Radiata Pine Wood Treated with Copper Nanoparticles: Leaching Analysis and Fungal Degradation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

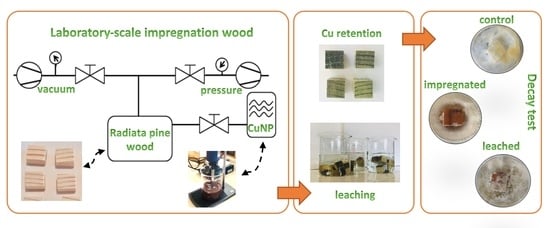

2.2. Wood Impregnation

2.3. Leaching Test and Copper Analysis during Leaching

2.4. Copper Retention in Wood by Energy Dispersive X-ray Fluorescence Analysis (EDXRF)

2.5. Decay Test

2.5.1. Fungal Activation

2.5.2. Wood Decay Test

2.6. Data Analysis

3. Results and Discussion

3.1. CuNPs Characterization and Their Performance in Wood Impregnation

3.2. Retention and Leachability of CuNPs in Radiata Pine Wood

3.3. Biodeterioration Assay Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- MacLean, J.D. Preservative Treatment of Wood by Pressure Methods; U.S. Department of Agriculture, Forest Service: Washington, DC, USA, 1952; pp. 1–160.

- Broda, M.; Mazela, B.; Frankowski, M. Durability of wood treated with aatmos and caffeine-towards the long-term carbon stor-age. Maderas. Cienc. Tecnol. 2018, 20, 455–468. [Google Scholar]

- Tarmian, A.; Zahedi Tajrishi, I.; Oladi, R.; Efhamisisi, D. Treatability of wood for pressure treatment processes: A literature review. Eur. J. Wood Prod. 2020, 78, 635–660. [Google Scholar] [CrossRef]

- Shiny, K.S.; Nair, S.; Mamatha, N.; Sundararaj, R. Decay resistance of wood treated with copper oxide nanoparticles synthesised using leaf extracts of Lantana camara L. and Nerium oleander L. Wood Mater. Sci. Eng. 2021, 2, 1–7. [Google Scholar] [CrossRef]

- Forest Products Laboratory. Wood Handbook-Wood as an Engineering Material; General Technical Report FPL-GTR-190; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010. [Google Scholar]

- Balasoiu, C.F.; Zagury, G.J.; Deschenes, L. Partitioning and speciation of chromium, copper, and arsenic in CCA-contaminated soils: Influence of soil composition. Sci. Total Environ. 2001, 280, 239–255. [Google Scholar] [CrossRef]

- Townsend, T.; Tolaymat, T.; Solo-Gabriele, H.; Dubey, B.; Stook, K.; Wadanambi, L. Leaching of CCA-treated wood: Implications for waste disposal. J. Hazard. Mater. 2004, 114, 75–91. [Google Scholar] [CrossRef]

- Karjalainen, A.-M.; Kilpi-Koski, J.; Väisänen, A.O.; Penttinen, S.; Van Gestel, C.A.M.; Penttinen, O.-P. Ecological risks of an old wood impregnation mill: Application of the Triad Approach. Integr. Environ. Assess. 2009, 5, 379–389. [Google Scholar] [CrossRef]

- Brischke, C. Wood Protection and Preservation. Forests 2020, 11, 549. [Google Scholar] [CrossRef]

- Lebow, S.T.; Tippie, M. Guide for Minimizing the Effect of Preservative-Treated Wood on Sensitive Environment; United States Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2001. [Google Scholar]

- Hasan, R.A.; Hu, L.; Solo-Gabriele, H.; Fieber, L.; Cai, Y.; Townsend, T.G. Field-scale leaching of arsenic, chromium and copper from weathered treated wood. Environ. Pollut. 2010, 158, 1479–1486. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Temiz, A.; Alfredsen, G.; Yildiz, U.C.; Gezer, E.D.; Kose, G.; Akbas, S.; Yildiz, S. Leaching and decay resistance of alder and pine wood treated with copper based wood preservatives. Maderas Cienc. Tecnol. 2014, 16, 63–76. [Google Scholar] [CrossRef] [Green Version]

- Clausen, C.A. Nanotechnology: Implications for the wood preservation industry. In Proceedings of the International Research Group on Wood Protection Annual Meeting, IRG/WP; 07-30415, Stockholm, Sweden, 20–24 May 2007; p. 15. [Google Scholar]

- De Filpo, G.; Palermo, A.M.; Rachiele, F.; Nicoletta, F.P. Preventing fungal growth in wood by titanium dioxide nanoparticles. Int. Biodeterior. Biodegrad. 2013, 85, 217–222. [Google Scholar] [CrossRef]

- Akhtari, M.; Nicholas, D. Evaluation of particulate zinc and copper as wood preservatives for termite control. Eur J. Wood Prod. 2013, 71, 395–396. [Google Scholar] [CrossRef]

- Lykidis, C.; Mantanis, G.; Adamopoulos, S.; Kalafata, K.; Arabatzis, I. Effects of nano-sized zinc oxide and zinc borate impregnation on brown rot resistance of black pine (Pinus nigra L.) wood. Wood Mater. Sci. Eng. 2013, 8, 242–244. [Google Scholar] [CrossRef]

- Mantanis, G.; Terzi, E.; Kartal, S.N.; Papadopoulos, A.N. Evaluation of mold, decay and termite resistance of pine wood treated with zinc-and copper-based nanocompounds. Int. Biodeter. Biodegr. 2014, 90, 140–144. [Google Scholar] [CrossRef]

- Rowell, R.M. Innovation in Wood Preservation. Polymers 2020, 12, 1511. [Google Scholar] [CrossRef]

- Nel, A.; Xia, T.; Mädler, L.; Li, N. Toxic potential of materials at the nanolevel. Science 2006, 311, 622–627. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Can, A.; Sivrikaya, H.; Hazer, B. Fungal inhibition and chemical characterization of wood treated with novel polystyrene-soybean oil copolymer containing silver nanoparticles. Int. Biodeterior. Biodegrad. 2018, 133, 210–215. [Google Scholar] [CrossRef]

- Cady, N.C.; Behnke, J.L.; Strickland, A.D. Copper-Based nanostructured coatings on natural cellulose: Nanocomposites exhibiting rapid and efficient inhibition of a multi-drug resistant wound pathogen, A. Baumannii, and mammalian cell biocompatibility in vitro. Adv. Funct. Mater. 2011, 21, 2506–2514. [Google Scholar] [CrossRef]

- Akhtari, M.; Arefkhani, M. Study of microscopy properties of wood impregnated with nanoparticles during exposed to white- rot fungus. Agric. Sci. Dev. 2013, 2, 116–199. [Google Scholar]

- Pařil, P.; Baar, J.; Čermák, P. Antifungal effects of copper and silver nanoparticles against white and brown-rot fungi. J. Mater. Sci. 2017, 52, 2720–2729. [Google Scholar] [CrossRef]

- Akhtari, M.; Ganjipour, M. Effect of nano-silver and nano-copper and nanozinc oxide on Paulownia wood exposed to white-rot fungus. In Proceedings of the 44th Annual Meeting of The International Research Group on Wood Protection, IRG/WP 13-30635, Çesme, Turkey, 17–20 June 2013; pp. 1–8. [Google Scholar]

- Bak, M.; Németh, R. Effect of different nanoparticle treatments on the decay resistance of wood. BioResources 2018, 13, 7886–7899. [Google Scholar] [CrossRef] [Green Version]

- Instituto Forestal (INFOR). Statistical Bulletin N° 174, ANUARIO FORESTAL 2020, Chilean Statistical Yearbook of Forestry, Chile. 2020. Available online: https://wef.infor.cl/ (accessed on 14 March 2021).

- Instituto Nacional de Normalización (INN). Norma Chilena Oficial 789/1.Of87. Maderas—Parte 1: Clasificación de Maderas Comerciales por su Durabilidad Natural; INN: Santiago, Chile, 1987; p. 4. [Google Scholar]

- Wong, A.; Lai, H.C.; Lim, N.P. Laboratory leaching tests to study the effects of post-treatment storage periods on CCA leachability and fixation in treated permeable and refractory Malaysian hardwoods. In Proceedings of the 37th Annual Meeting of the International Research Group on Wood Protection, Tromsø, Norway, 18–22 June 2006. [Google Scholar]

- AWPA. A3-08. Standard Methods for Determining Penetration of Preservatives and Fire Retardants. Book of Standards; American Wood Protection Association: Birmingham, AL, USA, 2010; p. 576. [Google Scholar]

- AWPA. E11-16. Standard Methods for Accelerated Evaluation of Preservative Leaching. Book of Standards; American Wood Protection Association: Birmingham, AL, USA, 2018; pp. 420–422. [Google Scholar]

- AWPA. A9-18. Standard Methods for Analysis of Treated Wood and Treating Solutions by X-ray Spectroscopy. Book of Standards; American Wood Protection Association: Birmingham, AL, USA, 2018; pp. 173–177. [Google Scholar]

- CEN EN 113. Wood Preservatives. Test Method for Determining the Protective Effectiveness against Wood Destroying Basidiomycetes. Determination of the Toxic Values; European Committee for Standardisation: Brussels, Belgium, 2020. [Google Scholar]

- Freeman, M.H.; McIntyre, C.R. Copper-based wood preservatives. For. Prod. J. 2008, 58, 6–27. [Google Scholar]

- Kartal, S.N.; Green III, F.; Clausen, C.A. Do the unique properties of nanometals affect leachability or efficacy against fungi and termites? Int. Biodeter. Biodegr. 2009, 63, 490–495. [Google Scholar] [CrossRef]

- Borges, C.C.; Duarte, P.J.; Junqueira, T.A. Nanoparticles-based wood preservatives: The next generation of wood protection? Cerne 2018, 24, 397–407. [Google Scholar] [CrossRef]

- Matsunaga, H.; Kiguchi, M.; Evans, P.D. Microdistribution of copper-carbonate and iron oxide nanoparticles in treated wood. J. Nanopart. Res. 2009, 11, 1087–1098. [Google Scholar] [CrossRef]

- Kollmann, F.F.P.; Côté, W.A. Principles of Wood Science and Technology; Solid wood; Springer: Berlin/Heidelberg, Germany, 1968; Volume 1. [Google Scholar]

- Lebow, S. Wood preservation. In Wood Handbook—Wood as an Engineering Materia; Ross, R.J., Ed.; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; pp. 1–27. [Google Scholar]

- Reinprecht, L. Wood Deterioration, Protection, and Maintenance; Blackwell: London, UK, 2016. [Google Scholar]

- Junta del Acuerdo de Cartagena (JUNAC). Manual del Grupo Andino Para la Preservación de Maderas; Editorial PRID-MADERA: Lima, Perú, 1988. [Google Scholar]

- Hill, C.A.S.; Papadopoulos, A.N. A review of methods used to determine the size of the cell wall microvoids of wood. J. Inst. Wood. Sci. 2001, 15, 337–345. [Google Scholar]

- Jasmani, L.; Rusli, R.; Khadiran, T.; Jalil, R.; Adnan, S. Application of Nanotechnology in Wood-Based Products Industry: A Review. Nanoscale Res. Lett. 2020, 15, 207. [Google Scholar] [CrossRef]

- Civardi, C. Assessing the Effectiveness and Environmental Risk of Nanocopper-Based Wood Preservatives. Ph.D. Thesis, ETH Zürich, Zürich, Suiza, 2016. [Google Scholar] [CrossRef]

- Lindeberg, J. X-Ray Based Tree-Ring Analysis. Ph.D. Thesis, Acta Universitatis Agriculturae Sueciae, Umeå, Sweden, 2004. [Google Scholar]

- Agenda 2020 Technology Alliance. U.S. Department of Energy, American Forest and Paper Association, Georgia Institute of Technology, Forest Products Industry Technology Roadmap; Agenda 2020 Technology Alliance: Atlanta, GA, USA, 2010. [Google Scholar]

- Thaler, N.; Humar, M. Copper leaching from copperethanolamin treated wood: Comparison of field test studies and laboratory standard procedures. Bioresources 2014, 9, 3038–3051. [Google Scholar] [CrossRef]

- Lebow, S. Leaching of Wood Preservative Components and Their Mobility in the Environment: Summary of Pertinent Literature; US Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1996; p. 36. [Google Scholar]

- Can, A.; Palanti, S.; Sivrikaya, H.; Hazer, B.; Stefanı, F. Physical, biological and chemical characterisation of wood treated with silver nanoparticles. Cellulose 2019, 26, 5075–5084. [Google Scholar] [CrossRef]

- Sigoillot, J.C.; Berrin, J.G.; Bey, M.; Lesage-Meessen, L.; Levasseur, A.; Lomascolo, A.; Record, E.; Uzan-Boukhris, E. Fungal strategies for lignin degradation. Adv. Bot. Res. 2012, 61, 263–308. [Google Scholar]

- Green III, F.; Clausen, C.A. Copper tolerance of brown-rot fungi: Oxalic acid production in southern pine treated with arsenic-free preservatives. Int. Biodeterior. Biodegrad. 2005, 56, 75–79. [Google Scholar] [CrossRef]

- Akgul, A.; Akgul, A. Mycoremediation of copper: Exploring the metal tolerance of brown rot fungi. BioResources 2018, 13, 7155–7171. [Google Scholar]

- Nicholas, D.; Rowlen, A.; Milsted, D. Effect of Concrete on the pH and Susceptibility of Treated Pine to Decay by Brown-Rot Fungi. Forests 2020, 11, 41. [Google Scholar] [CrossRef] [Green Version]

- Palza, H. Antimicrobial Polymers with Metal Nanoparticles. Int. J. Mol. Sci. 2015, 16, 2099–2116. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Civardi, C.; Kaiser, J.; Hirsch, C.; Mucchino, C.; Wichser, A.; Wick, P.; Schwarze, F. Release of copper amended particles from micronized copper pressure treated wood during mechanical abrasion. J. Nanotechnol. 2016, 14, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Karlsson, H.L.; Cronholm, P.; Hedberg, Y.; Tornberg, M.; De Battice, L.; Svedhem, S.; Wallinder, I.O. Cell membrane damage and protein interaction induced by copper containing nanoparticles—Importance of the metal release process. Toxicology 2013, 313, 59–69. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguayo, M.G.; Oviedo, C.; Reyes, L.; Navarrete, J.; Gómez, L.; Torres, H.; Gaviño, G.; Trollund, E. Radiata Pine Wood Treated with Copper Nanoparticles: Leaching Analysis and Fungal Degradation. Forests 2021, 12, 1606. https://0-doi-org.brum.beds.ac.uk/10.3390/f12111606

Aguayo MG, Oviedo C, Reyes L, Navarrete J, Gómez L, Torres H, Gaviño G, Trollund E. Radiata Pine Wood Treated with Copper Nanoparticles: Leaching Analysis and Fungal Degradation. Forests. 2021; 12(11):1606. https://0-doi-org.brum.beds.ac.uk/10.3390/f12111606

Chicago/Turabian StyleAguayo, María Graciela, Claudia Oviedo, Laura Reyes, José Navarrete, Liset Gómez, Hugo Torres, Gonzalo Gaviño, and Ejnar Trollund. 2021. "Radiata Pine Wood Treated with Copper Nanoparticles: Leaching Analysis and Fungal Degradation" Forests 12, no. 11: 1606. https://0-doi-org.brum.beds.ac.uk/10.3390/f12111606