ICSMA 8); Elsevier: Amsterdam, The Netherlands, 1989; pp. 463–468. [Google Scholar]

- Seeger, A. Evidence of enhanced self-organization in the work-hardening stage V of fcc metals. Philos. Mag. Lett. 2001, 81, 129–136. [Google Scholar] [CrossRef]

- Seeger, A.; Frank, W. Structure formation by dissipative processes in crystals with high defect densities. In Solid State Phenomena; Trans Tech Publications Ltd.: Pfaffikon, Switzerland, 1988; pp. 125–137. [Google Scholar]

- Stroh, A.N. A theoretical calculation of the stored energy in a work-hardened material. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1953, 218, 391–400. [Google Scholar]

- Wan, V.V.C.; Jiang, J.; MacLachlan, D.W.; Dunne, F.P.E. Microstructure-sensitive fatigue crack nucleation in a polycrystalline Ni superalloy. Int. J. Fatigue 2016, 90, 181–190. [Google Scholar] [CrossRef]

- Wan, V.V.C.; MacLachlan, D.W.; Dunne, F.P.E. A stored energy criterion for fatigue crack nucleation in polycrystals. Int. J. Fatigue 2014, 68, 90–102. [Google Scholar] [CrossRef]

- Zhang, T.; Jiang, J.; Britton, B.; Shollock, B.; Dunne, F. Crack nucleation using combined crystal plasticity modelling, high-resolution digital image correlation and high-resolution electron backscatter diffraction in a superalloy containing non-metallic inclusions under fatigue. Proc. R. Soc. A Math. Phys. Eng. Sci. 2016, 472, 20150792. [Google Scholar] [CrossRef]

- Zheng, Z.; Prastiti, N.G.; Balint, D.S.; Dunne, F.P.E. The dislocation configurational energy density in discrete dislocation plasticity. J. Mech. Phys. Solids 2019, 129, 39–60. [Google Scholar] [CrossRef]

- Hodowany, J.; Ravichandran, G.; Rosakis, A.; Rosakis, P. Partition of plastic work into heat and stored energy in metals. Exp. Mech. 2000, 40, 113–123. [Google Scholar] [CrossRef]

- Halford, G.R. Stored Energy of Cold Work Changes Induced by Cyclic Deformation. PhD Thesis, University of Illinois at Urbana-Champaign, Champaign, IL, USA, 1966. [Google Scholar]

- Titchener, A.L.; Bever, M.B. The stored energy of cold work. Prog. Met. Phys. 1958, 7, 247–338. [Google Scholar] [CrossRef]

- Adam, C.; Wolfenden, A. The influence of microstructure on the energy stored in deformed aluminium and aluminium alloys. Acta Metall. 1978, 26, 1307–1315. [Google Scholar] [CrossRef]

- Clarebrough, L.; Hargreaves, M.; West, G.; Head, A.K. The energy stored in fatigued metals. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1957, 242, 160–166. [Google Scholar]

- Chrysochoos, A.; Maisonneuve, O.; Martin, G.; Caumon, H.; Chezeaux, J. Plastic and dissipated work and stored energy. Nucl. Eng. Des. 1989, 114, 323–333. [Google Scholar] [CrossRef]

- Chrysochoos, A.; Wattrisse, B.; Muracciole, J.-M.; El Kaïm, Y. Fields of stored energy associated with localized necking of steel. J. Mech. Mater. Struct. 2009, 4, 245–262. [Google Scholar] [CrossRef] [Green Version]

- Rittel, D.; Wang, Z.; Merzer, M. Adiabatic shear failure and dynamic stored energy of cold work. Phys. Rev. Lett. 2006, 96, 075502. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wong, A.; Kirby, G., III. A hybrid numerical/experimental technique for determining the heat dissipated during low cycle fatigue. Eng. Fract. Mech. 1990, 37, 493–504. [Google Scholar] [CrossRef]

- Harvey, D.P., II; Bonenberger, R.J.; Wolla, J.M. Effects of sequential cyclic and monotonic loadings on damage accumulation in nickel 270. Int. J. Fatigue 1998, 20, 291–300. [Google Scholar] [CrossRef]

- Mughrabi, H. Cyclic plasticity of matrix and persistent slip bands in fatigued metals. In Continuum Models of Discrete Systems; North-Holland Publ. Co.: Amsterdam, The Netherlands, 1981. [Google Scholar]

- Steeds, J.W. Dislocation arrangement in copper single crystals as a function of strain. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1966, 292, 343–373. [Google Scholar]

- Mughbrabi, H.; Ackermann, F.U.; Herz, K. Persistent slipbands in fatigued face-centered and body-centered cubic metals. In Fatigue Mechanisms; ASTM International: West Conshohocken, PA, USA, 1979. [Google Scholar]

- Huang, E.-W.; Barabash, R.I.; Clausen, B.; Liaw, P.K. Cyclic-loading induced lattice-strain asymmetry in loading and transverse directions. Metall. Mater. Trans. A 2012, 43, 1454–1461. [Google Scholar] [CrossRef]

- Huang, E.W.; Chang, C.K.; Liaw, P.; Suei, T.R. Fatigue induced deformation and thermodynamics evolution in a nano particle strengthened nickel base superalloy. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 675–685. [Google Scholar] [CrossRef]

- Chen, L.; Liaw, P.; Wang, H.; He, Y.; McDaniels, R.; Jiang, L.; Yang, B.; Klarstrom, D. Cyclic deformation behavior of HAYNES® HR-120® superalloy under low-cycle fatigue loading. Mech. Mater. 2004, 36, 85–98. [Google Scholar] [CrossRef]

- Yang, B.; Liaw, P.; Morrison, M.; Liu, C.; Buchanan, R.; Huang, J.; Kuo, R.; Huang, J.; Fielden, D. Temperature evolution during fatigue damage. Intermetallics 2005, 13, 419–428. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, H.; Liaw, P.; Brooks, C.; Klarstrom, D. Temperature evolution during low-cycle fatigue of ULTIMET® alloy: Experiment and modeling. Mech. Mater. 2004, 36, 73–84. [Google Scholar] [CrossRef]

- Chrysochoos, A.; Berthel, B.; Latourte, F.; Galtier, A.; Pagano, S.; Wattrisse, B. Local energy analysis of high-cycle fatigue using digital image correlation and infrared thermography. J. Strain Anal. Eng. Des. 2008, 43, 411–422. [Google Scholar] [CrossRef]

- Chrysochoos, A.; Huon, V.; Jourdan, F.; Muracciole, J.M.; Peyroux, R.; Wattrisse, B. Use of full-field digital image correlation and infrared thermography measurements for the thermomechanical analysis of material behaviour. Strain 2010, 46, 117–130. [Google Scholar] [CrossRef]

- Wang, C.; Blanche, A.; Wagner, D.; Chrysochoos, A.; Bathias, C. Dissipative and microstructural effects associated with fatigue crack initiation on an Armco iron. Int. J. Fatigue 2014, 58, 152–157. [Google Scholar] [CrossRef] [Green Version]

- Kaleta, J.; Blotny, R.; Harig, H. Energy stored in a specimen under fatigue limit loading conditions. J. Test. Eval. 1991, 19, 326–333. [Google Scholar]

- Connesson, N.; Maquin, F.; Pierron, F. Dissipated energy measurements as a marker of microstructural evolution: 316L and DP600. Acta Mater. 2011, 59, 4100–4115. [Google Scholar] [CrossRef]

- Connesson, N.; Maquin, F.; Pierron, F. Experimental energy balance during the first cycles of cyclically loaded specimens under the conventional yield stress. Exp. Mech. 2011, 51, 23–44. [Google Scholar] [CrossRef]

- Maquin, F.; Pierron, F. Heat dissipation measurements in low stress cyclic loading of metallic materials: From internal friction to micro-plasticity. Mech. Mater. 2009, 41, 928–942. [Google Scholar] [CrossRef]

- Kamlah, M.; Haupt, P. On the macroscopic description of stored energy and self heating during plastic deformation. Int. J. Plast. 1997, 13, 893–911. [Google Scholar] [CrossRef]

- Granato, A.v.; Lücke, K. Theory of mechanical damping due to dislocations. J. Appl. Phys. 1956, 27, 583–593. [Google Scholar] [CrossRef]

- François, D.; Pineau, A.; Zaoui, A. Mechanical Behaviour of Materials; Springer: Dordrecht, The Netherlands, 1998. [Google Scholar]

- Ashby, M.F. Overview No. 80: On the engineering properties of materials. Acta Metall. 1989, 37, 1273–1293. [Google Scholar] [CrossRef]

- Huang, E.-W.; Barabash, R.I.; Wang, Y.; Clausen, B.; Li, L.; Liaw, P.K.; Ice, G.E.; Ren, Y.; Choo, H.; Pike, L.M. Plastic behavior of a nickel-based alloy under monotonic-tension and low-cycle-fatigue loading. Int. J. Plast. 2008, 24, 1440–1456. [Google Scholar] [CrossRef]

- Vinogradov, A.; Patlan, V.; Hashimoto, S. Spectral analysis of acoustic emission during cyclic deformation of copper single crystals. Philos. Mag. A 2001, 81, 1427–1446. [Google Scholar] [CrossRef]

- Vinogradov, A.; Yasnikov, I. On the nature of acoustic emission and internal friction during cyclic deformation of metals. Acta Mater. 2014, 70, 8–18. [Google Scholar] [CrossRef]

- Vinogradov, A.; Yasnikov, I.; Estrin, Y. Evolution of fractal structures in dislocation ensembles during plastic deformation. Phys. Rev. Lett. 2012, 108, 205504. [Google Scholar] [CrossRef] [PubMed]

- Vinogradov, A.; Yasnikov, I.; Estrin, Y. Stochastic dislocation kinetics and fractal structures in deforming metals probed by acoustic emission and surface topography measurements. J. Appl. Phys. 2014, 115, 233506. [Google Scholar] [CrossRef]

- Vinogradov, A.; Yasnikov, I.; Estrin, Y. Irreversible thermodynamics approach to plasticity: Dislocation density based constitutive modelling. Mater. Sci. Technol. 2015, 31, 1664–1672. [Google Scholar] [CrossRef]

- Vinogradov, A. Correlation between acoustic emission and internal friction in materials. In Advanced Materials Research; Trans. Tech. Publications Ltd.: Pfaffikon, Switzerland, 2006; pp. 313–322. [Google Scholar]

- Vinogradov, A.; Patlan, V.; Hashimoto, S.; Kitagawa, K. Acoustic emission during cyclic deformation of ultrafine-grain copper processed by severe plastic deformation. Philos. Mag. A 2002, 82, 317–335. [Google Scholar] [CrossRef]

- Vinogradov, A.; Yasnikov, I.; Merson, D. Phenomenological approach towards modelling the acoustic emission due to plastic deformation in metals. Scr. Mater. 2019, 170, 172–176. [Google Scholar] [CrossRef]

- Wadley, H.; Mehrabian, R. Acoustic emission for materials processing: A review. Mater. Sci. Eng. 1984, 65, 245–263. [Google Scholar] [CrossRef]

- Kabaldin, Y.G.; Murav’yev, S. Information models of self-organization and fatigue damage of metallic materials. Rus. Eng. Res. 2007, 27, 513–518. [Google Scholar] [CrossRef]

- Koslowski, M.; LeSar, R.; Thomson, R. Avalanches and scaling in plastic deformation. Phys. Rev. Lett. 2004, 93, 125502. [Google Scholar] [CrossRef] [PubMed]

- Zaiser, M. Scale invariance in plastic flow of crystalline solids. Adv. Phys. 2006, 55, 185–245. [Google Scholar] [CrossRef]

- Zaiser, M. Statistical modelling of dislocation systems. Mater. Sci. Eng. A 2001, 309, 304–315. [Google Scholar] [CrossRef]

- Kahirdeh, A.; Sauerbrunn, C.; Yun, H.; Modarres, M. A parametric approach to acoustic entropy estimation for assessment of fatigue damage. Int. J. Fatigue 2017, 100, 229–237. [Google Scholar] [CrossRef] [Green Version]

- Kahirdeh, A.; Khonsari, M.M. Acoustic entropy of the materials in the course of degradation. Entropy 2016, 18, 280. [Google Scholar] [CrossRef] [Green Version]

- Kahirdeh, A.; Khonsari, M. Energy dissipation in the course of the fatigue degradation: Mathematical derivation and experimental quantification. Int. J. Solids Struct. 2015, 77, 74–85. [Google Scholar] [CrossRef]

- Essmann, U.; Gösele, U.; Mughrabi, H. A model of extrusions and intrusions in fatigued metals I. Point-defect production and the growth of extrusions. Philos. Mag. A 1981, 44, 405–426. [Google Scholar] [CrossRef]

- Polák, J.; Helešic, J.; Obrtlík, K. Cyclic strain localization in copper single crystals and polycrystals. Scr. Metall. Mater. 1990, 24, 415–419. [Google Scholar] [CrossRef]

- Conrad, H.; White, J.; Cao, W.; Lu, X.; Sprecher, A. Effect of electric current pulses on fatigue characteristics of polycrystalline copper. Mater. Sci. Eng. A 1991, 145, 1–12. [Google Scholar] [CrossRef]

- Karpenko, G.; Kuzin, O.; Tkachev, V.; Rudenko, V. The effect of electric current on low-cycle fatigue of steel. Dokl. Akad. Nauk SSSR 1976, 227, 85–86. [Google Scholar]

- Bezborodko, L. Effect of alternating current on the strength of steel undergoing cyclic tensile-compressive and torsional loading. Strength Mater. 1984, 16, 267–270. [Google Scholar] [CrossRef]

- Zhao, Y.; Fang, H.; Fan, X. Slowing down metal fatigue damage with a magnetic field. Eng. Fract. Mech. 1993, 46, 347–352. [Google Scholar] [CrossRef]

- Bhat, I.; Muju, M.; Mazumdar, P. Possible effects of magnetic fields in fatigue. Int. J. Fatigue 1993, 15, 193–197. [Google Scholar] [CrossRef]

- Hayashi, S. Direct observation of the dislocation motion in ferromagnetic crystals under alternating magnetic fields. Jpn. J. Appl. Phys. 1973, 12, 182. [Google Scholar] [CrossRef]

- Çelik, A.; Yetim, A.F.; Alsaran, A.; Karakan, M. Effect of magnetic treatment on fatigue life of AISI 4140 steel. Mater. Des. 2005, 26, 700–704. [Google Scholar] [CrossRef]

- Fahmy, Y.; Hare, T.; Conrad, H.; Tooke, R. Effects of a pulsed magnetic treatment on the fatigue of low carbon steel. Scr. Mater. 1998, 38. [Google Scholar] [CrossRef]

- Jahmy, Y.; Hare, T.; Tooke, R. Effect of a pulsed magnetic treatment on the fatigue of low carbon steel. Scr. Mater. 1998, 38, 1355–1358. [Google Scholar]

- Zhang, H.-M.; Shang, D.-G.; Liu, X.-D.; Liu, Y.-N.; Zhang, Y. Effect of unconstraint vibration treatment on fatigue damage healing for copper film. Mater. Sci. Eng. A 2019, 138265. [Google Scholar] [CrossRef]

- Xiao, S.; Guo, J.; Li, S. The effect of electropulsing on dislocation structures in coplanar double-slip-oriented fatigued copper single crystals. Philos. Mag. Lett. 2002, 82, 617–622. [Google Scholar] [CrossRef]

- Xiao, S.; Guo, J.; Wu, S.; He, G.; Li, S. Recrystallization in fatigued copper single crystals under electropulsing. Scr. Mater. 2002, 46, 1–6. [Google Scholar] [CrossRef]

- Suhong, X.; Yizhou, Z.; Jingdong, G.; Shiding, W.; Ge, Y.; Shouxin, L.; Guanhu, H.; Benlian, Z. The effect of high current pulsing on persistent slip bands in fatigued copper single crystals. Mater. Sci. Eng. A 2002, 332, 351–355. [Google Scholar] [CrossRef]

- Tang, Y.; Hosoi, A.; Morita, Y.; Ju, Y. Restoration of fatigue damage in stainless steel by high-density electric current. Int. J. Fatigue 2013, 56, 69–74. [Google Scholar] [CrossRef]

- Lai, Z.; Ma, C.; Conrad, H. Cyclic softening by high density electric current pulses during low cycle fatigue of α-Ti. Scr. Metall. Mater. 1992, 27, 527–531. [Google Scholar] [CrossRef]

- Amiri, M.; Khonsari, M. Effect of surface cooling on fatigue life improvement. J. Fail. Anal. Prev. 2013, 13, 183–187. [Google Scholar] [CrossRef]

- Khonsari, M.M.; Amiri, M. Introduction to Thermodynamics of Mechanical Fatigue; CRC Press: BocaRaton, FL, USA, 2012. [Google Scholar]

- Kahirdeh, A.; Naderi, M.; Khonsari, M. On the role of cooling on fatigue failure of a woven glass/epoxy laminate. J. Compos. Mater. 2013, 47, 1803–1815. [Google Scholar] [CrossRef]

- Cao, W.d.; Conrad, H. On the effect of persistent slip band (PSB) parameters on fatigue life. Fatigue Fract. Eng. Mater. Struct. 1992, 15, 573–583. [Google Scholar] [CrossRef]

- TANG, Y. A Study on Restoration of Fatigue Damage in Stainless Steel by High-Density Pulse Current. Ph.D. Thesis, Nagoya University, Nagoya, Japan, 2013. [Google Scholar]

- Kuhlmann-Wilsdorf, D.; Laird, C. Dislocation behavior in fatigue. Mater. Sci. Eng. 1977, 27, 137–156. [Google Scholar] [CrossRef]

- Kuhlmann-Wilsdorf, D.; Laird, C. Dislocation behavior in fatigue V: Breakdown of loop patches and formation of persistent slip bands and of dislocation cells. Mater. Sci. Eng. 1980, 46, 209–219. [Google Scholar] [CrossRef]

- Mecke, K.; Blochwítz, C.; Kremling, V. The development of the dislocation structures during the fatigue process of FCC single crystals. Cryst. Res. Technol. 1982, 17, 1557–1570. [Google Scholar] [CrossRef]

- Tabata, T.; Fujita, H.; Hiraoka, M.-A.; Onishi, K. Dislocation behaviour and the formation of persistent slip bands in fatigued copper single crystals observed by high-voltage electron microscopy. Philos. Mag. A 1983, 47, 841–857. [Google Scholar] [CrossRef]

- Huang, M.; Rivera-Díaz-del-Castillo, P.; Bouaziz, O.; Van Der Zwaag, S. Irreversible thermodynamics modelling of plastic deformation of metals. Mater. Sci. Technol. 2008, 24, 495–500. [Google Scholar] [CrossRef]

- Huang, M. Modelling Plastic Deformation of Metals Using Irreversible Thermodynamics. Ph.D. Thesis, Technische Universiteit Delft, Delft, The Netherlands, 2008. [Google Scholar]

- Huang, M.; Castillo, P.R.D.d.; Van Der Zwaag, S. Modelling steady state deformation of fcc metals by non-equilibrium thermodynamics. Mater. Sci. Technol. 2007, 23, 1105–1108. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Estrin, Y.; Mecking, H. A unified phenomenological description of work hardening and creep based on one-parameter models. Acta Metall. 1984, 32, 57–70. [Google Scholar] [CrossRef]

- Kocks, U.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Bailey, J.; Hirsch, P. The dislocation distribution, flow stress, and stored energy in cold-worked polycrystalline silver. Philos. Mag. 1960, 5, 485–497. [Google Scholar] [CrossRef]

- Glazov, M.; Llanes, L.M.; Laird, C. Self-organized dislocation structures (SODS) in fatigued metals. Phys. Status Solidi A 1995, 149, 297–321. [Google Scholar] [CrossRef]

- Neumann, P. The interactions between dislocations and dislocation dipoles. Acta Metall. 1971, 19, 1233–1241. [Google Scholar] [CrossRef]

- Walgraef, D.; Aifantis, E.C. On the formation and stability of dislocation patterns—I: One-dimensional considerations. Int. J. Eng. Sci. 1985, 23, 1351–1358. [Google Scholar] [CrossRef]

- Walgraef, D.; Aifantis, E.C. On the formation and stability of dislocation patterns—II: Two-dimensional considerations. Int. J. Eng. Sci. 1985, 23, 1359–1364. [Google Scholar] [CrossRef]

- Kratochvil, J. Dislocation pattern formation in metals. Rev. Phys. Appl. 1988, 23, 419–429. [Google Scholar] [CrossRef]

- Saxlová, M.; Kratochvil, J.; Zatloukal, J. The model of formation and disintegration of vein dislocation structure. Mater. Sci. Eng. A 1997, 234, 205–208. [Google Scholar] [CrossRef]

- Pan, Q.; Zhou, H.; Lu, Q.; Gao, H.; Lu, L. History-independent cyclic response of nanotwinned metals. Nature 2017, 551, 214. [Google Scholar] [CrossRef] [PubMed]

- Bufford, D.C.; Wang, Y.M.; Liu, Y.; Lu, L. Synthesis and microstructure of electrodeposited and sputtered nanotwinned face-centered-cubic metals. MRS Bull. 2016, 41, 286–291. [Google Scholar] [CrossRef] [Green Version]

- Hodge, A.; Wang, Y.; Barbee Jr, T. Mechanical deformation of high-purity sputter-deposited nano-twinned copper. Scr. Mater. 2008, 59, 163–166. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; Chen, X.; Lu, L.; Lu, K.; Hoagland, R.; Misra, A. High-strength sputter-deposited Cu foils with preferred orientation of nanoscale growth twins. Appl. Phys. Lett. 2006, 88, 173116. [Google Scholar] [CrossRef] [Green Version]

- Takae, K.; Tanaka, H. Self-organization into ferroelectric and antiferroelectric crystals via the interplay between particle shape and dipolar interaction. Proc. Natl. Acad. Sci. USA 2018, 115, 9917–9922. [Google Scholar] [CrossRef] [Green Version]

- Naderi, M.; Amiri, M.; Khonsari, M.M. On the thermodynamic entropy of fatigue fracture. Proc. R. Soc. A Math. Phys. Eng. Sci. 2009, 466, 423–438. [Google Scholar] [CrossRef] [Green Version]

- Naderi, M.; Khonsari, M.M. On the role of damage energy in the fatigue degradation characterization of a composite laminate. Compos. Part B Eng. 2013, 45, 528–537. [Google Scholar] [CrossRef]

- Naderi, M.; Amiri, M.; Iyyer, N.; Kang, P.; Phan, N. Prediction of fatigue crack nucleation life in polycrystalline AA7075-T651 using energy approach. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 167–179. [Google Scholar] [CrossRef]

- Chen, B.; Jiang, J.; Dunne, F.P. Microstructurally-sensitive fatigue crack nucleation in Ni-based single and oligo crystals. J. Mech. Phys. Solids 2017, 106, 15–33. [Google Scholar] [CrossRef]

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naderi, M. On the Evidence of Thermodynamic Self-Organization during Fatigue: A Review. Entropy 2020, 22, 372. https://0-doi-org.brum.beds.ac.uk/10.3390/e22030372

Naderi M. On the Evidence of Thermodynamic Self-Organization during Fatigue: A Review. Entropy. 2020; 22(3):372. https://0-doi-org.brum.beds.ac.uk/10.3390/e22030372

Chicago/Turabian StyleNaderi, Mehdi. 2020. "On the Evidence of Thermodynamic Self-Organization during Fatigue: A Review" Entropy 22, no. 3: 372. https://0-doi-org.brum.beds.ac.uk/10.3390/e22030372