Tuning of Multivariable Model Predictive Control for Industrial Tasks

Abstract

:1. Introduction

2. MPC Problem Formulation

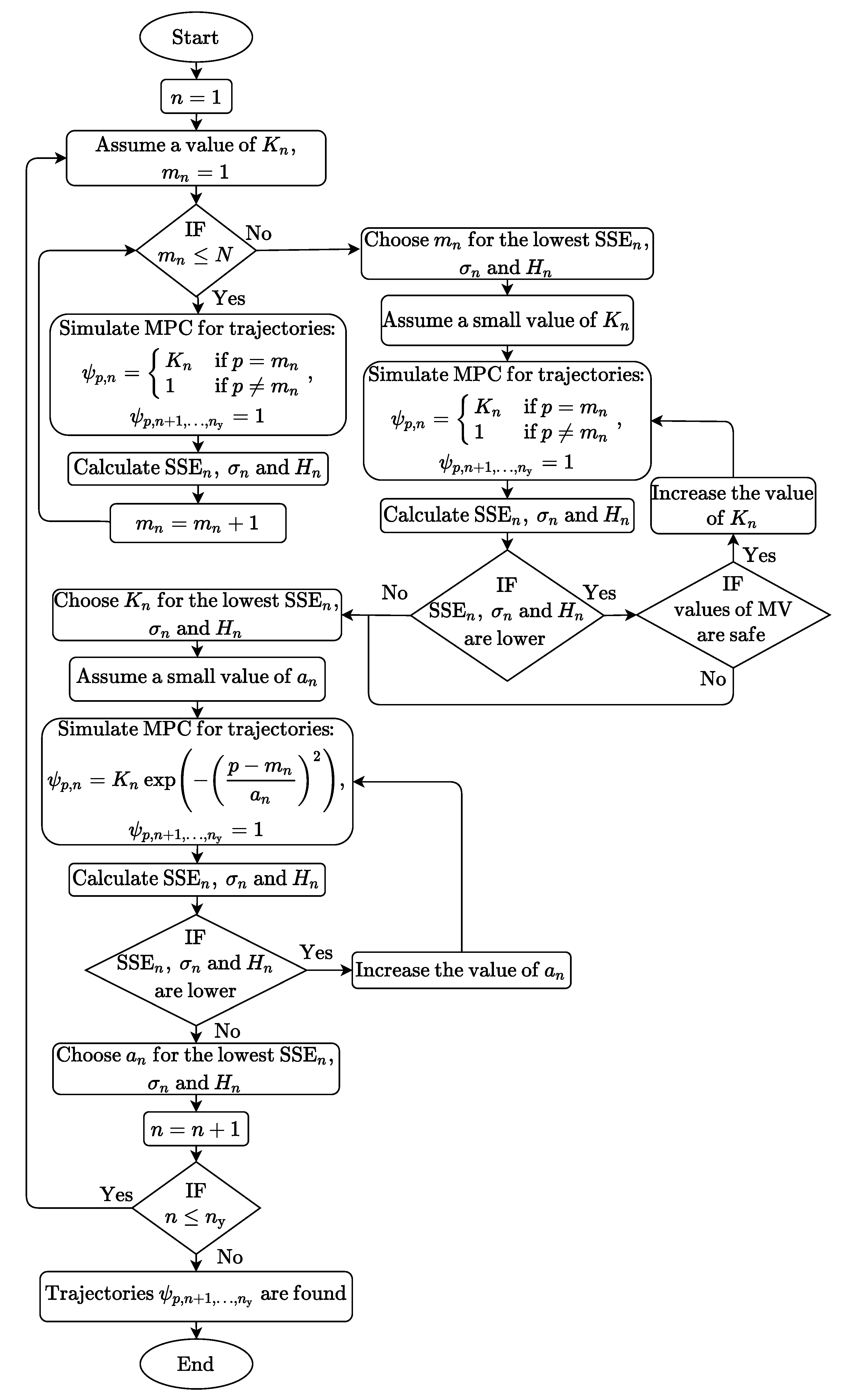

3. MPC Tuning Procedure

- The tuning coefficients for only one manipulated variable are calculated at the same time, i.e., , for the consecutive process outputs .

- If all the coefficients were optimised directly at the same time by a numerical optimisation procedure, we still would have as many as N decision variables. As an alternative, that sequence of coefficients is parameterised using Gauss-like functions [34]. At first, a very general approximation of the Gauss function is used in which for one point, the function has a value of ; for all other points, it has a default value equal to one:The function (5) is characterised by two parameters: and . The first one defines the chosen sampling instant within the prediction horizon for which the function has the value of . When the parameters and are selected, the trajectory of the weights is calculated precisely from the Gauss function:where defines the spread.

- The trajectory of the N coefficients is found for the controlled variable n. All other coefficients are tuned or have their default value.

- (a)

- The best trajectory (5) is found, i.e., its parameters and are determined.

- The constant value of the parameter is assumed. Its value has to be larger than one, and it should result in a noticeable change in control quality in comparison with the control quality achieved for the scenario in which all coefficients .

- The performance indices are calculated from simulations of the MPC algorithm for a few values of the parameter . It is recommended to start the tests from and analyse the results obtained in some neighbourhood of this value first.

- The value of the parameter is chosen for which the performance indices are the best.

- For the chosen value of , the performance indices are calculated from the simulations of the MPC algorithm for a few values of the parameter . This step should start with the values of the parameter that are lower than those assumed in the first step. Next, it is increased. It is recommended not to choose too large values of as this may result in dangerously large values of the manipulated variables.

- The value of the parameter is chosen for which the performance indices are the best.

- (b)

- The best trajectory (6) is found, i.e., its parameter is determined.

- The selected parameters and are used.

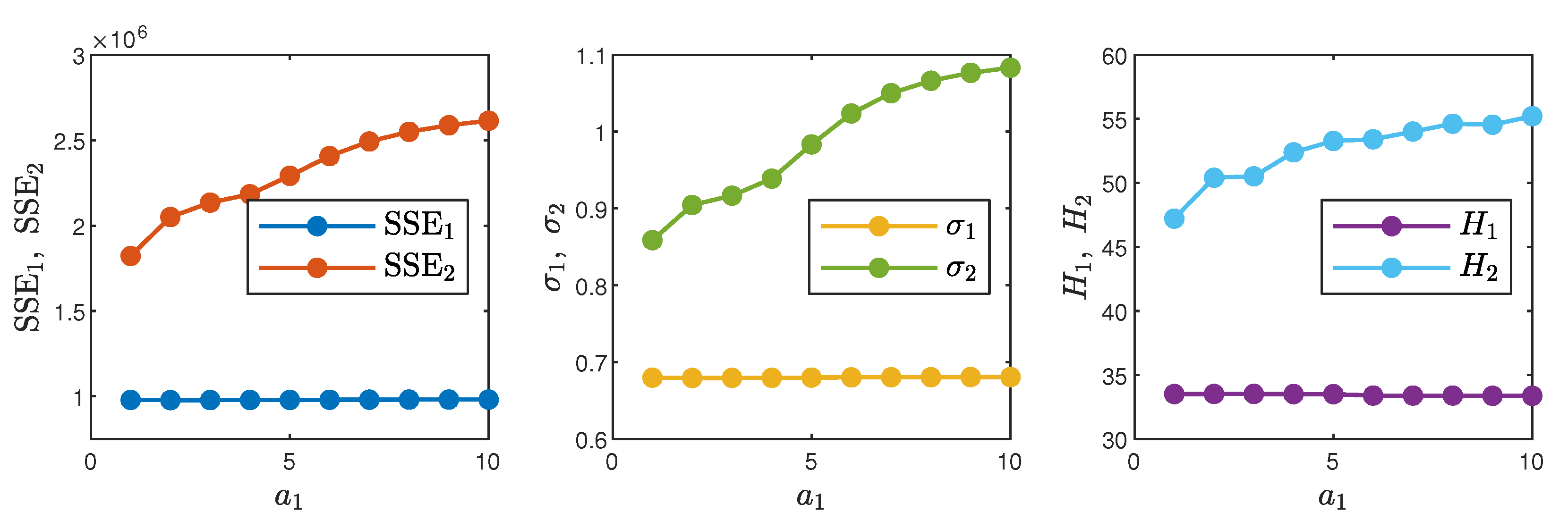

- The performance indices are calculated from the simulations of the MPC algorithm for a few values of the parameter . It is recommended to perform simulations starting from relatively low values of the parameter, e.g., , and slowly increase it until it is clear that any further increment results in no improvement of control quality.

- The value of the parameter is chosen for which the performance indices are the best.

- Tuning is repeated for the consecutive manipulated variables, for , i.e., the algorithm goes to Step 1.

- the Sum of Squared Errors () of the control error ,

- the Huber standard deviation of the control error ,

- the rational entropy of the control error .

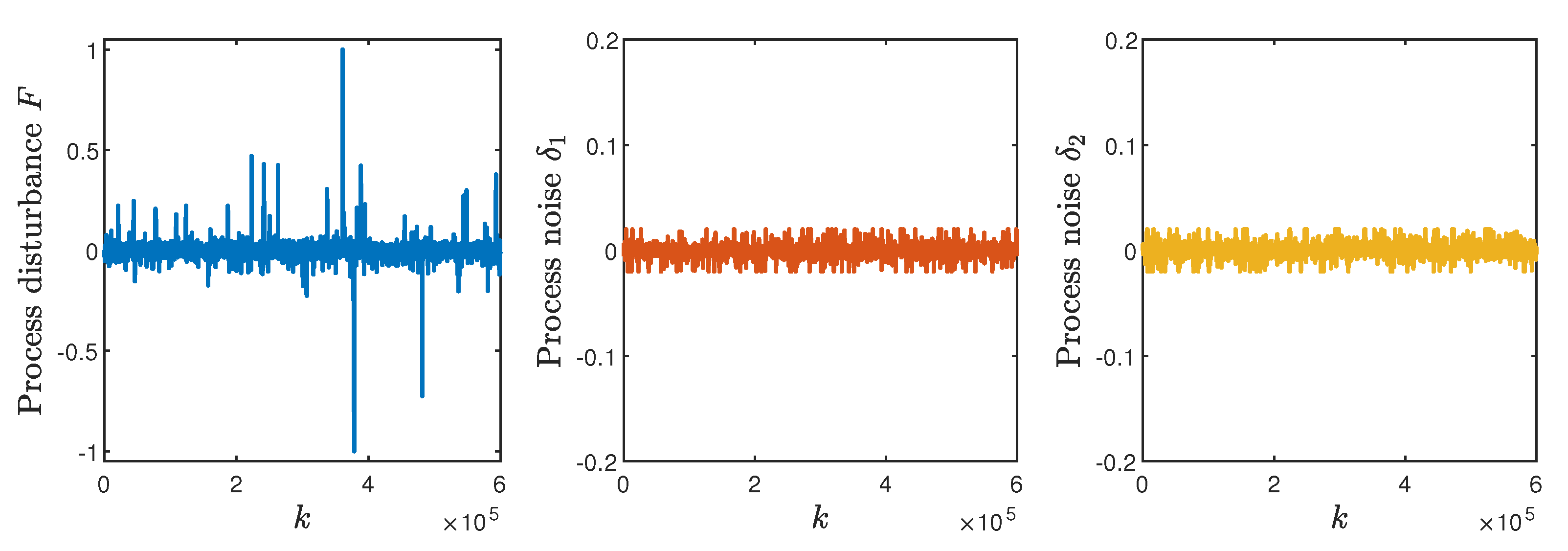

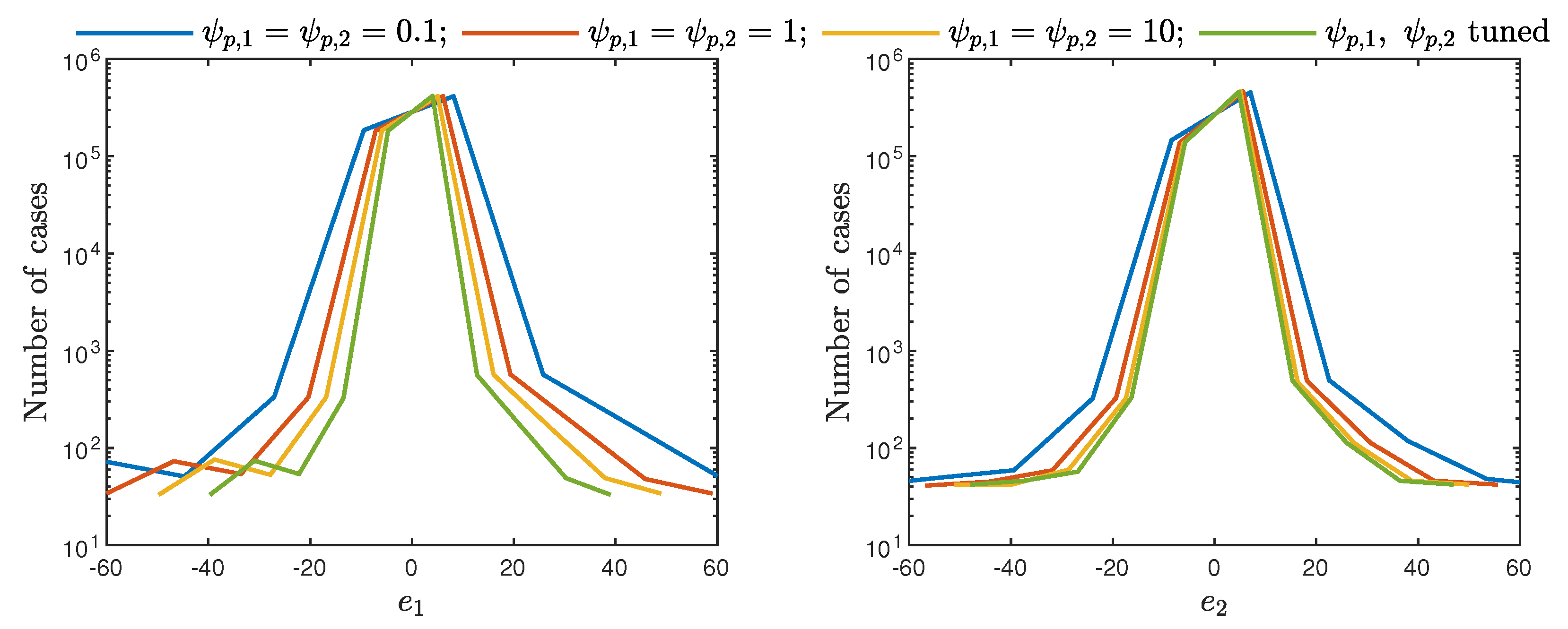

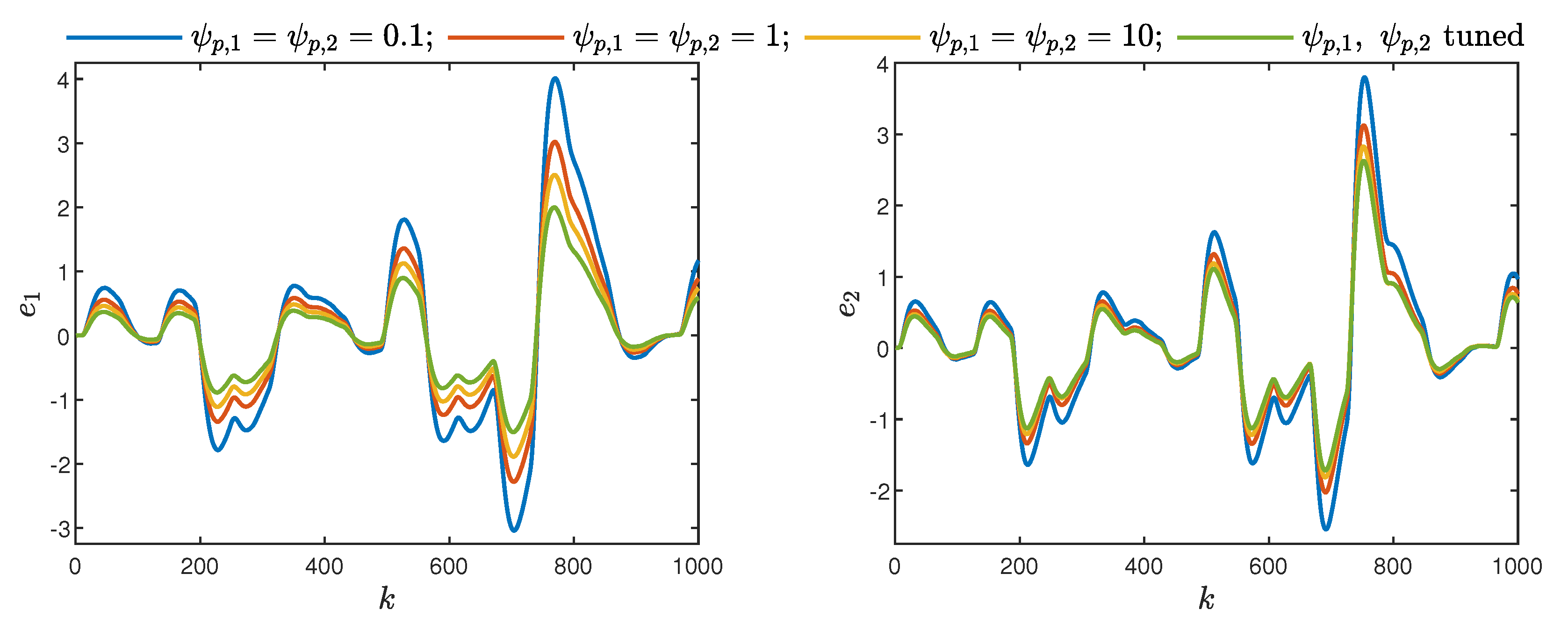

4. Simulation Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| the spread of the Gauss function | |

| the control error of the nth process output | |

| the MPC cost function | |

| the parameter that defines the maximum value of the functions (5) and (6) | |

| MIMO | Multiple-Input Multiple-Output |

| the parameter that defines for which sampling instant p the Functions (5) and (6) have the value of | |

| N | the prediction horizon |

| the control horizon | |

| the number of process inputs | |

| the number of process outputs | |

| SISO | Single-Input Single-Output |

| , | the vectors that define the minimal and maximal values of the process inputs |

| , | the predicted value for the nth process output and the predicted vector for the sampling instant calculated at the current sampling instant k |

| , | the set point value for the nth process output and the set-point vector for the sampling instant known at the current sampling instant k |

| , | the vectors that define the minimal and maximal predicted values of the process outputs |

| , | the increment of the nth process input and the increment of the input vector for the sampling instant calculated at the current sampling instant k |

| decision variable vector of the MPC algorithm | |

| , | the vectors that define the minimal and maximal changes of the process inputs |

| the weighting matrix related to the change of the signal | |

| the weighting coefficient related to the change of the signal | |

| the weighting matrix related to the predicted control error | |

| the weighting coefficient related to the predicted control error |

References

- Balaska, H.; Ladaci, S.; Djouambi, A.; Schulte, H.; Bourouba, B. Fractional order tube model reference adaptive control for a class of fractional order linear systems. Int. J. Appl. Math. Comput. Sci. 2020, 30, 23–34. [Google Scholar]

- Salazar, J.C.; Sanjuan, A.; Nejjari, F.; Sarrate, R. Health-aware and fault-tolerant control of an octorotor UAV system based on actuator reliability. Int. J. Appl. Math. Comput. Sci. 2020, 30, 47–59. [Google Scholar]

- Bania, P. An information based approach to stochastic control problems. Int. J. Appl. Math. Comput. Sci. 2020, 30, 47–59. [Google Scholar]

- Salcedo, J.V.; Martínez, M.; García-Nieto, S.; Hilario, A. T-S fuzzy BIBO stabilisation of non-linear systems under persistent perturbations using fuzzy Lyapunov functions and non-PDC control laws. Int. J. Appl. Math. Comput. Sci. 2020, 30, 529–550. [Google Scholar]

- Maciejowski, J. Predictive Control with Constraints; Prentice Hall: Harlow, UK, 2002. [Google Scholar]

- Tatjewski, P. Advanced Control of Industrial Processes, Structures and Algorithms; Springer: London, UK, 2007. [Google Scholar]

- Plamowski, S.; Kephart, R.W. The model order reduction method as an effective way to implement GPC controller for multidimensional objects. Algorithms 2020, 13, 178. [Google Scholar] [CrossRef]

- Marusak, P.M. Numerically efficient fuzzy MPC algorithm with advanced generation of prediction—application to a chemical reactor. Algorithms 2020, 13, 143. [Google Scholar] [CrossRef]

- Assandri, A.D.; de Prada, C.; Rueda, A.; Martínez, J.S. Nonlinear parametric predictive temperature control of a distillation column. Control. Eng. Pract. 2013, 21, 1795–1806. [Google Scholar] [CrossRef]

- Morales-Rodelo, K.; Francisco, M.; Alvarez, H.; Vega, P.; Revollar, S. Collaborative control applied to BSM1 for wastewater treatment plants. Processes 2020, 8, 1465. [Google Scholar] [CrossRef]

- Gallego, A.J.; Merello, G.M.; Berenguel, M.; Camacho, E.F. Gain-scheduling model predictive control of a Fresnel collector field. Control Eng. Pract. 2019, 82, 1–13. [Google Scholar] [CrossRef]

- Ramasamy, V.; Sidharthan, R.; Kannan, R.; Muralidharan, G. Optimal tuning of model predictive controller weights using genetic algorithm with interactive decision tree for industrial cement kiln process. Processes 2019, 7, 938. [Google Scholar] [CrossRef] [Green Version]

- Pour, F.; Puig, V.; Ocampo-Martinez, C. Multi-layer health-aware economic predictive control of a pasteurization pilot plant. Int. J. Appl. Math. Comput. Sci. 2018, 28, 97–110. [Google Scholar] [CrossRef] [Green Version]

- Rahman, M.; Avelin, A.; Kyprianidis, K. An approach for feedforward model predictive control of continuous pulp digesters. Processes 2019, 7, 602. [Google Scholar] [CrossRef] [Green Version]

- Chatrattanawet, N.; Kheawhom, S.; Chen, Y.S.; Arpornwichanop, A. Design and implementation of the off-line robust model predictive control for solid oxide fuel cells. Processes 2019, 7, 918. [Google Scholar] [CrossRef] [Green Version]

- Takács, G.; Batista, G.; Gulan, M.; Rohal’-Ilkiv, B. Embedded explicit model predictive vibration control. Mechatronics 2016, 36, 54–62. [Google Scholar] [CrossRef]

- Kaleli, A. Development of the predictive based control of an autonomous engine cooling system for variable engine operating conditions in SI engines: Design, modeling and real-time application. Control Eng. Pract. 2020, 100, 104424. [Google Scholar] [CrossRef]

- Hou, X.; Guo, S.; Shi, L.; Xing, H.; Yin, H.; Li, Z.; Zhou, M. Improved model predictive-based underwater trajectory tracking control for the biomimetic spherical robot under constraints. Appl. Sci. 2020, 10, 8106. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, H.; Che, Z.; Wang, Y.; Zeng, C. Extended State Observer-Based Predictive Speed Control for Permanent Magnet Linear Synchronous Motor. Processes 2019, 7, 618. [Google Scholar] [CrossRef] [Green Version]

- Sands, T. Comparison and interpretation methods for predictive control of mechanics. Algorithms 2019, 12, 232. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Yu, Y.; Guo, Q. Freeway traffic congestion reduction and environment regulation via model predictive control. Algorithms 2019, 12, 220. [Google Scholar] [CrossRef] [Green Version]

- Lima, P.F.; Pereira, G.C.; Mårtensson, J.; Wahlberg, B. Experimental validation of model predictive control stability for autonomous driving. Control Eng. Pract. 2018, 81, 244–255. [Google Scholar] [CrossRef]

- Scattolini, R.; Bittanti, S. On the choice of the horizon in long-range predictive control–some simple criteria. Automatica 1990, 26, 915–917. [Google Scholar] [CrossRef]

- Seborg, D.E.; Edgar, T.F.; Mellichamp, D.A.; Doyle, F.J., III. Process Dynamics and Control; John Wiley & Sons: New York, NY, USA, 2011. [Google Scholar]

- Ionescu, C.; Copot, D. Hands-on MPC tuning for industrial applications. Bull. Pol. Acad. Sci. Tech. Sci. 2019, 67, 925–945. [Google Scholar]

- Garriga, J.L.; Soroush, M. Model predictive control tuning methods: A review. Ind. Eng. Chem. Res. 2010, 49, 3505–3515. [Google Scholar] [CrossRef]

- Shridhar, R.; Cooper, D.J. A tuning strategy for unconstrained multivariable model predictive control. Ind. Eng. Chem. Res. 1998, 37, 4003–4016. [Google Scholar] [CrossRef]

- Shridhar, R.; Cooper, D.J. A tuning strategy for unconstrained SISO model predictive control. Ind. Eng. Chem. Res. 1997, 36, 729–746. [Google Scholar] [CrossRef]

- Trierweiler, J.; Farina, L. RPN tuning strategy for model predictive control. J. Process Control 2003, 13, 591–598. [Google Scholar] [CrossRef]

- Yamashita, A.S.; Alexandre, P.M.; Zanin, A.C.; Odloak, D. Reference trajectory tuning of model predictive control. Control Eng. Pract. 2016, 50, 1–11. [Google Scholar] [CrossRef]

- Exadaktylos, V.; Taylor, C. Multi-objective performance optimisation for model predictive control by goal attainment. Int. J. Control. 2010, 83, 1374–1386. [Google Scholar] [CrossRef]

- Sawulski, J.; Ławryńczuk, M. Optimisation-based tuning of dynamic matrix control algorithm for multiple-input multiple-output processes. In Proceedings of the 2018 23rd International Conference on Methods & Models in Automation & Robotics (MMAR), Miedzyzdroje, Poland, 27–30 August 2018; pp. 160–165. [Google Scholar]

- Júnior, G.A.; Martins, M.A.F.; Kalid, R. A PSO-based optimal tuning strategy for constrained multivariable predictive controllers with model uncertainty. ISA Trans. 2014, 53, 560–567. [Google Scholar] [CrossRef]

- Nebeluk, R.; Marusak, P. Efficient MPC algorithms with variable trajectories of parameters weighting predicted control errors. Arch. Control. Sci. 2020, 30, 325–363. [Google Scholar]

- Nebeluk, R.; Ławryńczuk, M. Tuning of nonlinear MPC algorithm for vehicle obstacle avoidance. In Advanced, Contemporary Control; Bartoszewicz, A., Kabziński, J., Kacprzyk, J., Eds.; Springer: Cham, Switzerland, 2020; Volume 1196, pp. 993–1005. [Google Scholar]

- Domański, P. Control Performance Assessment: Theoretical Analyses and Industrial Practice. In Control Performance Assessment: Theoretical Analyses and Industrial Practice; Springer: Cham, Switzerland, 2020; Volume 245. [Google Scholar]

- Domański, P.D. Performance assessment of predictive control—A survey. Algorithms 2020, 13, 97. [Google Scholar] [CrossRef] [Green Version]

- Cutler, C.R.; Ramaker, B.L. Dynamic matrix control–A computer control algorithm. In Proceedings of the AIChE National Meeting, Denver, CO, USA, 17–21 June 1979. [Google Scholar]

- Domański, P.; Ławryńczuk, M. Multi-criteria control performance assessment method for a multivariate MPC. In Proceedings of the American Control Conference (ACC 2020), Denver, CO, USA, 1–3 July 2020; pp. 1968–1973. [Google Scholar]

- Wood, R.K.; Berry, M.W. Terminal composition control of binary distillation column. Chem. Eng. Sci. 2019, 28, 1707–1717. [Google Scholar] [CrossRef]

- Ławryńczuk, M. Computationally Efficient Model Predictive Control Algorithms: A Neural Network Approach. In Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2014; Volume 3. [Google Scholar]

| Parameters | ||||||

|---|---|---|---|---|---|---|

| , tuned |

| Parameters | ||||||

|---|---|---|---|---|---|---|

| , tuned |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nebeluk, R.; Ławryńczuk, M. Tuning of Multivariable Model Predictive Control for Industrial Tasks. Algorithms 2021, 14, 10. https://0-doi-org.brum.beds.ac.uk/10.3390/a14010010

Nebeluk R, Ławryńczuk M. Tuning of Multivariable Model Predictive Control for Industrial Tasks. Algorithms. 2021; 14(1):10. https://0-doi-org.brum.beds.ac.uk/10.3390/a14010010

Chicago/Turabian StyleNebeluk, Robert, and Maciej Ławryńczuk. 2021. "Tuning of Multivariable Model Predictive Control for Industrial Tasks" Algorithms 14, no. 1: 10. https://0-doi-org.brum.beds.ac.uk/10.3390/a14010010