Development and Characterization of Embroidery-Based Textile Electrodes for Surface EMG Detection

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Development of Prototype

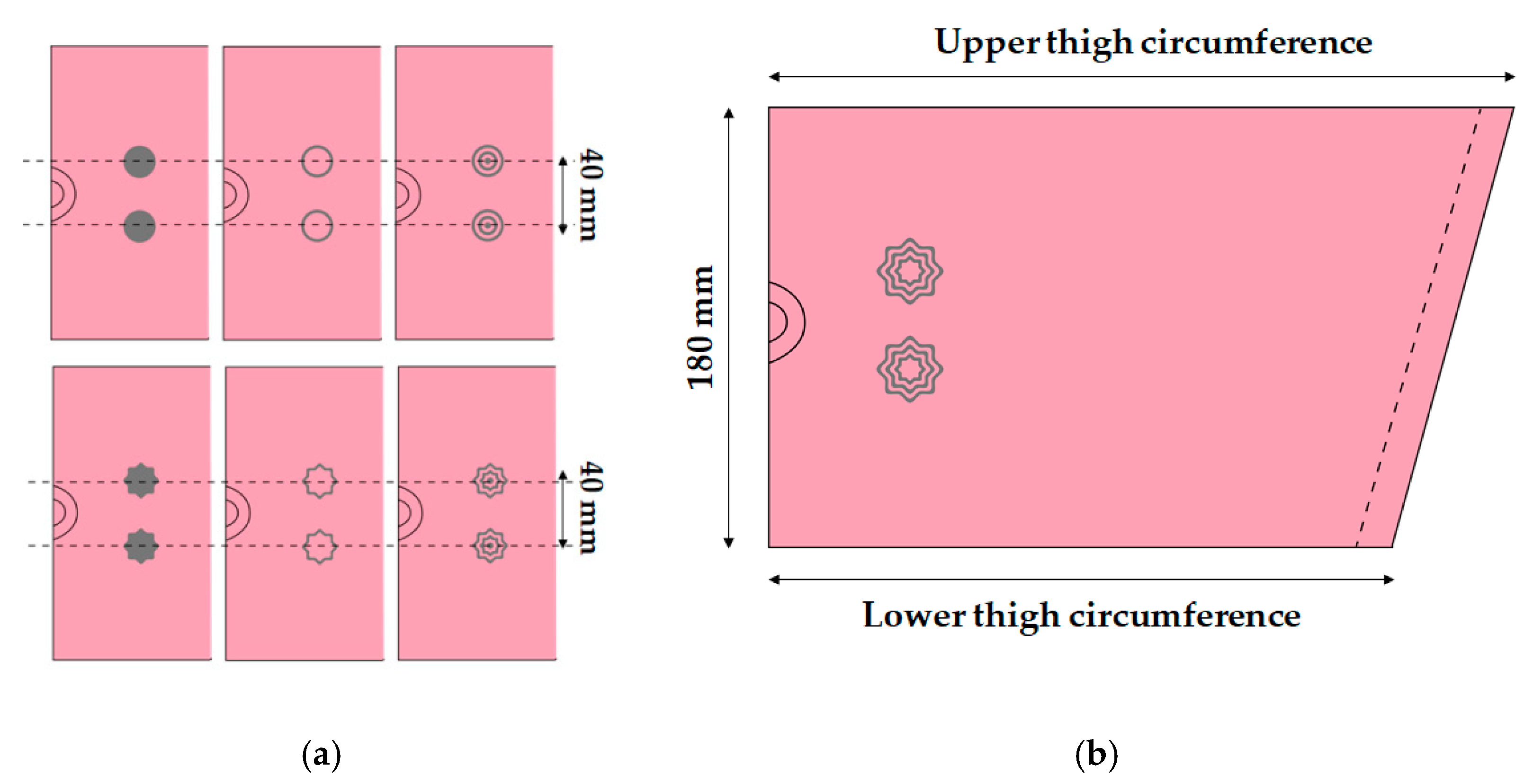

2.2.1. Design and Preparation of Embroidery Electrodes

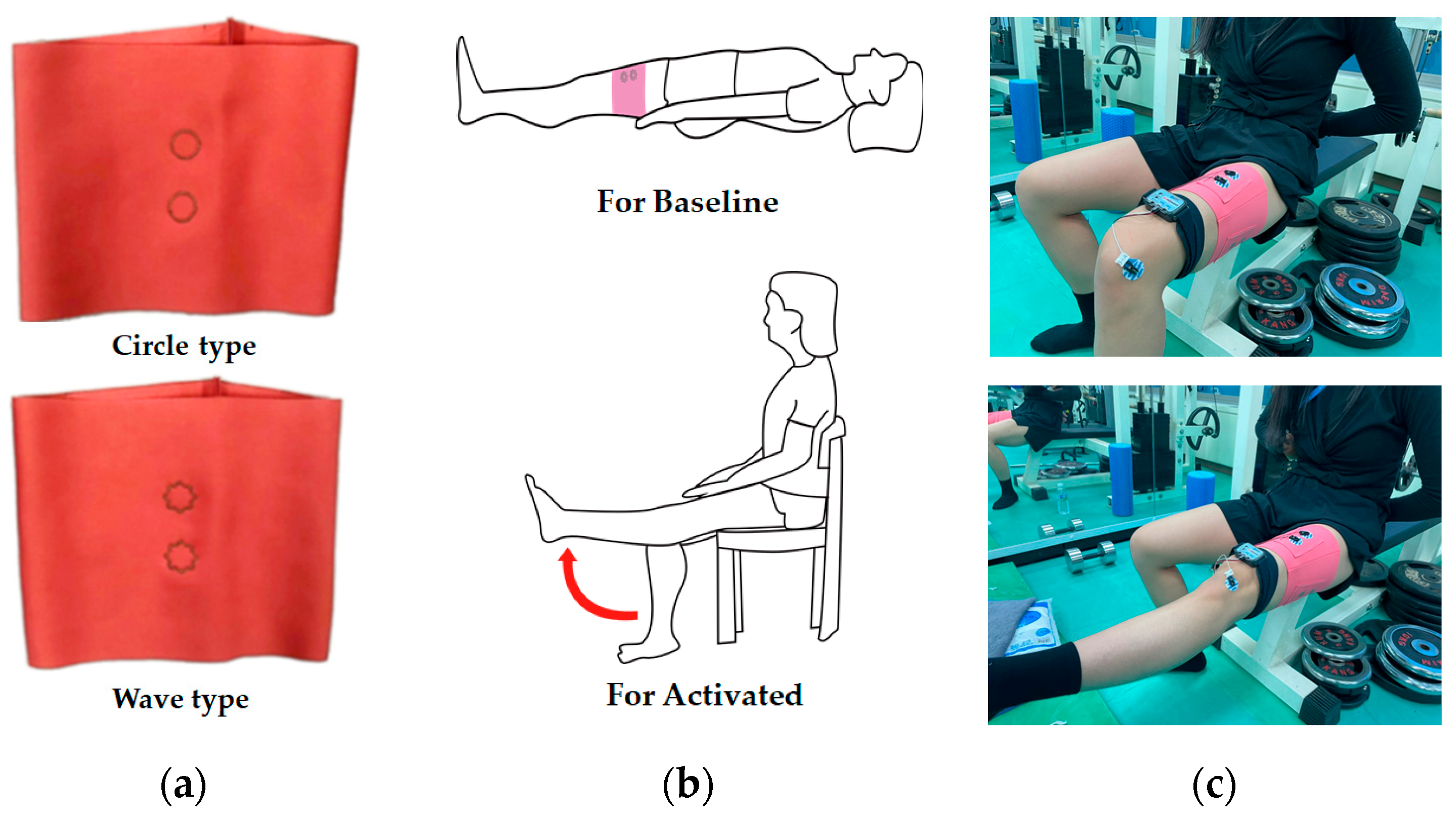

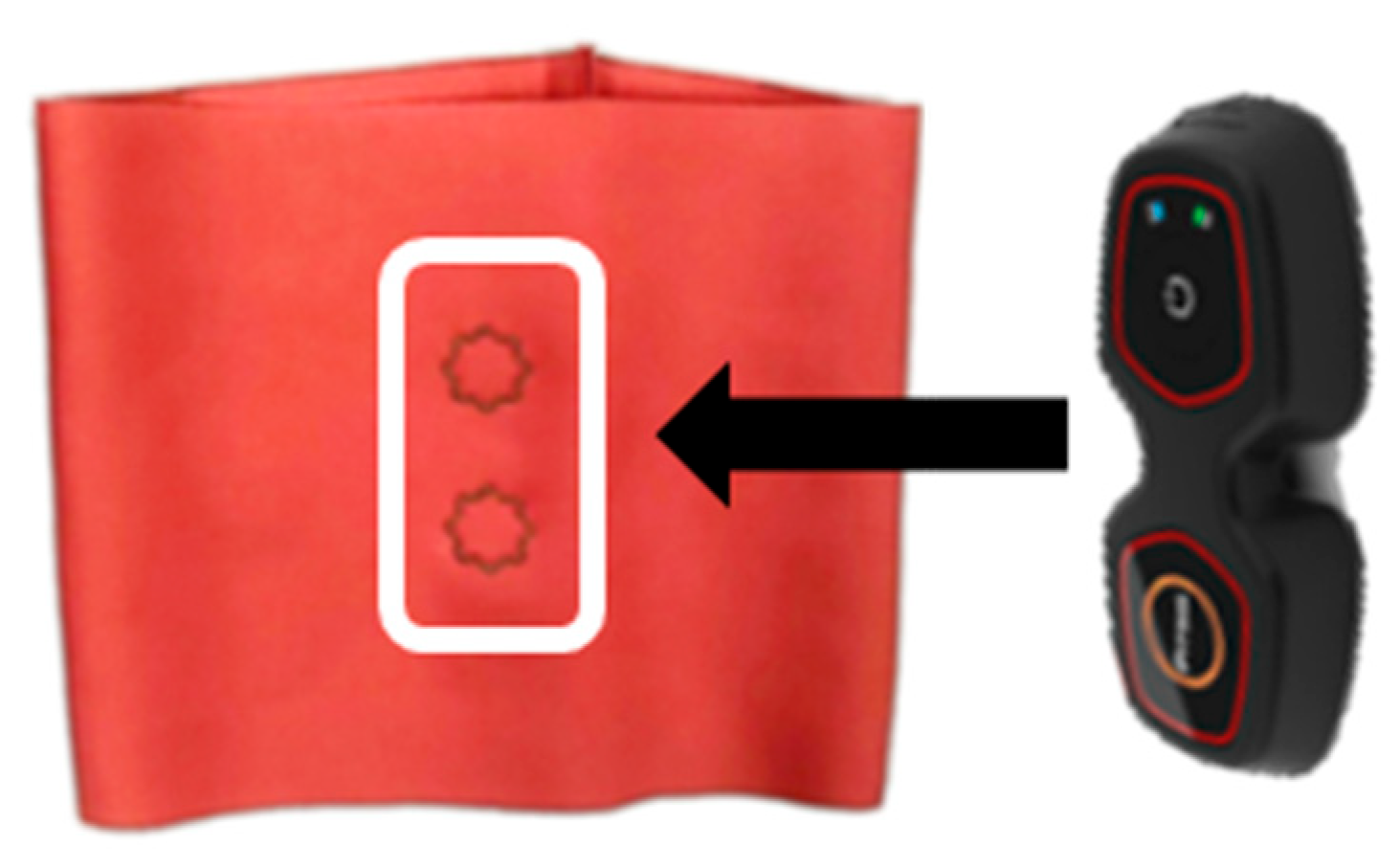

2.2.2. Preparation of Leg Sleeves Embedded the Embroidery Electrodes

2.3. Characterization

2.3.1. Morphology

2.3.2. Digital Image Correlation (DIC)

2.3.3. Skin-Electrode Impedance

2.3.4. sEMG Measurement and Data Processing

3. Results and Discussion

3.1. Morphology of the Embroidery-Based Textile Electrodes

3.2. Digital Image Correlation System Analysis of the Embroidery-Based Textile Electrodes

3.3. Skin-Electrode Impedance Analysis of the Embroidery Based Textile Electrodes

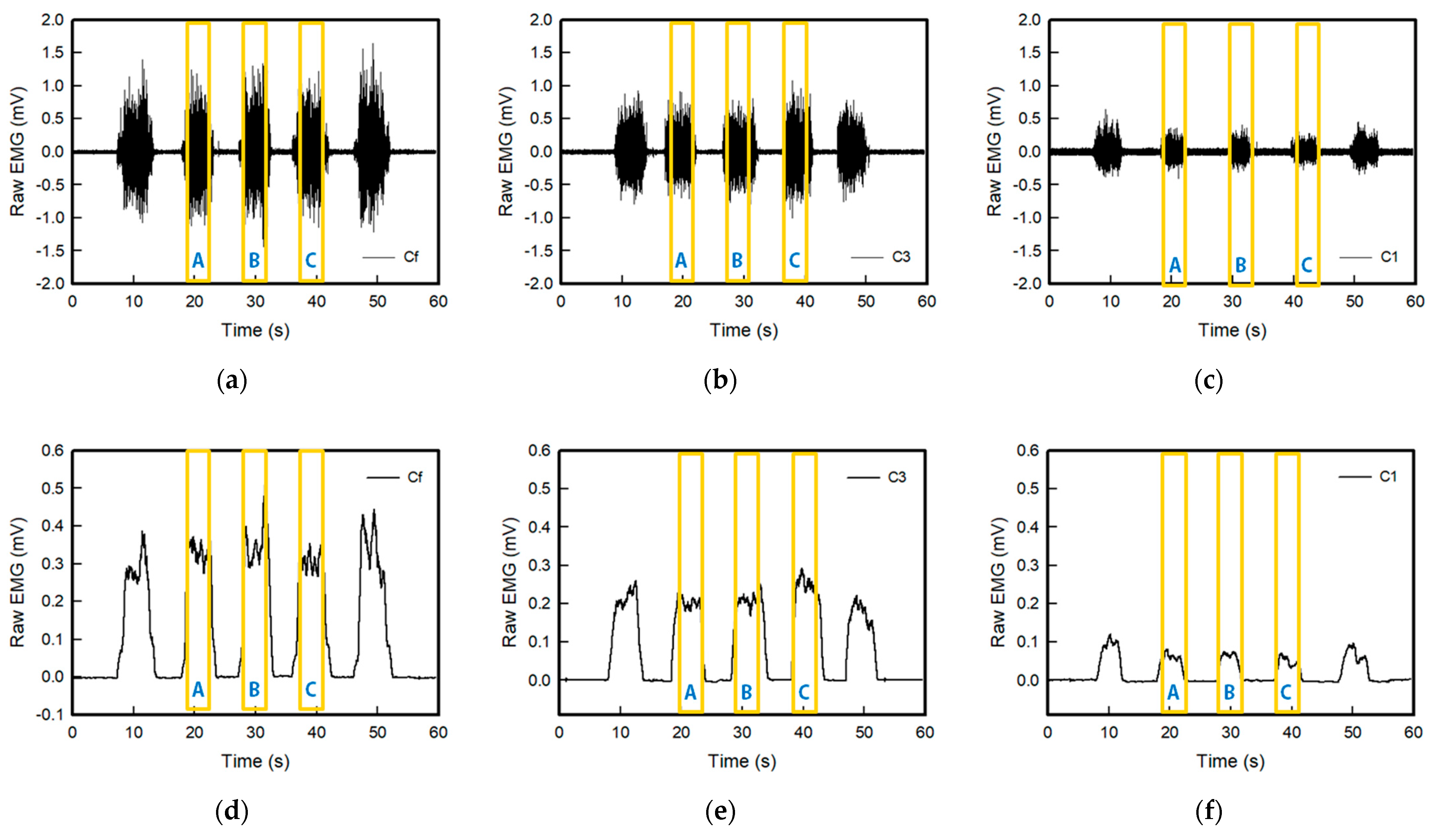

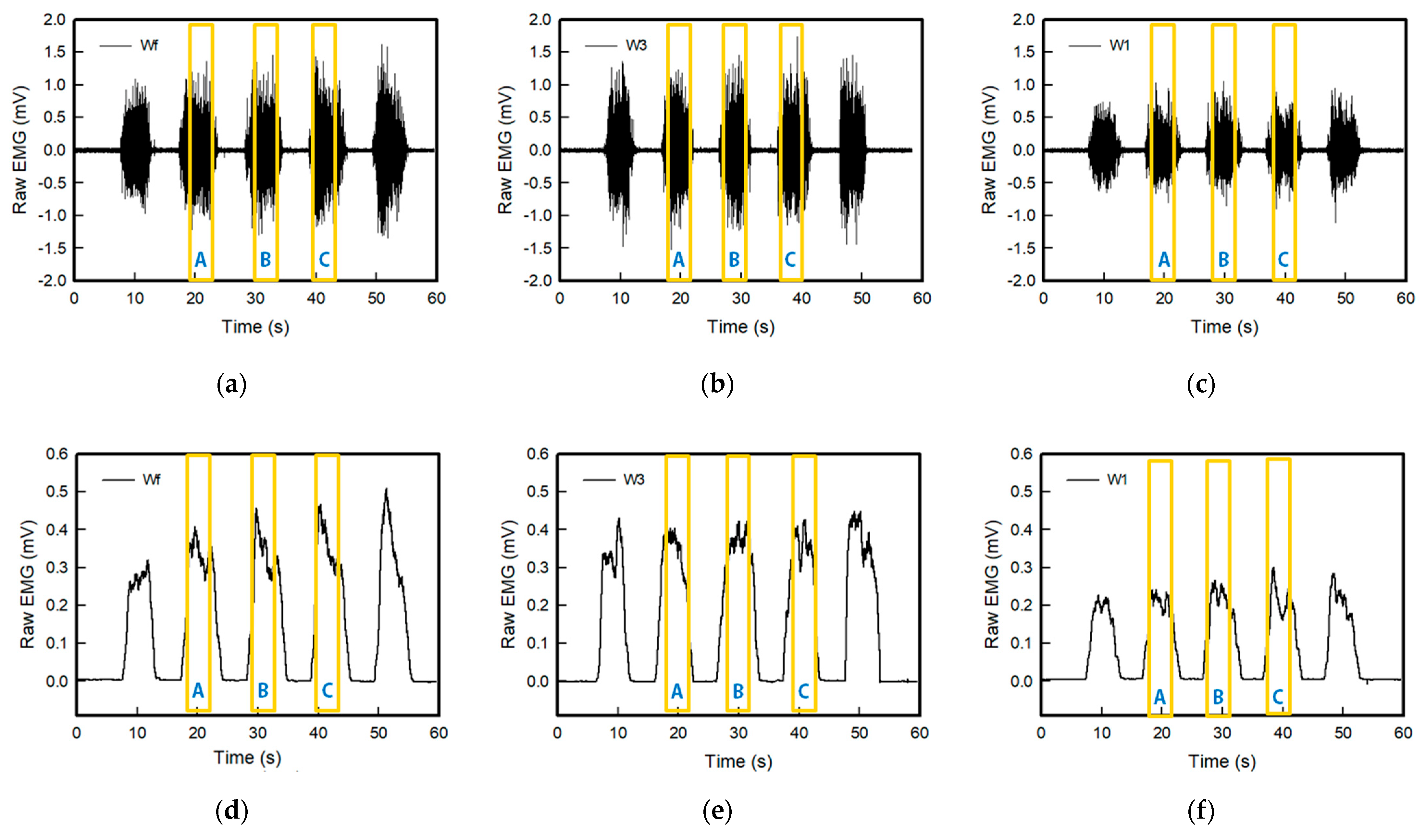

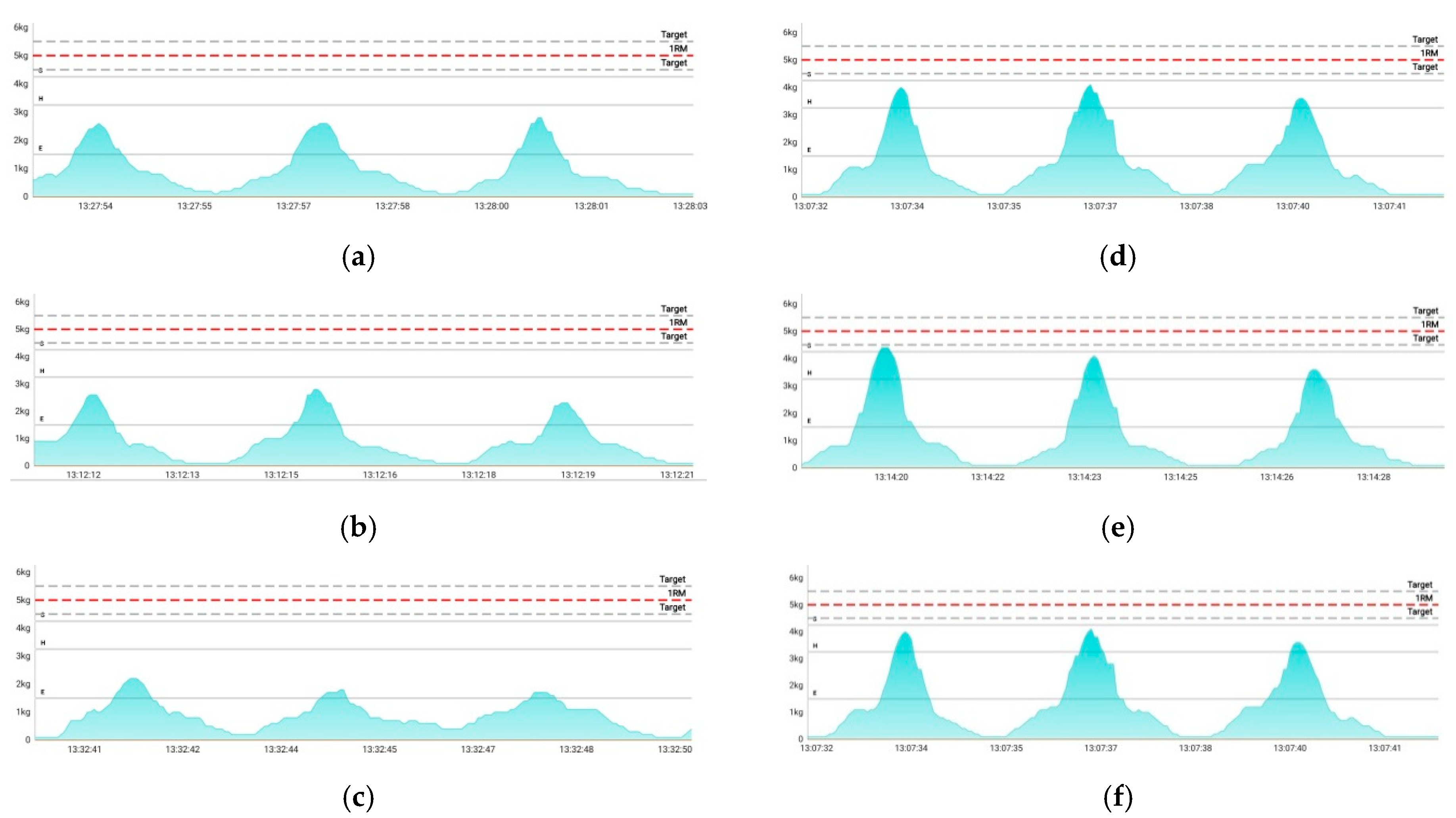

3.4. sEMG Signal and Average Rectified sEMG of the Embroidery-Based Textile Electrodes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guk, K.; Han, G.; Lim, J.; Jeong, K.; Kang, T.; Lim, E.-K.; Jung, J. Evolution of wearable devices with real-time disease monitoring for personalized healthcare. Nanomaterials 2019, 9, 813. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hughes-Riley, T.; Dias, T.; Cork, C. A historical review of the development of electronic textiles. Fibers 2018, 6, 34. [Google Scholar] [CrossRef] [Green Version]

- Choudhry, N.A.; Arnold, L.; Rasheed, A.; Khan, I.A.; Wang, L. Textronics—A review of textile-based wearable electronics. Adv. Eng. Mater. 2021, 23, 2100469. [Google Scholar] [CrossRef]

- Ismar, E.; Bahadir, S.K.; Kalaoglu, F.; Koncar, V. Futuristic clothes: Electronic textiles and wearable technologies. Glob. Chall. 2020, 4, 1900092. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tuvshinbayer, L.; Ehrmann, G.; Ehrmann, A. 50/60 Hz power grid noise as a skin contact measure of textile ECG electrodes. Textiles 2022, 2, 265–274. [Google Scholar] [CrossRef]

- Ehrmann, G.; Blachowicz, T.; Homburg, S.V.; Ehrmann, A. Measuring biosignals with single circuit boards. Bioengineering 2022, 9, 84. [Google Scholar] [CrossRef]

- Mamidwar, S.D.; Akshith, R.; Shakruwala, Z.; Chadha, U.; Srinivasan, K.; Chang, C.-Y. Recent advances on IoT-assisted wearable sensor systems healthcare monitoring. Biosensors 2021, 11, 372. [Google Scholar] [CrossRef]

- Gonçalves, C.; Silva, A.F.; Gomes, J.; Simoes, R. Wearable e-textile technologies: A review on sensors, actuators and control elements. Inventions 2018, 3, 14. [Google Scholar] [CrossRef] [Green Version]

- Angelucci, A.; Cavicchioli, M.; Cintorrino, I.A.; Lauricella, G.; Rossi, C.; Strati, S.; Aliverti, A. Smart textiles and sensorized garments for physiological monitoring: A review of available solutions and techniques. Sensors 2021, 21, 814. [Google Scholar] [CrossRef]

- Nigusse, A.B.; Mengistie, D.A.; Malengier, B.; Tseghai, G.B.; Langenhove, L.V. Wearable smart textiles for long-term electrocardiography monitoring—A review. Sensors 2021, 21, 4174. [Google Scholar] [CrossRef]

- Niu, X.; Gao, X.; Liu, Y.; Liu, H. Surface bioelectric dry electrodes: A review. Measurement 2021, 183, 109774. [Google Scholar] [CrossRef]

- Lynn, S.K.; Watkins, C.M.; Wong, M.A.; Balfany, K.; Feeney, D.F. Validity and reliability of surface electromyography measurements from a wearable athlete performance system. J. Sci. Med. Sport. 2018, 17, 205. [Google Scholar]

- Mazzetta, I.; Gentile, P.; Pessione, M.; Suppa, A.; Zampogna, A.; Bianchinim, E.; Irrera, F. Stand-alone wearable system for ubiquitous real-time monitoring of muscle activation potentials. Sensors 2018, 18, 1748. [Google Scholar] [CrossRef] [Green Version]

- Meziane, N.; Weabster, J.G.; Attari, M.; Nimunkar, A.J. Dry electrodes for electrocardiography. Physiol. Meas. 2013, 34, R47–R49. [Google Scholar] [CrossRef]

- Huang, Y.; Song, Y.; Gou, L.; Zou, Y. A novel wearable flexible dry electrode based on cowhide for ECG measurement. Biosensors 2021, 11, 101. [Google Scholar] [CrossRef]

- Prakash, A.; Sharma, S.; Sharma, N. A compact-sized surface EMG sensor for myoelectric hand prosthesis. Biomed. Eng. Lett. 2019, 9, 467–479. [Google Scholar] [CrossRef]

- Euler, L.; Guo, L.; Persson, N.-K. A review of textile-based electrodes developed for electrostimulation. Text. Res. J. 2021, 92, 1300–1320. [Google Scholar] [CrossRef]

- Acar, G.; Ozturk, O.; Golparvar, A.J.; Elboshra, T.A.; Böhringer, K.; Yapici, M.K. Wearable and flexible textile electrodes for biopotential signal monitoring: A review. Electronics 2019, 8, 479. [Google Scholar] [CrossRef] [Green Version]

- Blachowicz, T.; Ehrmann, G.; Ehrmann, A. Textile-based sensors for biosignal detection and monitoring. Sensors 2021, 21, 6042. [Google Scholar] [CrossRef]

- Arquilla, K.; Devendorf, L.; Webb, A.K.; Anderson, A.P. Detection of the complete ECG waveform with woven textile electrodes. Biosensors 2021, 11, 331. [Google Scholar] [CrossRef]

- Barrera, C.S.; Piña-Martínez, E.; Roberts, R.; Rodriguez-Leal, E. Impact of size and shape for textile surface electromyography electrodes: A study of the biceps brachii muscle. Text. Res. J. 2021, 00405175211048936. [Google Scholar] [CrossRef]

- Euler, L.; Guo, L.; Persson, N.-K. Textile electrodes: Influence of knitting construction and pressure on the contact impedance. Sensors 2021, 21, 1578. [Google Scholar] [CrossRef]

- Pani, D.; Achilli, A.; Spanu, A.; Bonfiglio, A.; Gazzoni, M.; Botter, A. Validation of polymer-based screen-printed textile electrodes for surface EMG detection. IEEE Trans. Neural. Syst. Rehabil. Eng. 2019, 27, 1370–1377. [Google Scholar] [CrossRef]

- Zaman, S.; Tao, X.; Cochrane, C.; Koncar, V. Understanding the washing damage to textile ECG dry skin electrodes, embroidered and fabric-based set up of equivalent laboratory test. Sensors 2020, 20, 1272. [Google Scholar] [CrossRef] [Green Version]

- Kamavuako, E.N.; Brown, M.; Bao, X.; Chihi, I.; Pitou, S.; Howard, M. Affordable embroidered EMG electrodes for myoelectric control of prostheses: A pilot study. Sensors 2021, 21, 5245. [Google Scholar] [CrossRef]

- Pitou, S.; Michael, B.; Thompson, K.; Howard, M. Hand-made embroidered electromyography: Towards a solution for low-income countries. Sensors 2020, 20, 3347. [Google Scholar] [CrossRef]

- Goncu-Berk, G.; Tuna, B.G. The effect of sleeve pattern and fit on e-textile electromyography (EMG) electrode performance in smart clothing design. Sensors 2021, 21, 5621. [Google Scholar] [CrossRef]

- Kim, S.; Lee, S.; Jeong, W. EMG measurement with textile-based electrodes in different electrode sizes and clothing pressures for smart clothing design optimization. Polymers 2020, 12, 2406. [Google Scholar] [CrossRef]

- Wu, W. Stretchable electronics: Functional materials, fabrication strategies and applications. Sci. Technol. Adv. Mater. 2019, 20, 188. [Google Scholar] [CrossRef] [Green Version]

- Shahandashti, P.F.; Pourkheyrollah, H.; Jahanshahi, A.; Ghafoorifard, H. Highly conformable stretchable dry electrodes based on inexpensive flex substrate for long-term biopotential (EMG/ECG) monitoring. Sens. Actuators A Phys. 2019, 295, 678–686. [Google Scholar] [CrossRef]

- Stauffer, F.; Thielen, M.; Sauter, C.; Chardonnens, S.; Bachmann, S.; Tybrandt, K.; Peters, C.; Hierold, C.; Vörös, J. Skin conformal polymer electrodes for clinical ECG and EEG recordings. Adv. Healthc. Mater. 2018, 7, 1700994. [Google Scholar] [CrossRef] [PubMed]

- Tang, D.; Yu, Z.; He, Y.; Asghar, W.; Zheng, Y.-N.; Li, F.; Shi, C.; Zarei, R.; Liu, Y.; Shang, J.; et al. Strain-insensitive elastic surface electromyographic(sEMG) electrode for efficient recognition of exercise intensities. Micromachines 2020, 11, 239. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Type | Sample Code | Number of Lines | Designed Image | Sample Image |

|---|---|---|---|---|

| Circle | Cf | Fill |  |  |

| C3 | 3 |  |  | |

| C1 | 1 |  |  | |

| Wave | Wf | Fill |  |  |

| W3 | 3 |  |  | |

| W1 | 1 |  |  |

| Sample Code | ||||||

|---|---|---|---|---|---|---|

| Cf | C3 | C1 | Wf | W3 | W1 | |

| 3D image |  |  |  |  |  |  |

| Area of conductive yarn |  |  |  |  |  |  |

| Total length (mm) | 812.0 | 565.0 | 360.0 | 822.0 | 693.0 | 419.0 |

| Total area (mm2) | 32.5 | 28.8 | 16.7 | 36.6 | 24.5 | 22.3 |

| 10% | 20% | 30% | ||||

|---|---|---|---|---|---|---|

| Circle | Wave | Circle | Wave | Circle | Wave | |

| Fill |  |  |  |  |  |  |

| 3 |  |  |  |  |  |  |

| 1 |  |  |  |  |  |  |

| 10% | 20% | 30% | ||||

|---|---|---|---|---|---|---|

| Circle | Wave | Circle | Wave | Circle | Wave | |

| Fill |  |  |  |  |  |  |

| 3 |  |  |  |  |  |  |

| 1 |  |  |  |  |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.; Kim, S.; Lim, D.; Jeong, W. Development and Characterization of Embroidery-Based Textile Electrodes for Surface EMG Detection. Sensors 2022, 22, 4746. https://0-doi-org.brum.beds.ac.uk/10.3390/s22134746

Kim H, Kim S, Lim D, Jeong W. Development and Characterization of Embroidery-Based Textile Electrodes for Surface EMG Detection. Sensors. 2022; 22(13):4746. https://0-doi-org.brum.beds.ac.uk/10.3390/s22134746

Chicago/Turabian StyleKim, Hyelim, Siyeon Kim, Daeyoung Lim, and Wonyoung Jeong. 2022. "Development and Characterization of Embroidery-Based Textile Electrodes for Surface EMG Detection" Sensors 22, no. 13: 4746. https://0-doi-org.brum.beds.ac.uk/10.3390/s22134746