1. Introduction

During drilling operation, a permanent concern is kick risk forecasting and well control. A kick is defined as the uncontrolled influx of formation fluid or gas into the wellbore, which occurs when the wellbore pressure at a certain location is less than the formation pressure, and requires a well control emergency plan [

1]. Influx fluids tend to have a high pressure; a gas kick is much more detrimental than a liquid kick due to gas expansion and, as a result, has a higher variation in pressure. Late kick detection and risk forecast increase the amount of formation fluid that enters the well borehole, which increases the kick pressure and makes it hard to control the kick and can even lead to an uncontrolled blowout. For well control safety, it is necessary to forecast the risk of a kick to reduce the shut-in time of a well and provide more time for the killing operation.

As a kick can pose a significant threat to safety drilling, a lot of work has been devoted to detecting kicks. Nowadays, kick-detection methods have developed from simple thresholding methods [

2] into complex intelligent methods based on machine learning [

3,

4,

5,

6,

7,

8,

9,

10]. Sun et al. [

3] proposed one integrated pattern-recognition model consisting of a dynamic multiphase wellbore flow model and improved the piecewise approximation and similarity measure algorithms for kick diagnosis. P. Andia and R. R. Israel [

4] utilized a cyber-physical approach that combined physics-based modeling with Bayesian mathematics for detecting a kick. Shi et al. [

5] adopted the random forest and support vector machine algorithms to detect a kick during drilling in real-time. Alouhali et al. [

6] trained and evaluated five models—Decision Tree, K-Nearest Neighbor (KNN), Sequential Minimal Optimization (SMO) Algorithm, Artificial Neural Network (ANN), and Bayesian Network—to detect kicks based on actual kick cases. The Decision Tree and K-Nearest Neighbor were shown to be slightly more accurate than the others. Hargreaves et al. [

7] used a Bayesian probabilistic framework to detect a kick early based on noisy drilling data. Pournazari et al. [

8] proposed a pattern-recognition system based on Symbolic Aggregate Approximation (SAX) to identify a kick. Unrau et al. [

9] undertook modern machine learning techniques to reduce false kick alarm rates while increasing the probability of kick detection. Brakel J et al. [

10] applied modern noise reduction and pattern-recognition signal processing to produce earlier and more informative kick-detection notification. However, their work was mainly done to detect a kick, whether or not by machine learning, not to predict the development trend of kick risk.

Once a kick occurs, the first thing to do is to decide whether and when to close the well. According to specifications for well control technology in oil and gas drilling by the Sinopec Group, an alarm should be triggered when the pit gain is 2 m3, and the well should be closed when the pit gain is 3 m3. As pit gain can indirectly reflect the volume and rate of formation fluid intrusion into the wellbore, pit gain can be treated as an important indicator of kick risk before well shut-in. Once the well is shut in, the casing annulus pressure will rise because of the wellbore afterflow and gas slippage, thus, casing pressure can be treated as the indicator of kick risk after well shut-in. Therefore, the kick risk can be forecasted through forecasting the pit gain before well shut-in and the casing pressure after well shut-in.

At present, as it was in the past, gas–liquid two-phase fluid dynamics is the main method used by scholars to simulate and forecast kick parameters before and after well shut-in. John Billingham [

11] considered the influences of wellbore afterflow and slippage and simulated and analyzed the change in wellbore pressure during shut-in by using a continuous gas column model. Avelar et al. [

12], Gao et al. [

13], and Sun et al. [

14] used gas–liquid two-phase flow to simulate the overflow and wellbore pressure distribution in deepwater drilling. Ren et al. [

15] established a gas–liquid two-phase flow model to determine the gas invasion velocity and location during drilling by using the relationship between the standpipe pressure and the gas invasion velocity and height. Aarsnes et al. [

16] and Meng et al. [

17] used a transient two-phase flow model to simulate and predict the annulus pressure profile in the gas invasion into the wellbore. Based on percolation mechanics and gas–liquid two-phase flow, Ren et al. [

18] considered the wellbore afterflow effect and gas slippage effect to simulate the bottom hole pressure during shut-in. Due to the laws of formation fluid invading the wellbore and those of the multiphase fluid flow in the wellbore being very complex when kick occurs, it is difficult to describe the physical process accurately using a mathematical model. Considering the difficulty and efficiency of calculation, the wellbore flow model can be simplified, resulting in a reduction in the accuracy of prediction. Besides, because of the complex downhole conditions, it is difficult to determine the intrusion rate of formation fluid and the distribution of gas–liquid two-phase in the wellbore accurately at the initial time. Empirical formulas or hypothetical methods are usually used, so the initial and boundary conditions do not reflect the actual annulus situation of the wellbore, thus reducing the prediction accuracy.

An alternative method is to construct a prediction model based on the parameters themselves and to use the already measured parameters to predict the subsequent parameters. For the prediction of short-term and medium-term time-varying parameters, the time series analysis method (e.g.; ARIMA) can reveal the development laws of the time series from the autocorrelation point of the parameters and has the advantage of having a high fitting degree [

19,

20]. Characteristic parameters, such as the pit gain and casing pressure, change regularly with time in a short period. Therefore, this method can extract the feature information in a short time, mine the valuable information hidden in the historical data in a short time, and construct the time series prediction model of pit gain and casing pressure to predict the pit gain and casing pressure after a kick. Time series analysis methods are widely used in the field of petroleum prediction, such as crude oil price fluctuations [

21], drilling site risk probability prediction [

22], oil and gas well production prediction [

23,

24], but they are not applied in the prediction of kick risk. Therefore, this paper uses the summation autoregressive moving average model (ARIMA) to predict pit gain before shut-in and casing pressure after shut-in and uses the predicted values of pit gain and casing pressure to analyze the kick risk before and after shut-in.

2. Mathematical Models

In the field of statistics, a set of random variables arranged in chronological order (X

1, X

2, …, X

t, …) is often used to represent the time series of a random event, denoted as {X

t, t

T}. The n ordered observations of the series are represented by {x

t, t = 1, 2,..., n}, referred to as the series of observations of series length n. The purpose of studying time series is to reveal the properties of a random time series {X

t}. To get the properties of a random time series {X

t}, we need to analyze the properties of its observation series {x

t} and infer the properties of the random time series {X

t} from the properties of the observation series [

25].

As the series of kick characterization parameters, such as the pit gain or casing pressure, are mostly a non-stationary time series, the autoregressive moving average model (ARIMA) is the most suitable [

26]. The expression of ARIMA (

p,

d,

q) is

where

is the observation series,

is the autoregressive coefficient,

is the random interference series,

is the mean value,

is the variance,

is the delay operator,

d is the differential order,

is the autoregressive coefficient polynomial for the stationary reversible ARMA (

p,

q) model, and

is the moving smoothing coefficient polynomial for the stationary reversible ARMA (

p,

q) model.

4. Results and Discussion

In this section, the proposed method is applied to the kick severity forecast in several wells, which is based on the prediction of pit gain and casing pressure.

4.1. Analysis and Calculation of the Kick Severity before Closing the Well

4.1.1. Case Study One

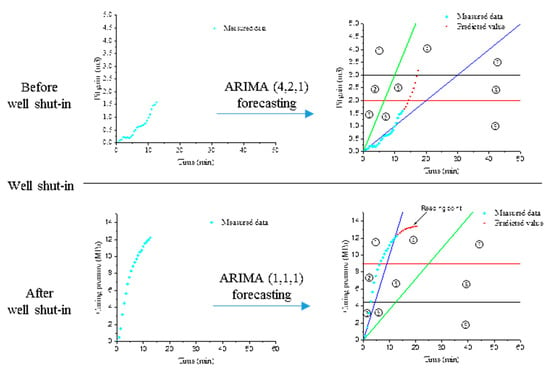

In

Section 3, the pit gain forecasting model ARIMA (4,2,1) of well SC-X1 was established;

Figure 9 shows the measured data and predicted values of pit gain vs. time in different periods.

Figure 9a–c show that with an increase in prediction time, the MRE increases gradually (from 8.3% to 8.7% and then to 14%). Specifically, the prediction accuracy decreases with an increase in prediction time, which can also be obtained from

Figure 9d,e. By comparing

Figure 9a,d, we can see that the more measured data there are, the smaller the MRE is (8.3% and 8%), which can also be obtained from

Figure 9b,e. Overall, the MRE based on the measurement data period of 0 to ~8.5 min is small (less than 8.2%).

Figure 10 is the result of forecasting the pit gain after 5 min using the ARIMA (4,2,1) model. The forecasted curve is plotted in the kick severity analysis chart based on the pit gain volume increment. It can be seen from the figure that the data are located in Area ⑥ before the prediction, the pit gain has not reached 2 m

3 at 12 min, and the well has not been closed at this time. By predicting the pit gain after 5 min, it can be seen that the pit gain curve is already in Area ④. At this time, the predicted pit gain has reached 3.18 m

3 and is also showing a gradually increasing trend. The well control risk is already large—the well needs to be immediately shut down and the appropriate well control measures need to be selected.

4.1.2. Case Study Two

In this case, one well in [

3] is used for analysis; the time sequence diagram of the pit gain before well shut-in is shown in

Figure 11. Using the same modeling process as described in

Section 3, the model ARIMA (2,2,1) is established.

Figure 12 shows the measured data and predicted values of the pit gain vs. time in different periods.

From

Figure 12, the same rule as

Figure 9 can be obtained.

Figure 12a–c show that with an increase in the prediction time, the MRE increases gradually (from 8.6% to 13.4% and then to 20.2%). Specifically, the prediction accuracy decreases with the increase in prediction time, which can also be obtained from

Figure 12d,e. By comparing

Figure 12a,d, it can be seen that the more measured data there are, the smaller the MRE is (8.6% and 3.6%), which can also be obtained from

Figure 12b,e. Overall, the MRE based on the measurement data period 0 to ~129 s is small (less than 5.4%).

Figure 13 is the result of the forecasted pit gain in the next 54 s using the ARIMA (2,2,1) model. The forecasted curve is plotted in the kick severity analysis chart based on the pit gain volume increment. It can be seen from the figure that the data are located in Area ⑥ before the prediction, the pit gain is less, there is a slower development trend, and the kick risk is relatively small. By predicting the pit gain after 54 s, it can be seen that the pit gain curve is already in Area ③, and although the pit gain is less, its development trend is rapid and the kick risk is greater. Thus, it needs to be immediately shut down and the appropriate well control measures need to be selected.

4.2. Analysis and Calculation of the Kick Severity after Well Shut-In

Figure 14 is the time sequence diagram of the casing pressure during well shut-in, and it can be seen that there is a marked upward trend in the sequence diagram.

Figure 14 shows the autocorrelation coefficient and partial autocorrelation coefficient of the casing pressure time series. It shows that the autocorrelation coefficient decreases to zero slowly, and the autocorrelation coefficient graph shows obvious triangular symmetry. Therefore, the casing pressure sequence is not a stationary sequence and needs differential processing.

Figure 15 shows the autocorrelation coefficient and partial autocorrelation coefficient of the casing pressure time series after the first-order difference; the first-order difference series has a strong short-term correlation.

Table 7 shows the unit root test results of the casing pressure time series after the first-order difference; the probability (

P) of the ADF test statistic is less than 0.05. Therefore, the series after the first-order difference is stable, and the model can be established.

Based on the autocorrelation and partial autocorrelation diagram of the first-order difference of the casing pressure shown in

Figure 16, the preliminary order of the model can be determined. It can be seen from the figure that both the autocorrelation coefficient and partial autocorrelation coefficient fall within two standard deviations after the delay of the first-order, and the model is established by ARIMA (1,1,1).

Table 8 shows the residual white noise test of the ARIMA (1,1,1) model. The probability P-value of the

Q-statistic is greater than 0.05, so the residual sequence is a white noise sequence, which satisfies the model’s requirements.

Table 9 shows the ARIMA (1,1,1) model’s unknown parameter prediction and the

statistic’s probability P-value. The P-value is less than 0.05, so the model meets the requirements.

From

Figure 17, the same rules as

Figure 9 and

Figure 12 can be obtained.

Figure 17a,b show that with an increase in prediction time, the MRE increases gradually (from 2.1% to 4%). Specifically, the prediction accuracy decreases with the increase of prediction time. Generally speaking, the MRE is small (less than 4%).

Figure 18 shows the change in casing pressure after well shut-in. The ARIMA (1,1,1) model is constructed by the time series method to predict the future casing pressure. It is predicted that the reading point of the casing pressure will be in Area ④, the kick will be more serious, and the risk to well control will be larger, so it needs to be dealt with in time.

4.3. Discussion

The application of this paper can be divided into two stages—the prediction of pit gain before well shut-in and the prediction of casing pressure after well shut-in. After the occurrence of a kick, the prediction model is established based on the real-time data of the previous pit gain, the development trend of the pit gain is predicted, and the next step is taken with reference to the predicted pit gain. If the predicted pit gain is small (for example less than 2 m3), for the commonly used managed pressure drilling technology at present, the well may not need to be shut in. By adjusting the surface equipment of managed pressure drilling, the bottom hole pressure can be increased, the kick can be recycled out, and drilling time can be saved. If the predicted overflow is large (for example more than 2 m3), closing the well before 2 m3 can reduce formation fluid intrusion, which will be helpful to reduce the risk of a killing operation. After well shut-in, it is generally necessary to wait for casing pressure to return to a stable state on the drilling rig, then calculate the formation pressure, design a well killing construction report, and configure heavy mud. The prediction model in this paper can save killing time by predicting the casing pressure so that drilling operators can make preparations for killing the well in advance.

This method is suitable for short-term prediction but is not very good for long-term prediction. Our future work will consider the multimodel coupling method to improve long-term prediction accuracy.

5. Conclusions

Studies and field applications of measured data during drilling are kick warning and have been used to determine whether a kick occurs or not. However, there is no research on forecasting the severity of a kick by using measured data after a kick occurs.

In view of the time-varying characteristics of the characterization parameters after a kick, combined with the high degree of fitting a time series analysis method, the established time series model can be used for the prediction of pit gain and casing pressure.

Since pit gain and casing pressure can indirectly reflect the bottom hole condition, the changes in pit gain and casing pressure with time can be used to judge the severity of the kick. Combined with the prediction model, the severity of the kick can be predicted.

In this paper, the proposed method has been applied to pit gain forecasting in two wells and casing pressure forecasting in one well. The same rules can be seen in the case studies—an increase in prediction time, a gradual increase in MRE, and the more measured data, the smaller the MRE. Future work will consider the multimodel coupling method to improve long-term prediction accuracy.

The comparison between measured data and predicted data has shown that the proposed method has high prediction accuracy and repeatability. It has a certain guiding significance for the prediction of kick development trends, the analysis of kick severity, the selection of well control measures by engineers, and the reduction of the risk of a killing operation.