1. Introduction

The sustainable construction industry focuses on the production of new environmentally friendly solutions connected with the replacement of conventional materials. Cement production is an intensive consumer of power, natural nonrenewable raw materials, and fossil fuels in a high-temperature process. The contribution of the cement manufacturing sector to the total global anthropogenic CO

2 emissions is approximately 8% [

1,

2]. These environmental impacts are associated with CO

2 emissions from clinker production (especially the thermal decomposition of calcium carbonate) and combustion of fossil fuels. CO

2 is a greenhouse gas that contributes to global warming and related climate changes. Therefore, cement production urgently needs to apply the principle of sustainability and to use supplementary cementitious materials and substitutes for conventional fossil fuels when heating cement kilns through the use of alternative fuels with adequate calorific values. Recycling of appropriate products, such as waste and/or by-products, has become an attractive alternative to their disposal in accordance with the waste management hierarchy, as well as with European Union (EU) policies and Agenda 21 targets related to sustainable development. Benefits related to the usage of alternative fuels are associated with a reduction in environmental and economic burdens. Different types of gaseous, liqud, and solid wastes (hazardous and non-hazardous) are used as alternative fuels in cement kilns, such as waste gases from refinery, landfill, and pyrolysis, waste oils and fats, wax suspensions, chemical waste, asphalt slurry, industrial sludge, municipal sewage sludge, agricultural waste, rubber and tires, plastics, and textiles [

3]. At present, attention is being paid to the replacement of fossil fuels with carbon neutral materials (agricultural biomass, municipal solid waste, or meat and bone from animal-based meals) [

4]. The potential of these alternative fuels is related to their suitability for the combustion process and ensuring conditions of high-energy efficiency [

5]. This strategy of the cement industry based on the partial substitution of traditional fossil fuels with alternative fuels for cement clinker production is of high importance and an attractive alternative to nonrenewable fossil fuels [

4]. However, the use of alternative fuels must abide by the rules related to a reduction in CO

2 emissions during the burning process in a cement kiln [

6]. An increasing proportion of alternative fuels in the combustion process led to a need to implement bypass technology in production, thereby ensuring the removal of exhaust gases from the cement rotary kiln. Bypasses with different configurations are so far the only possible method of reducing the amount of chlorides in the cement kiln atmosphere [

7,

8]. Large quantities of particulate material present in the flue gases are removed from the kiln by air pollution control devices. Cement kiln dust (CKD), also known as bypass dust (BPD), is a finely dispersed particulate material, composed of oxidized, anhydrous, micron-sized particles accumulated in the dust collectors such as cyclones, bag houses, or electrostatic precipitators during the high-temperature Portland cement clinker process. This by-product containing fine particulates of unburned and partially burned raw materials is rich in alkalis, chlorides, and sulfates and may also contain heavy metals [

9]. Alkaline chlorides are introduced to the cement kiln through the fuel. Thus, the chemical composition of BPD is determined by the clinker burning technology, the type of alternative fuel burned, the raw materials, and the exhaust gas removal system [

10,

11]. According to the Environmental Protection Agency (EPA) [

12], BPD is considered as a potentially hazardous waste due to its caustic and irritating nature. Due to its high alkali content exceeding the cement clinker standard tolerances, the BPD by-product is not possible to return to the feedstock of clinker manufacturing. The amount of BPD generated per ton of clinker produced is equal to approximately 15–20% (by mass) [

13,

14,

15]. The total volume of BPD generated in the Slovak Cement Factories is about 6% of the total annual production of clinker, which currently ends up in an on-site landfill for hazardous waste. High amounts of BPD per year lead to the high cost of collection, transportation, and landfilling due to a lack of adequate methods for its reuse and recycling. The existence of this waste and its growing production pose a serious environmental problem. Therefore, it is mandatory to minimize this by-product of cement production, or to handle it in a sustainable manner.

Literature sources indicate that BPD can be reused in a number of different ways for various purposes. As reported in many papers, the most common applications of BPD are in soil consolidation and stabilization [

10,

16]. BPD addition can lead to an increase in the shear strength of a soil and/or control the shrink-swell properties of a soil, thus improving the load-bearing capacity of a sub-grade to support pavements and foundations [

17]. BPD combined with fly ash was successfully used for stabilizing road beds and, especially, clay soils [

18]. Among modern engineering applications of BPD, its significant application potential and widespread utilization is in the construction sector. Mostly, BPD is applied as a partial replacement of cement in the production of mortar/concrete [

10,

19,

20,

21,

22], cement bricks [

23], concrete paving blocks [

24,

25], asphalt pavement/concrete [

26], and sand sidewalks [

9]. The presence of clinker phases and free lime in BPD may be responsible for its binding properties. Many papers reported the effect of used BPD on the different properties of mortar, and concrete [

10,

21,

22,

27]. There were a fewer older works devoted to the characterization of BPD and its influence on the properties, the results of which were summarized in [

28]. Wide variation in the chemical composition of CKDs limits their potential application as a sustainable binder component in concrete. However, BPD application in suitable amounts is not adversely affecting their properties. As presented in [

19], concretes with lower percentages of BPD (about 5%) reach compressive strength, flexural strength, toughness, and freezing and thawing resistance comparable to the traditional concrete.

The presence of free CaO and significant amounts of soluble sodium and potassium compounds (chlorides and sulfates) in BPD causes its high alkalinity [

29]. Thanks to BPD’s alkaline nature, it can be used as an alkali activator of supplementary cementitious materials [

30,

31,

32]. In recent years, many scientific advances in the preparation technology and the insights into the performances of new binders with a geopolymer matrix developed by blending BPDs with the fly ash and/or granulated blast furnace steel slag (GGBS) have performed [

15,

33,

34]. As shown in [

35], BPD addition enhances the geopolymerization reaction. The alkaline-modified alternative constituents improve the fresh mixture properties of the cement mortar/concrete and contribute to a reduction in the environmental impact. Successful utilization of BPD for fly ash and GGBS activation in ternary/quaternary cement system, leading to its higher strength, depends on the dissolution rate of additives, the alkalinity of the reacting system, and the existence of the optimum free lime and sulfate content [

32,

36]. In accordance with paper [

37], the alkali activated cements are characterized by more durable geopolymer matrix and lower carbon footprint than ordinary Portland cement. Heikal et al. [

31] reported on more durable binder with optimized mix composition of GGBS, BPD, and/or micro-silica, where 20% BPD amount was used.

The incorporation of BPD in cement-blended material represents the most advanced strategy for an environmentally friendly waste management solution for BPD. Taking this aspect of BPD into account, alternative cement binder materials are becoming an important research topic.

Limited studies were aimed at evaluating the performance of cement mortars incorporating BPD and supplementary cementitious materials for infrastructure applications are currently available. Evaluation of the physico-mechanical and durability-related properties of concrete paving blocks containing BPD as a partial replacement or as an addition to cement indicated that up to 40–60% BPD could be used for producing environmentally friendly paving blocks for traffic applications [

24]. As presented in [

38], cement binders containing BPD can significantly improve the properties of the sub-grade.

BPD can be a constituent of cement binder with a high proportion of mineral components. A representative example is the hydraulic road binder. European standard requirements for a normal hardening hydraulic road binder refer to the physical and chemical properties of binder mixture, as well as the mechanical properties after 56 days of hardening. To the author’s knowledge, there are few reports on the use of BPD in quaternary cement mixes but with a different composition for this purpose. Therefore, this study highlights its significance and originality.

Scientific hypothesis was supported by positive initial results that BPD containing a combination of the activators (CaO, and different forms of alkalis) can potentially result in a new binding system with favorable mechanical properties when used in conjunction with GGBS.

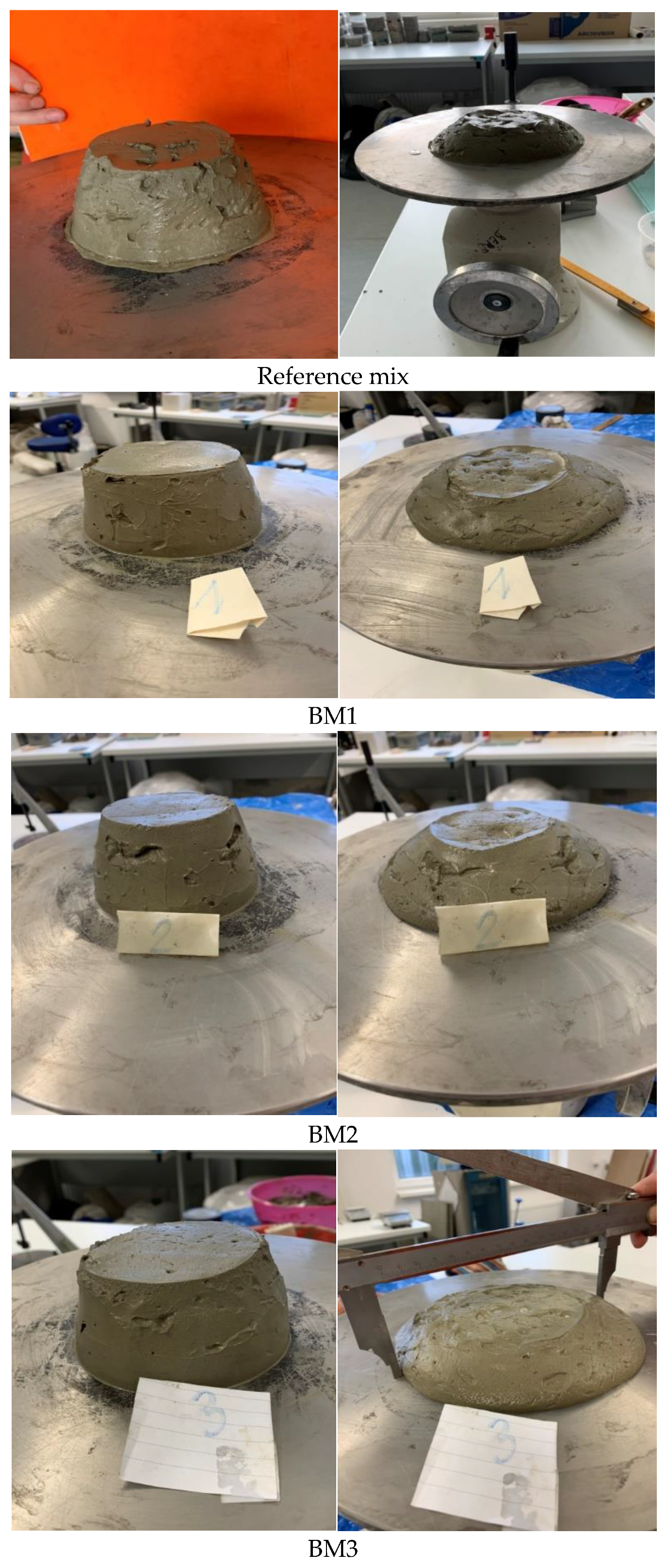

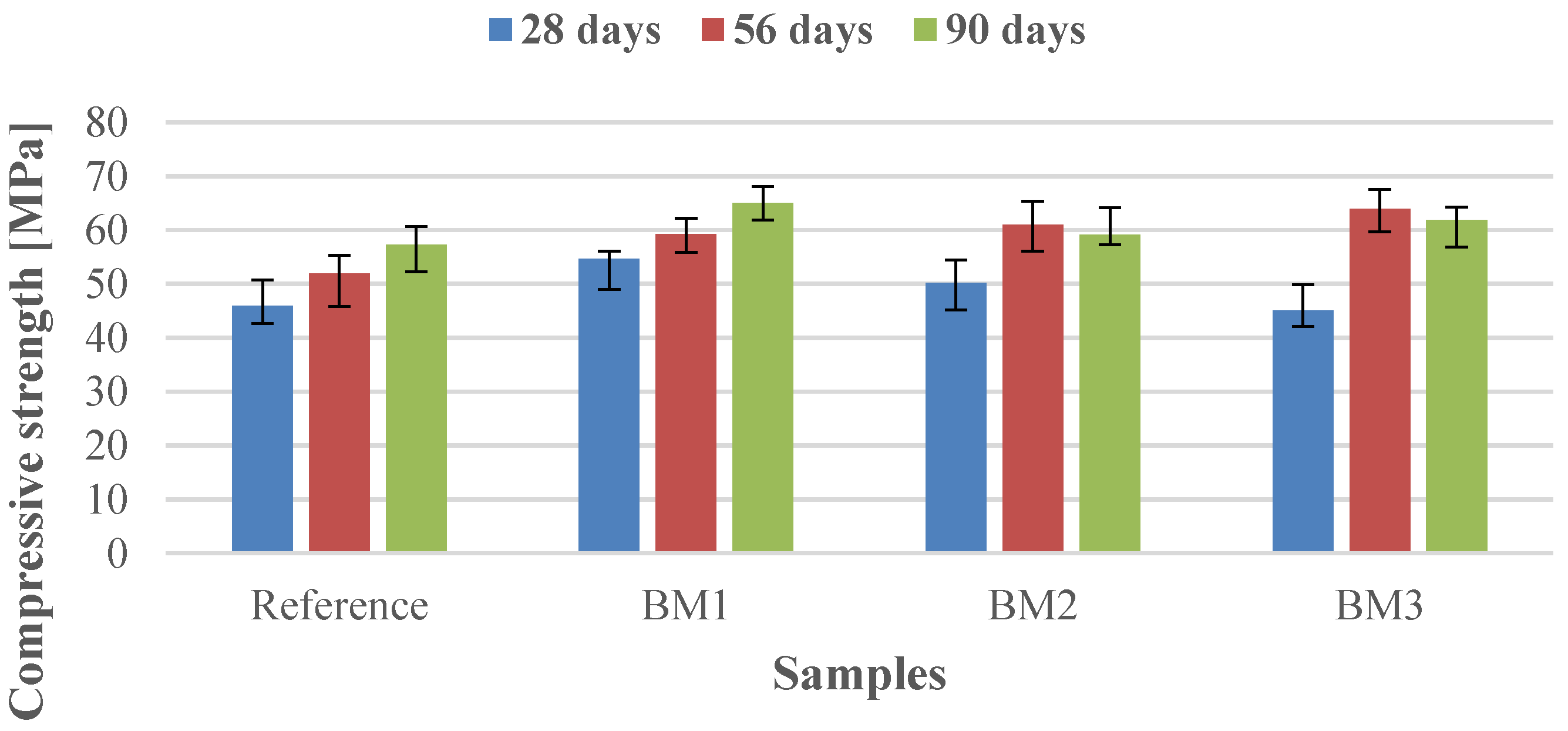

The main objective of the research was a comprehensive solution for the use of BPD in preparing experimental mixes for an eco-friendly normal hardening hydraulic road binder, with the key properties of fresh cement pastes and hardened specimens tested according to the standard in [

39]. Another partial objective is to contribute to the available knowledge about adoption of alternative hydraulic road binder material that can significantly improve its performance with BPD addition for geopolymer formation in the binder system, and environmental protection. Therefore, the novelty of our research is in utilizing and evaluating the properties of a hydraulic road binder containing cement clinker and limestone as the major binder constituents with a portion of supplementary cement material (GGBS) and in combination with the additional substance of BPD. The scientific problem lies in understanding the influence of the physico-chemical characteristics of BPD on its performance as an effective binder component, and on the properties of fresh mixes and hardened mortar specimens. The outcome of this research is expected to provide critical information on the development of mortar properties in accordance with the standard requirements.

The choice of this additional binder constituent was motivated by the improvement in properties of the binder mix (mainly workability) in accordance with the standard in [

39]. Three experimental mixes with variations in the main constituents (cement clinker and limestone) and GGBS were prepared. The BPD amount in the experimental mixtures was constant at 10% of the total weight in accordance with the standard recommended content of an additional binder constituent in normal hardening road binder. An additional aim of this research was to assess the critical properties, including the fineness, chemical and phase composition of dry binder mixes, the behavior of fresh mixes (initial setting time, consistency), and compressive strength of hardened bodies, and to interpret the obtained results. To achieve these aims, all standard requirements with respect to the properties of a normal hardening road binder were tested. The experimental investigations were organized in two phases. In the first, the properties of BPD and experimental binder mixtures were assessed in terms of their compliance with standard requirements for their mix composition. In the second, the resulting properties of fresh pastes and specimens hardened under normal conditions were evaluated.