High Precision Positioning with Multi-Camera Setups: Adaptive Kalman Fusion Algorithm for Fiducial Markers

Abstract

:1. Introduction

2. Description of the Initial Problem

3. Method

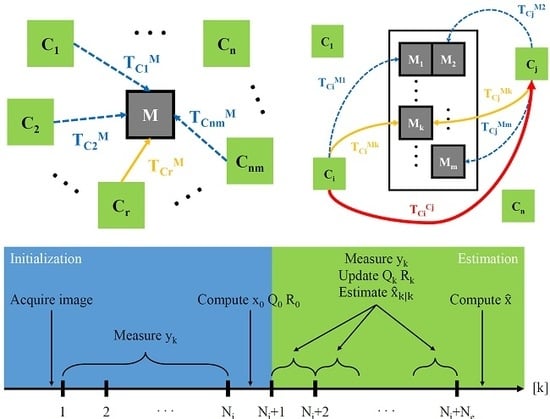

3.1. Adaptive Kalman Fusion Algorithm for Multiple Cameras and Fiducial Markers

| Algorithm 1: The proposed algorithm for multi-camera pose fusion. |

|

3.2. Setup Calibration Procedure

3.3. Position Estimation Procedure

4. Simulation Results

4.1. Monte Carlo Setup

- 3 cameras, a precision gauge with 5 markers, and one marker whose position must be estimated;

- 5 cameras, a precision gauge with 3 markers, and one marker whose position must be estimated;

- 5 cameras, a precision gauge with 5 markers, and one marker whose position must be estimated.

- Noises from different cameras and from different elements of the pose (X, Y, Z, , , and ) are considered completely uncorrelated. In real circumstances this might not be the case (e.g., the noise induced by the environment illumination which affects all the measurements in a similar manner) thus, any relaxed conditions are contributing to an increased precision of the estimation. This additional information is harnessed using the update procedure for Q and R covariance matrices (which in this case would no longer be diagonal);

- The precision of one camera measurement along the Z axis is 5 times lower compared with the X and Y axis. In the simulation this is taken as it is, but in a real situation, this effect can be diminished by placing the camera setup in an optimal configuration. For instance, the measurement along the Z axis from one camera can be replaced by measurements from two cameras placed in lateral positions, for which the Z axis motion is decomposed in X and Y components that have a higher precision.

4.2. Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Albus, J.S.; Barbera, A.J. RCS: A cognitive architecture for intelligent multi-agent systems. IFAC Proc. Vol. 2004, 37, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Prasanna, S.; Rao, S. An overview of wireless sensor networks applications and security. Int. J. Soft Comput. Eng. 2012, 2. [Google Scholar]

- Apolle, R.; Brückner, S.; Frosch, S.; Rehm, M.; Thiele, J.; Valentini, C.; Lohaus, F.; Babatz, J.; Aust, D.E.; Hampe, J.; et al. Utility of fiducial markers for target positioning in proton radiotherapy of oesophageal carcinoma. Radiother. Oncol. 2019, 133, 28–34. [Google Scholar] [CrossRef]

- Fiala, M. Artag fiducial marker system applied to vision based spacecraft docking. In Proceedings of the International Conference on Intelligent Robots and Systems (IROS) 2005 Workshop on Robot Vision for Space Applications, Edmonton, AB, Canada, 2 August 2005; pp. 35–40. [Google Scholar]

- Gales, S.; Tanaka, K.A.; Balabanski, D.L.; Negoita, F.; Stutman, D.; Tesileanu, O.; Ur, C.A.; Ursescu, D.; Andrei, I.; Ataman, S.; et al. The extreme light infrastructure-nuclear physics (ELI-NP) facility: New horizons in physics with 10 PW ultra-intense lasers and 20 MeV brilliant gamma beams. Rep. Prog. Phys. Phys. Soc. 2018, 81, 094301. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, K.A.; Spohr, K.M.; Balabanski, D.L.; Balascuta, S.; Capponi, L.; Cernaianu, M.O.; Cuciuc, M.; Cucoanes, A.; Dancus, I.; Dhal, A.; et al. Current status and highlights of the ELI-NP research program. Matter Radiat. Extrem. 2020, 5, 024402. [Google Scholar] [CrossRef] [Green Version]

- Popescu, D.C.; Cernaianu, M.O.; Dumitrache, I. Automatic rough alignment for key components in laser driven experiments using fiducial markers. J. Phys. Conf. Ser. 2018, 1079, 012013. [Google Scholar] [CrossRef]

- Popescu, D.C.; Cernăianu, M.O. Method and System for Automatic Positioning of Elements for Configurations of Experiments with High-Power Lasers; Romanian patent RO132327B1; Library Catalog: ESpacenet; OSIM: Bucharest, Romania, 2019. [Google Scholar]

- Fiala, M. ARTag, a fiducial marker system using digital techniques. In Proceedings of the 2005 IEEE Computer Society Conference on Computer Vision and Pattern Recognition (CVPR’05), San Diego, CA, USA, 20–25 June 2005; Volume 2, pp. 590–596. [Google Scholar] [CrossRef]

- Boby, R.A.; Saha, S.K. Single image based camera calibration and pose estimation of the end-effector of a robot. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 2435–2440. [Google Scholar] [CrossRef]

- Cai, C.; Dean-León, E.; Somani, N.; Knoll, A. 6D image-based visual servoing for robot manipulators with uncalibrated stereo cameras. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems, Chicago, IL, USA, 14–18 September 2014; pp. 736–742. [Google Scholar] [CrossRef] [Green Version]

- Chen, D.; Peng, Z.; Ling, X. A low-cost localization system based on artificial landmarks with two degree of freedom platform camera. In Proceedings of the 2014 IEEE International Conference on Robotics and Biomimetics (ROBIO 2014), Bali, Indonesia, 5–10 December 2014; pp. 625–630. [Google Scholar] [CrossRef]

- Babinec, A.; Jurišica, L.; Hubinský, P.; Duchoň, F. Visual Localization of Mobile Robot Using Artificial Markers. Procedia Eng. 2014, 96, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Bi, S.; Yang, D.; Cai, Y. Automatic Calibration of Odometry and Robot Extrinsic Parameters Using Multi-Composite-Targets for a Differential-Drive Robot with a Camera. Sensors 2018, 18, 3097. [Google Scholar] [CrossRef] [Green Version]

- Houben, S.; Droeschel, D.; Behnke, S. Joint 3D laser and visual fiducial marker based SLAM for a micro aerial vehicle. In Proceedings of the 2016 IEEE International Conference on Multisensor Fusion and Integration for Intelligent Systems (MFI), Baden-Baden, Germany, 19–21 September 2016; pp. 609–614. [Google Scholar] [CrossRef]

- Muñoz-Salinas, R.; Marín-Jimenez, M.J.; Medina-Carnicer, R. SPM-SLAM: Simultaneous localization and mapping with squared planar markers. Pattern Recognit. 2019, 86, 156–171. [Google Scholar] [CrossRef]

- Muñoz-Salinas, R.; Medina-Carnicer, R. UcoSLAM: Simultaneous localization and mapping by fusion of keypoints and squared planar markers. Pattern Recognit. 2020, 101, 107193. [Google Scholar] [CrossRef] [Green Version]

- Xing, B.; Zhu, Q.; Pan, F.; Feng, X. Marker-Based Multi-Sensor Fusion Indoor Localization System for Micro Air Vehicles. Sensors 2018, 18, 1706. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Poulose, A.; Han, D.S. Hybrid Indoor Localization Using IMU Sensors and Smartphone Camera. Sensors 2019, 19, 5084. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, Y.; Niu, X.; Du, J.; Chang, L.; Tang, H.; Zhang, H. Artificial Marker and MEMS IMU-Based Pose Estimation Method to Meet Multirotor UAV Landing Requirements. Sensors 2019, 19, 5428. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Popescu, D.C.; Cernaianu, M.O.; Ghenuche, P.; Dumitrache, I. An assessment on the accuracy of high precision 3D positioning using planar fiducial markers. In Proceedings of the 2017 21st International Conference on System Theory, Control and Computing (ICSTCC), Sinaia, Romania, 19–21 October 2017; pp. 471–476. [Google Scholar] [CrossRef]

- Sarmadi, H.; Muñoz-Salinas, R.; Berbís, M.A.; Medina-Carnicer, R. Simultaneous Multi-View Camera Pose Estimation and Object Tracking With Squared Planar Markers. IEEE Access 2019, 7, 22927–22940. [Google Scholar] [CrossRef]

- Garrido-Jurado, S.; Muñoz-Salinas, R.; Madrid-Cuevas, F.J.; Marín-Jiménez, M.J. Automatic generation and detection of highly reliable fiducial markers under occlusion. Pattern Recognit. 2014, 47, 2280–2292. [Google Scholar] [CrossRef]

- Garrido-Jurado, S.; Muñoz-Salinas, R.; Madrid-Cuevas, F.J.; Medina-Carnicer, R. Generation of fiducial marker dictionaries using Mixed Integer Linear Programming. Pattern Recognit. 2016, 51, 481–491. [Google Scholar] [CrossRef]

- Kalman, R.E. A New Approach to Linear Filtering and Prediction Problems. J. Basic Eng. 1960, 82, 35–45. [Google Scholar] [CrossRef] [Green Version]

- Hao, Y.; Xu, A.; Sui, X.; Wang, Y. A Modified Extended Kalman Filter for a Two-Antenna GPS/INS Vehicular Navigation System. Sensors 2018, 18, 3809. [Google Scholar] [CrossRef] [Green Version]

- Hosseinyalamdary, S. Deep Kalman Filter: Simultaneous Multi-Sensor Integration and Modelling; A GNSS/IMU Case Study. Sensors 2018, 18, 1316. [Google Scholar] [CrossRef] [Green Version]

- Bischoff, O.; Wang, X.; Heidmann, N.; Laur, R.; Paul, S. Implementation of an ultrasonic distance measuring system with kalman filtering in wireless sensor networks for transport logistics. Procedia Eng. 2010, 5, 196–199. [Google Scholar] [CrossRef] [Green Version]

- Li, S.E.; Li, G.; Yu, J.; Liu, C.; Cheng, B.; Wang, J.; Li, K. Kalman filter-based tracking of moving objects using linear ultrasonic sensor array for road vehicles. Mech. Syst. Signal Process. 2018, 98, 173–189. [Google Scholar] [CrossRef]

| Scenario | |||||

|---|---|---|---|---|---|

| Pose Element | UM | One Camera | #1 | #2 | #3 |

| X | (m) | 75.68 | 11.1 | 21.04 | 17.4 |

| Y | (m) | 75.1 | 11.14 | 12.7 | 11.88 |

| Z | (m) | 298.68 | 30.74 | 30.01 | 28.28 |

| AX | (deg) | 0.019 | 0.0016 | 0.0014 | 0.0013 |

| AY | (deg) | 0.019 | 0.0022 | 0.0024 | 0.0022 |

| AZ | (deg) | 0.019 | 0.0019 | 0.0018 | 0.0016 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popescu, D.C.; Dumitrache, I.; Caramihai, S.I.; Cernaianu, M.O. High Precision Positioning with Multi-Camera Setups: Adaptive Kalman Fusion Algorithm for Fiducial Markers. Sensors 2020, 20, 2746. https://0-doi-org.brum.beds.ac.uk/10.3390/s20092746

Popescu DC, Dumitrache I, Caramihai SI, Cernaianu MO. High Precision Positioning with Multi-Camera Setups: Adaptive Kalman Fusion Algorithm for Fiducial Markers. Sensors. 2020; 20(9):2746. https://0-doi-org.brum.beds.ac.uk/10.3390/s20092746

Chicago/Turabian StylePopescu, Dragos Constantin, Ioan Dumitrache, Simona Iuliana Caramihai, and Mihail Octavian Cernaianu. 2020. "High Precision Positioning with Multi-Camera Setups: Adaptive Kalman Fusion Algorithm for Fiducial Markers" Sensors 20, no. 9: 2746. https://0-doi-org.brum.beds.ac.uk/10.3390/s20092746