A Review of the Degradation of Photovoltaic Modules for Life Expectancy

Abstract

:1. Introduction

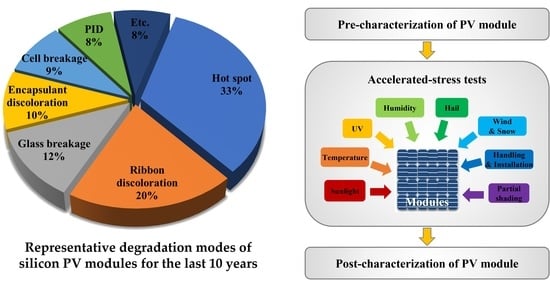

2. Degradation of a PV Module

2.1. Hot Spots

2.2. Corrosion of a PV Module

2.3. Discoloration of a PV Module

2.4. Delamination of a PV Module

2.5. Cracks and Breakage of PV Modules

2.6. PID

2.7. Bubbles

2.8. Junction Box Failure

3. Life Expectancy

3.1. Effect of Different Weather Conditions on the Degradation Rate

3.2. Accelerated-Stress Test Types

3.2.1. Thermal Cycling

3.2.2. Damp Heat

3.2.3. Ultraviolet (UV) Light Exposure

3.2.4. Static and Dynamic Mechanical Loads

3.2.5. Reverse-Bias Hot-Spot Test and Bypass-Diode Thermal Test

3.2.6. Hail Test

4. Solutions to Minimize the Degradation Rate

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Renewables 2020. International Energy Agency. 2020. Available online: https://www.iea.org/reports/renewables-2020 (accessed on 24 December 2020).

- Tsanakas, J.A.; Ha, L.; Buerhop, C. Faults and infrared thermographic diagnosis in operating c-Si photovoltaic modules: A review of research and future challenges. Renew. Sustain. Energy Rev. 2016, 62, 695–709. [Google Scholar] [CrossRef]

- Virtuani, A.; Caccivio, M.; Annigoni, E.; Friesen, G.; Chianese, D.; Ballif, C.; Sample, T. 35 years of photovoltaics: Analysis of the TISO-10-kW solar plant, lessons learnt in safety and performance—Part 1. Prog. Photovolt. Res. Appl. 2019, 27, 328–339. [Google Scholar] [CrossRef]

- Da Fonseca, J.E.F.; de Oliveira, F.S.; Prieb, C.W.M.; Krenzinger, A. Degradation analysis of a photovoltaic generator after operating for 15 years in southern Brazil. Sol. Energy 2020, 196, 196–206. [Google Scholar] [CrossRef]

- Ishii, T.; Masuda, A. Annual degradation rates of recent crystalline silicon photovoltaic modules. Prog. Photovolt. Res. Appl. 2017, 25, 953–967. [Google Scholar] [CrossRef]

- Jordan, D.C.; Silverman, T.J.; Wohlgemuth, J.H.; Kurtz, S.R.; VanSant, K.T. Photovoltaic failure and degradation modes. Prog. Photovolt Res. Appl. 2017, 25, 318–326. [Google Scholar] [CrossRef]

- Martín-Martínez, S.; Cañas-Carretón, M.; Honrubia-Escribano, A.; Gómez-Lázaro, E.J.E.C. Performance evaluation of large solar photovoltaic power plants in Spain. Energy Convers. Manag. 2019, 183, 515–528. [Google Scholar] [CrossRef]

- Lovati, M.; Salvalai, G.; Fratus, G.; Maturi, L.; Albatici, R.; Moser, D. New method for the early design of BIPV with electric storage: A case study in northern Italy. Sustain. Cities Soc. 2019, 48, 101400. [Google Scholar] [CrossRef] [Green Version]

- Singh, R.; Sharma, M.; Rawat, R.; Banerjee, C. Field Analysis of three different silicon-based Technologies in Composite Climate Condition–Part II–Seasonal assessment and performance degradation rates using statistical tools. Renew. Energy 2020, 147, 2102–2117. [Google Scholar] [CrossRef]

- Gaglia, A.G.; Lykoudis, S.; Argiriou, A.A.; Balaras, C.A.; Dialynas, E. Energy efficiency of PV panels under real outdoor conditions–An experimental assessment in Athens, Greece. Renew. Energy 2017, 101, 236–243. [Google Scholar] [CrossRef]

- Jurasz, J.K.; Dąbek, P.B.; Campana, P.E. Can a city reach energy self-sufficiency by means of rooftop photovoltaics Case study from Poland. J. Clean. Prod. 2020, 245, 118813. [Google Scholar] [CrossRef]

- Chandel, S.S.; Naik, M.N.; Sharma, V.; Chandel, R. Degradation analysis of 28 year field exposed mono-c-Si photovoltaic modules of a direct coupled solar water pumping system in western Himalayan region of India. Renew. Energy 2015, 78, 193–202. [Google Scholar] [CrossRef]

- Thotakura, S.; Kondamudi, S.C.; Xavier, J.F.; Quanjin, M.; Reddy, G.R.; Gangwar, P.; Davuluri, S.L. Operational performance of megawatt-scale grid integrated rooftop solar PV system in tropical wet and dry climates of India. Case Stud. Therm. Eng. 2020, 18, 100602. [Google Scholar] [CrossRef]

- Tongsopit, S.; Junlakarn, S.; Wibulpolprasert, W.; Chaianong, A.; Kokchang, P.; Hoang, N.V. The economics of solar PV self-consumption in Thailand. Renew. Energy 2019, 138, 395–408. [Google Scholar] [CrossRef]

- Dechthummarong, C.; Wiengmoon, B.; Chenvidhya, D.; Jivacate, C.; Kirtikara, K. Physical deterioration of encapsulation and electrical insulation properties of PV modules after long-term operation in Thailand. Sol. Energy Mater. Sol. Cells 2010, 94, 1437–1440. [Google Scholar] [CrossRef]

- Park, J.H.; Lee, H.D.; Tae, D.H.; Ferreira, M.; Rho, D.S. A Study on Disposal Diagnosis Algorithm of PV Modules Considering Performance Degradation Rate. J. Korea Acad. Ind. Coop. Soc. 2019, 20, 493–502. [Google Scholar]

- Teah, H.S.; Yang, Q.; Onuki, M.; Teah, H.Y. Incorporating External Effects into Project Sustainability Assessments: The Case of a Green Campus Initiative Based on a Solar PV System. Sustainability 2019, 11, 5786. [Google Scholar] [CrossRef] [Green Version]

- Jordan, D.C.; Deline, C.; Deceglie, M.; Silverman, T.J.; Luo, W. PV Degradation–Mounting & Temperature. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; pp. 673–679. [Google Scholar]

- Dhimish, M.; Alrashidi, A. Photovoltaic Degradation Rate Affected by Different Weather Conditions: A Case Study Based on PV Systems in the UK and Australia. Electronics 2020, 9, 650. [Google Scholar] [CrossRef] [Green Version]

- Jordan, D.C.; Wohlgemuth, J.H.; Kurtz, S.R. Technology and climate trends in pv module degradation. In Proceedings of the 27th European Photovoltaic Solar Energy Conference and Exhibition, Frankfurt, Germany, 24–28 September 2012. [Google Scholar]

- Herrmann, W.; Bogdanski, N.; Reil, F.; Köhl, M.; Weiss, K.-A.; Assmus, M.; Heck, M. PV module degradation caused by thermomechanical stress: Real impacts of outdoor weathering versus accelerated testing in the laboratory. In Reliability of Photovoltaic Cells, Modules, Components, and Systems III; International Society for Optics and Photonics: Bellingham, DC, USA, 2010; Volume 7773, p. 77730I. [Google Scholar]

- John, H.W. Photovoltaic Module Reliability; Wiley: Hoboken, NY, USA, 2020. [Google Scholar]

- Bouguerra, S.; Yaiche, M.R.; Gassab, O.; Sangwongwanich, A.; Blaabjerg, F. The Impact of PV Panel Positioning and Degradation on the PV Inverter Lifetime and Reliability. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 3114–3126. [Google Scholar] [CrossRef]

- Majumdar, D.; Pal, S.B.; Ganguly, R. Comparative Reliability Analysis of PV Modules under tropical conditions. In Proceedings of the Innovations in Energy Management and Renewable Resources (52042), Kolkata, India, 5–7 February 2021; pp. 1–5. [Google Scholar]

- Yan, W.; Liu, W.; Kong, W. Reliability evaluation of PV modules based on exponential dispersion process. Energy Rep. 2021, 7, 3023. [Google Scholar] [CrossRef]

- Muller, M.; Repins, I. Proceedings of the PV Reliability Workshop. 22–26 February 2021. Available online: https://www.nrel.gov/docs/fy21osti/80055.pdf (accessed on 26 February 2021).

- Kurtz, S. Reliability and Durability of PV Modules. In Photovoltaic Solar Energy; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2017; pp. 491–501. [Google Scholar]

- Jordan, D.C.; Kurtz, S.R. Photovoltaic Degradation Rates-an Analytical Review. Prog. Photovolt. Res. Appl. 2013, 21, 12–29. [Google Scholar] [CrossRef] [Green Version]

- Wohlgemuth, J. Tutorial/short course on reliability: PV cells, modules, and systems. In Proceedings of the IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011. [Google Scholar]

- Lannoy, A.; Procaccia, H. Evaluation et Maîtrise du Vieillissement Industriel; Lavoisier: Paris, France, 2005. [Google Scholar]

- Charki, A.; Laronde, R.; Bigaud, D. The time-variant degradation of a photovoltaic system. J. Sol. Energy Eng. 2013, 135, 024503. [Google Scholar] [CrossRef]

- Wohlgemuth, J.H.; Cunningham, D.W.; Monus, P.; Miller, J.; Nguyen, A. Long term reliability of photovoltaic modules. In Proceedings of the 2006 IEEE 4th World Conference on Photovoltaic Energy Conference, Waikoloa, HI, USA, 7–12 May 2006; pp. 2050–2053. [Google Scholar]

- Quintana, M.A.; King, D.L.; McMahon, T.J.; Osterwald, C.R. Commonly observed degradation in field-aged photovoltaic module. In Proceedings of the Conference Record of the Twenty-Ninth IEEE Photovoltaic Specialists Conference, New Orleans, LA, USA, 19–24 May 2002; pp. 1436–1439. [Google Scholar]

- Osterwald, C.R.; McMahon, T.J. History of accelerated and qualification testing of terrestrial photovoltaic modules: A literature review. Prog. Photovolt. Res. Appl. 2009, 17, 11–33. [Google Scholar] [CrossRef]

- Munoz, M.A.; Alonso-García, M.C.; Vela, N.; Chenlo, F. Early degradation of silicon PV modules and guaranty conditions. Sol. Energy 2011, 85, 2264–2274. [Google Scholar] [CrossRef]

- Vázquez, M.; Rey-Stolle, I. Photovoltaic module reliability model based on field degradation studies. Prog. Photovolt. Res. Appl. 2008, 16, 419–433. [Google Scholar] [CrossRef] [Green Version]

- Chowdhury, S.; Cho, E.C.; Cho, Y.; Kim, Y.; Yi, J. Analysis of Cell to Module Loss Factor for Shingled PV Module. KSNRE 2020, 16, 1–12. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Mehrdadi, B.; Dales, M.; Mather, P. Output-power enhancement for hot spotted polycrystalline photovoltaic solar cells. Trans. Device Mater. Reliab. 2017, 18, 37–45. [Google Scholar] [CrossRef]

- Molenbroek, E.; Waddington, D.W.; Emery, K.A. Hot spot susceptibility and testing of PV modules. In Proceedings of the 22th IEEE Photovoltaic Specialists Conference (Las Vegas), Las Vegas, NV, USA, 7–11 October 1991; pp. 547–552. [Google Scholar]

- Cox III, C.H.; Silversmith, D.J.; Mountain, R.W. Reduction of photovoltaic cell reverse breakdown by a peripheral bypass diode. In Proceedings of the 16 IEEE Photovoltaics Specialists Conference, San Diego, CA, USA, 28 September 1982. [Google Scholar]

- Rauschenbach, H.S.; Maiden, E.E. Breakdown phenomena in reverse biased silicon solar cells. In Proceedings of the Record of the 9th IEEE Photovoltaic Specialists Conference, Silver Spring, MD, USA, 19–24 May 2002. [Google Scholar]

- Kim, J.-H.; Park, J.; Kim, D.; Park, N. Study on Mitigation Method of Solder Corrosion for Crystalline Silicon Photovoltaic Modules. Int. J. Photoenergy 2014, 2014, 809075. [Google Scholar] [CrossRef]

- Li, J.; Shen, Y.-C.; Hacke, P.; Kempe, M. Electrochemical mechanisms of leakage-current-enhanced delamination and corrosion in Si photovoltaic modules. Sol. Energy Mater. Sol. Cells 2018, 188, 273–279. [Google Scholar] [CrossRef]

- Oreski, G.; Rauschenbach, A.; Hirschl, C.; Kraft, M.; Eder, G.C.; Pinter, G. Crosslinking and post-crosslinking of ethylene vinyl acetate in photovoltaic modules. J. Appl. Polym. Sci. 2017, 134, 44912. [Google Scholar] [CrossRef]

- Czanderna, A.W.; Pern, F.J. Encapsulation of PV Modules Using Ethylene Vinyl Acetate Copolymer as a Pottant: A Critical Review. Sol. Energy Mater. Sol. Cells 1996, 43, 101–181. [Google Scholar] [CrossRef]

- Kim, N.; Lee, S.; Zhao, X.G.; Kim, D.; Oh, C.; Kang, H. Reflection and durability study of different types of backsheets and their impact on c-Si PV module performance. Sol. Energy Mater. Sol. Cells 2016, 146, 91–98. [Google Scholar] [CrossRef]

- Omazic, A.; Oreski, G.; Halwachs, M.; Eder, G.C.; Hirschl, C.; Neumaier, L.; Pinter, G.; Erceg, M. Relation between degradation of polymeric components in crystalline silicon PV module and climatic conditions: A literature review. Sol. Energy Mater. Sol. Cells 2019, 192, 123–133. [Google Scholar] [CrossRef]

- Wohlgemuth, J.H.; Hacke, P.; Bosco, N.; Miller, D.C.; Kempe, M.D.; Kurtz, S.R. Assessing the causes of encapsulant delamination in PV modules. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016; pp. 248–254. [Google Scholar]

- Kraft, A.; Labusch, L.; Ensslen, T.; Dürr, I.; Bartsch, J.; Glatthaar, M.; Glunz, S.; Reinecke, H. Investigation of Acetic Acid Corrosion Impact on Printed Solar Cell Contacts. IEEE J. Photovolt. 2015, 5, 736–743. [Google Scholar] [CrossRef]

- Kempe, M.D.; Jorgensen, G.J.; Terwilliger, K.M.; McMahon, T.J.; Kennedy, C.E.; Borek, T.T. Acetic Acid Production and Glass Transition Concerns with Ethylene-Vinyl Acetate Used in Photovoltaic Devices. Sol. Energy Mater. Sol. Cells 2007, 91, 315–329. [Google Scholar] [CrossRef]

- Xiong, H.; Gan, C.; Yang, X.; Hu, Z.; Niu, H.; Li, J.; Si, J.; Xing, P.; Luo, X. Corrosion behavior of crystalline silicon solar cells. Microelectron. Reliab. 2017, 70, 49–58. [Google Scholar] [CrossRef]

- Oreski, G.; Wallner, G.M. Evaluation of the aging behavior of ethylene copolymer films for solar applications under accelerated weathering conditions. Sol. Energy 2009, 83, 1040–1047. [Google Scholar] [CrossRef]

- Kim, D.; Kim, N.; Hong, W.S.; Kang, H.; Lee, K.; Oh, C. Degradation of Backsheets for Crystalline Photovoltaic Modules under Damp Heat Test. KSNRE 2016, 12, 36–43. [Google Scholar] [CrossRef]

- Kojima, T.; Yanagisawa, T. The evaluation of accelerated test for degradation a stacked a-Si solar cell and EVA films. Sol. Energy Mater. Sol. Cells 2004, 81, 119–123. [Google Scholar] [CrossRef]

- Berman, D.; Faiman, D. EVA browning and the time-dependence of I− V curve parameters on PV modules with and without mirror-enhancement in a desert environment. Sol. Energy Mater. Sol. Cells 1997, 45, 401–412. [Google Scholar] [CrossRef]

- Osterwald, C.R.; Anderberg, A.; Rummel, S.; Ottoson, L. Degradation analysis of weathered crystalline-silicon PV modules. In Proceedings of the Conference Record of the Twenty-Ninth IEEE Photovoltaic Specialists Conference, New Orleans, LA, USA, 19–24 May 2002; pp. 1392–1395. [Google Scholar]

- Kempe, M.D. Modeling of rates of moisture ingress into photovoltaic modules. Sol. Energy Mater. Sol. Cells 2006, 90, 2720–2738. [Google Scholar] [CrossRef]

- Kempe, M.D. Ultraviolet light test and evaluation methods for encapsulants of photovoltaic modules. Sol. Energy Mater. Sol. Cells 2010, 94, 246–253. [Google Scholar] [CrossRef]

- Realini, A. Mean time before failure of photovoltaic modules. Final Rep. (MTBF Proj.) Fed. Off. Educ. Sci. Tech. Rep. 2003, 99, 1–58. [Google Scholar]

- Park, N.C.; Jeong, J.S.; Kang, B.J.; Kim, D.H. The effect of encapsulant discoloration and delamination on the electrical characteristics of photovoltaic module. Microelectron. Reliab. 2013, 53, 1818–1822. [Google Scholar] [CrossRef]

- Wohlgemuth, J.H.; Kurtz, S. Reliability testing beyond qualification as a key component in photovoltaic’s progress toward grid parity. In Proceedings of the 2011 International Reliability Physics Symposium, Monterey, CA, USA, 10–14 April 2011. [Google Scholar]

- Dallas, W.; Polupan, O.; Ostapenko, S. Resonance ultrasonic vibrations for crack detection in photovoltaic silicon wafers. Meas. Sci. Technol. 2007, 18, 852. [Google Scholar] [CrossRef]

- Rueland, E.; Herguth, A.; Trummer, A.; Wansleben, S.; Fath, P. Optical u-crack detection in combination with stability testing for in-line inspection of wafers and cells. In Proceedings of the 20th EU PVSEC Barcelona, Barcelona, Spain, 6–10 June 2005; pp. 3242–3245. [Google Scholar]

- Schütze, M.; Junghänel, M.; Friedrichs, O.; Wichtendahl, R.; Scherff, M.; Müller, J.; Wawer, P. Investigations of potential induced degradation of silicon photovoltaic modules. In Proceedings of the 26th European PV Solar Energy Conference, Hamburg, Germany, 5 September 2011. [Google Scholar]

- Schütze, M.; Junghänel, M.; Koentopp, M.B.; Cwikla, S.; Friedrich, S.; Müller, J.W.; Wawer, P. Laboratory study of potential induced degradation of silicon photovoltaic modules. In Proceedings of the 2011 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011; pp. 000821–000826. [Google Scholar]

- Pingel, S.; Frank, O.; Winkler, M.; Daryan, S.; Geipel, T.; Hoehne, H.; Berghold, J. Potential induced degradation of solar cells and panels. In Proceedings of the 2010 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 20–25 June 2010; pp. 002817–002822. [Google Scholar]

- Mau, S.; Krametz, T.; Jahna, W.; Fechner, H. Quality testing for PV-modules according to standards and performance control for supporting manufacturing. In Proceedings of the 19th EUPVSEC, Paris, France, 7–11 June 2004. [Google Scholar]

- Hacke, P.; Terwilliger, K.; Smith, R.; Glick, S.; Pankow, J.; Kempe, M.; Kloos, M. System voltage potential-induced degradation mechanisms in PV modules and methods for test. In Proceedings of the 2011 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011. [Google Scholar]

- Chang, M.; Chen, C.; Hsueh, C.H.; Hsieh, W.J.; Yen, E.; Ho, K.L.; Chuang, H.P.; Lee, C.Y.; Chen, H. The reliability investigation of PV junction box based on 1GW worldwide field database. In Proceedings of the 2015 IEEE 42nd Photovoltaic pecialist Conference (PVSC), New Orleans, LA, USA, 14–19 June 2015. [Google Scholar]

- Review of Failures of Photovoltaic Modules, from Photovoltaic Power System Program Task 13 Report No. IEA-PVPS T13-0l. 2014. Available online: https://iea-pvps.org/wp-content/uploads/2020/01/IEA-PVPS_T13-01_2014_Review_of_Failures_of_Photovoltaic_Modules_Final.pdf (accessed on 1 March 2014).

- Wu, Z.; Lyu, S.; Peng, Q.; Han, H.; Zhu, D. Thermomechanical Stress Distribution Analysis of Junction Box on Silicon Photovoltaic Modules Based on Finite Element Analysis. IEEE J. Photovolt. 2019, 9, 1716–1720. [Google Scholar] [CrossRef]

- Chowdhury, S.; Kumar, M.; Dutta, S.; Park, J.; Kim, J.; Kim, S.; & Yi, J. High-efficiency Crystalline Silicon Solar Cells: A Review. KSNRE 2019, 15, 36–45. [Google Scholar] [CrossRef]

- Zahid, M.A.; Chowdhury, S.; Mallem, K.; Cho, E.C.; Yi, J. Review on the Progress in Building Integrated Photovoltaic Materials and Module Technology. KSNRE 2019, 15, 47–54. [Google Scholar] [CrossRef]

- Lin, G.J.; Wang, L.J.; Liu, J.Q.; Xiong, W.P.; Song, M.H.; Wu, Z.H. Accelerated aging tests of high concentration multijunction solar cells. Procedia Environ. Sci. 2011, 11, 1147–1152. [Google Scholar] [CrossRef] [Green Version]

- Kawai, S.; Tanahashi, T.; Fukumoto, Y.; Tamai, F.; Masuda, A.; Kondo, M. Causes of degradation identified by the extended thermal cycling test on commercially available crystalline silicon photovoltaic modules. IEEE J. Photovolt. 2017, 7, 1511–1518. [Google Scholar] [CrossRef]

- Tsanakas, J.A.; Karoglou, M.; Delegou, E.T.; Botsaris, P.N.; Bakolas, A.; Moropoulou, A. Assessment of the Performance and Defect Investigation of PV Modules after Accelerated Ageing Tests. Renew. Energy Power Qual. J. 2013, 1, 866–872. [Google Scholar] [CrossRef] [Green Version]

- Mathiak, G.; Althaus, J.; Menzler, S.; Lichtschläger, L.; Herrmann, W. PV Module Corrosion from ammonia and salt mist—Experimental study with full-size modules. In Proceedings of the 27th European Photovoltaic Solar Energy Conference and Exhibition, Frankfurt, Germany, 24–28 September 2012; pp. 3536–3540. [Google Scholar]

- Khan, F.; Rezgui, B.D.; Kim, J.H. Reliability Study of c-Si PV Module Mounted on a Concrete Slab by Thermal Cycling Using Electroluminescence Scanning: Application in Future Solar Roadways. Materials 2020, 13, 470. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Oliveira, M.C.C.; Cardoso, A.S.A.D.; Viana, M.M.; Lins, V.d.F.C. The causes and effects of degradation of encapsulant ethylene vinyl acetate copolymer (EVA) in crystalline silicon photovoltaic modules: A review. Renew. Sustain. Energy Rev. 2018, 81, 2299–2317. [Google Scholar] [CrossRef]

- Gagliardi, M.; Paggi, M. Multiphysics analysis of backsheet blistering in photovoltaic modules. Sol. Energy 2019, 183, 512–520. [Google Scholar] [CrossRef]

- Hülsmann, P.; Weiss, K.A. Simulation of water ingress into PV-modules: IEC-testing versus outdoor exposure. Sol. Energy 2015, 115, 347–353. [Google Scholar] [CrossRef]

- Dadaniya, A.; Datla, N.V. Degradation prediction of encapsulant-glass adhesion in the photovoltaic module under outdoor and accelerated exposures. Sol. Energy 2020, 208, 419–429. [Google Scholar] [CrossRef]

- Zhu, J.; Wu, D.; Montiel-Chicharro, D.; Betts, T.R.; Gottschalg, R. Realistic Adhesion Test for Photovoltaic Modules Qualification. IEEE J. Photovolt. 2018, 8, 218–223. [Google Scholar] [CrossRef]

- Wu, D.; Zhu, J.; Betts, T.R.; Gottschalg, R. Degradation of interfacial adhesion strength within photovoltaic mini-modules during damp-heat exposure. Prog. Photovolt Res. Appl. 2014, 22, 796–809. [Google Scholar] [CrossRef] [Green Version]

- Sharma, V.; Chandel, S.S. Performance and degradation analysis for long term reliability of solar photovoltaic systems: A review. Renew. Sustain. Energy Rev. 2013, 27, 753–767. [Google Scholar] [CrossRef]

- Rosa-Clot, M.; Tina, G.M.; Nizetic, S. Floating photovoltaic plants and wastewater basins: An Australian project. Energy Procedia 2017, 134, 664–674. [Google Scholar] [CrossRef]

- Masuda, A.; Yamamoto, C.; Uchiyama, N.; Ueno, K.; Yamazaki, T.; Mitsuhashi, K.; Tsutsumida, A.; Watanabe, J.; Shirataki, J.; Matsuda, K. Sequential and combined acceleration tests for crystalline Si photovoltaic modules. Jpn. J. Appl. Phys. 2016, 55, 04ES10. [Google Scholar] [CrossRef]

- Li, Y.T.; Lin, W.Y.; Yang, W.L.; Hsieh, C.F. Sequential acceleration tests with Pressure Cooker Test (PCT) and UV for backsheets of PV modules. Energy Procedia 2018, 150, 44–49. [Google Scholar] [CrossRef]

- Gambogi, W.; Heta, Y.; Hashimoto, K.; Kopdhick, J.; Felder, T.; MacMaster, S.; Bradley, A.; Hamzavytehrany, B.; Garreau-Iles, L.; Aoki, T.; et al. A Comparison of Key PV Backsheet and Module Performance from Fielded Module Exposures and Accelerated Tests. IEEE J. Photovolt. 2014, 4, 935–941. [Google Scholar] [CrossRef]

- Gopalakrishna, H.; Arularasu, P.; Dolia, K.; Sinha, A.; Tamizhmani, G. Characterization of Encapsulant Degradation in Accelerated UV Stressed Mini-Modules with UV-cut and UV-pass EVA. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; pp. 1961–1964. [Google Scholar]

- IEC 61215-1-1 2016 Terrestrial Photovoltaic (PV) Modules-Design Qualification and Type Approval-Part 1-1: Special Requirements for Testing of Crystalline Silicon Photovoltaic (PV) Module. Available online: https://webstore.iec.ch/publication/24313 (accessed on 9 March 2016).

- Weiss, K.-A.; Assmus, M.; Jack, S.; Koehl, M. Measurement and simulation of dynamic mechanical loads on PV-modules. In Reliability of Photovoltaic Cells, Modules, Components, and Systems II; International Society for Optics and Photonics: Bellingham, DC, USA, 2009; Volume 7412, p. 741203. [Google Scholar]

- Reil, F.; Hermann, W.; Jahn, U. Breakage characteristics of crystalline PV modules under mechanical stress and their influence on the electrical behavior. In Proceedings of the 25th Symposium Photovoltaic Solar Energy Kloster Banz, Bad Staffelstein, Germany, 6–10 September 2010. [Google Scholar]

- Kipness, M. IEEE Recommended Practice for Qualification Of Photovoltaic (PV) Modules. SASB/SCC21—SCC21—Fuel CellsPhotovolt. Dispersed Gener. Energy Storage. 1996. Available online: https://0-standards-ieee-org.brum.beds.ac.uk/standard/1262-1995.html (accessed on 12 April 1996).

- Wohlgemuth, J.H.; Cunningham, D.W.; Placer, N.V.; Kelly, G.J.; Nguyen, A.M. The effect of cell thickness on module reliability. In Proceedings of the 2008 33rd IEEE Photovoltaic Specialists Conference, San Diego, CA, USA, 11–16 May 2008; pp. 23–26. [Google Scholar]

- Pingel, S.; Zemen, Y.; Frank, O.; Geipel, T.; Berghold, J. Mechanical stability of solar cells within solar panels. In Proceedings of the 24th European Photovoltaic Solar Energy Conference, Hamburg, Germany, 21–25 September 2009; pp. 3459–3463. [Google Scholar]

- Koch, S.; Kupke, J.; Tornow, D.; Schoppa, M.; Krauter, S.; Grunow, P. Dynamic Mechanical Load Tests on Crystalline Silicon Modules. In Proceedings of the 25th EPVSEC, Valencia, Spain, 6–10 September 2010; Volume 25, pp. 3998–4001. [Google Scholar]

- Schill, C.; Brachmann, S.; Koehl, M. Impact of soiling on IV-curves and efficiency of PV-modules. Sol. Energy 2015, 112, 259–262. [Google Scholar] [CrossRef]

- Stein, J.S.; McCaslin, S.; Hansen, C.W.; Boyson, W.E.; Robinson, C.D. Measuring PV system series resistance without full IV curves. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference, PVSC 2014 (Institute of Electrical and Electronics Engineers Inc.), Denver, CO, USA, 8–13 June 2014; pp. 2032–2036. [Google Scholar]

- Guerriero, P.; Codecasa, L.; d’Alessandro, V.; Daliento, S. Dynamic electro-thermal modeling of solar cells and modules. Sol. Energy 2019, 179, 326–334. [Google Scholar] [CrossRef]

- Fertig, F.; Rein, S.; Schubert, M.; Warta, W. Impact of Junction Breakdown in Multi-Crystalline Silicon Solar Cells on Hot Spot Formation and Module Performance. In Proceedings of the 26th European PV Solar Energy Conference and Exhibition, Hamburg, Germany, 5–9 September 2011. [Google Scholar]

- Chaibi, Y.; Salhi, M.; El-jouni, A.; Essadki, A. A new method to extract the equivalent circuit parameters of a photovoltaic panel. Sol. Energy 2018, 163, 376–386. [Google Scholar] [CrossRef]

- Vodermayer, C.; Mayer, M.; Mayer, M.; Müller, T.; Niess, M.; Wotruba, G.; Becker, G.; Zehner, M.; Schumacher, J. First results-correlation between IR images and electrical behavior and energy yield of PV modules. In Proceedings of the 23rd European Photovoltaic Solar Energy Conference and Exhibition, Valencia, Spain, 1–5 September 2008. [Google Scholar]

- Kim, K.A.; Krein, P.T. Hot spotting and second breakdown effects on reverse I-V characteristics for mono-crystalline Si Photovoltaics. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 1007–1014. [Google Scholar]

- Kim, K.A.; Seo, G.S.; Cho, B.H.; Krein, P.T. Photovoltaic Hot-Spot Detection for Solar Panel Substrings Using AC Parameter Characterization. IEEE Trans. Power Electron. 2016, 31, 1121–1130. [Google Scholar] [CrossRef]

- Ma, M.; Liu, H.; Zhang, Z.; Yun, P.; Liu, F. Rapid diagnosis of hot spot failure of crystalline silicon PV module based on I-V curve. Microelectron. Reliab. 2019, 100–101, 113402. [Google Scholar] [CrossRef]

- Green, M.A. Solar Cells: Operating Principles, Technology and System Applications; University of New South Wales: Kensington, NSW, Australia, 1986. [Google Scholar]

- Olalla, C.; Hasan, M.N.; Deline, C.; Maksimović, D. Mitigation of hot-spots in photovoltaic systems using distributed power electronics. Energies 2018, 11, 726. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.A.; Krein, P.T. Reexamination of Photovoltaic Hot Spotting to Show Inadequacy of the Bypass Diode. IEEE J. Photovolt. 2015, 5, 1435–1441. [Google Scholar] [CrossRef]

- Spanoche, S.A.; Stewart, J.D.; Hawley, S.L.; Opris, I.E. Model-based method for partially shaded PV modules hot spot suppression. In Proceedings of the 2012 IEEE 38th Photovoltaic Specialists Conference (PVSC) PART 2, Austin, TX, USA, 3–8 June 2012; pp. 1–7. [Google Scholar]

- Corrado, M.; Infuso, A.; Paggi, M. Simulated hail impacts on flexible photovoltaic laminates: Testing and modelling. Meccanica 2017, 52, 1425–1439. [Google Scholar] [CrossRef] [Green Version]

- Guo, B.; Javed, W.; Pett, C.; Wu, C.Y.; Scheffe, J.R. Electrodynamic dust shield performance under simulated operating conditions for solar energy applications. Sol. Energy Mater. Sol. Cells 2018, 185, 80–85. [Google Scholar] [CrossRef]

- Punge, H.J.; Kunz, M. Hail observations and hailstorm characteristics in Europe: A review. Atmos. Res. 2016, 176–177, 159–184. [Google Scholar] [CrossRef]

- Kraemer, F.; Wiese, S.; Peter, E.; Seib, J. Mechanical problems of novel back contact solar modules. Microelectron. Reliab. 2013, 53, 1095–1100. [Google Scholar] [CrossRef]

- Kilikeviciene, K.; Matijosius, J.; Kilikevicius, A.; Jurevicius, M.; Makarskas, V.; Caban, J.; Marczuk, A. Research of the energy losses of photovoltaic (PV) modules after hail simulation using a newly-created testbed. Energies 2019, 12, 4537. [Google Scholar] [CrossRef] [Green Version]

- Elgharbawy, A.S.A.A. Review on Corrosion in Solar Panels. Int. J. Smart Grid-Ijsmartgrid 2018, 2, 218–220. [Google Scholar]

- Kempe, M.D.; Jorgensen, G.J.; Terwilliger, K.M.; McMahon, T.J.; Kennedy, C.E.; Borek, T.T. Ethylene-vinyl acetate potential problems for photovoltaic packaging. In Proceedings of the 2006 IEEE 4th World Conference on Photovoltaic Energy Conference, Waikoloa, HI, USA, 7–12 May 2006; pp. 2160–2163. [Google Scholar]

- Kadırgan, F. Electrochemical nano-coating processes in solar energy systems. Int. J. Photoenergy 2006, 2006, 084891. [Google Scholar] [CrossRef]

- Zweibel, K.; Mason, J.; Fthenakis, V. A solar grand plan. Sci. Am. 2008, 298, 64–73. [Google Scholar] [CrossRef]

- Openair-Plasma for Better Performance and Long-Term Efficiency of Solar Systems. Available online: https://www.plasmatreat.com/industrial-applications/new-energies/solar-technology.html (accessed on 31 January 2021).

- Wohlgemuth, J.H.; Kempe, M.D.; Miller, D.C. Discoloration of PV encapsulants. In Proceedings of the2013 IEEE 39th Photovoltaic Specialists Conference (PVSC), Tampa, FL, USA, 16–21 June 2013; pp. 3260–3265. [Google Scholar]

- Gabor, A.M.; Janoch, R.; Anselmo, A.; Field, H. Solar panel design factors to reduce the impact of cracked cells and the tendency for crack propagation. In Proceedings of the 2015 NREL PV Module Reliability Workshop, Denver, CO, USA, 24 February 2015. [Google Scholar]

| Country | Module Type | Degradation Rate | Cause of Degradation |

|---|---|---|---|

| Spain [7] | Multi-Si Solar Cell | −0.8% to −1.1%/year | Wind speed |

| Italy [8] | Multi-Si Solar Cell | −0.8% to −1.1%/year | PV cell shading |

| Cyprus [9] | Multi-Si Solar Cell | −0.8% to −1.1%/year | Solar irradiance and cell temp |

| Greece [10] | Multi-Si Solar Cell | −0.9% to −1.13%/year | Ambient temp, solar irradiation and wind speed |

| Poland [11] | Multi-Si Solar Cell | >−0.9%/year | Elevated air temp |

| India [12] | Mono-Si Solar Cells | −1.4%/year | High cell temp and humidity |

| Southern India [13] | Multi-Si Solar Cell | −1.3%/year | Air temp and high irradiance |

| Thailand [14] | Multi-Si Solar Cell | −1.5% to −4.9%/year | Humidity and moisture |

| Northern Thailand [15] | Multi-Si Solar Cell | −1.5%/year | Delamination of EVA 1 sheet |

| Japan [16] | Multi-Si Solar Cell | −1.15%/year | Ambient environmental factors |

| Singapore [17] | Multi-Si Solar Cell | −2.0%/year | Ambient temp |

| Republic of Korea [18] | Multi-Si Solar Cell | −1.3%/year | Corrosion and discoloration |

| Scotland, UK [19] | Multi-Si Solar Cell | −1.05% to −1.16%/year | Extreme low temp and humidity |

| Australia [19] | Multi-Si Solar Cell | −1.35% to −1.46%/year | Extreme high temp and moisture |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Rabelo, M.; Padi, S.P.; Yousuf, H.; Cho, E.-C.; Yi, J. A Review of the Degradation of Photovoltaic Modules for Life Expectancy. Energies 2021, 14, 4278. https://0-doi-org.brum.beds.ac.uk/10.3390/en14144278

Kim J, Rabelo M, Padi SP, Yousuf H, Cho E-C, Yi J. A Review of the Degradation of Photovoltaic Modules for Life Expectancy. Energies. 2021; 14(14):4278. https://0-doi-org.brum.beds.ac.uk/10.3390/en14144278

Chicago/Turabian StyleKim, Jaeun, Matheus Rabelo, Siva Parvathi Padi, Hasnain Yousuf, Eun-Chel Cho, and Junsin Yi. 2021. "A Review of the Degradation of Photovoltaic Modules for Life Expectancy" Energies 14, no. 14: 4278. https://0-doi-org.brum.beds.ac.uk/10.3390/en14144278