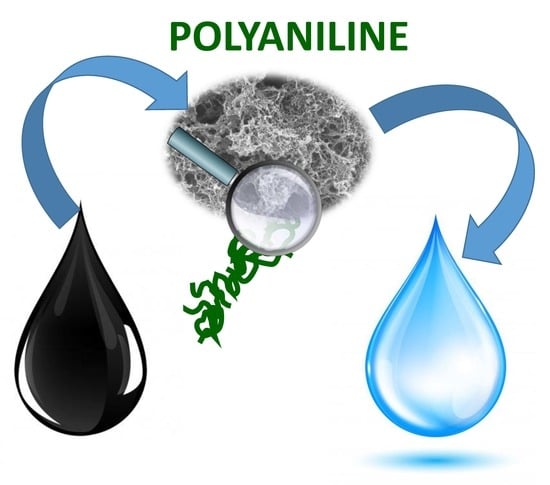

Polyanilines as New Sorbents for Hydrocarbons Removal from Aqueous Solutions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Preparation

2.1.1. PANI1 Synthesis

2.1.2. PANI2 Synthesis

2.1.3. PANI3 Synthesis

2.2. Materials Characterization

2.3. Sorption Experiments

2.4. Recycling Tests

3. Results and Discussion

3.1. Characterization of PANIs

3.2. HC Removal by PANIs

3.3. Recycling Tests

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shiflett, M.B.; Foley, H.C. Ultrasonic deposition of high-selectivity nanoporous carbon membranes. Science 1999, 285, 1902–1905. [Google Scholar] [CrossRef] [PubMed]

- Merkel, T.C.; Freeman, B.D.; Spontak, R.J.; He, Z.; Pinnau, I.; Meakin, P.; Hill, A.J. Ultrapermeable, reverse-selective nanocomposite membranes. Science 2002, 296, 519–522. [Google Scholar] [CrossRef] [Green Version]

- Yuan, J.; Liu, X.; Akbulut, O.; Hu, J.; Suib, S.L.; Kong, J.; Stellacci, F. Superwetting nanowire membranes for selective absorption. Nat. Nanotechnol. 2008, 3, 332–336. [Google Scholar] [CrossRef] [PubMed]

- Alcaraz-Espinoza, J.J.; Chávez-Guajardo, A.E.; Medina-Llamas, J.C.; Andrade, C.A.S.; De Melo, C.P. Hierarchical composite Polyaniline-(Electrospun Polystyrene) fibers applied to heavy metal remediation. ACS Appl. Mater. Interfaces 2015, 7, 7231–7240. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Huang, X.; Asefa, T. Nanostructured polymers with high surface areausing inorganic templates for the efficient extraction of anionic dyes from solutions. Chem. Commun. 2015, 51, 16135–16138. [Google Scholar] [CrossRef] [PubMed]

- Della Pina, C.; De Gregorio, M.A.; Clerici, L.; Dellavedova, P.; Falletta, E. Polyaniline (PANI): An innovative support for sampling and removal of VOCs in air matrices. J. Hazard. Mater. 2018, 344, 308–315. [Google Scholar] [CrossRef]

- Chang, J.C.; MacDiarmid, A.G. Polyaniline: Protonic acid doping of the emeraldine form to the metallic regime. Synth. Met. 1986, 13, 193–205. [Google Scholar] [CrossRef]

- Cionti, C.; Della Pina, C.; Meroni, D.; Falletta, E.; Ardizzone, S. Triply green polyaniline: UV irradiation-induced synthesis of a highly porous PANI/TiO2 composite and its application in dye removal. Chem. Commun. 2018, 54, 10702–10705. [Google Scholar] [CrossRef]

- Chen, Z.; Della Pina, C.; Falletta, E.; Rossi, M. A green route to conducting polyaniline by copper catalysis. J. Catal. 2009, 367, 93–96. [Google Scholar] [CrossRef]

- Bocchini, S.; Castellino, M.; Della Pina, C.; Rajana, K.; Falletta, E.; Chiolerio, A. Inkjet printed doped polyaniline: Navigating through physics and chemistry for the next generation devices. Appl. Surf. Sci. 2018, 456, 246–258. [Google Scholar] [CrossRef] [Green Version]

- Castagna, R.; Tunesi, M.; Saglio, B.; Della Pina, C.; Sironi, A.; Albani, D.; Bertarelli, C.; Falletta, E. Ultrathin electrospun PANI nanofibers for neuronal tissue engineering. J. Appl. Polym. Sci. 2016, 133, 43885. [Google Scholar] [CrossRef]

- Chen, Z.; Della Pina, C.; Falletta, E.; Lo Faro, M.; Pasta, M.; Rossi, M.; Santo, N. Facile synthesis of polyaniline using gold catalyst. J. Catal. 2008, 259, 1–4. [Google Scholar] [CrossRef]

- Nasar, A.; Mashkoor, F. Application of polyaniline-based adsorbents for dye removal from water and wastewater. Environ. Sci. Pollut. Res. 2019, 26, 5333–5356. [Google Scholar] [CrossRef] [PubMed]

- Krishnani, K.K.; Srinives, S.; Mohapatra, B.C.; Boddu, V.M.; Hao, J.; Meng, X.; Mulchandani, A. Hexavalent chromium removal mechanism using conducting polymers. J. Hazard. Mater. 2013, 252, 99–106. [Google Scholar] [CrossRef]

- Pouget, J.P.; Jozefowicz, M.E.; Epstein, A.J.; Tang, X.; MacDiarmid, A.G. X-ray structure of polyaniline. Macromolecules 1991, 24, 779–789. [Google Scholar] [CrossRef]

- Ansari, R.; Keivani, M.B. Polyaniline conducting electroactive polymers: Thermal and environmental stability studies. J. Chem. 2006, 3, 202–217. [Google Scholar] [CrossRef] [Green Version]

- Alves, W.F.; Venancio, E.C.; Leite, F.L.; Kanda, D.H.F.; Malmonge, L.F.; Malmonge, J.A.; Mattoso, L.H.C. Thermo-analyses of polyaniline and its derivatives. Thermochim. Acta 2010, 502, 43–46. [Google Scholar] [CrossRef]

- Chandrakanthi, N.; Careem, M.A. Thermal stability of polyaniline. Polym. Bull. 2000, 44, 101–108. [Google Scholar] [CrossRef]

- Lu, X.; Tan, C.Y.; Xu, J.; He, C. Thermal degradation of electrical conductivity of polyacrylic acid doped polyaniline: Effect of molecular weight of the dopants. Synth. Met. 2003, 138, 429–440. [Google Scholar] [CrossRef]

- Ramamurthy, P.C.; Mallya, A.N.; Joseph, A.; Harrell, W.R.; Gregory, R.V. Synthesis and characterization of high molecular weight polyaniline for organic electronic applications. Polym. Eng. Sci. 2012, 52, 1821–1830. [Google Scholar] [CrossRef]

- Zheng, W.; Min, Y.; MacDiarmid, A.G.; Angelopoulos, M.; Liao, Y.H.; Epstein, A.J. Aggregation and molecular conformation of doped polyaniline in chloroform solution. Synth. Met. 1997, 84, 109–110. [Google Scholar] [CrossRef]

- Falletta, E.; Costa, P.; Della Pina, C.; Lanceros-Mendez, S. Development of high sensitive polyaniline based piezoresistive films by conventional and green chemistry approaches. Sens. Actuat. A Phys. 2014, 22, 13–21. [Google Scholar] [CrossRef]

- Capodici, M.; Cosenza, A.; Di Trapani, D.; Mannina, G.; Torregrossa, M.; Viviani, G. Treatment of Oily Wastewater with Membrane Bioreactor Systems. Water 2017, 9, 412. [Google Scholar] [CrossRef] [Green Version]

- Saleem, J.; Riaz, M.A.; McKay, G. Oil sorbents from plastic wastes and polymers: A review. J. Hazard. Mat. 2018, 341, 424–437. [Google Scholar] [CrossRef]

- Saleem, J.; Ning, C.; Barford, J.; McKay, G. Combating oil spill problem using plastic waste. Waste Manag. 2015, 44, 34–38. [Google Scholar] [CrossRef]

- Bandura, L.; Woszuk, A.; Kołodyńka, D.; Franus, W. Application of Mineral Sorbents for Removal of Petroleum Substances: A Review. Minerals 2017, 7, 37. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.; Guo, M.; Wu, Y.; Wu, Q.; Zhang, R. Removal of Emulsified Oil from Water by Fruiting Bodies of Macro-Fungus (Auricularia polytricha). PLoS ONE 2014, 9, e95162. [Google Scholar] [CrossRef]

- Water Quality—Determination of Hydrocarbon Oil Index—Part 2: Method Using Solvent Extraction and Gas Chromatography. ISO 9377-2:2002. Available online: https://www.iso.org/obp/ui/#iso:std:iso:9377:-2:ed-1:v1:en. (accessed on 17 January 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Della Pina, C.; De Gregorio, M.A.; Dellavedova, P.; Falletta, E. Polyanilines as New Sorbents for Hydrocarbons Removal from Aqueous Solutions. Materials 2020, 13, 2161. https://0-doi-org.brum.beds.ac.uk/10.3390/ma13092161

Della Pina C, De Gregorio MA, Dellavedova P, Falletta E. Polyanilines as New Sorbents for Hydrocarbons Removal from Aqueous Solutions. Materials. 2020; 13(9):2161. https://0-doi-org.brum.beds.ac.uk/10.3390/ma13092161

Chicago/Turabian StyleDella Pina, Cristina, Maria Antonietta De Gregorio, Pierluisa Dellavedova, and Ermelinda Falletta. 2020. "Polyanilines as New Sorbents for Hydrocarbons Removal from Aqueous Solutions" Materials 13, no. 9: 2161. https://0-doi-org.brum.beds.ac.uk/10.3390/ma13092161