Silica Bottle Resonator Sensor for Refractive Index and Temperature Measurements

Abstract

:1. Introduction

2. Theoretical Analysis

3. Results and Discussion

3.1. WGMs of the Bottle Resonator

3.2. Refractive Index Sensing

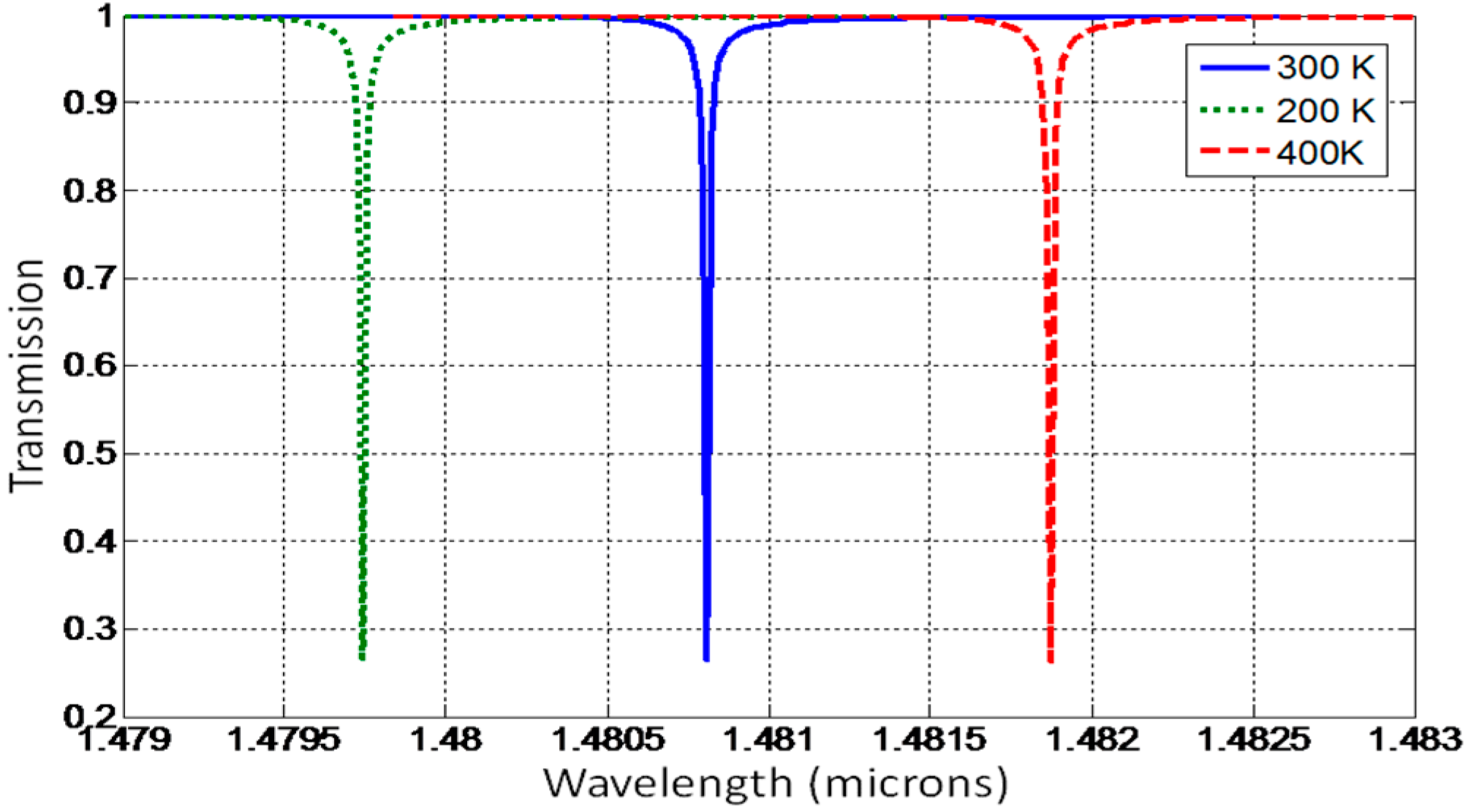

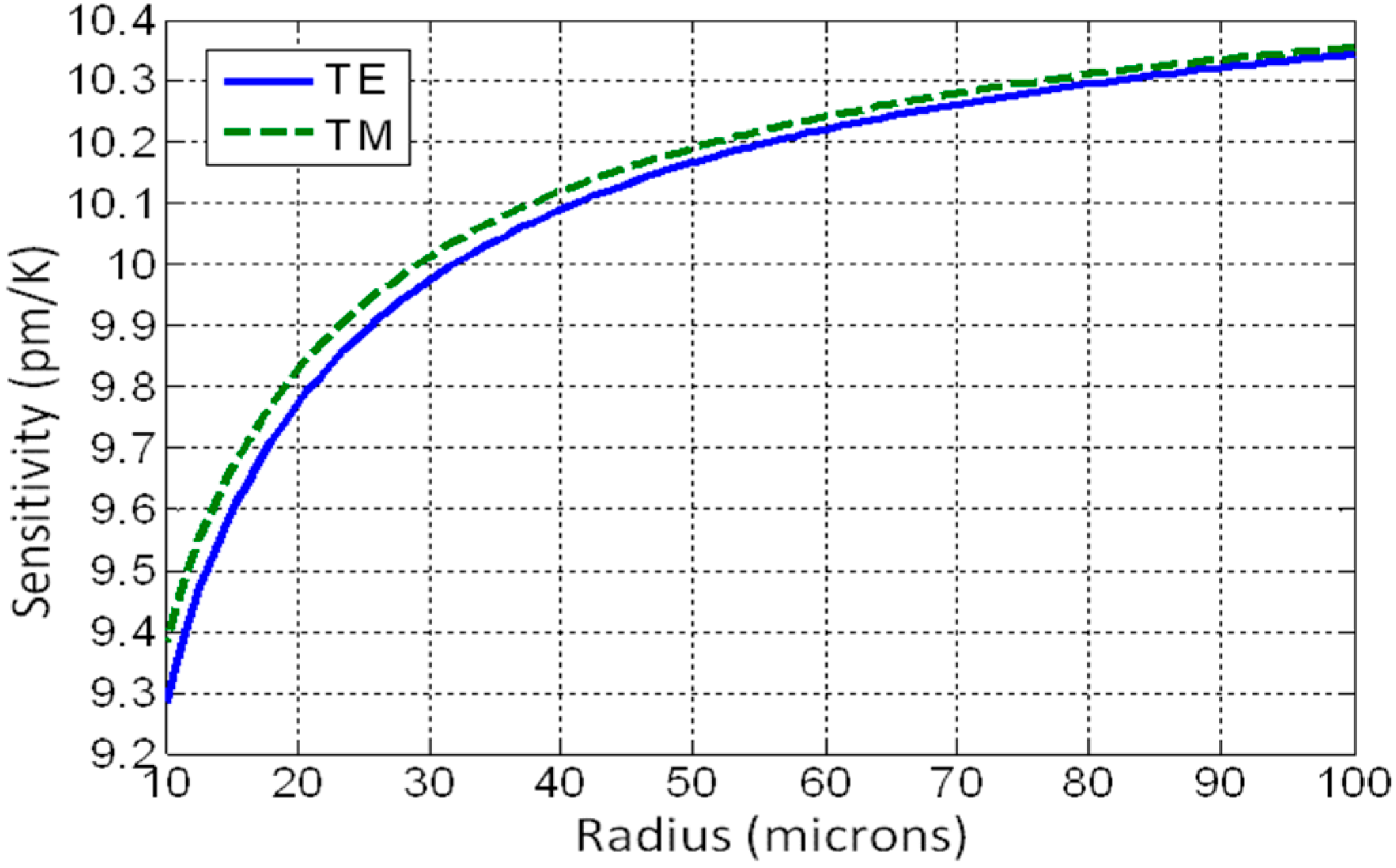

3.3. Temperature Sensing

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chiasera, A.; Dumeige, Y.; Féron, P.; Ferrari, M.; Jestin, Y.; Conti, G.N.; Pelli, S.; Soria, S.; Righini, G.C. Spherical whispering-gallery-mode microresonators. Laser Photon. Rev. 2010, 4, 457–482. [Google Scholar] [CrossRef]

- Matsko, A.B.; Savchenkov, A.A.; Strekalov, D.; Ilchenko, V.S.; Maleki, L. Review of applications of whispering-gallery mode resonators in photonics and nonlinear optics. IPN Progr. Rep. 2005, 42–162. [Google Scholar]

- Wang, J.; Zhan, T.; Huang, G.; Chu, P.K.; Mei, Y. Optical microcavities with tubular geometry: Properties and applications. Laser Photonics Rev. 2014, 8, 521–547. [Google Scholar] [CrossRef]

- Berini, P. Long-range surface plasmonpolaritons. Adv. Opt. Photon. 2009, 1, 484–588. [Google Scholar] [CrossRef]

- Berini, P.; Charbonneau, R.; Lahoud, N. Long-range surface plasmonsm on ultrathin membranes. Nano Lett. 2007, 7, 1376–1380. [Google Scholar] [CrossRef] [PubMed]

- Charbonneau, R.; Tencer, M.; Lahoud, N.; Berini, P. Demonstration of surface sensing using long-range surface plasmon waveguides on silica. Sens. Actuators B Chem. 2008, 134, 455–461. [Google Scholar] [CrossRef]

- Nemova, G.; Kashyap, R. A Compact Integrated Planar Waveguide Refractive Index Sensor Based on a Corrugated Metal Grating. J. Lightwave Technol. 2007, 25, 2244–2250. [Google Scholar] [CrossRef]

- Nemova, G.; Kashyap, R. Theoretical model of a planar integrated refractive index sensor based on surface plasmon-polariton excitation with a long period grating. J. Opt. Soc. Am. B 2007, 24, 2696–2701. [Google Scholar] [CrossRef]

- Kashyap, R. Fiber Bragg Gratings, 2nd ed.; Academic Press: Burlington, VT, USA, 2010. [Google Scholar]

- Fang, X.; Liao, C.R.; Wang, D.N. Femtosecond laser fabricated fiber Bragg grating in microfiber for refractive index sensing. Opt. Lett. 2010, 35, 1007–1009. [Google Scholar] [CrossRef] [PubMed]

- White, I.M.; Fan, X. On the performance quantification of resonant refractive index sensors. Opt. Express 2008, 16, 2010–2020. [Google Scholar]

- Luan, N.; Wang, R.; Lv, W.; Lu, Y.; Yao, J. Surface plasmon resonance temperature sensor based on photonic crystal fibers randomly filled with silver nanowires. Sensors 2014, 14, 16035–16045. [Google Scholar] [CrossRef] [PubMed]

- Foreman, M.R.; Swaim, J.D.; Vollmer, F. Whispering gallery mode sensors. Adv. Opt. Photonics 2015, 7, 168–240. [Google Scholar]

- Ma, Q.; Rossmann, T.; Guo, Z. Micro-temperature sensor based on optical whispering gallery mode of fiber taper-microsphere coupling system. Proc. SPIE 2009, 7420. [Google Scholar] [CrossRef]

- Murugan, G.S.; Petrovich, M.N.; Jung, Y.; Wilkinson, J.S.; Zervas, M.N. Hollow-bottle optical microresonators. Opt. Express 2011, 19, 20773–20784. [Google Scholar]

- Landau, L.D.; Lifshitz, E.M. Quantum Mechanics; Pergamon Press: Oxford, UK, 1977. [Google Scholar]

- Sumetsky, M.; Fini, J.M. Surface nanoscale axial photonics. Opt. Express 2011, 19, 26470–26485. [Google Scholar] [CrossRef] [PubMed]

- Sumetsky, M. Theory of SNAP devices: Basic equations and comparison with the experiment. Opt. Express 2012, 20, 22537–22554. [Google Scholar] [CrossRef] [PubMed]

- Lam, C.C.; Leung, P.T.; Young, K. Explicit asymptotic formulas for the positions, widths, and strengths of resonances in Mie scattering. J. Opt. Soc. Am. B 1992, 9, 1585–1592. [Google Scholar] [CrossRef]

- Abramowitz, M.; Stegun, I. Handbook of Mathematical Functions; Dover publications: Mineola, NY, USA, 1970. [Google Scholar]

- Brockner, R. Properties and structure of vitreous silica. J. Non-Cryst. Solids 1970, 5, 123–175. [Google Scholar] [CrossRef]

- Waxler, R.M.; Cleek, G.W. Refractive Indices of Fused Silica at Low Temperatures. J. Res. Natl. Bureau Stand. A Phys. Chem. 1971, 75A, 279–281. [Google Scholar] [CrossRef]

- Sumetsky, M. Nanophotonics of optical fibers. Nanophotonics 2013, 2, 393–406. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nemova, G.; Kashyap, R. Silica Bottle Resonator Sensor for Refractive Index and Temperature Measurements. Sensors 2016, 16, 87. https://0-doi-org.brum.beds.ac.uk/10.3390/s16010087

Nemova G, Kashyap R. Silica Bottle Resonator Sensor for Refractive Index and Temperature Measurements. Sensors. 2016; 16(1):87. https://0-doi-org.brum.beds.ac.uk/10.3390/s16010087

Chicago/Turabian StyleNemova, Galina, and Raman Kashyap. 2016. "Silica Bottle Resonator Sensor for Refractive Index and Temperature Measurements" Sensors 16, no. 1: 87. https://0-doi-org.brum.beds.ac.uk/10.3390/s16010087