Combined Freeze-Thaw and Chloride Attack Resistance of Concrete Made with Recycled Brick-Concrete Aggregate

Abstract

:1. Introduction

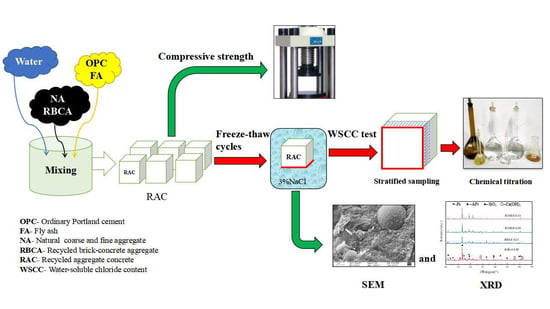

2. Experimental Program

2.1. Experimental Materials

2.1.1. Cement

2.1.2. Natural Aggregates

2.1.3. Recycled Aggregates

2.1.4. Other Materials

2.2. Mix Proportion

2.3. Experimental Methods

2.3.1. Freeze-Thaw Cycles in NaCl Solution

2.3.2. Water-Soluble Chloride Test

3. Results and Discussion

3.1. Compressive Strength of Recycled Concrete

3.1.1. Compressive Strength and RBCA Content

3.1.2. Compressive Strength and FA Content

3.2. The Mass Loss Rate (MLR)

3.3. The Relative Dynamic Elastic Modulus (RDEM)

3.4. Water-Soluble Chloride Content (WSCC)

3.4.1. WSCC and RBCA Content

3.4.2. WSCC and FA Content

3.5. SEM and XRD

4. Conclusions

- The replacement of virgin aggregates with RBCA composed of 30% recycled brick aggregate and 70% recycled concrete aggregate led to a decrease in 28 days compressive strength. The R80 series concrete had a margin of increase of 2.2–7.9% than that of R100 series concrete. The best dosage of FA in combination with recycled aggregate was discovered to be 15%;

- When the RBCA content increased from 80% to 100%, concrete specimens were susceptible to more damage based on the increased MLR and sharper reduction in RDEM. The concrete MLR was lowest with 15% FA, while RDEM loss was lowest with 30% FA. The addition of 15% FA improved the resistance of concrete following 3% NS-45FT, while the RDMA of various RBCA concrete varied according to the amount of FA;

- All WSCC followed the same trend, decreasing within 30 mm of the sodium chloride-eroded surface, recovering slightly, and reaching a constant value in the area beyond 30 mm. The chloride penetration resistance of concrete containing 30% FA was the best, owing to the concrete’s low WSCC value.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tam, V.; Soomro, M.; Jorge Evangelista, A.C. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Fot, J.; Ern, R. Transition to circular economy in the construction industry: Environmental aspects of waste brick recycling scenarios. Waste Manag. 2020, 118, 510–520. [Google Scholar] [CrossRef]

- Tang, Z.; Li, W.; Tam, V.W.; Yan, L. Mechanical behaviors of CFRP-confined sustainable geopolymeric recycled aggregate co-ncrete under static and cyclic compression. Compos. Struct. 2020, 252, 112750. [Google Scholar] [CrossRef]

- Gebremariam, A.T.; Maio, F.D.; Vahidi, A.; Rem, P. Innovative technologies for recycling End-of-Life concrete waste in the built environment. Resour. Conserv. Recycl. 2020, 163, 104911. [Google Scholar] [CrossRef]

- Tian, Y.; Yan, X.; Zhang, M.; Lu, D.; Li, W. Internal transport and corrosion behaviors of sulfate corrosion media carried by recycled aggregate in concrete. Constr. Build. Mater. 2020, 260, 120480. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Fawzy, A.M. Experimental investigation on permeability indices and strength of modified pervious concrete with recycled concrete aggregate. Constr. Build. Mater. 2018, 193, 105–127. [Google Scholar] [CrossRef]

- Alqarni, A.S.; Abbas, H.; Al-Shwikh, K.M.; Al-Salloum, Y.A. Treatment of recycled concrete aggregate to enhance concrete performance. Constr. Build. Mater. 2021, 307, 124960. [Google Scholar] [CrossRef]

- Bravo, M.; De Brito, J.; Evangelista, L.; Pacheco, J. Durability and shrinkage of concrete with CDW as recycled aggregates: Benefits from superplasticizer’s incorporation and influence of CDW composition. Constr. Build. Mater. 2018, 168, 818–830. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S. Effect of the quality of parent concrete on the properties of high performance recycled aggregate concrete. Constr. Build. Mater. 2015, 77, 501–508. [Google Scholar] [CrossRef]

- Ohemeng, E.A.; Ekolu, S.O.; Quainoo, H. Models for predicting strength properties of recycled concretes made with non-treated CRCAs: Empirical approach. Constr. Build. Mater. 2021, 307, 124585. [Google Scholar] [CrossRef]

- Contreras-Llanes, M.; Romero, M.; Gázquez, M.J.; Bolívar, J.P. Recycled Aggregates from Construction and Demolition Waste in the Manufacture of Urban Pavements. Materials 2021, 14, 6605. [Google Scholar] [CrossRef] [PubMed]

- Sahraei Moghadam, A.; Omidinasab, F.; Abdalikia, M. The effect of initial strength of concrete wastes on the fresh and hardened properties of recycled concrete reinforced with recycled steel fibers. Constr. Build. Mater. 2021, 300, 124284. [Google Scholar] [CrossRef]

- Yang, J.; Shaban, W.M.; Elbaz, K.; Thomas, B.S.; Li, L. Properties of concrete containing strengthened crushed brick aggregate by pozzolan slurry. Constr. Build. Mater. 2020, 247, 118612. [Google Scholar] [CrossRef]

- Poon, C.S.; Chan, D. Paving blocks made with recycled concrete aggregate and crushed clay brick. Constr. Build. Mater. 2006, 20, 569–577. [Google Scholar] [CrossRef]

- Diamond, S.; Mindess, S. Sem investigations of fracture surfaces using stereo pairs: I. fracture surfaces of rock and of cement paste. Cem. Concr. Res. 1992, 22, 67–78. [Google Scholar] [CrossRef]

- Yang, C.C.; Su, J.K. Approximate migration coefficient of interfacial transition zone and the effect of aggregate content on the migration coefficient of mortar. Cem. Concr. Res. 2002, 32, 1559–1565. [Google Scholar] [CrossRef]

- Macedo, R.; Ulsen, C.; Mueller, A. Quantification of residual cement paste on recycled concrete aggregates containing limestone by selective dissolution. Constr. Build. Mater. 2019, 229, 116875. [Google Scholar] [CrossRef]

- Wang, P.; Mo, R.; Li, S.; Xu, J.; Jin, Z.; Zhao, T.; Wang, D. A chemo-damage-transport model for chloride ions diffusion in cement-based materials: Combined effects of sulfate attack and temperature. Constr. Build. Mater. 2021, 325, 133–134. [Google Scholar] [CrossRef]

- Xu, P.; Zhou, J.; Li, G.; Wang, P.; Chi, H. Corrosion inhibition efficiency of compound nitrite with D-sodium gluconate on car-bon steel in simulated concrete pore solution. Constr. Build. Mater. 2021, 288, 123101. [Google Scholar] [CrossRef]

- Wang, D.; Zhou, X.; Meng, Y.; Chen, Z. Durability of concrete containing fly ash and silica fume against combined freezing-thawing and sulfate attack. Constr. Build. Mater. 2017, 147, 398–406. [Google Scholar] [CrossRef]

- Wang, P.; Wang, Y.; Zhao, T.; Xiong, C.; Fan, Z. Effectiveness Protection Performance of an Internal Blending Organic Corrosion Inhibitor for Carbon Steel in Chloride Contaminated Simulated Concrete Pore Solution. J. Adv. Concr. Technol. 2020, 18, 116–128. [Google Scholar] [CrossRef] [Green Version]

- Tunstall, L.E.; Scherer, G.W.; Prud’Homme, R.K. A new hypothesis for air loss in cement systems containing fly ash. Cem. Concr. Res. 2021, 142, 106352. [Google Scholar] [CrossRef]

- Ma, H.; Yu, H.; Li, C.; Tan, Y.; Cao, W.; Da, B. Freeze-Thaw damage to high-performance concrete with synthetic fibre and fly ash due to ethylene glycol deicer. Constr. Build. Mater. 2018, 187, 197–204. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Chan, D. Influence of fly ash as cement replacement on the properties of recycled aggregate concrete. J. Mater. Civ. Eng. 2007, 19, 709–717. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Combined influence of recycled concrete aggregates and high contents of fly ash on concrete properties. Constr. Build. Mater. 2017, 157, 554–572. [Google Scholar] [CrossRef]

- Wang, D.; Zhou, X.; Fu, B.; Zhang, L. Chloride ion penetration resistance of concrete containing fly ash and silica fume against combined freezing-thawing and chloride attack. Constr. Build. Mater. 2018, 169, 740–747. [Google Scholar] [CrossRef] [Green Version]

- Thomas, M. Chloride thresholds in marine concrete. Cem. Concr. Res. 1996, 26, 513–519. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Li, J.B.; Zhang, C. On relationships between the mechanical properties of recycled aggregate concrete: An overview. Mater. Struct. 2006, 39, 655–664. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Dashti, J.; Ganjavi, B. Optimizing Compressive Behavior of Concrete Containing Fine Recycled Refractory Brick Aggregate Together with Calcium Aluminate Cement and Polyvinyl Alcohol Fibers Exposed to Acidic Environment. Constr. Build. Mater. 2018, 164, 837–849. [Google Scholar] [CrossRef]

- Zhang, S.; He, P.; Niu, L. Mechanical properties and permeability of fiber-reinforced concrete with recycled aggregate made from waste clay brick. J. Clean. Prod. 2020, 268, 121690. [Google Scholar] [CrossRef]

- Zheng, C.; Cong, L.; Geng, D.; Li, X.; Liu, Z.; Li, L. Mechanical properties of recycled concrete with demolished waste concrete aggregate and clay brick aggregate. Results Phys. 2018, 9, 1317–1322. [Google Scholar] [CrossRef]

- Boukour, S.; Benmalek, M.L. Performance evaluation of a resinous cement mortar modified with crushed clay brick and tire rubber aggregate. Constr. Build. Mater. 2016, 120, 473–481. [Google Scholar] [CrossRef]

- Lutz, M.P.; Zimmerman, R.W. Effect of the interphase zone on the conductivity or diffusivity of a particulate composite using Maxwell’s homogenization method. Int. J. Eng. Sci. 2016, 98, 51–59. [Google Scholar] [CrossRef] [Green Version]

- China Standards: GB 175-2007. Common Portland Cement; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; Standardization Administration of China: Beijing, China, 2007. [Google Scholar]

- China Standards: JGJ 52-2006. Standard for Technical Requirements and Test Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete; China Architecture & Building Press: Beijing, China, 2006. [Google Scholar]

- China Standards: GB/T 25177-2010. Recycled Coarse Aggregate for Concrete; China Standards Press: Beijing, China, 2010. [Google Scholar]

- González, J.; Gayarre, F.L.; Pérez, L.; Ros, P.S.; López, M. Influence of recycled brick aggregates on properties of structural co-ncrete for manufacturing precast prestressed beams. Constr. Build. Mater. 2017, 149, 507–514. [Google Scholar] [CrossRef]

- Chen, F.; Wu, K.; Ren, L.; Xu, J.; Zheng, H. Internal Curing Effect and Compressive Strength Calculation of Recycled Clay Brick Aggregate Concrete. Materials 2019, 12, 1815. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Jia, Y.; Li, T.; Hou, D.; Zheng, Q. Molecular dynamics study on ions and water confined in the nanometer channel of Friedel’s salt: Structure, dynamics and interfacial interaction. Phys. Chem. Chem. Phys. 2018, 20, 27049–27058. [Google Scholar] [CrossRef]

- Matschei, T.; Lothenbach, B.; Glasser, F.P. The AFm phase in Portland cement. Cem. Concr. Res. 2007, 37, 118–130. [Google Scholar] [CrossRef]

- Glasser, F.P.; Kindness, A.; Stronach, S.A. Stability and solubility relationships in AFm phases: Part I. Chloride, sulfate and hydroxide. Cem. Concr. Res. 1999, 29, 861–866. [Google Scholar] [CrossRef]

- Zuquan, J.; Wei, S.; Yunsheng, Z.; Jinyang, J.; Jianzhong, L. Interaction between sulfate and chloride solution attack of concretes with and without fly ash. Cem. Concr. Res. 2007, 37, 1223–1232. [Google Scholar] [CrossRef]

- Elakneswaran, Y.; Nawa, T.; Kurumisawa, K. Electrokinetic potential of hydrated cement in relation to adsorption of chlorides. Cem. Concr. Res. 2009, 39, 340–344. [Google Scholar] [CrossRef]

- Florea, M.V.A.; Brouwers, H.J.H. Chloride Binding Related to Hydration Products: Part I: Ordinary Portland Cement. Cem. Concr. Res. 2012, 42, 282–290. [Google Scholar] [CrossRef]

| SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | CaO (%) | MgO (%) | SO3 (%) | Specific Surface Area (m2/kg) | Initial Setting Time (min) | Final Setting Time (min) | Soundness |

|---|---|---|---|---|---|---|---|---|---|

| 14.1 | 5.19 | 2.17 | 43.5 | 5.00 | 2.93 | 348 | 195 | 255 | qualified |

| No. | Aggregate Sources | Proportion (%) | Water Absorption (%) | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Crushing Value Index (%) |

|---|---|---|---|---|---|---|

| RBCA | Waste concrete | 70 | 12.8 | 2302 | 1020 | 20.3 |

| Waste brick | 30 | |||||

| RCA | Waste concrete | 100 | 6.1 | 2409 | 1120 | 15.9 |

| RBA | Waste brick | 100 | 18.0 | 2051 | 858 | 25.5 |

| No. | Coarse Aggregate | Natural Sand | Binding Material | Water | ||

|---|---|---|---|---|---|---|

| RBCA | Natural Gravel | OPC | FA | |||

| R100-FA0 | 1201 | 0 | 619 | 450.0 | 0 | 180 |

| R100-FA15 | 1201 | 0 | 619 | 382.5 | 67.5 | 180 |

| R100-FA30 | 1201 | 0 | 619 | 315.0 | 135 | 180 |

| R80-FA0 | 960.8 | 240.2 | 619 | 450.0 | 0 | 180 |

| R80-FA15 | 960.8 | 240.2 | 619 | 382.5 | 67.5 | 180 |

| R80-FA30 | 960.8 | 240.2 | 619 | 315.0 | 135 | 180 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Wang, J.; Wang, N.; Wu, C.; Zhang, X.; Wang, D.; Ma, Z. Combined Freeze-Thaw and Chloride Attack Resistance of Concrete Made with Recycled Brick-Concrete Aggregate. Materials 2021, 14, 7267. https://0-doi-org.brum.beds.ac.uk/10.3390/ma14237267

Yu Y, Wang J, Wang N, Wu C, Zhang X, Wang D, Ma Z. Combined Freeze-Thaw and Chloride Attack Resistance of Concrete Made with Recycled Brick-Concrete Aggregate. Materials. 2021; 14(23):7267. https://0-doi-org.brum.beds.ac.uk/10.3390/ma14237267

Chicago/Turabian StyleYu, Yao, Jian Wang, Ninghui Wang, Chenjie Wu, Xiaojing Zhang, Dezhi Wang, and Zhipeng Ma. 2021. "Combined Freeze-Thaw and Chloride Attack Resistance of Concrete Made with Recycled Brick-Concrete Aggregate" Materials 14, no. 23: 7267. https://0-doi-org.brum.beds.ac.uk/10.3390/ma14237267