Normalized Model Reference Adaptive Control Applied to High Starting Torque Scalar Control Scheme for Induction Motors

Abstract

:1. Introduction

2. Preliminaries

2.1. Required Angular Electrical Frequency

2.2. Needed Voltage Amplitude

2.3. Methodology Background

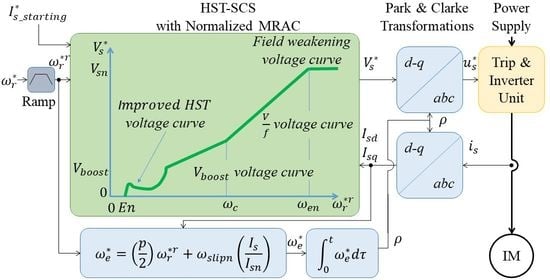

3. Proposal

3.1. Proposed N-MRAC for Nonlinear Systems

3.2. N-MRAC Applied to HST-SCS for IM

3.2.1. Calculus for the Angular Electrical Frequency

3.2.2. Proposed HST-SCS Voltage Amplitude

3.2.3. Setpoint of the Starting Stator Current Direct Component

4. Experimental Results

4.1. HST-SCS Experimental Setup

4.2. Comparative Experimental Results and Discussion

4.2.1. Starting Load Torque equals 16% Tnom

4.2.2. Starting Load Torque equals 100% Tnom

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| IM | Induction motors. |

| PC | Personal computer. |

| HST | High starting torque. |

| SCS | Scalar control scheme. |

| APBC | Adaptive passivity-based controller. |

| MRAC | Model reference adaptive controller. |

| MIMO | Multiple-input multiple-output. |

| BIBO | Bounded-input bounded-output. |

| FOC | Field-oriented control. |

| DTC | Direct torque control. |

| RMS | Root mean square. |

| PWM | Pulse width modulation. |

| IAE | Integral absolute error. |

| VFD | Variable frequency drives. |

| ISI | Integral square input. |

Main Notation

| , and | Required rotor, actual, and electrical angular speed. |

| and | Rated rotor and required angular speed. |

| and | Actual and rated angular slip speed. |

| and | Park transformation and its inverse. |

| and | Clarke transformation and its inverse. |

| Needed stator voltage amplitude. | |

| Needed two-phase alternating instantaneous voltage in - coordinates. | |

| Needed three-phase alternating instantaneous voltage. | |

| Rated voltage per phase (RMS value). |

| and | Rated and actual current per phase (RMS value). |

| and | Actual stator current direct and quadrature component per phase |

| (Instantaneous value). | |

| , , and | Stator, rotor, and magnetizing instantaneous current. |

| Rated power factor. | |

| Rated electrical frequency in Hz. | |

| p | Number of poles. |

| VFD enable. | |

| boost voltage. | |

| Starting voltage curve for HST. | |

| Vboost voltage curve. | |

| V/f voltage curve. | |

| Weakening flux zone voltage curve. | |

| and | Controller parameters for and , respectively. |

| Cut angular frequency, switching point between and . | |

| and | Stator and rotor resistance. |

| and | Stator and rotor leakage inductance. |

| , , and | Stator, rotor, and magnetizing inductance. |

| Leakage or coupling coefficient, given by . | |

| Stator transient resistance, with . | |

| Stator flux magnitude. |

Appendix A

References

- Hannan, M.; Jamal, A.; Mohamed, A.; Hussain, A. Optimization techniques to enhance the performance of induction motor drives: A review. Renew. Sustain. Energy Rev. 2017, 2, 1611–1626. [Google Scholar] [CrossRef]

- Bose, B.K. Modern Power Electronics and AC Drives; Prentice Hall PTR: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

- Vas, P. Electrical Machines and Drives: Space Vector Theory Approach; Oxford Clarendon Press: Oxford, UK, 1992. [Google Scholar]

- Varma, G.H.K.; Barry, V.R.; Kumar Jain, R. A Total-Cross-Tied-Based Dynamic Photovoltaic Array Reconfiguration for Water Pumping System. IEEE Access 2022, 10, 2169–3536. [Google Scholar] [CrossRef]

- Carbone, L.; Cosso, S.; Kumar, K.; Marchesoni, M.; Passalacqua, M.; Vaccaro, L. Stability Analysis of Open-Loop V/Hz Controlled Asynchronous Machines and Two Novel Mitigation Strategies for Oscillations Suppression. Energies 2022, 15, 1404. [Google Scholar] [CrossRef]

- Lee, K.; Han, Y. Reactive-Power-Based Robust MTPA Control for V/f Scalar-Controlled Induction Motor Drives. IEEE Trans. Industy Electron. 2022, 69, 169–178. [Google Scholar] [CrossRef]

- Otkun, O. Scalar speed control of induction motors with difference frequency. J. Polytech. 2020, 238, 267–276. [Google Scholar] [CrossRef]

- Bala Duranay, Z.; Guldemir, H.; Tuncer, S. Implementation of a V/f Controlled Variable Speed Induction Motor Drive. Int. J. Eng. Technol. 2020, 8, 35–48. [Google Scholar]

- Tshiloz, K.; Djurovic, S. Scalar controlled induction motor drive speed estimation by adaptive sliding window search of the power signal. Int. J. Electr. Power Energy Syst. 2017, 91, 80–91. [Google Scholar] [CrossRef]

- Koga, K.; Ueda, R.; Sonoda, T. Constitution of V/f control for reducing the steady-state speed error to zero in induction-motor drive system. IEEE Trans. Industy Appl. 1992, 28, 463–471. [Google Scholar] [CrossRef]

- Munoz-García, A.; Lipo, T.A.; Novotny, D.W. A new induction motor V/f control method capable of high-performance regulation at low speeds. IEEE Trans. Industy Appl. 1998, 34, 813–821. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.C.; Fang, C.H. Sensorless scalar-controlled induction motor drives with modified flux observer. IEEE Trans. Energy Convers. 2003, 18, 181–186. [Google Scholar] [CrossRef]

- Smith, A.; Gadoue, S.; Armstrong, M.; Finch, J. Improved method for the scalar control of induction motor drives. IET Electr. Power Appl. 2003, 7, 487–498. [Google Scholar] [CrossRef] [Green Version]

- Control Techniques. Commander SE Advanced User Guide; Control Techniques Drives Limited: Hong Kong, China, 2002. [Google Scholar]

- Zhang, Z.; Bazzi, A.M. Robust Sensorless Scalar Control of Induction Motor Drives with Torque Capability Enhancement at Low Speeds. In Proceedings of the 2019 IEEE International Electric Machines Drives Conference (IEMDC), San Diego, CA, USA, 12–15 May 2019; pp. 1706–1710. [Google Scholar]

- Travieso-Torres, J.C.; Vilaragut-Llanes, M.; Costa-Montiel, A.; Duarte-Mermoud, M.A.; Aguila-Camacho, N.; Contreras-Jara, C.; Alvarez-Gracia, A. New adaptive high starting torque scalar control scheme for induction motors based on passivity. Energies 2020, 13, 1276. [Google Scholar] [CrossRef] [Green Version]

- Travieso-Torres, J.C.; Contreras-Jara, C.; Díaz, M.; Aguila-Camacho, N.; Duarte-Mermoud, M.A. New Adaptive Starting Scalar Control Scheme for Induction Motor Variable Speed Drives. IEEE Trans. Energy Convers. 2021, 37, 729–736. [Google Scholar] [CrossRef]

- Travieso-Torres, J.C.; Duarte-Mermoud, M.A.; Sepúlveda, D.I. Passivity-based control for stabilization, regulation and tracking purposes of a class of nonlinear systems. Int. J. Adapt. Control. Signal Process. 2007, 21, 582–602. [Google Scholar] [CrossRef]

- Narendra, K.S.; Annaswamy, A.M. Stable Adaptive Systems; Dovers Publications: Mineola, NY, USA, 2005. [Google Scholar]

- Park, R.H. Two-reaction theory of synchronous machines generalized method of analysis-part I. Trans. Am. Inst. Electr. Eng. 1929, 48, 716–727. [Google Scholar] [CrossRef]

- Mandic, D.P.; Kanna, S.; Xia, Y.; Moniri, A.; Junyent-Ferre, A.; Constantinides, A.G. A data analytics perspective of power grid analysis-part 1: The Clarke and related transforms. IEEE Signal Process. Mag. 2019, 36, 110–116. [Google Scholar] [CrossRef]

- O’Rourke, C.J.; Qasim, M.M.; Overlin, M.R.; Kirtley, J.L. A geometric interpretation of reference frames and transformations: dq0, Clarke, and Park. IEEE Trans. Energy Convers. 2019, 34, 2070–2083. [Google Scholar] [CrossRef] [Green Version]

| Symbol | Quantity | Values |

|---|---|---|

| rated output power | kW | |

| rated phase voltage | 220 V | |

| rated phase current | A | |

| rated power factor | ||

| rated electrical frequency | 50 Hz | |

| p | poles number | 4 |

| rated rotor angular speed | 152 rad/s | |

| motor inertia (data-sheet) | 0.2 kgm/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Travieso-Torres, J.C.; Duarte-Mermoud, M.A. Normalized Model Reference Adaptive Control Applied to High Starting Torque Scalar Control Scheme for Induction Motors. Energies 2022, 15, 3606. https://0-doi-org.brum.beds.ac.uk/10.3390/en15103606

Travieso-Torres JC, Duarte-Mermoud MA. Normalized Model Reference Adaptive Control Applied to High Starting Torque Scalar Control Scheme for Induction Motors. Energies. 2022; 15(10):3606. https://0-doi-org.brum.beds.ac.uk/10.3390/en15103606

Chicago/Turabian StyleTravieso-Torres, Juan Carlos, and Manuel A. Duarte-Mermoud. 2022. "Normalized Model Reference Adaptive Control Applied to High Starting Torque Scalar Control Scheme for Induction Motors" Energies 15, no. 10: 3606. https://0-doi-org.brum.beds.ac.uk/10.3390/en15103606