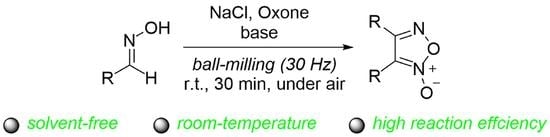

Mechanochemical Dimerization of Aldoximes to Furoxans

Abstract

:1. Introduction

2. Results and Discussion

3. Materials and Methods

3.1. General Information

3.2. Mechanochemical Synthesis and Characterization of Products 2a–r, 3s and 3t

3.3. Mechanochemial Synthesis of 2a from 1a and 1a’

3.4. Mechanochemial Synthesis of 4a from 1a and 2a from 4a

3.5. Deoxygenation Reaction of 2a

3.6. Synthesis of 2a in Liquid Phase

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Kaufman, J.V.R.; Picard, J.P. The furoxans. Chem. Rev. 1959, 59, 429–461. [Google Scholar] [CrossRef]

- Feelisch, M.; Schönafinger, K.; Noack, E. Thiol-mediated generation of nitric oxide accounts for the vasodilator action of furoxans. Biochem. Pharmacol. 1992, 44, 1149–1157. [Google Scholar] [CrossRef] [Green Version]

- Medana, C.; Ermondi, G.; Fruttero, R.; Stilo, A.D.; Ferretti, C.; Gasco, A. Furoxans as nitric oxide donors. 4-Phenyl-3-furoxancarbonitrile: Thiol-mediated nitric oxide release and biological evaluation. J. Med. Chem. 1994, 37, 4412–4416. [Google Scholar] [CrossRef] [PubMed]

- Takayama, H.; Shirakawa, S.; Kitajima, M.; Aimi, N.; Yamaguchi, K.; Hanasaki, Y.; Ide, T.; Katsuura, K.; Fujiwara, M.; Ijichi, K.; et al. Utilization of wieland furoxan synthesis for preparation of 4-aryl-1,2,5-oxadiazole-3-yl carbamate derivatives having potent anti-HIV activity. Bioorg. Med. Chem. Lett. 1996, 6, 1993–1996. [Google Scholar] [CrossRef]

- Lolli, M.L.; Cena, C.; Medana, C.; Lazzarato, L.; Morini, G.; Coruzzi, G.; Manarini, S.; Fruttero, R.; Gasco, A. A new class of ibuprofen derivatives with reduced gastrotoxicity. J. Med. Chem. 2001, 44, 3463–3468. [Google Scholar] [CrossRef] [PubMed]

- Boiani, M.; Cerecetto, H.; González, M.; Risso, M.; Olea-Azar, C.; Piro, O.E.; Castellano, E.E.; De Ceráin, A.L.; Ezpeleta, O.; Monge-Vega, A. 1,2,5-Oxadiazole N-oxide derivatives as potential anti-cancer agents: Synthesis and biological evaluation. Part IV. Eur. J. Med. Chem. 2001, 36, 771–782. [Google Scholar] [CrossRef]

- Santos, J.L.D.; Lanaro, C.; Chelucci, R.C.; Gambero, S.; Bosquesi, P.L.; Reis, J.S.; Lima, L.M.; Cerecetto, H.; González, M.; Costa, F.F.; et al. Design, synthesis, and pharmacological evaluation of novel hybrid compounds to treat sickle cell disease symptoms. Part II: Furoxan derivatives. J. Med. Chem. 2012, 55, 7583–7592. [Google Scholar] [CrossRef]

- Jovené, C.; Chugunova, E.A.; Goumont, R. The properties and the use of substituted benzofuroxans in pharmaceutical and medicinal chemistry: A comprehensive review. Mini Rev. Med. Chem. 2013, 13, 1089–1136. [Google Scholar] [CrossRef]

- Godovikova, T.I.; Golova, S.P.; Strelenko, Y.A.; Antipin, M.Y.; Struchkov, Y.T.; Khmel’nitskii, L.I. Synthesis and properties of unsubstituted furoxan. Mendeleev Commun. 1994, 4, 7–9. [Google Scholar] [CrossRef]

- Curini, M.; Epifano, F.; Marcotullio, M.C.; Rosati, O.; Ballini, R.; Bosica, G. Alumina promoted cyclization of α-nitro-oximes: A new entry to the synthesis of 1,2,5-oxadiazoles N-oxides(furoxans). Tetrahedron Lett. 2000, 41, 8817–8820. [Google Scholar] [CrossRef]

- Das, O.; Paria, S.; Paine, T.K. Copper(II)-mediated oxidation of 1,2-dioxime to furoxan. Tetrahedron Lett. 2008, 49, 5924–5927. [Google Scholar] [CrossRef]

- Matsubara, R.; Ando, A.; Hasebe, H.; Kim, H.; Tsuneda, T.; Hayashi, M. Synthesis and synthetic application of chloro- and bromofuroxans. J. Org. Chem. 2020, 85, 5959–5972. [Google Scholar] [CrossRef] [PubMed]

- Dyall, L.K. Oxidative cyclizations. VII. Cyclization of 2-substituted anilines with alkaline hypohalite. Aust. J. Chem. 1984, 37, 2013–2026. [Google Scholar] [CrossRef]

- Dyall, L.K.; Harvey, J.J.; Jarman, T.B. Oxidative cyclizations. VIII. Mechanisms of oxidation of ortho-substituted benzenamines and improved cyclizations by bis(acetato-O)phenyliodine. Aust. J. Chem. 1992, 45, 371–384. [Google Scholar] [CrossRef]

- Sun, T.; Hao, A.; Shen, J.; Song, L. Simple and practical procedure for the preparation of benzofurazan-N-oxides in the presence of cyclodextrin in neutral condition. Synth. Commun. 2009, 39, 4309–4314. [Google Scholar] [CrossRef]

- Gaughran, R.J.; Picard, J.P.; Kaufman, J.V.R. Contribution to the chemistry of benzfuroxan and benzfurazan derivatives. J. Am. Chem. Soc. 1954, 76, 2233–2236. [Google Scholar] [CrossRef]

- Sheremetev, A.B.; Aleksandrova, N.S.; Ignat’ev, N.V.; Schulte, M. Straightforward one-pot synthesis of benzofuroxans from o-halonitrobenzenes in ionic liquids. Mendeleev Commun. 2012, 22, 95–97. [Google Scholar] [CrossRef]

- Leyva, E.; Leyva-Ramos, S.; Jiménez-Cataño, R.; De Luna-Méndez, T.A.; Cárdenas-Chaparro, A. One-pot methodology for conversion of o-halogen nitrobenzenes to benzofuroxans. Synth. Commun. 2017, 47, 604–608. [Google Scholar] [CrossRef]

- Stolle, A.; Szuppa, T.; Leonhardt, S.E.S.; Ondruschka, B. Ball milling in organic synthesis: Solutions and challenges. Chem. Soc. Rev. 2011, 40, 2317–2329. [Google Scholar] [CrossRef]

- James, S.L.; Adams, C.J.; Bolm, C.; Braga, D.; Collier, P.; Friščić, T.; Grepioni, F.; Harris, K.D.M.; Hyett, G.; Jones, W.; et al. Mechanochemistry: Opportunities for new and cleaner synthesis. Chem. Soc. Rev. 2012, 41, 413–447. [Google Scholar] [CrossRef] [Green Version]

- Friščić, T. Supramolecular concepts and new techniques in mechanochemistry: Cocrystals, cages, rotaxanes, open metal–organic frameworks. Chem. Soc. Rev. 2012, 41, 3493–3510. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.-E.; Li, F.; Wang, G.-W. Mechanochemistry of fullerenes and related materials. Chem. Soc. Rev. 2013, 42, 7535–7570. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.-W. Mechanochemical organic synthesis. Chem. Soc. Rev. 2013, 42, 7668–7700. [Google Scholar] [CrossRef] [PubMed]

- Hernández, J.G.; Bolm, C. Altering product selectivity by mechanochemistry. J. Org. Chem. 2017, 82, 4007–4019. [Google Scholar] [CrossRef]

- Andersen, J.; Mack, J. Mechanochemistry and organic synthesis: From mystical to practical. Green Chem. 2018, 20, 1435–1443. [Google Scholar] [CrossRef]

- Bolm, C.; Hernándezm, J.G. Mechanochemistry of gaseous reactants. Angew. Chem. Int. Ed. 2019, 58, 3285–3299. [Google Scholar] [CrossRef]

- Wang, G.-W.; Komatsu, K.; Murata, Y.; Shiro, M. Synthesis and X-ray structure of dumb-bell-shaped C120. Nature 1997, 387, 583–586. [Google Scholar] [CrossRef]

- Su, Y.-T.; Wang, G.-W. FeCl3-Mediated cyclization of [60]fullerene with N-benzhydryl sulfonamides under high-speed vibration milling conditions. Org. Lett. 2013, 15, 3408–3411. [Google Scholar] [CrossRef]

- Zhao, Y.; Rocha, S.V.; Swager, T.M. Mechanochemical synthesis of extended iptycenes. J. Am. Chem. Soc. 2016, 138, 13834–13837. [Google Scholar] [CrossRef]

- Turberg, M.; Ardila-Fierro, K.J.; Bolm, C.; Hernández, J.G. Altering copper-catalyzed A3 couplings by mechanochemistry: One-pot synthesis of 1,4-diamino-2-butynes from aldehydes, amines, and calcium carbide. Angew. Chem. Int. Ed. 2018, 57, 10718–10722. [Google Scholar] [CrossRef]

- Seo, T.; Ishiyama, T.; Kubota, K.; Ito, H. Solid-state Suzuki–Miyaura cross-coupling reactions: Olefin-accelerated C–C coupling using mechanochemistry. Chem. Sci. 2019, 10, 8202–8210. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kubota, K.; Pang, Y.; Miura, A.; Ito, H. Redox reactions of small organic molecules using ball milling and piezoelectric materials. Science 2019, 366, 1500–1504. [Google Scholar] [CrossRef] [PubMed]

- Pisanò, G.; Cazin, C.S.J. Mechanochemical synthesis of Cu(I)-N-heterocyclic carbene complexes. Green Chem. 2020, 22, 5253–5256. [Google Scholar] [CrossRef]

- Pang, Y.; Lee, J.W.; Kubota, K.; Ito, H. Solid-state radical C–H trifluoromethylation reactions using ball milling and piezoelectric materials. Angew. Chem. Int. Ed. 2020, 59, 22570–22576. [Google Scholar] [CrossRef]

- Das, D.; Bhosle, A.A.; Panjikar, P.C.; Chatterjee, A.; Banerjee, M. Mn(I)-catalyzed mechanochemical C–H bond activation: C-2 selective alkenylation of indoles. ACS Sustain. Chem. Eng. 2020, 8, 19105–19116. [Google Scholar] [CrossRef]

- Pisanò, G.; Cazin, C.S.J. General mechanochemical synthetic protocol to late transition metal-NHC (N-heterocyclic carbene) complexes. ACS Sustain. Chem. Eng. 2021, 9, 9625–9631. [Google Scholar] [CrossRef]

- Li, L.; Wang, G.-W. Mechanochemical solvent-free synthesis of indenones from aromatic carboxylic acids and alkynes. J. Org. Chem. 2021, 86, 14102–14112. [Google Scholar] [CrossRef]

- Ni, S.; Hribersek, M.; Baddigam, S.K.; Ingner, F.J.L.; Orthaber, A.; Gates, P.J.; Pilarski, L.T. Mechanochemical solvent-free catalytic C–H methylation. Angew. Chem. Int. Ed. 2021, 60, 6660–6666. [Google Scholar] [CrossRef]

- Yoshimura, A.; Zhu, C.; Middleton, K.R.; Todora, A.D.; Kastern, B.J.; Maskaev, A.V.; Zhdankin, V.V. Hypoiodite mediated synthesis of isoxazolines from aldoximes and alkenes using catalytic KI and Oxone as the terminal oxidant. Chem. Commun. 2013, 49, 4800–4802. [Google Scholar] [CrossRef]

- Yoshimura, A.; Middleton, K.R.; Todora, A.D.; Kastern, B.J.; Koski, S.R.; Maskaev, A.V.; Zhdankin, V.V. Hypervalent iodine catalyzed generation of nitrile oxides from oximes and their cycloaddition with alkenes or alkynes. Org. Lett. 2013, 15, 4010–4013. [Google Scholar] [CrossRef]

- Zhao, G.; Liang, L.; Wen, C.H.E.; Tong, R. In situ generation of nitrile oxides from NaCl-Oxone oxidation of various aldoximes and their 1,3-dipolar cycloaddition. Org. Lett. 2019, 21, 315–319. [Google Scholar] [CrossRef]

- Chen, K.; Niu, C.; Wang, G.-W. Reaction of aldoximes with sodium chloride and Oxone under ball-milling conditions. Molecules 2020, 25, 3719. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Wang, G.-W. Direct oxidative amidation of aldehydes with anilines under mechanical milling conditions. J. Org. Chem. 2008, 73, 2955–2958. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.-W.; Gao, J. Solvent-free bromination reactions with sodium bromide and oxone promoted by mechanical milling. Green Chem. 2012, 14, 1125–1131. [Google Scholar] [CrossRef]

- Schmidt, R.; Stolle, A.; Ondruschka, B. Aromatic substitution in ball mills: Formation of aryl chlorides and bromides using potassium peroxomonosulfate and NaX. Green Chem. 2012, 14, 1673–1679. [Google Scholar] [CrossRef]

- Friščić, T.; Jones, W. Recent advances in understanding the mechanism of cocrystal formation via grinding. Cryst. Growth Des. 2009, 9, 1621–1637. [Google Scholar] [CrossRef]

- Štrukil, V.; Margetić, D.; Igrc, M.D.; Eckert-Maksić, M.; Friščić, T. Desymmetrisation of aromatic diamines and synthesis of non-symmetrical thiourea derivatives by click-mechanochemistry. Chem. Commun. 2012, 48, 9705–9707. [Google Scholar] [CrossRef]

- Tan, D.; Štrukil, V.; Mottillo, C.; Friščić, T. Mechanosynthesis of pharmaceutically relevant sulfonyl-(thio)ureas. Chem. Commun. 2014, 50, 5248–5250. [Google Scholar] [CrossRef]

- Jiang, Z.-J.; Li, Z.-H.; Yu, J.-B.; Su, W.-K. Liquid-assisted grinding accelerating: Suzuki-Miyaura reaction of aryl chlorides under high-speed ball-milling conditions. J. Org. Chem. 2016, 81, 10049–10055. [Google Scholar] [CrossRef]

- Li, H.-G.; Wang, G.-W. Liquid-assisted one-pot mechanosynthesis and properties of neutral donor−acceptor [2]rotaxanes. J. Org. Chem. 2017, 82, 6341–6348. [Google Scholar] [CrossRef]

- Xua, W.; Wang, J.; Liu, C.; Chen, C.-L. Experimental and computational studies of the isomerization between Z and E isomers of benzaldoximes. J. Chin. Chem. Soc. 2004, 51, 1259–1266. [Google Scholar] [CrossRef]

- Mukaiyama, T.; Nambu, H.; Okamoto, M. Deoxygenations of isocyanates and diphenylketene by tertiary phosphites. J. Org. Chem. 1962, 27, 3651–3654. [Google Scholar] [CrossRef]

- McIntosh, M.L.; Naffziger, M.R.; Ashburn, B.O.; Zakharovb, L.N.; Carter, R.G. Highly regioselective nitrile oxide dipolar cycloadditions with ortho-nitrophenyl alkynes. Org. Biomol. Chem. 2012, 10, 9204–9213. [Google Scholar] [CrossRef]

- Hwang, K.-J.; Park, Y.C.; Kim, H.J.; Lee, J.H. Synthesis and antifungal activities of furoxan derivatives designed as novel fungicide. Biosci. Biotechnol. Biochem. 1998, 62, 1693–1697. [Google Scholar] [CrossRef]

- Ovchinnikov, I.V.; Strelenko, Y.A.; Popov, N.A.; Finogenov, A.O.; Makhova, N.N. A study of the reaction mechanism of 3-nitro-4-R-furoxans formation by nitrosation of dipotassium salts of 1-hydroxyimino-2,2-dinitro-1-R-ethanes. Russ. Chem. Bull. Int. Ed. 2011, 60, 855–860. [Google Scholar] [CrossRef]

- Kadama, K.S.; Gandhi, T.; Gupte, A.; Gangopadhyay, A.K.; Sharma, R. Alkyl nitrites: Novel reagents for one-pot synthesis of 3,5-disubstituted isoxazoles from aldoximes and alkynes. Synthesis 2016, 48, 3996–4008. [Google Scholar] [CrossRef] [Green Version]

- Sheldon, R.A. Organic synthesis-past, present and future. Chem. Ind. 1992, 23, 903–906. [Google Scholar]

- Sheldon, R.A. The E Factor: Fifteen years on. Green Chem. 2007, 9, 1273–1283. [Google Scholar] [CrossRef]

- Sheldon, R.A. The E factor 25 years on: The rise of green chemistry and sustainability. Green Chem. 2017, 19, 18–43. [Google Scholar] [CrossRef]

- Roschangar, F.; Sheldon, R.A.; Senanayake, C.H. Overcoming barriers to green chemistry in the pharmaceutical industry—The Green Aspiration Level™ concept. Green Chem. 2014, 17, 752–768. [Google Scholar] [CrossRef]

- Trost, B. The Atom Economy—A Search for Synthetic Efficiency. Science 1991, 254, 1471–1477. [Google Scholar] [CrossRef] [PubMed]

- Curzons, A.D.; Mortimer, D.N.; Constable, D.J.C.; Cunningham, V.L. So you think your process is green, how do you know?—Using principles of sustainability to determine what is green—A corporate perspective. Green Chem. 2001, 3, 1–6. [Google Scholar] [CrossRef]

| Entry | NaCl (Equiv.) | Oxone (Equiv.) | Base (Equiv.) | Yield of 2a (%) b |

|---|---|---|---|---|

| 1 | 1.0 | 1.0 | Na2CO3 (1.0) | 8 |

| 2 | 1.0 | 1.0 | NaOtBu (1.0) | trace |

| 3 | 1.0 | 1.0 | NaOAc (1.0) | trace |

| 4 | 1.0 | 1.0 | NaHCO3 (1.0) | trace |

| 5 | 1.0 | 1.0 | K2CO3 (1.0) | 36 |

| 6 | 1.0 | 1.0 | Cs2CO3 (1.0) | 7 |

| 7 | 1.0 | 1.0 | DMAP (1.0) | 0 |

| 8 | 1.0 | 1.0 | DBU (1.0) | 0 |

| 9 | 1.0 | 1.0 | DABCO (1.0) | 0 |

| 10 | 1.0 | 1.0 | NEt3(1.0) | 79 |

| 11 | 1.0 | 1.0 | NEt3 (1.25) | 69 |

| 12 | 1.0 | 1.0 | NEt3 (1.5) | 53 |

| 13 | 1.0 | 1.0 | NEt3 (0.75) | 62 |

| 14 | 1.0 | 1.0 | NEt3 (0.5) | 38 |

| 15 c | 1.0 | 1.0 | NEt3 (1.0) | trace |

| 16 d | 1.0 | 1.0 | NEt3 (1.0) | 47 |

| 17 e | 1.0 | 1.0 | NEt3 (1.0) | 78 |

| 18 | 1.5 | 1.0 | NEt3 (1.0) | 79 |

| 19 | 1.0 | 1.5 | NEt3 (1.0) | 77 |

| 20 f,g | 1.0 | 1.0 | NEt3 (1.0) | 50 |

| 21 f,h | 1.0 | 1.0 | NEt3 (1.0) | 55 |

| 22 f,i | 1.0 | 1.0 | NEt3 (1.0) | 51 |

| 23 f,j | 1.0 | 1.0 | NEt3 (1.0) | 71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, R.-K.; Chen, K.; Niu, C.; Wang, G.-W. Mechanochemical Dimerization of Aldoximes to Furoxans. Molecules 2022, 27, 2604. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules27082604

Fang R-K, Chen K, Niu C, Wang G-W. Mechanochemical Dimerization of Aldoximes to Furoxans. Molecules. 2022; 27(8):2604. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules27082604

Chicago/Turabian StyleFang, Run-Kai, Kuan Chen, Chuang Niu, and Guan-Wu Wang. 2022. "Mechanochemical Dimerization of Aldoximes to Furoxans" Molecules 27, no. 8: 2604. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules27082604