Comparison of Fracture Load of the Four Translucent Zirconia Crowns

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tooth Preparation and Model Preparation

2.2. Statistical Analysis

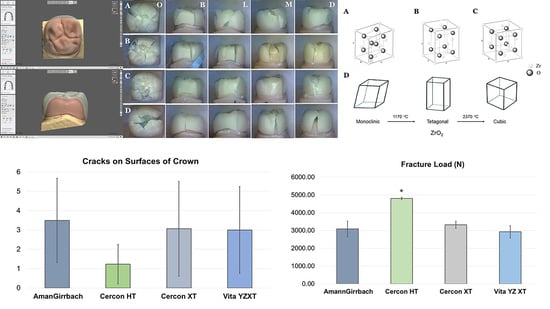

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Lopez-Suarez, C.; Rodriguez, V.; Pelaez, J.; Agustin-Panadero, R.; Suarez, M.J. Comparative fracture behavior of monolithic and veneered zirconia posterior fixed dental prostheses. Dent. Mater. J. 2017, 36, 816–821. [Google Scholar] [CrossRef] [Green Version]

- Humagain, M.; Rokaya, D. Integrating Digital Technologies in Dentistry to Enhance the Clinical Success. Kathmandu Univ. Med. J. 2019, 17, 256–257. [Google Scholar]

- Kontonasaki, E.; Rigos, A.E.; Ilia, C.; Istantsos, T. Monolithic Zirconia: An Update to Current Knowledge. Optical Properties, Wear, and Clinical Performance. Dent. J. 2019, 7, 90. [Google Scholar] [CrossRef] [Green Version]

- Amornvit, P.; Rokaya, D.; Peampring, C.; Sanohkan, S. Confocal 3D optical intraoral scanners and comparison of image capturing accuracy. Comput. Mater. Contin. 2021, 66, 303–314. [Google Scholar] [CrossRef]

- Rokaya, D.; Mahat, Y.; Sapkota, B.; Kc, B.S. Full Coverage Crowns and Resin-bonded Bridge Combination for Missing Mandibular Anterior Teeth. Kathmandu Univ. Med. J. 2018, 16, 97–99. [Google Scholar]

- Kuroe, T.; Itoh, H.; Caputo, A.A.; Konuma, M. Biomechanics of cervical tooth structure lesions and their restoration. Quintessence Int. 2000, 31, 267–274. [Google Scholar] [PubMed]

- Park, J.K.; Lee, W.S.; Kim, H.Y.; Kim, W.C.; Kim, J.H. Accuracy evaluation of metal copings fabricated by computer-aided milling and direct metal laser sintering systems. J. Adv. Prosthodont. 2015, 7, 122–128. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, M.J.; Choi, Y.J.; Kim, S.K.; Heo, S.J.; Koak, J.Y. Marginal Accuracy and Internal Fit of 3-D Printing Laser-Sintered Co-Cr Alloy Copings. Materials 2017, 10, 93. [Google Scholar] [CrossRef] [Green Version]

- Ioannidis, A.; Mühlemann, S.; Özcan, M.; Hüsler, J.; Hämmerle, C.H.F.; Benic, G.I. Ultra-thin occlusal veneers bonded to the enamel and made of ceramic or hybrid materials exhibit load-bearing capacities not different from conventional restorations. J. Mech. Behav. Biomed. Mater. 2019, 90, 433–440. [Google Scholar] [CrossRef] [Green Version]

- Avetisyan, A.; Markaryan, M.; Rokaya, D.; Tovani-Palone, M.R.; Zafar, M.S.; Khurshid, Z.; Vardanyan, A.; Heboyan, A. Characteristics of Periodontal Tissues in Prosthetic Treatment with Fixed Dental Prostheses. Molecules 2021, 26, 1331. [Google Scholar] [CrossRef]

- Heboyan, A.; Syed, A.U.Y.; Rokaya, D.; Cooper, P.R.; Manrikyan, M.; Markaryan, M. Cytomorphometric Analysis of Inflammation Dynamics in the Periodontium Following the Use of Fixed Dental Prostheses. Molecules 2020, 25, 4650. [Google Scholar] [CrossRef] [PubMed]

- Poggio, C.E.; Ercoli, C.; Rispoli, L.; Maiorana, C.; Esposito, M. Metal-free materials for fixed prosthodontic restorations. Cochrane Database Syst. Rev. 2017, 12, CD009606. [Google Scholar] [CrossRef] [PubMed]

- Heck, K.; Paterno, H.; Lederer, A.; Litzenburger, F.; Hickel, R.; Kunzelmann, K.H. Fatigue resistance of ultrathin CAD/CAM ceramic and nanoceramic composite occlusal veneers. Dent. Mater. 2019, 35, 1370–1377. [Google Scholar] [CrossRef] [PubMed]

- Dérand, T. Stress analysis of cemented or resin-bonded loaded porcelain inlays. Dent. Mater. 1991, 7, 21–24. [Google Scholar] [CrossRef]

- Kontonasaki, E.; Giasimakopoulos, P.; Rigos, A.E. Strength and aging resistance of monolithic zirconia: An update to current knowledge. Jpn. Dent. Sci. Rev. 2020, 56, 1–23. [Google Scholar] [CrossRef]

- Milling, P. Preparation design for traditional fixed full crown restorations. In Preparations for Fixed Prosthodontics; Munksgaard Danmark: Copenhagen, Denmark, 2012; pp. 155–163. [Google Scholar]

- Dhima, M.; Carr, A.B.; Salinas, T.J.; Lohse, C.; Berglund, L.; Nan, K.A. Evaluation of fracture resistance in the aqueous environment under dynamic loading of lithium disilicate restorative systems for posterior applications. Part 2. J. Prosthodont. 2014, 23, 353–357. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, K.; Harada, A.; Inagaki, R.; Kanno, T.; Niwano, Y.; Milleding, P.; Örtengren, U. Fracture resistance of monolithic zirconia molar crowns with reduced thickness. Acta Odontol. Scand. 2015, 73, 602–608. [Google Scholar] [CrossRef] [PubMed]

- Gautam, C.; Joyner, J.; Gautam, A.; Rao, J.; Vajtai, R. Zirconia based dental ceramics: Structure, mechanical properties, biocompatibility and applications. Dalton Trans. 2016, 45, 19194–19215. [Google Scholar] [CrossRef]

- Nakamura, K.; Adolfsson, E.; Milleding, P.; Kanno, T.; Ortengren, U. Influence of grain size and veneer firing process on flexural strength of zirconia ceramics. Eur. J. Oral Sci. 2012, 120, 249–254. [Google Scholar] [CrossRef]

- Kang, S.H.; Chang, J.; Son, H.H. Flexural strength and microstructure of two lithium disilicate glass-ceramics for CAD/CAM restoration in the dental clinic. Restor. Dent. Endod. 2013, 38, 134–140. [Google Scholar] [CrossRef]

- Holand, W.; Schweiger, M.; Frank, M.; Rheinberger, V.A. comparison of the microstructure and properties of the IPS Empress 2 and the IPS Empress glass-ceramics. J. Biomed. Mater. Res. 2000, 53, 297–303. [Google Scholar] [CrossRef]

- Lima, J.C.; Tribst, J.P.; Anami, L.C.; de Melo, R.M.; Moura, D.M.; Souza, R.O.; Bottino, M.A. Long-term fracture load of all-ceramic crowns: Effects of veneering ceramic thickness, application techniques, and cooling protocol. J. Clin. Exp. Dent. 2020, 12, e1078–e1085. [Google Scholar] [CrossRef]

- Zhang, Y. Making yttria-stabilized tetragonal zirconia translucent. Dent. Mater. 2014, 30, 1195–1203. [Google Scholar] [CrossRef] [Green Version]

- Dal Piva, A.O.; Tribst, J.P.; Borges, A.L.; de Melo, R.M.; Bottino, M.A. Influence of substrate design for in vitro mechanical testing. J. Clin. Exp. Dent. 2019, 11, e119–e125. [Google Scholar] [CrossRef]

- Amanngirrbach. Available online: https://www.amanngirrbach.com/en/products/cadcam-material/ceramic/zolid-zirconia/zi/ (accessed on 20 July 2021).

- Cerecon. Available online: https://www.dentsplysirona.com/content/dam/dentsply/pim/manufacturer/Prosthetics/CAD_CAM_materials/Materials/Zirconia/Cercon_xt_disc/BRO_Cercon_EN_lowres.pdf (accessed on 8 May 2021).

- VITA YZ ST Multicolor CAD/CAM-Blank. Available online: https://www.laboshop.com/index.php?id=6&L=1&artnr=1173A35&pg=12&aw=ROH&bl=1 (accessed on 20 July 2021).

- Lawson, N.C.; Jurado, C.A.; Huang, C.T.; Morris, G.P.; Burgess, J.O.; Liu, P.R.; Kinderknecht, K.E.; Lin, C.P.; Givan, D.A. Effect of Surface Treatment and Cement on Fracture Load of Traditional Zirconia (3Y), Translucent Zirconia (5Y), and Lithium Disilicate Crowns. J. Prosthodont. 2019, 28, 659–665. [Google Scholar] [CrossRef]

- Kim, J.H.; Park, J.H.; Park, Y.B.; Moon, H.S. Fracture load of zirconia crowns according to the thickness and marginal design of coping. J. Prosthet. Dent. 2012, 108, 96–101. [Google Scholar] [CrossRef]

- Erdfelder, E.; Faul, F.; Buchner, A. GPOWER: A general power analysis program. Behav. Res. Methods. Instrum. Comput. 1996, 28, 1–11. [Google Scholar] [CrossRef]

- Sorrentino, R.; Navarra, C.O.; Di Lenarda, R.; Breschi, L.; Zarone, F.; Cadenaro, M.; Spagnuolo, G. Effects of Finish Line Design and Fatigue Cyclic Loading on Phase Transformation of Zirconia Dental Ceramics: A Qualitative Micro-Raman Spectroscopic Analysis. Materials 2019, 12, 863. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saridag, S.; Tak, O.; Alniacik, G. Basic properties and types of zirconia: An overview. World J. Stomatol. 2013, 2, 40–47. [Google Scholar] [CrossRef]

- Bocanegra-Bernal, M.H.; de la Torre, S.D. Phase transitions in zirconium dioxide and related materials for high performance engineering ceramics. J. Mater. Sci. 2002, 37, 4947–4971. [Google Scholar] [CrossRef]

- Piconi, C.; Maccauro, G. Zirconia as a ceramic biomaterial. Biomaterials 1999, 20, 1–25. [Google Scholar] [CrossRef]

- Rekow, E.D.; Silva, N.R.F.A.; Coelho, P.G.; Zhang, Y.; Guess, P.; Thompson, V.P. Performance of Dental Ceramics: Challenges for Improvements. J. Dent. Res. 2011, 90, 937–952. [Google Scholar] [CrossRef] [Green Version]

- Chevalier, J.; Cales, B.; Drouin, J.M. Low-Temperature Aging of Y-TZP Ceramics. J. Am. Ceram. Soc. 1999, 82, 2150–2154. [Google Scholar] [CrossRef]

- Amat, N.F.; Muchtar, A.; Amril, M.S.; Ghazali, M.J.; Yahaya, N. Effect of sintering temperature on the aging resistance and mechanical properties of monolithic zirconia. J. Mater. Res. Technol. 2019, 8, 1092–1101. [Google Scholar] [CrossRef]

- Dehestani, M.; Adolfsson, E. Phase Stability and Mechanical Properties of Zirconia and Zirconia Composites. Int. J. Appl. Ceram. Technol. 2013, 10, 129–141. [Google Scholar] [CrossRef]

- Yang, H.; Ji, Y. Low-temperature Degradation of Zirconia-based All-ceramic Crowns Materials: A Mini Review and Outlook. J. Mater. Sci. Technol. 2016, 32, 593–596. [Google Scholar] [CrossRef]

- Sato, T.; Shimada, M. Transformation of Yttria-Doped Tetragonal ZrO2 Polycrystals by Annealing in Water. J. Am. Ceram. Soc. 1985, 68, 356. [Google Scholar] [CrossRef]

- Baladhandayutham, B.; Lawson, N.C.; Burgess, J.O. Fracture load of ceramic restorations after fatigue loading. J. Prosthet. Dent. 2015, 114, 266–271. [Google Scholar] [CrossRef]

- Yan, J.; Kaizer, M.R.; Zhang, Y. Load-bearing capacity of lithium disilicate and ultra-translucent zirconias. J. Mech. Behav. Biomed. Mater. 2018, 88, 170–175. [Google Scholar] [CrossRef]

- Christoforo1, A.L.; Silveira, M.E.; da Silva Dias, A.M.; De Araujo, V.A.; Lahr, F.A.R. Numerical Study of Finite Fracture Growth in an Epoxy Resin. Int. J. Mater. Eng. 2016, 6, 15–21. [Google Scholar] [CrossRef] [Green Version]

- Milewski, G. Numerical and experimental analysis of effort of human tooth hard tissues in terms of proper occlusal loadings. Acta Bioeng. Biomech. 2005, 7, 47–59. [Google Scholar]

- Dal Piva, A.M.O.; Tribst, J.P.M.; Benalcázar Jalkh, E.B.; Anami, L.C.; Bonfante, E.A.; Bottino, M.A. Minimal tooth preparation for posterior monolithic ceramic crowns: Effect on the mechanical behavior, reliability, and translucency. Dent. Mater. 2021, 37, e140–e150. [Google Scholar] [CrossRef] [PubMed]

- Alshiddi, I.F.; Habib, S.R.; Zafar, M.S.; Bajunaid, S.; Labban, N.; Alsarhan, M. Fracture Load of CAD/CAM Fabricated Cantilever Implant-Supported Zirconia Framework: An In Vitro Study. Molecules 2021, 26, 2259. [Google Scholar] [CrossRef] [PubMed]

| Crown Materials (N = 28) | Chemical Composition | Translucency | Manufacturer | Reference |

|---|---|---|---|---|

| AmannGirrbach (n = 7) | ZrO2 Y2O3: 4–5.6% HfO2: ≤5% Al2O3: ≤0.5% Al2O3, Other oxides including Silicon oxide: <1% | 30% | Amann Girrbach GmbH, Pforzheim, Germany | [26] |

| Cercon HT (n = 7) | ZrO2 Y2O3: 5% HfO2: <3% Al2O3, Other oxides including Silicon oxide: <1% | 41% | Dentsply Sirona, Bensheim, Germany | [2] |

| Cercon XT (n = 7) | ZrO2 Yttrium oxide (Y2O3): 9% HfO2: <3 % Al2O3, Other oxides including Silicon oxide: <1% | 49% | Dentsply Sirona, Bensheim, Germany | [27] |

| Vita YZ XT (n = 7) | ZrO2 Yttrium oxide: 8–10% HfO2: 1–3% Al2O3, Other oxides including Silicon oxide: <1% | 50% | Zahnfabrik, Bäd Sackingen, Germany | [28] |

| Specimen | AmannGirrbach (n = 7) | Cercon HT (n = 7) | Cercon XT (n = 7) | Vita YZ XT (n = 7) |

|---|---|---|---|---|

| 1 | 3116.44 | 4694.21 | 3395.24 | 2647.03 |

| 2 | 2426.12 | 4922.22 | 3252.99 | 2750.66 |

| 3 | 3425.61 | 4752.21 | 3376.96 | 3124.21 |

| 4 | 2526.83 | 4823.54 ψ | 3479.74 | 3081.29 |

| 5 | 3234.94 | 4807.57 ψ | 3581.93 | 3309.39 |

| 6 | 3573.10 | 4821.90 ψ | 3122.34 | 3198.18 |

| 7 | 3302.76 | 4812.91 ψ | 3015.11 | 2342.32 § |

| Mean | 3086.54 | 4804.94 | 3317.76 | 2921.87 |

| SD | 441.74 | 70.12 | 199.80 | 349.67 |

| CV (%) | 14.31% | 1.46% | 6.02% | 11.97% |

| AmannGirrbach | Cercon HT | Cercon XT | Vita YZ XT | |

|---|---|---|---|---|

| AmannGirrbach | - | <0.0001 * | 0.748 | 0.961 |

| Cercon HT | <0.0001 * | - | <0.0001 * | <0.0001 * |

| Cercon XT | 0.748 | <0.0001 * | - | 0.135 |

| Vita YZ XT | 0.961 | <0.0001 * | 0.135 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kongkiatkamon, S.; Booranasophone, K.; Tongtaksin, A.; Kiatthanakorn, V.; Rokaya, D. Comparison of Fracture Load of the Four Translucent Zirconia Crowns. Molecules 2021, 26, 5308. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26175308

Kongkiatkamon S, Booranasophone K, Tongtaksin A, Kiatthanakorn V, Rokaya D. Comparison of Fracture Load of the Four Translucent Zirconia Crowns. Molecules. 2021; 26(17):5308. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26175308

Chicago/Turabian StyleKongkiatkamon, Suchada, Kittipong Booranasophone, Apichat Tongtaksin, Valailuck Kiatthanakorn, and Dinesh Rokaya. 2021. "Comparison of Fracture Load of the Four Translucent Zirconia Crowns" Molecules 26, no. 17: 5308. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26175308