Investigation of a Magnetic Tunnel Junction Based Sensor for the Detection of Defects in Reinforced Concrete at High Lift-Off

Abstract

:1. Introduction

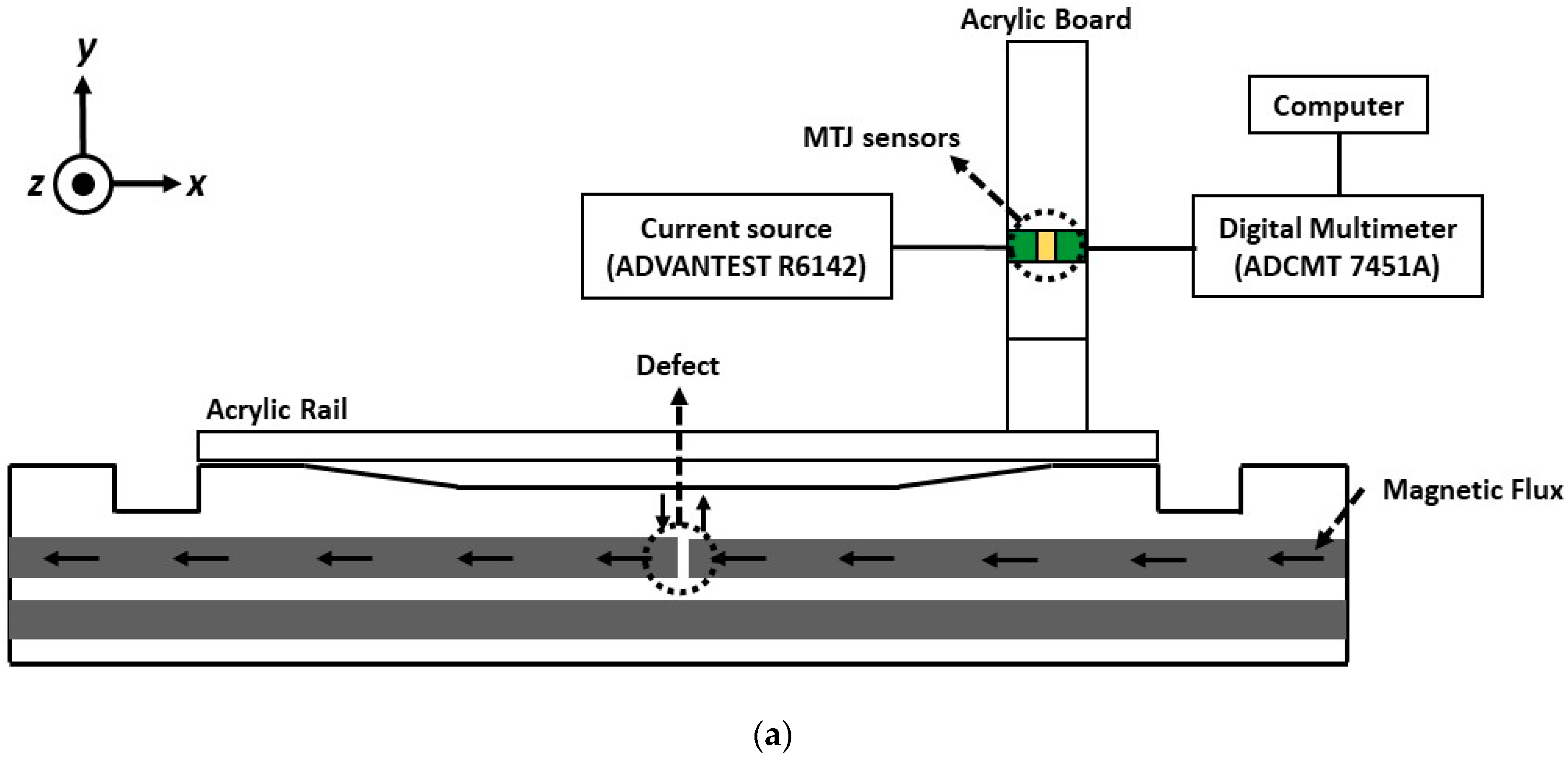

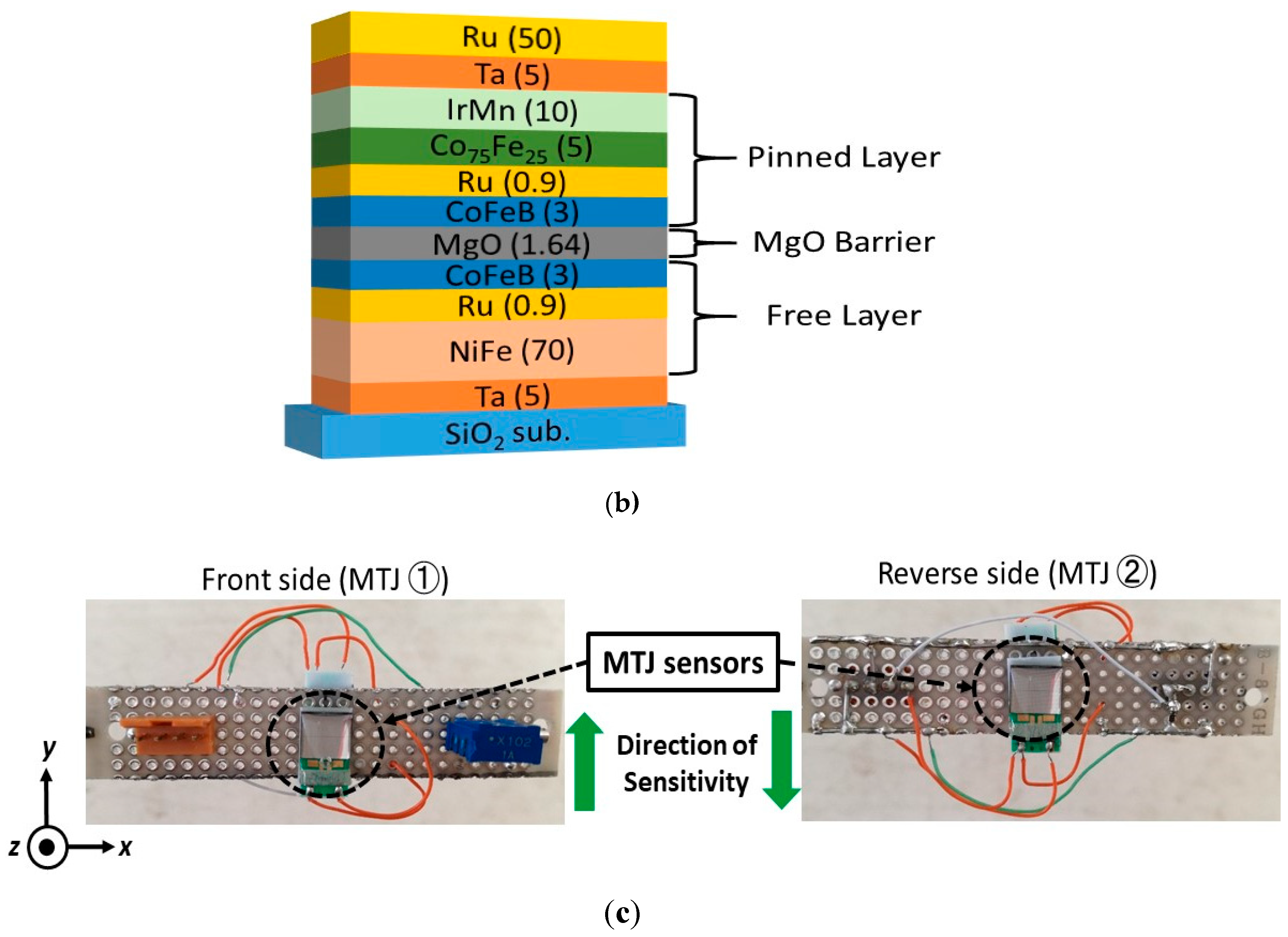

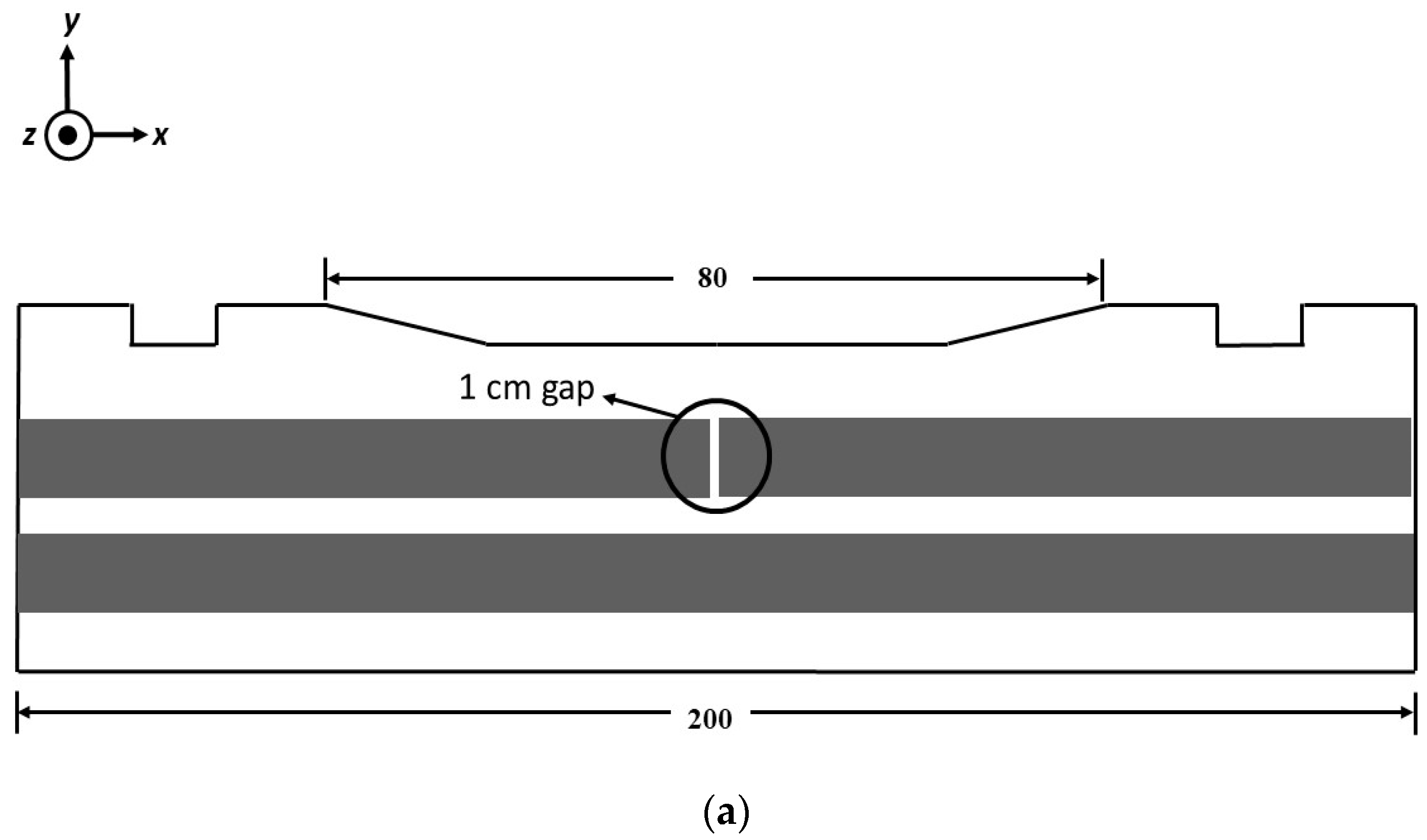

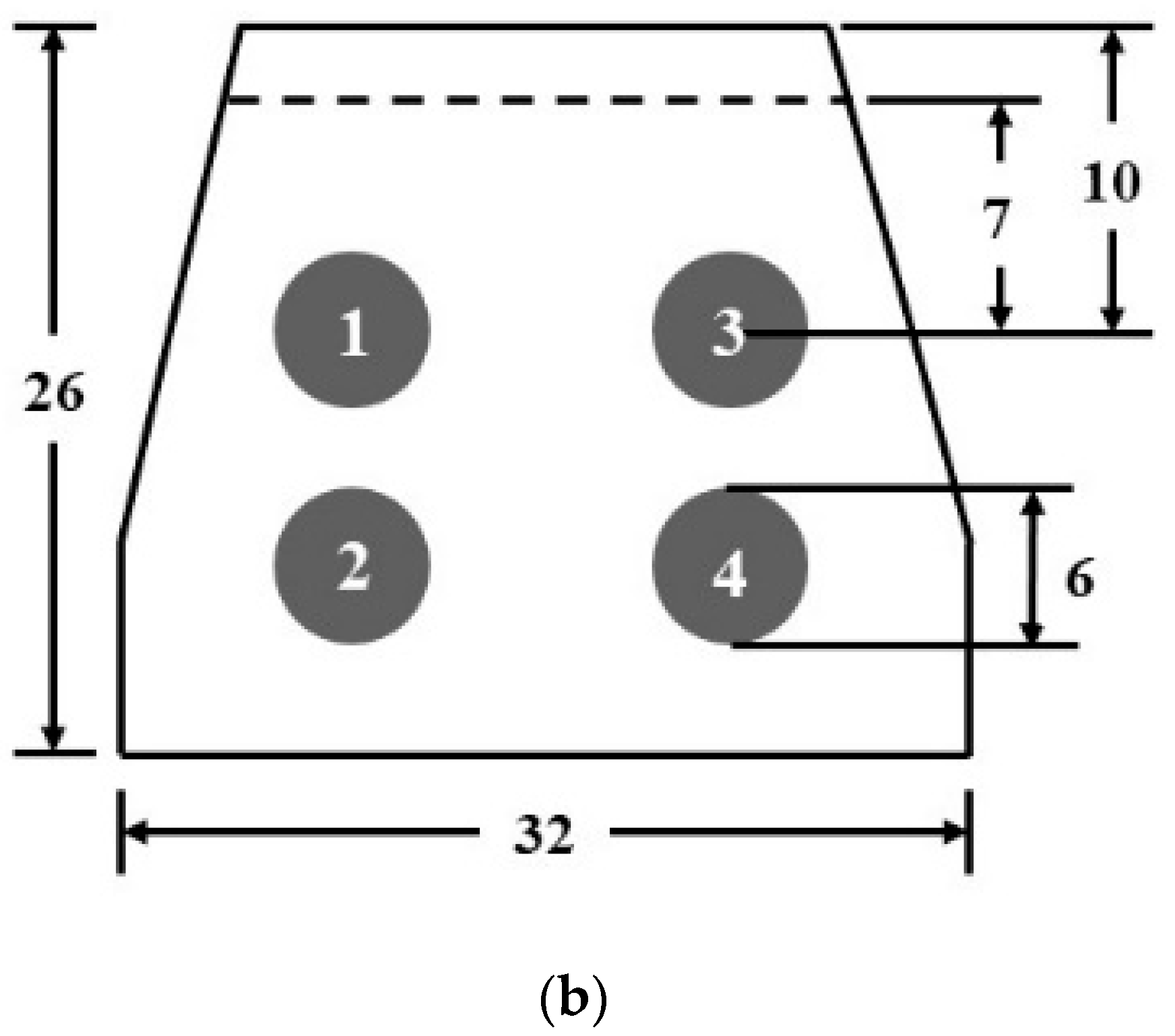

2. Materials and Methods

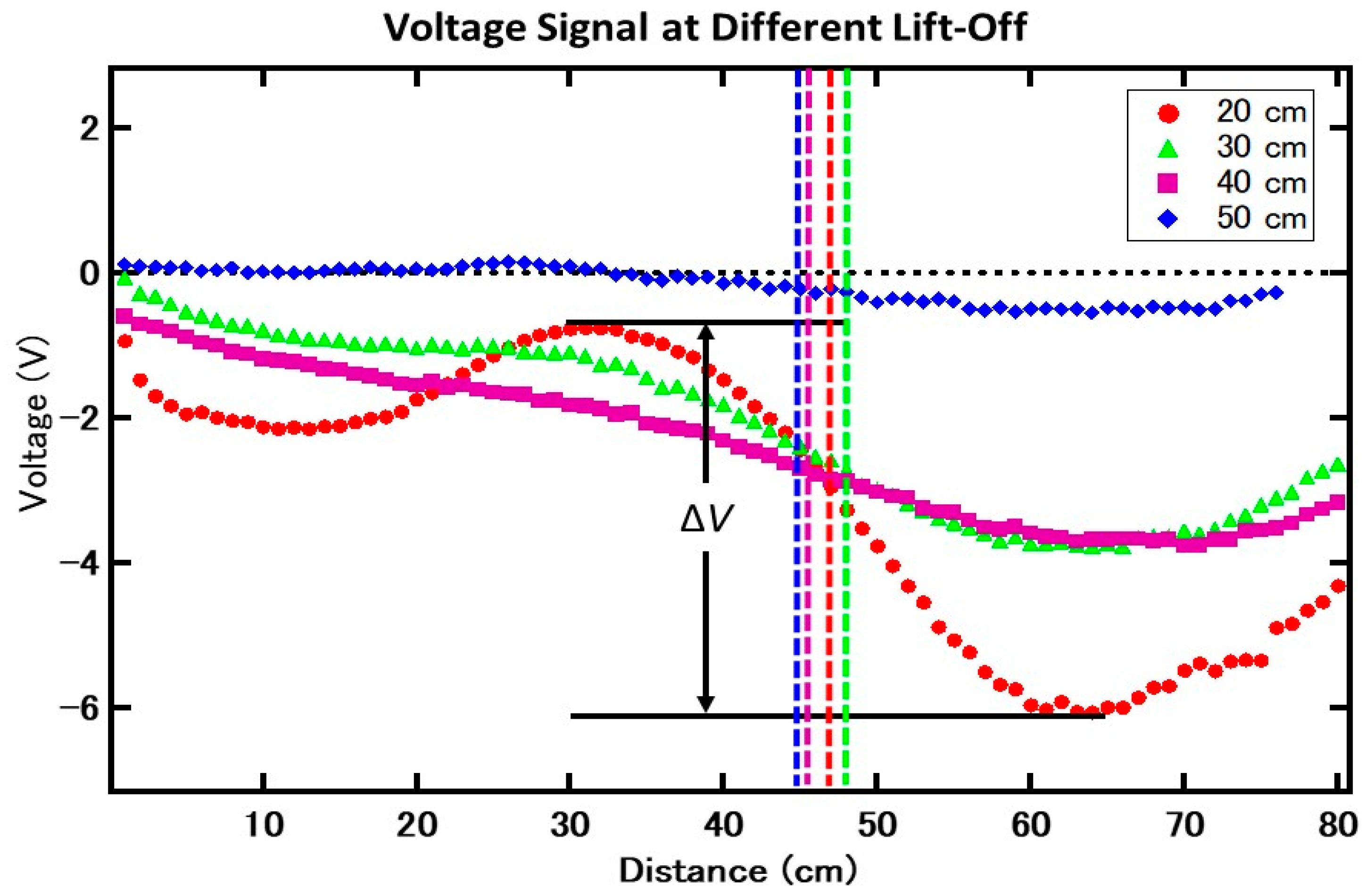

3. Results and Discussion

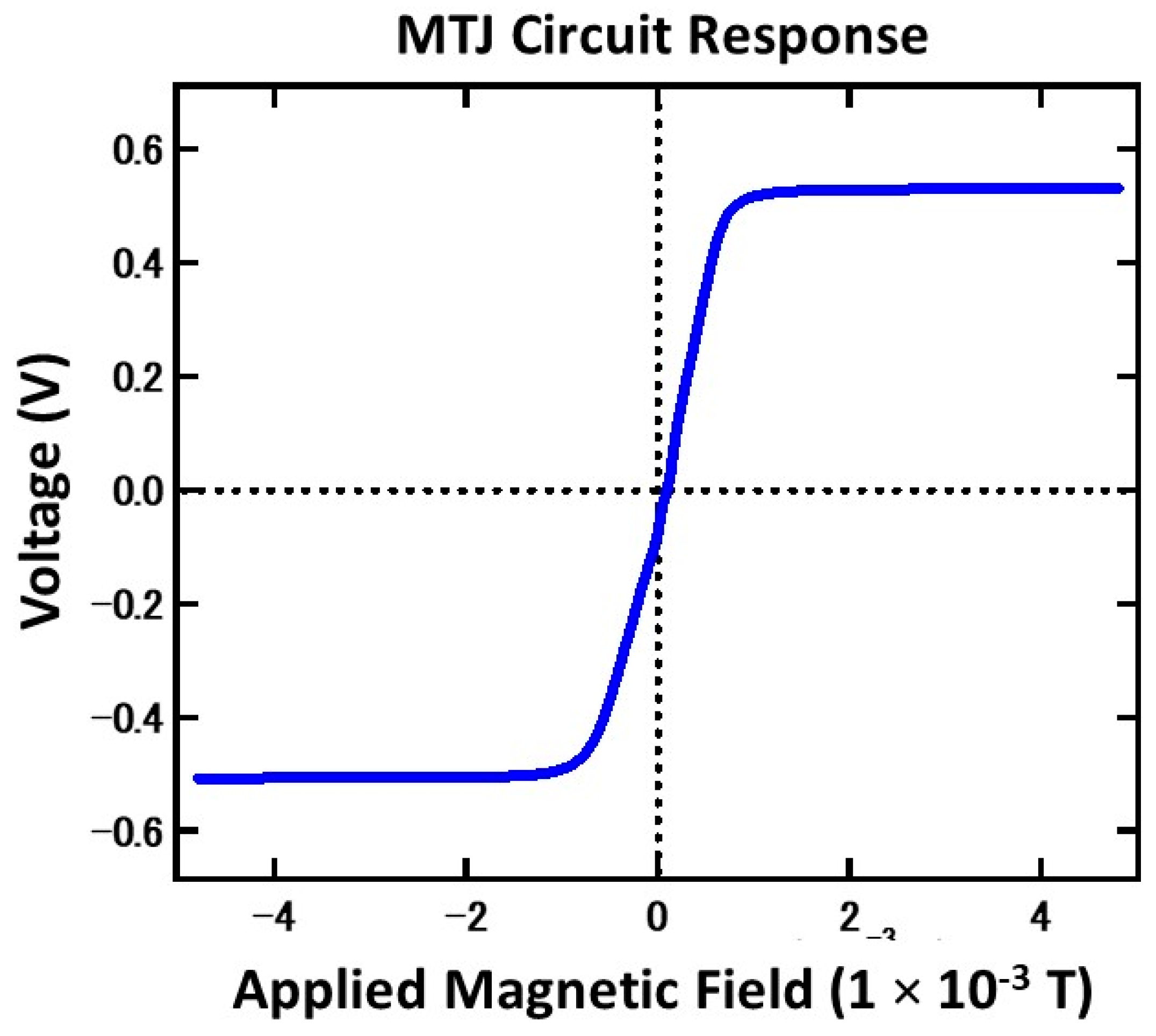

3.1. Circuit Response

3.2. Concrete Specimen Measurement

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Almusallam, A.A. Effect of degree of corrosion on the properties of reinforcing steel bars. Const. Build. Mate. 2001, 15, 361–368. [Google Scholar] [CrossRef]

- Sanchez, J.; Fullea, J.; Andrade, C. Corrosion-induced brittle failure in reinforcing steel. Theo. Appl. Frac. Mech. 2017, 92, 229–232. [Google Scholar] [CrossRef]

- Verma, S.K.; Bhadauria, S.S.; Akhtar, S. Review of Nondestructive Testing Methods for Condition Monitoring of Concrete Structures. J. Constr. Eng. 2013, 2013, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Drinkwater, B.W.; Wilcox, P.D. Ultrasonic arrays for non-destructive evaluation: A review. NDT E Int. 2006, 39, 525–541. [Google Scholar] [CrossRef]

- Hanke, R.; Fuchs, T.; Uhlmann, N. X-ray based methods for non-destructive testing and material characterization. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2008, 591, 14–18. [Google Scholar] [CrossRef]

- Bhagi, P.C.R. Magnetic Flux Leakage Testing: Basics. J. Non-Destr. Test. Eval. 2012, 13, 7–19. [Google Scholar]

- Hirose, M.; Maeda, T.; Matsuda, K.; Yokota, M.; Hattori, A.; Miyagawa, T. Establishment of the criterion in non-destructive test method for fracture of reinforcing steel bar by measuring magnetic flux density. J. Stru. Eng. 2012, 58A, 867–878. [Google Scholar]

- Wu, D.; Zhang, Z.; Liu, Z.; Xia, X. 3-D FEM Simulation and Analysis on the Best Range of Lift-off Values in MFL Testing. J. Test. Eval. 2015, 43, 673–680. [Google Scholar] [CrossRef]

- Kato, D.; Oogane, M.; Fujiwara, K.; Nisjikawa, T.; Naganuma, H.; Ando, Y. Fabrication of Magnetic Tunnel Junctions with Amorphous CoFeSiB Ferromagnetic Electrode for Magnetic Field Sensor Devices. Appl. Phys. Express 2013, 6, 103004. [Google Scholar] [CrossRef]

- Cardoso, S.; Leitao, D.C.; Gameiro, L.; Cardoso, F.; Ferreira, R.; Paz, E.; Freitas, P.P. Magnetic tunnel junction sensors with pTesla sensitivity. Microsyst. Technol. 2014, 20, 793–802. [Google Scholar] [CrossRef]

- Tsukada, K.; Kiwa, T.; Kawata, T.; Ishihara, Y. Low-Frequency Eddy Current Imaging Using MR Sensor Detecting Tangential Magnetic Field Components for Nondestructive Evaluation. IEEE Trans. Magn. 2006, 42, 3315–3317. [Google Scholar] [CrossRef]

- Fujiwara, K.; Oogane, M.; Kanno, A.; Imada, M.; Jono, J.; Terauchi, T.; Okuno, T.; Aritomi, Y.; Morikawa, M.; Tsuchida, M.; et al. Magnetocardiography and magnetoencephalography measurements at room temperature using tunnel magneto-resistance sensors. Appl. Phys. Express 2018, 11, 023001. [Google Scholar] [CrossRef]

- Zhang, H.; Liao, L.; Zhao, R.; Zhou, J.; Yang, M.; Xia, R. The non-destructive test of steel corrosion in reinforced concrete bridges using a micro-magnetic sensor. Sensors 2016, 16, 1439. [Google Scholar] [CrossRef] [PubMed]

- Jin, Z.; Ihsan, M.A.; Oogane, M.; Fujiwara, K.; Ando, Y. Serial magnetic tunnel junction based sensors for detecting far-side pits in metallic specimens. Jpn. J. Appl. Phys. 2019, 58, 043003. [Google Scholar] [CrossRef]

- Fujiwara, K.; Oogane, M.; Yokota, S.; Nishikawa, T.; Naganuma, H.; Ando, Y. Fabrication of magnetic tunnel junctions with a bottom synthetic antiferro-coupled free layers for high sensitive magnetic field sensor devices. J. Appl. Phys. 2012, 111, 07C710. [Google Scholar] [CrossRef]

- Ishikawa, K.; Oogane, M.; Fujiwara, K.; Jono, J.; Tsuchida, M.; Ando, Y. Investigation of magnetic sensor properties of magnetic tunnel junctions with superparamagnetic free layer at low frequencies for biomedical imaging applications. Jpn. J. Appl. Phys. 2016, 55, 123001. [Google Scholar] [CrossRef]

- Guerrero, R.; Pannetier-Lecoeur, M.; Fermon, C.; Cardoso, S.; Ferreira, R.; Freitas, P.P. Low frequency noise in arrays of magnetic tunnel junctions connected in series and parallel. J. Appl. Phys. 2009, 105, 113922. [Google Scholar] [CrossRef]

- Cao, J.; Freitas, P.P. Wheatstone bridge sensor composed of linear MgO magnetic tunnel junctions. J. Appl. Phys. 2010, 107, 7–10. [Google Scholar] [CrossRef]

- Franco, F.; Cardoso, S.; Freitas, P.P. Reconfigurable Spintronics Wheatstone Bridge Sensors with Offset Voltage Compensation at Wafer Level. IEEE Trans. Magn. 2019, 55, 1–5. [Google Scholar] [CrossRef]

- Fujiwara, K.; Oogane, M.; Kato, D.; Nishikawa, T.; Naganuma, H.; Ando, Y. Fabrication of Integrated Magnetic Tunnel Junctions for Detection of Bio-magnetic Field. Jpn. Soc. Med. Bio. Eng. 2014, 52, O-505–O-506. [Google Scholar]

- Jin, Z.; Oogane, M.; Fujiwara, K.; Ando, Y. Magnetic sensor based on serial magnetic tunnel junctions for highly sensitive detection of surface cracks. J. Appl. Phys. 2017, 122, 174502. [Google Scholar] [CrossRef]

- Dutta, S.M.; Ghorbel, F.H.; Stanley, R.K. Dipole Modeling of Magnetic Flux Leakage. IEEE Trans. Magn. 2009, 45, 1959–1965. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohd Noor Sam, M.A.I.; Jin, Z.; Oogane, M.; Ando, Y. Investigation of a Magnetic Tunnel Junction Based Sensor for the Detection of Defects in Reinforced Concrete at High Lift-Off. Sensors 2019, 19, 4718. https://0-doi-org.brum.beds.ac.uk/10.3390/s19214718

Mohd Noor Sam MAI, Jin Z, Oogane M, Ando Y. Investigation of a Magnetic Tunnel Junction Based Sensor for the Detection of Defects in Reinforced Concrete at High Lift-Off. Sensors. 2019; 19(21):4718. https://0-doi-org.brum.beds.ac.uk/10.3390/s19214718

Chicago/Turabian StyleMohd Noor Sam, Muhamad Arif Ihsan, Zhenhu Jin, Mikihiko Oogane, and Yasuo Ando. 2019. "Investigation of a Magnetic Tunnel Junction Based Sensor for the Detection of Defects in Reinforced Concrete at High Lift-Off" Sensors 19, no. 21: 4718. https://0-doi-org.brum.beds.ac.uk/10.3390/s19214718