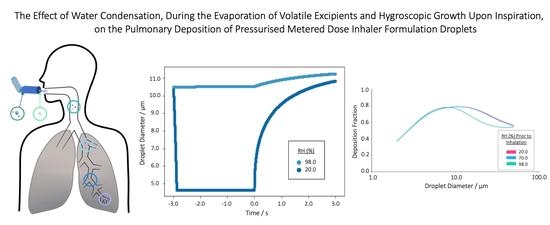

Water Uptake by Evaporating pMDI Aerosol Prior to Inhalation Affects Both Regional and Total Deposition in the Respiratory System

Abstract

:1. Introduction

2. Experimental

2.1. The Single Particle Electrodynamic Lung (SPEL)

2.2. ICRP Model with Specific Hygroscopic Growth

3. Results

3.1. Evaporation Dynamics of Individual Droplets Consisting of Volatile Solvents

3.2. Effect of Water Uptake during HFA Evaporation on Total and Regional Dose in the Lung

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dolovich, M.B.; Dhand, R. Aerosol drug delivery: Developments in device design and clinical use. Lancet 2011, 377, 1032–1045. [Google Scholar] [CrossRef]

- Newman, S.P. Principles of metered-dose inhaler design. Respir. Care 2005, 50, 1177–1190. [Google Scholar] [PubMed]

- Myrdal, P.B.; Sheth, P.; Stein, S.W. Advances in Metered Dose Inhaler Technology: Formulation Development. AAPS PharmSciTech 2014, 15, 434–455. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cripps, A.; Riebe, M.; Schulze, M.; Woodhouse, R. Pharmaceutical transition to non-CFC pressurized metered dose inhalers. Respir. Med. 2000, 94, S3–S9. [Google Scholar] [CrossRef] [Green Version]

- Saleem, I.Y.; Smyth, H.D.C. Tuning Aerosol Particle Size Distribution of Metered Dose Inhalers Using Cosolvents and Surfactants. BioMed Res. Int. 2013, 2013, 574310. [Google Scholar] [CrossRef]

- Brambilla, G.; Ganderton, D.; Garzia, R.; Lewis, D.; Meakin, B.; Ventura, P. Modulation of aerosol clouds produced by pressurised inhalation aerosols. Int. J. Pharm. 1999, 186, 53–61. [Google Scholar] [CrossRef]

- Ulrik, C.S.; Lange, P. Targeting small airways in asthma: Improvement in clinical benefit? Clin. Respir. J. 2011, 5, 125–130. [Google Scholar] [CrossRef]

- Murnane, D.; Hutter, V.; Harang, M. Pharmaceutical Aerosols and Pulmonary Drug Delivery. In Aerosol Science: Technology and Applications; Colbeck, I., Lazaridis, M., Eds.; John Wiley & Sons, Ltd.: Chichester, UK, 2014; pp. 221–269. [Google Scholar]

- Gavtash, B.; Versteeg, H.K.; Hargrave, G.; Myatt, B.; Lewis, D.; Church, T.; Brambilla, G. Transient flashing propellant flow models to predict internal flow characteristics, spray velocity, and aerosol droplet size of a pMDI. Aerosol Sci. Technol. 2017, 51, 564–575. [Google Scholar] [CrossRef] [Green Version]

- Clark, A. Metered Atomisation for Respiratory Drug Delivery. Ph.D. Thesis, Loughborough University, Loughborough, UK, 1991. [Google Scholar]

- Dunbar, C.A. Atomization mechanisms of the pressurized metered dose inhaler. Part. Sci. Technol. 1997, 15, 253–271. [Google Scholar] [CrossRef]

- Mason-Smith, N.; Duke, D.J.; Kastengren, A.L.; Traini, D.; Young, P.M.; Chen, Y.; Lewis, D.A.; Edgington-Mitchell, D.; Honnery, D. Revealing pMDI Spray Initial Conditions: Flashing, Atomisation and the Effect of Ethanol. Pharm. Res. 2017, 34, 718–729. [Google Scholar] [CrossRef]

- Ganderton, D.; Lewis, D.; Davies, R.; Meakin, B.; Brambilla, G.; Church, T. Modulite: A means of designing the aerosols generated by pressurized metered dose inhalers. Respir. Med. 2002, 96, S3–S8. [Google Scholar] [CrossRef] [Green Version]

- Harnor, K.; Perkins, A.; Wastie, M.; Wilson, C.; Sims, E.; Feely, L.; Farr, S. Effect of vapour pressure on the deposition pattern from solution phase metered dose inhalers. Int. J. Pharm. 1993, 95, 111–116. [Google Scholar] [CrossRef]

- Gavtash, B.; Versteeg, H.K.; Hargrave, G.; Myatt, B.; Lewis, D.; Church, T.; Brambilla, G. A model of transient internal flow and atomization of propellant/ethanol mixtures in pressurized metered dose inhalers (pMDI). Aerosol Sci. Technol. 2018, 52, 494–504. [Google Scholar] [CrossRef]

- Myatt, B.; Lewis, D.; Church, T.; Brambilla, G.; Hargrave, G.; Versteeg, H.; Long, E.; Gavtash, B. PDA analysis of HFA/Ethanol pMDI aerosols: An improved test protocol and new findings. In Proceedings of the ICLASS 2015—13th International Conference on Liquid Atomization and Spray Systems, Tainan, Taiwan, 23–27 August 2015. [Google Scholar]

- Lewis, D.; Young, P.; Buttini, F.; Church, T.; Colombo, P.; Forbes, B.; Haghi, M.; Johnson, R.; O’Shea, H.; Salama, R.; et al. Towards the bioequivalence of pressurised metered dose inhalers 1: Design and characterisation of aerodynamically equivalent beclomethasone dipropionate inhalers with and without glycerol as a non-volatile excipient. Eur. J. Pharm. Biopharm. 2014, 86, 31–37. [Google Scholar] [CrossRef]

- Smyth, H.; Hickey, A.J.; Brace, G.; Barbour, T.; Gallion, J.; Grove, J. Spray Pattern Analysis for Metered Dose Inhalers I: Orifice Size, Particle Size, and Droplet Motion Correlations. Drug Dev. Ind. Pharm. 2006, 32, 1033–1041. [Google Scholar] [CrossRef]

- Polli, G.P.; Grim, W.M.; Bacher, F.A.; Yunker, M.H. Influence of Formulation on Aerosol Particle Size. J. Pharm. Sci. 1969, 58, 484–486. [Google Scholar] [CrossRef]

- Dunbar, C.A.; Hickey, A.J. Evaluation of probability density functions to approximate particle size distributions of representative pharmaceutical aerosols. J. Aerosol Sci. 2000, 31, 813–831. [Google Scholar] [CrossRef]

- Dunbar, C.; Watkins, A.; Miller, J. An Experimental Investigation of the Spray Issued from a pMDI Using Laser Diagnostic Techniques. J. Aerosol Med. 1997, 10, 351–368. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Hargrave, G.K.; Myatt, B.J.; Lewis, D.; Church, T.; Brambilla, G. Using Phase Doppler Anemometry and High Speed Imaging to Analyze MDI Spray Plume Dynamics. Respiratory Drug Delivery Europe. In Proceedings of the RDD Europe 2017, Antibes, France, 25–28 April 2017. [Google Scholar]

- Eshel, G.; Levy, G.J.; Mingelgrin, U.; Singer, M.J. Critical Evaluation of the Use of Laser Diffraction for Particle-Size Distribution Analysis. Soil Sci. Soc. Am. J. 2004, 68, 736–743. [Google Scholar] [CrossRef]

- Stein, S.W. Size distribution measurements of metered dose inhalers using Andersen Mark II cascade impactors. Int. J. Pharm. 1999, 186, 43–52. [Google Scholar] [CrossRef]

- Stein, S.W.; Myrdal, P.B. A theoretical and experimental analysis of formulation and device parameters affecting solution MDI size distributions. J. Pharm. Sci. 2004, 93, 2158–2175. [Google Scholar] [CrossRef] [PubMed]

- Sheth, P.; Stein, S.W.; Myrdal, P.B. The influence of initial atomized droplet size on residual particle size from pressurized metered dose inhalers. Int. J. Pharm. 2013, 455, 57–65. [Google Scholar] [CrossRef] [PubMed]

- Stein, S.W.; Myrdal, P.B. The Relative Influence of Atomization and Evaporation on Metered Dose Inhaler Drug Delivery Efficiency. Aerosol Sci. Technol. 2006, 40, 335–347. [Google Scholar] [CrossRef] [Green Version]

- Sheth, P.; Grimes, M.R.; Stein, S.W.; Myrdal, P.B. Impact of droplet evaporation rate on resulting in vitro performance parameters of pressurized metered dose inhalers. Int. J. Pharm. 2017, 528, 360–371. [Google Scholar] [CrossRef]

- Brambilla, G.; Church, T.; Lewis, D.; Meakin, B. Plume temperature emitted from metered dose inhalers. Int. J. Pharm. 2011, 405, 9–15. [Google Scholar] [CrossRef]

- Martin, A.R.; Finlay, W.H. The Effect of Humidity on the Size of Particles Delivered from Metered-Dose Inhalers. Aerosol Sci. Technol. 2005, 39, 283–289. [Google Scholar] [CrossRef]

- Lange, C.F.; Finlay, W.H. Overcoming the Adverse Effect of Humidity in Aerosol Delivery via Pressurized Metered-Dose Inhalers during Mechanical Ventilation. Am. J. Respir. Crit. Care Med. 2000, 161, 1614–1618. [Google Scholar] [CrossRef]

- Kim, C.S.; Trujillo, D.; Sackner, M.A. Size aspects of metered-dose inhaler aerosols. Am. Rev. Respir. Dis. 1985, 132, 137–142. [Google Scholar]

- Mitchell, J.P.; Nagel, M.W.; Doyle, C.C.; Wiersema, K.J. The Effect of Humidification on the Size Distribution of Metered-Dose Inhaler (Pmdi) Aerosols to the Mechanically Ventilated Patient. In Proceedings of the Drug Delivery to the Lungs (DDL XIII), London, UK, 12–13 December 2002; pp. 36–39. [Google Scholar]

- Ivey, J.W.; Bhambri, P.; Church, T.K.; Lewis, D.A.; McDermott, M.T.; Elbayomy, S.; Finlay, W.H.; Vehring, R. Humidity affects the morphology of particles emitted from beclomethasone dipropionate pressurized metered dose inhalers. Int. J. Pharm. 2017, 520, 207–215. [Google Scholar] [CrossRef]

- Gregson, F.K.A.; Ordoubadi, M.; Miles, R.E.H.; Haddrell, A.E.; Barona, D.; Lewis, D.; Church, T.; Vehring, R.; Reid, J.P. Studies of competing evaporation rates of multiple volatile components from a single binary-component aerosol droplet. Phys. Chem. Chem. Phys. 2019, 21, 9709–9719. [Google Scholar] [CrossRef]

- Pu, Y.; Kline, L.C.; Berry, J. The application of “in-flight” laser diffraction to the particle size characterization of a model suspension metered dose inhaler. Drug Dev. Ind. Pharm. 2010, 37, 552–558. [Google Scholar] [CrossRef]

- Zhu, B.; Traini, D.; Chan, H.-K.; Young, P.M. The effect of ethanol on the formation and physico-chemical properties of particles generated from budesonide solution-based pressurized metered-dose inhalers. Drug Dev. Ind. Pharm. 2013, 39, 1625–1637. [Google Scholar] [CrossRef]

- de Boer, A.; Gjaltema, D.; Hagedoorn, P.; Frijlink, H.W. Characterization of inhalation aerosols: A critical evaluation of cascade impactor analysis and laser diffraction technique. Int. J. Pharm. 2002, 249, 219–231. [Google Scholar] [CrossRef]

- Crim, C.; Holmes, M.; Lee, B.; Cavanaugh, R.; Lincourt, W. Evaluation of particle size distribution of albuterol sulfate hydrofluoroalkane administered via metered-dose inhaler with and without valved holding chambers. Ann. Allergy Asthma Immunol. 2005, 94, 80–85. [Google Scholar] [CrossRef]

- Smyth, H.D.C.; Beck, V.P.; Williams, D.; Hickey, A.J. The influence of formulation and spacer device on the in vitro performance of solution chlorofluorocarbon-free propellant-driven metered dose inhalers. AAPS PharmSciTech 2004, 5, 1–7. [Google Scholar]

- Newman, S.P. Spacer devices for metered dose inhalers. Clin. Pharmacokinet. 2004, 43, 349–360. [Google Scholar] [CrossRef]

- Davis, E.J. Electrodynamic balance stability characteristics and applications to the study of aerocolloidal particles. Langmuir 1985, 1, 379–387. [Google Scholar] [CrossRef]

- Davis, E.J.; Buehler, M.F.; Ward, T.L. The double-ring electrodynamic balance for microparticle characterization. Rev. Sci. Instrum. 1990, 61, 1281–1288. [Google Scholar] [CrossRef]

- Rovelli, G.; Miles, E.H.R.; Reid, P.J.; Clegg, L.S. Hygroscopic properties of aminium sulfate aerosols. Atmos. Chem. Phys. 2017, 17, 4369–4385. [Google Scholar] [CrossRef] [Green Version]

- Haddrell, A.; Rovelli, G.; Lewis, D.; Church, T.; Reid, J. Identifying time-dependent changes in the morphology of an individual aerosol particle from its light scattering pattern. Aerosol Sci. Technol. 2019, 53, 1334–1351. [Google Scholar] [CrossRef]

- Davies, J.F.; Haddrell, A.E.; Miles, R.E.H.; Bull, C.R.; Reid, J.P. Bulk, Surface and Gas-Phase Limited Water Transport in Aerosol. J. Phys. Chem. A 2012, 116, 10987–10998. [Google Scholar] [CrossRef] [PubMed]

- International Commission on Radiological Protection. Human Respiratory Tract Model for Radiological Protection—ICRP 66. Ann. ICRP 1994, 24, 492. [Google Scholar]

- Haddrell, A.E.; Davies, J.F.; Reid, J.P. Dynamics of Particle Size on Inhalation of Environmental Aerosol and Impact on Deposition Fraction. Environ. Sci. Technol. 2015, 49, 14512–14521. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kulmala, M.; Vesala, T.; Wagner, P. An analytical expression for the rate of binary condensational particle growth: Comparison with numerical results. J. Aerosol Sci. 1992, 23, 133–136. [Google Scholar] [CrossRef]

- Haddrell, A.E.; Davies, J.F.; Miles, R.E.; Reid, J.P.; Dailey, L.A.; Murnane, D. Dynamics of aerosol size during inhalation: Hygroscopic growth of commercial nebulizer formulations. Int. J. Pharm. 2014, 463, 50–61. [Google Scholar] [CrossRef] [Green Version]

- Davies, J.F.; Miles, R.E.H.; Haddrell, A.E.; Reid, J.P. Influence of organic films on the evaporation and condensation of water in aerosol. Proc. Natl. Acad. Sci. USA 2013, 110, 8807–8812. [Google Scholar] [CrossRef] [Green Version]

- Haddrell, A.E.; Hargreaves, G.; Davies, J.F.; Reid, J.P. Control over hygroscopic growth of saline aqueous aerosol using Pluronic polymer additives. Int. J. Pharm. 2013, 443, 183–192. [Google Scholar] [CrossRef]

- Yu, K.N.P.; Lau, B.; Nikezic, D. Assessment of environmental radon hazard using human respiratory tract models. J. Hazard. Mater. 2006, 132, 98–110. [Google Scholar] [CrossRef]

- Hofmann, W. Modelling inhaled particle deposition in the human lung—A review. J. Aerosol Sci. 2011, 42, 693–724. [Google Scholar] [CrossRef]

- Su, Y.-Y.; Miles, R.E.H.; Li, Z.-M.; Reid, J.P.; Xu, J. The evaporation kinetics of pure water droplets at varying drying rates and the use of evaporation rates to infer the gas phase relative humidity. Phys. Chem. Chem. Phys. 2018, 20, 23453–23466. [Google Scholar] [CrossRef] [Green Version]

- Hinds, W.C. Aerosol Technology: Properties, Behaviour, and Measurement of Airborne Particles; John Wiley & Sons, Ltd.: Chichester, UK, 1999. [Google Scholar]

- Clegg, S.L.; Seinfeld, J.H.; Brimblecombe, P. Thermodynamic modelling of aqueous aerosols containing electrolytes and dissolved organic compounds. J. Aerosol Sci. 2001, 32, 713–738. [Google Scholar] [CrossRef]

- Ferron, G.A.; Haider, B.; Kreyling, W.G. A method for the approximation of the relative humidity in the upper human airways. Bull. Math. Biol. 1985, 47, 565–589. [Google Scholar] [CrossRef]

- Dennis, J.; Berg, E.; Sandell, D.; Ali, A.; Lamb, P.; Tservistas, M.; Karlsson, M.; Mitchell, J. Cooling the NGI—An approach to size a nebulised aerosol more accurately. Pharmeuropa Sci. Notes 2008, 2008, 27–30. [Google Scholar]

- European Pharmacopoeia. Preparations for Nebulisation; Section 2.9.44—European Directorate for the Quality of Medicines and Healthcare (EDQM); Council of Europe: Strasbourg, France, 2012. [Google Scholar]

- United States Pharmacopeia USP 35-NF 30. Chapter 1601: Products for Nebulization; United States Pharmacopeial Convention: Rockville, MD, USA, 2012. [Google Scholar]

- Davies, J.F.; Haddrell, A.E.; Rickards, A.M.J.; Reid, J.P. Simultaneous Analysis of the Equilibrium Hygroscopicity and Water Transport Kinetics of Liquid Aerosol. Anal. Chem. 2013, 85, 5819–5826. [Google Scholar] [CrossRef]

- Broday, D.M.; Georgopoulos, P.G. Growth and deposition of hygroscopic particulate matter in the human lungs. Aerosol Sci. Technol. 2001, 34, 144–159. [Google Scholar] [CrossRef]

- Longest, P.W.; Hindle, M. Condensational Growth of Combination Drug-Excipient Submicrometer Particles for Targeted High Efficiency Pulmonary Delivery: Comparison of CFD Predictions with Experimental Results. Pharm. Res. 2011, 29, 707–721. [Google Scholar] [CrossRef] [Green Version]

- Hindle, M.; Longest, P.W. Evaluation of Enhanced Condensational Growth (ECG) for Controlled Respiratory Drug Delivery in a Mouth-Throat and Upper Tracheobronchial Model. Pharm. Res. 2010, 27, 1800–1811. [Google Scholar] [CrossRef] [Green Version]

- Tian, G.; Longest, P.W.; Li, X.; Hindle, M. Targeting Aerosol Deposition to and Within the Lung Airways Using Excipient Enhanced Growth. J. Aerosol Med. Pulm. Drug Deliv. 2013, 26, 248–265. [Google Scholar] [CrossRef] [PubMed]

| Abbreviation | Definition |

|---|---|

| pMDI | Pressurised metered dose inhaler |

| SPEL | Single Particle Electrodynamic Lung |

| HFA | Hydrofluoroalkane |

| ICRP | International Commission of Radiological Protection |

| RH | Relative humidity |

| MMAD | Mass median aerodynamic diameter |

| FPF | Fine particle fraction |

| CK-EDB | Comparative kinetic electrodynamic balance |

| MMD | Mass median diameter |

| GSD | Geometric standard deviation |

| ET | Extrathoracic region |

| BB | Bronchial region |

| Bb | Bronchiolar region |

| BR | Combined bronchial and bronchiolar region |

| AI | Alveolar interstitial region |

| Symbol | Definition |

|---|---|

| GFr | Radial growth factor |

| r(RH) | Radius of wet droplet at a specific RH |

| r(RH) = 0 | Radius of dry particle at 0% RH |

| I | Mass flux of water |

| a | Droplet radius |

| S∞ | Saturation ratio of water in the gas phase away from droplet surface |

| aw | Water activity at the droplet surface |

| R | The gas constant |

| T∞ | Temperature of the gas phase |

| M | Molar mass of water |

| A | Stefan flow correction factor |

| D | Diffusion coefficient of water in the gas phase |

| pv,∞ | Saturation vapour pressure of water |

| L | Latent heat of vaporisation of water |

| K | Thermal conductivity of the carrier gas |

| βM | Fuchs–Sutugin transitional correction factor for mass transfer |

| βT | Fuchs–Sutugin transitional correction factor for heat transfer |

| Sh | Sherwood number |

| η | Deposition efficiency (also filtration efficiency) |

| aICRP | Constant used to calculate the deposition efficiency in the ICRP model |

| RICRP | Function of droplet diameter and airflow used to calculate the deposition efficiency in the ICRP model |

| p | Constant used to calculate the deposition efficiency in the ICRP model |

| ηTotal | Total deposition efficiency |

| ηae | Aerodynamic deposition efficiency |

| ηth | Thermodynamic deposition efficiency |

| DE | Deposition fraction |

| ηj | Total deposition efficiency for region j |

| j | Region of the ICRP model (also respiratory system) |

| φj | Volumetric fraction for region j |

| N | Number of regions |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Legh-Land, V.; Haddrell, A.E.; Lewis, D.; Murnane, D.; Reid, J.P. Water Uptake by Evaporating pMDI Aerosol Prior to Inhalation Affects Both Regional and Total Deposition in the Respiratory System. Pharmaceutics 2021, 13, 941. https://0-doi-org.brum.beds.ac.uk/10.3390/pharmaceutics13070941

Legh-Land V, Haddrell AE, Lewis D, Murnane D, Reid JP. Water Uptake by Evaporating pMDI Aerosol Prior to Inhalation Affects Both Regional and Total Deposition in the Respiratory System. Pharmaceutics. 2021; 13(7):941. https://0-doi-org.brum.beds.ac.uk/10.3390/pharmaceutics13070941

Chicago/Turabian StyleLegh-Land, Victoria, Allen E. Haddrell, David Lewis, Darragh Murnane, and Jonathan P. Reid. 2021. "Water Uptake by Evaporating pMDI Aerosol Prior to Inhalation Affects Both Regional and Total Deposition in the Respiratory System" Pharmaceutics 13, no. 7: 941. https://0-doi-org.brum.beds.ac.uk/10.3390/pharmaceutics13070941