Investigation of Exposure to Occupational Noise among Forestry Machine Operators: A Case Study in Brazil

Abstract

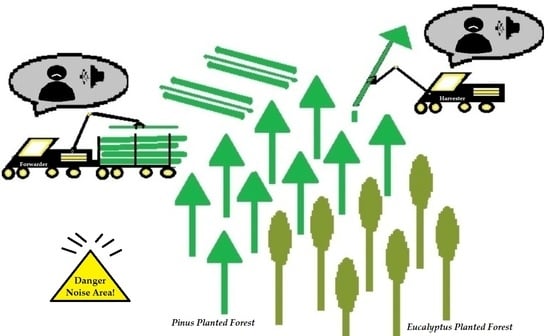

:1. Introduction

2. Materials and Methods

2.1. Study Characterization

2.2. Characteristics of Self-Propelled Forestry Machines and Operators

2.3. Parameterization of Dosimetry

2.4. Determination of Homogeneous Groups

2.5. Statistical Analysis

3. Results

3.1. Exposure to Occupational Noise

3.2. Exploratory Analysis of the Homogeneous Groups

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ringdahl, O.; Hellström, T.; Lindroos, O. Potentials of possible machine systems for directly loading logs in cut-to-length harvesting. Can. J. For. Res. 2012, 42, 970–985. [Google Scholar] [CrossRef] [Green Version]

- Kärhä, K.; Poikela, A.; Palander, T. Productivity and costs of harwarder systems in industrial roundwood thinnings. Croat. J. For. Eng. 2018, 39, 23–33. [Google Scholar]

- Kulak, D.; Sowa, J.M.; Szewczyk, G.; Stańczykiewicz, A. The accessibility of post-fire areas for mechanized thinning operations. Forests 2020, 11, 471. [Google Scholar] [CrossRef]

- Nurminen, T.; Korpunen, H.; Uusitalo, J. Time consumption analysis of the mechanized cut-to-length harvesting system. Silva. Fenn. 2006, 40, 335–363. [Google Scholar] [CrossRef] [Green Version]

- Poje, A.; Grigolato, S.; Potočnik, I. Operator Exposure to Noise and Whole-Body Vibration in a Fully Mechanised CTL Forest Harvesting System in Karst Terrain. Croat. J. For. Eng. 2019, 40, 139–150. [Google Scholar]

- Schönauer, M.; Hoffmann, S.; Maack, J.; Jansen, M.; Jaeger, D. Comparison of Selected Terramechanical Test Procedures and Cartographic Indices to Predict Rutting Caused by Machine Traffic during a Cut-to-Length Thinning-Operation. Forests 2021, 12, 113. [Google Scholar] [CrossRef]

- Ghaffariyan, M.R.; Sessions, J.; Brown, M. Machine productivity and residual harvesting residues associated with a cut-to-length harvest system in southern Tasmania. South. For. 2012, 74, 229–235. [Google Scholar] [CrossRef]

- Gerasimov, Y.; Sokolov, A. Ergonomic evaluation and comparison of wood harvesting systems in Northwest Russia. Appl. Ergon. 2014, 45, 318–338. [Google Scholar] [CrossRef]

- Bayne, K.M.; Parker, R.J. The introduction of robotics for New Zealand forestry operations: Forest sector employee perceptions and implications. Technol. Soc. 2012, 34, 138–148. [Google Scholar] [CrossRef]

- Gerasimov, Y.; Seliverstov, A.; Syunev, V. Industrial round-wood damage and operational efficiency losses associated with the maintenance of a single-grip harvester head model: A case study in Russia. Forests 2012, 3, 864–880. [Google Scholar] [CrossRef]

- Bembenek, M.; Tsioras, P.A.; Karaszewski, Z.; Zawieja, B.; Bakinowska, E.; Mederski, P.S. Effect of day or night and cumulative shift time on the frequency of tree damage during CTL harvesting in various stand conditions. Forests 2020, 11, 743. [Google Scholar] [CrossRef]

- Magagnotti, N.; Spinelli, R. Integrating animal and mechanical operations in protected areas. Croat. J. For. Eng. J. Theory Appl. For. Eng. 2011, 32, 489–499. [Google Scholar]

- Poje, A.; Spinelli, R.; Magagnotti, N.; Mihelic, M. Exposure to noise in wood chipping operations under the conditions of agro-forestry. Int. J. Ind. Ergon. 2015, 50, 151–157. [Google Scholar] [CrossRef]

- Yovi, E.Y.; Yamad, Y. Addressing occupational ergonomics issues in indonesian forestry: Laborers, operators, or equivalent workers. Croat. J. For. Eng. 2019, 40, 351–363. [Google Scholar] [CrossRef]

- Albizu-Urionabarrenetxea, P.M.; Tolosana-Esteban, E.; Roman-Jordan, E. Safety and health in forest harvesting operations. Diagnosis and preventive actions. A review. For. Syst. 2013, 22, 392–400. [Google Scholar] [CrossRef]

- Sedmíková, M.; Löwe, R.; Jankovský, M.; Natov, P.; Linda, R.; Dvořák, J. Estimation of over-and under-bark volume of scots pine timber produced by harvesters. Forests 2020, 11, 626. [Google Scholar] [CrossRef]

- Robert, K.; Elisabeth, Q.; Josef, B. Analysis of occupational accidents with agricultural machinery in the period 2008–2010 in Austria. Saf. Sci. 2015, 72, 319–328. [Google Scholar] [CrossRef]

- Bolaji, B.O.; Olanipekun, M.U.; Adekunle, A.A.; Adeleke, A.E. An analysis of noise and its environmental burden on the example of Nigerian manufacturing companies. J. Clean. Prod. 2018, 172, 1800–1806. [Google Scholar] [CrossRef]

- Hu, S.; Mu, Y.; Liu, G.; Zhang, L. Research on effecting mechanism of environmental parameters on human ear. Build. Environ. 2017, 118, 289–299. [Google Scholar] [CrossRef]

- Shende, S.B.; Deoghare, A.B.; Pandey, K.M. Characterization of harmonic response of human middle ear using finite element approach. J. Comput. Sci. 2018, 29, 94–98. [Google Scholar] [CrossRef]

- Petrone, G.; Melillo, G.; Laudiero, A.; De Rosa, S. A Statistical Energy Analysis (SEA) model of a fuselage section for the prediction of the internal Sound Pressure Level (SPL) at cruise flight conditions. Aerosp. Sci. Technol. 2019, 88, 340–349. [Google Scholar] [CrossRef]

- Borz, S.A.; Talagai, N.; Cheţa, M.; Chiriloiu, D.; Montoya, A.V.G.; Vizuete, D.D.C.; Marcu, M.V. Physical strain, exposure to noise and postural assessment in motor-manual felling of willow short rotation coppice: Results of a preliminary study. Croat. J. For. Eng. 2019, 40, 377–388. [Google Scholar] [CrossRef]

- Burella, G.; Moro, L.; Colbourne, B. Noise sources and hazardous noise levels on fishing vessels: The case of Newfoundland and Labrador’s fleet. Ocean. Eng. 2019, 173, 116–130. [Google Scholar] [CrossRef]

- Naskrent, B.; Grzywiński, W.; Łukowski, A.; Polowy, K. Influence of cutting attachment on noise level emitted by brush cutter during tending of young forests. Croat. J. For. Eng. 2020, 41, 129–135. [Google Scholar] [CrossRef]

- Araújo, S.A. Perda auditiva induzida pelo ruído em trabalhadores de metalúrgica. Rev. Bras. Otorrinolaringol. 2002, 68, 47–52. [Google Scholar] [CrossRef] [Green Version]

- Oishi, N.; Schacht, J. Emerging treatments for noise-induced hearing loss. Expert Opin. Emerg. Drugs 2011, 16, 235–245. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, H.; Ding, E.; Sheng, R.; Cheng, J.; Cai, W.; Guo, J.; Wang, N.; Zhang, H.; Zhu, B. Genetic variation in KCNQ4 gene is associated with susceptibility to noise-induced hearing loss in a Chinese population. Environ. Toxicol. Pharmacol. 2018, 63, 55–59. [Google Scholar] [CrossRef] [PubMed]

- Neri, F.; Laschi, A.; Foderi, C.; Fabiano, F.; Bertuzzi, L.; Marchi, E. Determining noise and vibration exposure in conifer cross-cutting operations by using Li-Ion batteries and electric chainsaws. Forests 2018, 9, 501. [Google Scholar] [CrossRef] [Green Version]

- Farias, V.H.V.; Buriti, A.K.L.; Rosa, M.R.D. da Ocorrência de perda auditiva induzida pelo ruído em carpinteiros. Rev. CEFAC 2011, 14, 413–422. [Google Scholar] [CrossRef] [Green Version]

- Hayes, S.H.; Manohar, S.; Majumdar, A.; Allman, B.L.; Salvi, R. Noise-induced hearing loss alters hippocampal glucocorticoid receptor expression in rats. Hear. Res. 2019, 379, 43–51. [Google Scholar] [CrossRef]

- Balanay, J.A.G.; Kearney, G.D.; Mannarino, A.J. Noise exposure assessment among groundskeepers in a university setting: A pilot study. J. Occup. Environ. Hyg. 2016, 13, 193–202. [Google Scholar] [CrossRef] [PubMed]

- Ghaffariyan, M.R. Analysis of forestry work accidents in five Australian forest companies for the period 2004 to 2014. J. For. Sci. 2016, 62, 545–552. [Google Scholar] [CrossRef] [Green Version]

- Akay, A.E.; Acar, H.H. Using GIS Techniques for Modeling Noise Propagation from Mechanized Harvesting Equipment. Eur. J. For. Eng. 2019, 5, 92–98. [Google Scholar] [CrossRef]

- Teixeira, L.R.; Azevedo, T.M.; Bortkiewicz, A.; Corrêa da Silva, D.T.; de Abreu, W.; de Almeida, M.S.; de Araujo, M.A.N.; Gadzicka, E.; Ivanov, I.D.; Leppink, N.; et al. WHO/ILO work-related burden of disease and injury: Protocol for systematic reviews of exposure to occupational noise and of the effect of exposure to occupational noise on cardiovascular disease. Environ. Int. 2019, 125, 567–578. [Google Scholar] [CrossRef] [PubMed]

- Iftime, M.D.; Dumitrascu, A.E.; Dumitrascu, D.I.; Ciobanu, V.D. An investigation on major physical hazard exposures and health effects of forestry vehicle operators performing wood logging processes. Int. J. Ind. Ergon. 2020, 80, 103041. [Google Scholar] [CrossRef]

- Guarnaccia, C.; Mastorakis, N.E.; Quartieri, J. Noise sources analysis in a wood manufacturing company. Int. J. Mech. 2013, 7, 37–44. [Google Scholar]

- Instituto Nacional de Meteorologia. Available online: https://portal.inmet.gov.br/dadoshistoricos (accessed on 18 February 2021).

- Viel, J.A.; da Rosa, K.K.; Junior, C.W.M. Revista Brasileira de Geografia Física. Rev. Bras. Geogr. Física 2020, 13, 2255–2268. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 9612:2009. In Acoustics—Determination of Occupational Noise Exposure—Engineering Method; BSI Standards Limited: Geneva, Switzerland, 2009. [Google Scholar]

- Boger, M.E.; Barbosa-Branco, A.; Ottoni, Á.C. The noise spectrum influence on Noise-Induced Hearing Loss prevalence in workers. Braz. J. Otorhinolaryngol. 2009, 75, 328–334. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brasil Norma Regulamentadora 15: Atividade e Operações Insalubres; Ministério do trabalho: Rio Branco, Brazil, 1978. Available online: https://sit.trabalho.gov.br/portal/index.php/ctpp-nrs/nr-15?view=default (accessed on 4 March 2021).

- Portugal Norma Portuguesa 1733: Estimativa da Exposição ao Ruído Durante o Exercício de Uma Actividade Profissional, com Vista à Protecção da Audição; Direcção Geral da Qualidade: Lisboa, Portugal, 1981. Available online: https://comum.rcaap.pt/bitstream/10400.26/7315/7/Anexo%206%20-%20NP%20-%201733%20-%201981.pdf (accessed on 4 March 2021).

- Brasil Norma Regulamentadora 9: Programa de Prevenção de Riscos Ambientais; Ministério do trabalho: Rio Branco, Brasília, 1978. Available online: https://sit.trabalho.gov.br/portal/index.php/ctpp-nrs/nr-9?view=default (accessed on 4 March 2021).

- European Union. Directive 2003/10/EC of the European Parliament and of the Council; Official Journal of the European Communities: Brussels, Belgium, 2003. [Google Scholar]

- Kuehn, J. Noise Measurement. In Instrumentation Reference Book; Elsevier: Amsterdam, The Netherlands, 2010; pp. 593–614. ISBN 978-0-7506-8308-1. [Google Scholar]

- National Institute for Occupational Safety andHealth NIOSH: Criteria for a Recommended Standard—Occupational Noise Exposure; U.S. Department of Health And Human Services: Cincinnati, OH, USA, 1998. Available online: https://www.cdc.gov/niosh/docs/98-126/pdfs/98-126.pdf (accessed on 4 March 2021).

- Schulz, T.Y. Individual fit-testing of earplugs: A review of uses. Noise Health 2011, 13, 152–162. [Google Scholar] [CrossRef] [PubMed]

- Lilliefors, H.W. On the Kolmogorov-Smirnov test for the exponential distribution with mean unknown. J. Am. Stat. Assoc. 1969, 64, 387–389. [Google Scholar] [CrossRef]

- Bartlett, M.S. Properties of Sufficiency and Statistical Tests. Phys. Eng. Sci. 1937, 268–282. [Google Scholar] [CrossRef]

- Friedman, M. The Use of Ranks to Avoid the Assumption of Normality Implicit in the Analysis of Variance. J. Am. Stat. Assoc. 1937, 32, 675–701. [Google Scholar] [CrossRef]

- R Development Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Computing Statistical: Vienna, Austria, 2020; ISBN 3-900051-07-0. [Google Scholar]

- Al-Arja, O.A.; Awadallah, T.S. Assessment of occupational noise exposure in coffee grinding shops. Appl. Acoust. 2020, 158, 107047. [Google Scholar] [CrossRef]

- Fernandes, H.C.; de Brito, A.B.; Minette, L.J.; Leite, D.M.; Leite, E.D. Application of ergonomic index indices in the evaluation of the cabin of a forest tractor “Feller-Buncher”. Sci. For. 2011, 39, 273–281. [Google Scholar]

- Fonseca, A.; Aghazadeh, F.; de Hoop, C.; Ikuma, L.; Al-Qaisi, S. Effect of noise emitted by forestry equipment on workers’ hearing capacity. Int. J. Ind. Ergon. 2015, 46, 105–112. [Google Scholar] [CrossRef]

- Nieuwenhuis, M.; Lyons, M. Health and Safety Issues and Perceptions of Forest Harvesting Contractors in Ireland. Int. J. For. Eng. 2002, 13, 69–76. [Google Scholar] [CrossRef]

- Kurt, R.E.; McKenna, S.A.; Gunbeyaz, S.A.; Turan, O. Investigation of occupational noise exposure in a ship recycling yard. Ocean. Eng. 2017, 137, 440–449. [Google Scholar] [CrossRef] [Green Version]

- Sowa, J.M.; Leszczyński, K. Analysis of noise level affecting machine operators during timber harvesting in poland. In Proceedings of the Meeting the Needs of Tomorrows’ Forests—New Developments in Forest Engineering; Formec: Vienna, Austria, 2007; pp. 1–6. [Google Scholar]

- Cheţa, M.; Marcu, M.V.; Borz, S.A. Workload, exposure to noise, and risk of musculoskeletal disorders: A case study of motor-manual tree feeling and processing in poplar clear cuts. Forests 2018, 9, 300. [Google Scholar] [CrossRef] [Green Version]

- Rech, J.; Dumont, F.; Le Bot, A.; Arrazola, P.J. Reduction of noise during milling operations. CIRP J. Manuf. Sci. Technol. 2017, 18, 39–44. [Google Scholar] [CrossRef]

- Rehn, B.; Lundström, R.; Nilsson, L.; Liljelind, I.; Järvholm, B. Variation in exposure to whole-body vibration for operators of forwarder vehicles—Aspects on measurement strategies and prevention. Int. J. Ind. Ergon. 2005, 35, 831–842. [Google Scholar] [CrossRef]

- Melemez, K.; Tunay, M. The investigation of the ergonomic aspects of the noise caused by agricultural tractors used in Turkish forestry. Afr. J. Agric. Res. 2010, 5, 243–249. [Google Scholar] [CrossRef]

- Santos, L.N.; Fernandes, H.C.; Souza, A.P.; Furtado Júnior, M.R.; Silva, R.M. Avaliação dos níveis de ruído e vibração de um conjunto trator-pulverizador, em função da velocidade de trabalho. Eng. Na Agric. 2014, 22, 112–118. [Google Scholar] [CrossRef]

- Gerasimov, Y.; Sokolov, A. Ergonomic characterization of harvesting work in Karelia. Croat. J. For. Eng. 2009, 30, 159–170. [Google Scholar]

- Lima, C.F.; Lima, R.C.A.; de Souza, A.P.; Minette, L.J.; Schettino, S.; Vieira, M.P.L.; Nascimento, G.S.P. Occupational Noise and Vibration Assessments in Forest Harvesting Equipment in North-eastern Brazil. J. Exp. Agric. Int. 2019, 40, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Caruso, C.C. Possible broad impacts of long work hours. Ind. Health 2006, 44, 531–536. [Google Scholar] [CrossRef] [Green Version]

- Barck-Holst, P.; Nilsonne, Å.; Åkerstedt, T.; Hellgren, C. Reduced working hours and stress in the Swedish social services: A longitudinal study. Int. Soc. Work 2017, 60, 897–913. [Google Scholar] [CrossRef]

- Bonnet, F.; Nélisse, H.; Nogarolli, M.A.C.; Voix, J. In-ear noise dosimetry under earplug: Method to exclude wearer-induced disturbances. Int. J. Ind. Ergon. 2019, 74. [Google Scholar] [CrossRef]

- Lin, Y.T.; Chen, T.W.; Chang, Y.C.; Chen, M.L.; Hwang, B.F. Relationship between time-varying exposure to occupational noise and incident hypertension: A prospective cohort study. Int. J. Hyg. Environ. Health 2020, 226, 113487. [Google Scholar] [CrossRef]

- Potočnik, I.; Pentek, T.; Poje, A. Severity analysis of accidents in forest operations. Croat. J. For. Eng. 2009, 30, 171–184. [Google Scholar]

- Noweir, M.H.; Zytoon, M.A. Occupational exposure to noise and hearing thresholds among civilian aircraft maintenance workers. Int. J. Ind. Ergon. 2013, 43, 495–502. [Google Scholar] [CrossRef]

- Rubio-Romero, J.C.; Carrillo-Castrillo, J.A.; Soriano-Serrano, M.; Galindo-Reyes, F.; de la Varga-Salto, J. A longitudinal study of noise exposure and its effects on the hearing of olive oil mill workers. Int. J. Ind. Ergon. 2018, 67, 60–66. [Google Scholar] [CrossRef]

- McLain, S.C.; Autenrieth, D.A.; Yang, X.; Brazile, W.J. Noise Exposures and Hearing Protector Use at Small Logging Operations. Small Scale For. 2020. [Google Scholar] [CrossRef]

- Poje, A.; Potočnik, I. Influence of working conditions on overlapping of cutting and ground skidding in group work. Croat. J. For. Eng. 2007, 28, 157–167. [Google Scholar]

- Neitzel, R.L.; Hong, O.; Quinlan, P.; Hulea, R. Pilot task-based assessment of noise levels among firefighters. Int. J. Ind. Ergon. 2013, 43, 479–486. [Google Scholar] [CrossRef] [Green Version]

- Burella, G.; Moro, L. A Comparative Study of the Methods to Assess Occupational Noise Exposures of Fish Harvesters. Saf. Health Work 2020. [Google Scholar] [CrossRef]

- Chapman, L.J.; Husberg, B. Agriculture, Forestry, and Fishing Sector. J. Saf. Res. 2008, 39, 171–173. [Google Scholar] [CrossRef]

- Akay, A.O.; Akgul, M.; Demir, M.; Acar, H.H. Analysis of factors associated with the amount of forest road reconstruction activity in Turkey: Autoregressive distributed lag modelling approach. For. Ecol. Manag. 2020, 458. [Google Scholar] [CrossRef]

- Iftime, M.D.; Dumitrascu, A.E.; Ciobanu, V.D. Chainsaw operators’ exposure to occupational risk factors and incidence of professional diseases specific to the forestry field. Int. J. Occup. Saf. Ergon. 2020, 0, 1–38. [Google Scholar] [CrossRef]

- Garmer, K.; Sjöström, H.; Hiremath, A.M.; Tilwankar, A.K.; Kinigalakis, G.; Asolekar, S.R. Development and validation of three-step risk assessment method for ship recycling sector. Saf. Sci. 2015, 76, 175–189. [Google Scholar] [CrossRef]

- Riccioni, S.; Cecchini, M.; Monarca, D.; Colantoni, A.; Longo, L.; Cavalletti, P.; Bedini, R. Overview of the noise measurements process in recent years. Contemp. Eng. Sci. 2015, 8, 1179–1191. [Google Scholar] [CrossRef]

- Poje, A.; Mihelič, M. Influence of chain sharpness, tension adjustment and type of electric chainsaw on energy consumption and cross-cutting time. Forests 2020, 11, 1017. [Google Scholar] [CrossRef]

| Genus | Study Area | Size Cutting Area (ha) | Diametric Distribution (cm) | Mean Individual Tree Volume (m3) | Cutting Age (Year) | Terrain Slope (%) | Relief Classification |

|---|---|---|---|---|---|---|---|

| Eucalyptus | 1 | 4.22 | 11–11.9 | 0.43 | 11.4 | 10 to 15 | Wavy |

| 2 | 6.16 | 11–11.9 | 0.32 | 11.0 | 10 to 15 | Wavy | |

| 3 | 1.22 | 10–10.9 | 0.39 | 10.9 | 15 to 20 | Wavy | |

| 4 | 2.88 | 6–6.9 | 0.12 | 6.5 | 20 to 25 | Strong wavy | |

| 5 | 1.13 | 6–6.9 | 0.12 | 6.5 | 27 to 30 | Strong wavy | |

| 6 | 0.84 | 6–6.9 | 0.35 | 6.3 | 30 to 40 | Strong wavy | |

| Pinus | 7 | 6.23 | 18–19.9 | 0.66 | 19.0 | 27 to 30 | Strong wavy |

| 8 | 5.30 | 18–19.9 | 0.54 | 19.0 | 33 to 35 | Strong wavy | |

| 9 | 2.27 | 18–19.9 | 0.66 | 19.0 | 27 to 30 | Strong wavy | |

| 10 | 3.54 | 18–19.9 | 0.66 | 19.0 | 20 to 25 | Strong wavy | |

| 11 | 4.61 | 18–19.9 | 0.66 | 19.0 | 5 to 8 | Smooth wavy | |

| 12 | 4.39 | 19–19.9 | 0.65 | 19.0 | 27 to 30 | Strong wavy |

| Forest Planted | Self-Propelled Forest Machines | Identification | Brand | Model | Accumulated Hours of Use (h) |

|---|---|---|---|---|---|

| Pinus | Harvester | HVP1 | Ponsse | Bear | 5740 |

| HVP2 | Ponsse | Bear | 6110 | ||

| HVP3 | Ponsse | Bear | 6200 | ||

| Forwarder | FWP1 | Ponsse | Elephantking | 6276 | |

| FWP2 | Ponsse | Elephantking | 6360 | ||

| FWP3 | Ponsse | Elephantking | 13,352 | ||

| FWP4 | Ponsse | Elephantking | 6380 | ||

| Eucalyptus | Harvester | HV1 | Ponsse | Ergo | 13,547 |

| HV2 | Ponsse | Ergo | 11,214 | ||

| HV3 | Ponsse | Ergo | 13,980 | ||

| HV4 | Ponsse | Ergo | 14,600 | ||

| HV5 | Ponsse | Ergo | 14,278 | ||

| HV6 | Ponsse | Ergo | 12,790 | ||

| HV7 | Ponsse | Ergo | 12,366 | ||

| HV8 | John Deere | 1270 | 274 | ||

| Forwarder | FW1 | Ponsse | Elephantking | 10,781 | |

| FW2 | Ponsse | Elephantking | 15,155 | ||

| FW3 | Ponsse | Elephantking | 15,880 | ||

| FW4 | Ponsse | Elephantking | 15,658 | ||

| FW5 | Ponsse | Elephantking | 11,700 | ||

| FW6 | Ponsse | Elephantking | 11,450 | ||

| FW7 | Ponsse | Elephantking | 11,093 |

| Homogeneous Groups | Identification | Lavg [dB(A)] | MEDP [h] | NPdB [(A)] |

|---|---|---|---|---|

| GH1 | HVP1 | 84.3 | 8 h 49 | 67.3 |

| HVP2 | 84.3 | 8 h 50 | 67.3 | |

| HVP3 | 89.6 | 4 h 13 | 72.6 | |

| GH2 | FWP1 | 84.4 | 8 h 41 | 67.4 |

| FWP2 | 84.0 | 9 h 11 | 67.0 | |

| FWP3 | 84.3 | 8 h 50 | 67.3 | |

| FWP4 | 84.3 | 8 h 50 | 67.3 | |

| GH3 | HV1 | 83.9 | 9 h 19 | 66.9 |

| HV2 | 84.2 | 8 h 56 | 67.2 | |

| HV3 | 84.2 | 8 h 56 | 67.2 | |

| HV4 | 84.4 | 8 h 41 | 67.4 | |

| HV5 | 84.1 | 9 h 03 | 67.1 | |

| HV6 | 86.5 | 6 h 30 | 69.5 | |

| HV7 | 91.2 | 3 h 23 | 74.2 | |

| HV8 | 85.2 | 7 h 46 | 68.2 | |

| GH4 | FW1 | 83.9 | 9 h 19 | 66.9 |

| FW2 | 84.2 | 8 h 56 | 67.2 | |

| FW3 | 84.4 | 8 h 41 | 67.4 | |

| FW4 | 84.2 | 8 h 56 | 67.2 | |

| FW5 | 84.0 | 8 h 19 | 67.0 | |

| FW6 | 84.8 | 8 h 13 | 67.8 | |

| FW7 | 84.1 | 9 h 03 | 67.1 |

| Homogeneous Groups | Median [dB(A)] | Amplitude [dB(A)] |

|---|---|---|

| GH1 | 77.9 | 18.8 |

| GH2 | 75.7 | 8.4 |

| GH3 | 77.5 | 9.2 |

| GH4 | 75.9 | 5.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Camargo, D.A.; Munis, R.A.; Simões, D. Investigation of Exposure to Occupational Noise among Forestry Machine Operators: A Case Study in Brazil. Forests 2021, 12, 299. https://0-doi-org.brum.beds.ac.uk/10.3390/f12030299

Camargo DA, Munis RA, Simões D. Investigation of Exposure to Occupational Noise among Forestry Machine Operators: A Case Study in Brazil. Forests. 2021; 12(3):299. https://0-doi-org.brum.beds.ac.uk/10.3390/f12030299

Chicago/Turabian StyleCamargo, Diego Aparecido, Rafaele Almeida Munis, and Danilo Simões. 2021. "Investigation of Exposure to Occupational Noise among Forestry Machine Operators: A Case Study in Brazil" Forests 12, no. 3: 299. https://0-doi-org.brum.beds.ac.uk/10.3390/f12030299