Insulation and Evaporative Resistance of Clothing for Sugarcane Harvesters and Chemical Sprayers, and Their Application in PHS Model-Based Exposure Predictions

Abstract

:1. Introduction

- (a)

- measure the insulation and evaporative resistance of the clothing used in the agricultural sector for the sugar industry for two tasks—sugarcane harvesting and chemical spraying and-

- (b)

- utilize the outcome in a predicted heat strain model (PHS) according to an international standard [6] for allowed exposure time prediction and recommendations.

2. Materials and Methods

2.1. Measurements of Clothing Properties

2.1.1. Clothing Insulation

2.1.2. Evaporative Resistance

2.1.3. Data Presentation

2.2. Exposure Evaluation According to Predicted Heat Strain Model (PHS)

3. Results

3.1. Manikin Tests

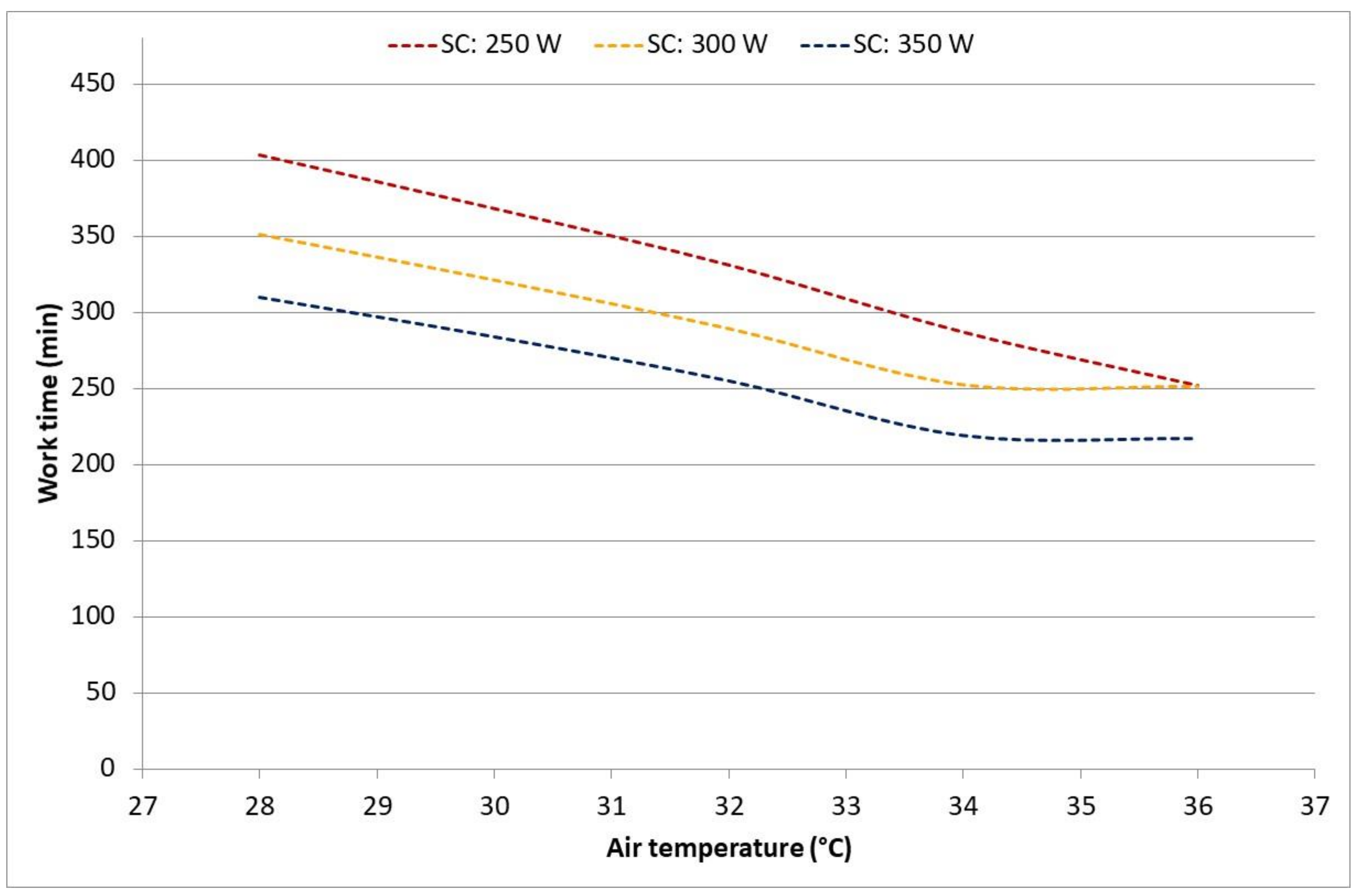

3.2. Evaluation of Heat Strain with PHS

4. Discussion

4.1. Manikin Tests

4.2. Evaluation of Heat Strain with PHS

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Roncal-Jiménez, C.; García-Trabanino, R.; Barregard, L.; Lanaspa, M.A.; Wesseling, C.; Harra, T.; Aragón, A.; Grases, F.; Jarquin, E.R.; González, M.; et al. Heat stress nephropathy from exercise-induced uric acid crystalluria: A perspective on mesoamerican nephropathy. Am. J. Kidney Dis. 2016, 67, 20–30. [Google Scholar] [CrossRef] [PubMed]

- Wesseling, C.; Aragón, A.; González, M.; Weiss, I.; Glaser, J.; Bobadilla, N.A.; Roncal-Jiménez, C.; Correa-Rotter, R.; Johnson, R.J.; Barregard, L. Kidney function in sugarcane cutters in Nicaragua—A longitudinal study of workers at risk of Mesoamerican nephropathy. Environ. Res. 2016, 147, 125–132. [Google Scholar] [CrossRef] [PubMed]

- Moran, D.S.; Gaffin, S.L. Clinical Management of Heat-Related Illnesses. Chapter 11. In Wilderness Medicine, 5th ed.; Auerbach, P.S., Ed.; Mosby Elsevier: Maryland Heights, MO, USA, 2007; pp. 268–283. [Google Scholar]

- Knochel, J.P. Environmental heat illness: An eclectic review. Arch. Intern. Med. 1974, 133, 841–864. [Google Scholar] [CrossRef] [PubMed]

- Knochel, J.P.; Reed, G. Disorders of heat regulation. In Clinical Disorders of Fluid and Electrolyte Metabolism; Kleeman, C.R., Maxwell, M.H., Narin, R.G., Eds.; McGraw-Hill: New York, NY, USA, 1987. [Google Scholar]

- ISO 7933:2004. Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Heat Stress Using Calculation of the Predicted Heat Strain; The International Organisation for Standardisation: Geneva, Switzerland, 2004. [Google Scholar]

- Hänel, S.E. A joint Nordic project to develop an improved thermal manikin for modeling and measuring human heat exchange. In Paper Presented at the Medical and Biophysical Aspects on Protective Clothing; Centre de Recherches du Service de Santk des Armks: Lyon, France, 1983; pp. 280–282. [Google Scholar]

- Kuklane, K.; Heidmets, S.; Johansson, T. Improving thermal comfort in an orthopaedic aid: Better Boston Brace for scoliosis patients. In Proceedings of the Paper Presented at the 6th International Meeting on Manikins and Modelling (6I3M), The Hong Kong Polytechnic University. Hong Kong, China, 16–18 October 2006; pp. 343–351. [Google Scholar]

- ISO 15831:2004. Clothing—Physiological Effects—Measurement of Thermal Insulation by Means of a Thermal Manikin; International Organisation for Standardisation: Geneva, Switzerland, 2004. [Google Scholar]

- ISO 9920:2007. Ergonomics of the Thermal Environment—Estimation of Thermal Insulation and Water Vapour Resistance of a Clothing Ensemble; International Organisation for Standardisation: Geneva, Switzerland, 2007. [Google Scholar]

- Havenith, G.; Kuklane, K.; Fan, J.; Hodder, S.; Ouzzahra, Y.; Lundgren, K.; Au, Y.; Loveday, D. A Database of Static Clothing Thermal Insulation and Vapor Permeability Values of Non-Western Ensembles for Use in ASHRAE Standard 55, ISO 7730, and ISO 9920. ASHRAE Trans. 2015, 121, 197–215. [Google Scholar]

- ASTM F2370-15. Standard Test Method for Measuring the Evaporative Resistance of Clothing Using a Sweating Manikin; [Standard]; American Society of Testing and Materials International (ASTM): Philadelphia, PA, USA, 2015. [Google Scholar]

- Wang, F.; Kuklane, K.; Gao, C.; Holmér, I. Development and validity of a universal empirical equation to predict skin surface temperature on thermal manikins. J. Biol. 2010, 35, 197–203. [Google Scholar] [CrossRef]

- Bröde, P.; Fiala, D.; Lemke, B.; Kjellström, T. Estimated work ability in outdoor warm environments depends on the chosen heat stress assessment metric. Int. J. Biometerol. 2017. [Google Scholar] [CrossRef] [PubMed]

- Lundgren-Kownacki, K.; Martínez, N.; Johansson, B.; Psikuta, A.; Annaheim, S.; Kuklane, K. Human responses in heat—Comparison of the Predicted Heat Strain and the Fiala multi-node model for a case of intermittent work. J. Therm. Biol. 2017, 70, 45–52. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, F.; Gao, C.; Kuklane, K.; Holmér, I. Effects of various protective clothing and thermal environments on heat strain of unacclimated men: The PHS (predicted heat strain) model revisited. Ind. Health 2013, 51, 266–274. [Google Scholar] [CrossRef]

- Lundgren, K.; Kuklane, K.; Venugopal, V. Occupational heat stress and associated productivity loss estimation using the PHS model (ISO 7933): A case study from workplaces in Chennai, India. Glob Health Action 2014, 7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ISO 8996:2004. Ergonomics of the Thermal Environment—Determination of Metabolic Rate; International Organisation for Standardisation: Geneva, Switzerland, 2004. [Google Scholar]

- Fiala, D.; Havenith, G. Modelling Human Heat Transfer and Temperature Regulation. In Studies in Mechanobiology, Tissue Engineering and Biomaterials; Gefen, A., Ed.; Springer: New York, NY, USA, 2015. [Google Scholar]

- Gao, C.; Kuklane, K.; Holmér, I. Cooling vests with phase change materials: The effects of melting temperature on heat strain alleviation in an extremely hot environment. Eur. J. Appl. Physiol. 2011, 111, 1207–1216. [Google Scholar] [CrossRef]

- Kuklane, K.; Gao, C.; Holmér, I. Ventilation solutions in clothing. In Proceedings of the 10th Joint International Scientific Conference CLOTECH 2012: Innovations in Textile Materials & Protective Clothing, Warsaw, Poland, 20–21 September 2012; pp. 205–212. [Google Scholar]

- Zhao, M.; Kuklane, K.; Lundgren, K.; Gao, C.; Wang, F. A ventilation cooling shirt worn during office work in a hot climate: Cool or not? Int. J. Occup. Saf. Ergon. 2015, 21, 457–463. [Google Scholar] [CrossRef] [PubMed]

- Parsons, K. Human Thermal Environments, 3rd ed.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2014. [Google Scholar]

- ISO 15265:2004. Ergonomics of Thermal Environments—Strategy of Evaluation of the Risk for the Prevention of Constraints or Discomfort under Thermal Working Conditions; International Organization for Standardization: Geneva, Switzerland, 2004. [Google Scholar]

- Malchaire, J.; Kampmann, B.; Mehnert, P.; Gebhardt, H.; Piette, A.; Havenith, G.; Holmér, I.; Parsons, K.; Alfano, G.; Griefahn, B. Assessment of the risk of heat disorders encountered during work in hot conditions. Int. Arch. Occup. Environ. Health 2002, 75, 153–162. [Google Scholar] [CrossRef] [PubMed]

- Petersson, J.; Kuklane, K.; Gao, C. Is there a need to integrate human thermal models with weather forecasts to predict thermal stress? Int. J. Environ. Res. Public Health 2019, 16, 4586. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Parameter | SC | CP |

|---|---|---|

| Acclimatization | 1 | 1 |

| Drink freely available | 1 | 1 |

| Body height | 1.75 | 1.75 |

| Body mass | 70 | 70 |

| Body surface area (calculated from mass and height, m2) | 1.84 | 1.84 |

| Posture: (1 = sitting, 2 = standing, 3 = crouching) | 2 | 2 |

| Air temperature | 34 (28–36) | 34 (28–36) |

| Air velocity | 2.0 | 2.0 |

| Metabolic energy production | 250, 300, 350 | 200, 250, 300 |

| Clothing basic insulation (1 clo = 0.155 m2 K/W) | 0.69 | 1.14 |

| Static moisture permeability index(calculated from insulation and evaporative resistance) | 0.55 | 0.19 |

| Fraction covered by reflective clothing | 0 | 0 |

| Angle between wind and walking direction | not used | not used |

| Walking speed | 0.5 | 0.5 |

| Mechanical power | 0 | 0 |

| Air Layer | Textile | Sugarcane Cutters | Chemical Sprayers | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Body Parts | IT (=Ia) | ITr (=Iar) | Diff (%) | skinIT | IT | ITr | ITr/IT | Diff (%) | IT | ITr | ITr/IT | Diff (%) |

| L.Hand | 0.108 | 0.055 | −48.7 | 0.135 | 0.180 | 0.114 | 0.63 | −36.5 | 0.181 | 0.123 | 0.68 | −32.1 |

| Hands | 0.100 | 0.053 | −47.5 | 0.132 | 0.137 | 0.077 | 0.56 | −44.0 | 0.172 | 0.115 | 0.67 | −33.3 |

| R.Hand | 0.093 | 0.050 | −46.5 | 0.129 | 0.109 | 0.057 | 0.52 | −47.9 | 0.165 | 0.108 | 0.65 | −34.8 |

| Feet | 0.103 | 0.057 | −44.7 | 0.122 | 0.181 | 0.144 | 0.80 | −20.0 | 0.208 | 0.149 | 0.72 | −28.1 |

| Lower Arms | 0.101 | 0.056 | −44.2 | 0.142 | 0.172 | 0.105 | 0.61 | −39.3 | 0.259 | 0.165 | 0.64 | −36.1 |

| L.Lower leg | 0.082 | 0.051 | −38.3 | 0.111 | 0.168 | 0.128 | 0.76 | −24.0 | 0.269 | 0.205 | 0.76 | −23.8 |

| Arms | 0.104 | 0.069 | −33.4 | 0.147 | 0.194 | 0.115 | 0.59 | −40.5 | 0.258 | 0.160 | 0.62 | −38.1 |

| Upper arms | 0.105 | 0.078 | −25.8 | 0.149 | 0.209 | 0.122 | 0.59 | −41.4 | 0.259 | 0.158 | 0.61 | −39.3 |

| Lower legs | 0.082 | 0.063 | −23.2 | 0.116 | 0.181 | 0.147 | 0.81 | −18.9 | 0.255 | 0.212 | 0.83 | −16.9 |

| Total | 0.098 | 0.076 | −22.0 | 0.131 | 0.191 | 0.143 | 0.75 | −25.3 | 0.257 | 0.188 | 0.73 | −26.8 |

| Legs | 0.089 | 0.071 | −19.8 | 0.118 | 0.206 | 0.154 | 0.74 | −25.6 | 0.287 | 0.205 | 0.71 | −28.6 |

| Head, hands & feet excluded | 0.093 | 0.076 | −18.4 | 0.131 | 0.195 | 0.146 | 0.75 | −25.3 | 0.278 | 0.200 | 0.72 | −28.3 |

| Belly | 0.093 | 0.078 | −16.2 | 0.121 | 0.331 | 0.261 | 0.79 | −21.1 | 0.457 | 0.322 | 0.70 | −29.6 |

| Thighs | 0.095 | 0.080 | −15.2 | 0.121 | 0.229 | 0.160 | 0.70 | −29.9 | 0.316 | 0.202 | 0.64 | −35.9 |

| R.Lower leg | 0.082 | 0.075 | −8.1 | 0.121 | 0.194 | 0.166 | 0.86 | −14.4 | 0.241 | 0.219 | 0.91 | −9.2 |

| Buttocks | 0.070 | 0.064 | −7.9 | 0.107 | 0.253 | 0.220 | 0.87 | −13.1 | 0.396 | 0.281 | 0.71 | −29.1 |

| Torso | 0.092 | 0.086 | −6.3 | 0.135 | 0.187 | 0.163 | 0.87 | −12.8 | 0.283 | 0.226 | 0.80 | −20.2 |

| Back | 0.093 | 0.090 | −4.0 | 0.146 | 0.158 | 0.141 | 0.89 | −11.3 | 0.228 | 0.190 | 0.83 | −16.7 |

| Chest | 0.105 | 0.104 | −0.6 | 0.152 | 0.160 | 0.141 | 0.88 | −11.8 | 0.262 | 0.216 | 0.82 | −17.7 |

| Head | 0.174 | 0.184 | 5.9 | 0.144 | 0.208 | 0.208 | 1.00 | 0.1 | 0.198 | 0.193 | 0.98 | −2.2 |

| Body Parts | Textile Skin | Sugarcane Cutters | Chemical Sprayers |

|---|---|---|---|

| R.Hand | 4.6 | 6.0 | 446.6 |

| Hands | 5.8 | 9.2 | 305.3 |

| L.Lower leg | 7.8 | 32.6 | 132.4 |

| Legs | 7.8 | 28.1 | 65.7 |

| Thighs | 7.4 | 27.7 | 56.7 |

| L.Hand | 7.7 | 16.1 | 245.8 |

| Lower Arms | 8.1 | 14.7 | 87.0 |

| Belly | 6.9 | 43.7 | 585.3 |

| Lower legs | 9.1 | 29.4 | 99.5 |

| Total | 8.2 | 20.9 | 81.0 |

| Head, hands & feet excluded | 8.3 | 21.2 | 92.2 |

| Hands & feet excluded | 8.4 | 20.6 | 73.7 |

| Hands excluded | 8.4 | 22.2 | 78.1 |

| Feet | 7.4 | 65.6 | 188.8 |

| Arms | 8.7 | 18.4 | 73.9 |

| R.Lower leg | 10.3 | 26.3 | 66.5 |

| Torso | 8.7 | 18.2 | 180.9 |

| Back | 9.0 | 13.8 | 165.1 |

| Upper arms | 9.1 | 21.2 | 70.4 |

| Buttocks | 9.2 | 32.3 | 98.6 |

| Chest | 9.2 | 14.6 | 203.1 |

| Head | 9.9 | 16.0 | 20.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuklane, K.; Toma, R.; Lucas, R.A.I. Insulation and Evaporative Resistance of Clothing for Sugarcane Harvesters and Chemical Sprayers, and Their Application in PHS Model-Based Exposure Predictions. Int. J. Environ. Res. Public Health 2020, 17, 3074. https://0-doi-org.brum.beds.ac.uk/10.3390/ijerph17093074

Kuklane K, Toma R, Lucas RAI. Insulation and Evaporative Resistance of Clothing for Sugarcane Harvesters and Chemical Sprayers, and Their Application in PHS Model-Based Exposure Predictions. International Journal of Environmental Research and Public Health. 2020; 17(9):3074. https://0-doi-org.brum.beds.ac.uk/10.3390/ijerph17093074

Chicago/Turabian StyleKuklane, Kalev, Róbert Toma, and Rebekah A.I. Lucas. 2020. "Insulation and Evaporative Resistance of Clothing for Sugarcane Harvesters and Chemical Sprayers, and Their Application in PHS Model-Based Exposure Predictions" International Journal of Environmental Research and Public Health 17, no. 9: 3074. https://0-doi-org.brum.beds.ac.uk/10.3390/ijerph17093074