1. Introduction

The overall demand for agricultural products is expected to grow by 1.1 percent per year over the period 2010–2050, down from 2.2 percent per year in 1970–2010 [

1]. Population growth, increases in per capita consumption and shifts in diets leading to greater consumption of livestock products are the main drivers of these expected changes. In developed countries, the food supply will exceed the demand, and their aging populations mean that the quality and healthiness of food will be critical determinants of consumption. Functional foods will be designed to provide added value to health-conscious consumers, and biotechnology will be applied to satisfy this growing demand [

2]; however, there will also be a focus on the foods that animals eat, as they ultimately determine what humans eat.

On the other hand, global food security could be in jeopardy, due to mounting pressures on natural resources and due to climate change, both of which threaten the sustainability of food systems at large. Planetary boundaries may well be surpassed if current trends continue [

2]. There is a need to establish the right incentives to harness agriculture’s environmental services to protect watersheds and biodiversity, and to ensure food production using sustainable technologies. Since food production is responsible for a large share of greenhouse gas (GHG) emissions [

2], future efforts to address climate change will need to find ways to reduce food losses and waste.

In this review, we aim to analyse the contribution of the olive oil value chain to a more sustainable food production system. Specifically, we focus on the use of waste and by-products from the olive production and the extraction industry as animal feed, and the justification of this use as a practical strategy within a framework encompassing bioeconomy, circular economy and sustainable resource policy. The review is organised as follows: the next section reviews the concept of the bioeconomy and the biomass value pyramid. It is followed by a brief description of waste in the olive value chain. The third section analyses the state-of-the-art in olive oil by-product valorisation and the relevance of animal feed alternatives. Finally, we present a brief policy analysis of the consequences of the implementation of the value pyramid to this sector and we make some proposals for future research directions.

2. The Role of Waste for Feed in the Bioeconomy

The bioeconomy encompasses the production of renewable biological resources and the conversion of these resources and waste streams into value-added products, such as food, feed, bio-based products and bioenergy. In 2014, it employed around 18.6 million people and generated approximately EUR 2.2 trillion (bioeconomy sectors amount to 9% of the total EU economy) [

3]. Food security has been identified as a key societal challenge, especially considering the unprecedented growth of the world population, among other factors. An increasingly important source of additional biomass is the waste produced by the agricultural, forestry and fishery sectors. The linear economic model of ‘take–make–dispose’ has proven to be unsustainable; in contrast, the circular economy approach aims to maintain the value of products and materials for as long as possible while minimising resource use and waste generation [

4].

Current strategies based on a broader understanding of the bioeconomy focus on three sectors of biomass use: biomass for food and feed, industrial bio-based products, and bioenergy. National bioeconomy strategies do not clearly prioritise any one of these sectors over the others; furthermore, separate sector-specific R&D programmes are often applied. The strategic approach to the bioeconomy should take the biomass value pyramid as its point of reference (see

Figure 1). Biomass is most valuable when used as pharmaceuticals or fine chemicals for health and lifestyle purposes. Food and animal feed comes in second, with chemicals in third place. Using biomass as a source of energy is assigned the lowest priority.

According to the pyramid, the biomass can be employed for energy generation only after higher value uses are satisfied. A recent review of official bioeconomy strategies [

6] revealed persistent conflicts between the different uses of biomass for food, material and energy production, and identified a need for bioeconomy policies to take into account the societal debates on agriculture and food. Paradoxically, the development of high-value, innovative materials and products is a priority objective in most of the strategies, but when it comes to commercial application, the implementation of the strategies is predominantly focused on bio-based (bulk) chemicals or materials and bioenergy. The vast majority of countries with bioeconomy policies support bioenergy and biofuels, which is the lowest level of the value pyramid. This is the most widely-adopted option in the olive oil sector.

A rational approach to biomass valorisation has not been fully implemented as the policy debate and scientific research has focused on the two extremes of the pyramid. Researchers have paid attention to the most economically valuable components of biomass (pharmaceuticals and fine chemicals), while current industrial use centres on low-value applications such as energy.

It is well known that a reduction in dietary saturated fat has generally been thought to improve cardiovascular health. Dietary and policy recommendations frequently focus on reducing saturated fatty acid (FA) consumption to improve cardio-metabolic health. Olive oil by-products are a low-cost way of improving the FA profile of milk fat and increasing the FAs considered beneficial, such as polyunsaturated FAs. Besides, olive by-products may be a source of functional components such as plant sterol, which has been shown to reduce blood cholesterol levels. A number of ‘functional’ foods are available, which have been fortified with these natural phytonutrients. Olive oil and olive by-products are an abundant source of these functional components and much effort has been devoted to deriving phytosterols from olive by-products.

The next section describes olive waste as a valuable source of biomass and highly functional molecules. It also outlines the current academic and policy options for this resource use.

3. Biomass from the Olive Oil Industry

Olive cultivation has its origins in Mediterranean regions, although it has expanded to other regions of the world that have a Mediterranean climate. Olive by-products have been used to feed small Mediterranean ruminants (goat and sheep), as well as dairy cows and non-ruminants. This paper focuses on olives for oil production, which yields a high volume of by-products and waste relative to the final product (oil); our analysis does not address the table olive industry, where the fruit is consumed after treatment.

The European Union is the world leader in production of olive oil (around 2.1 million tonnes or 68% of world production).

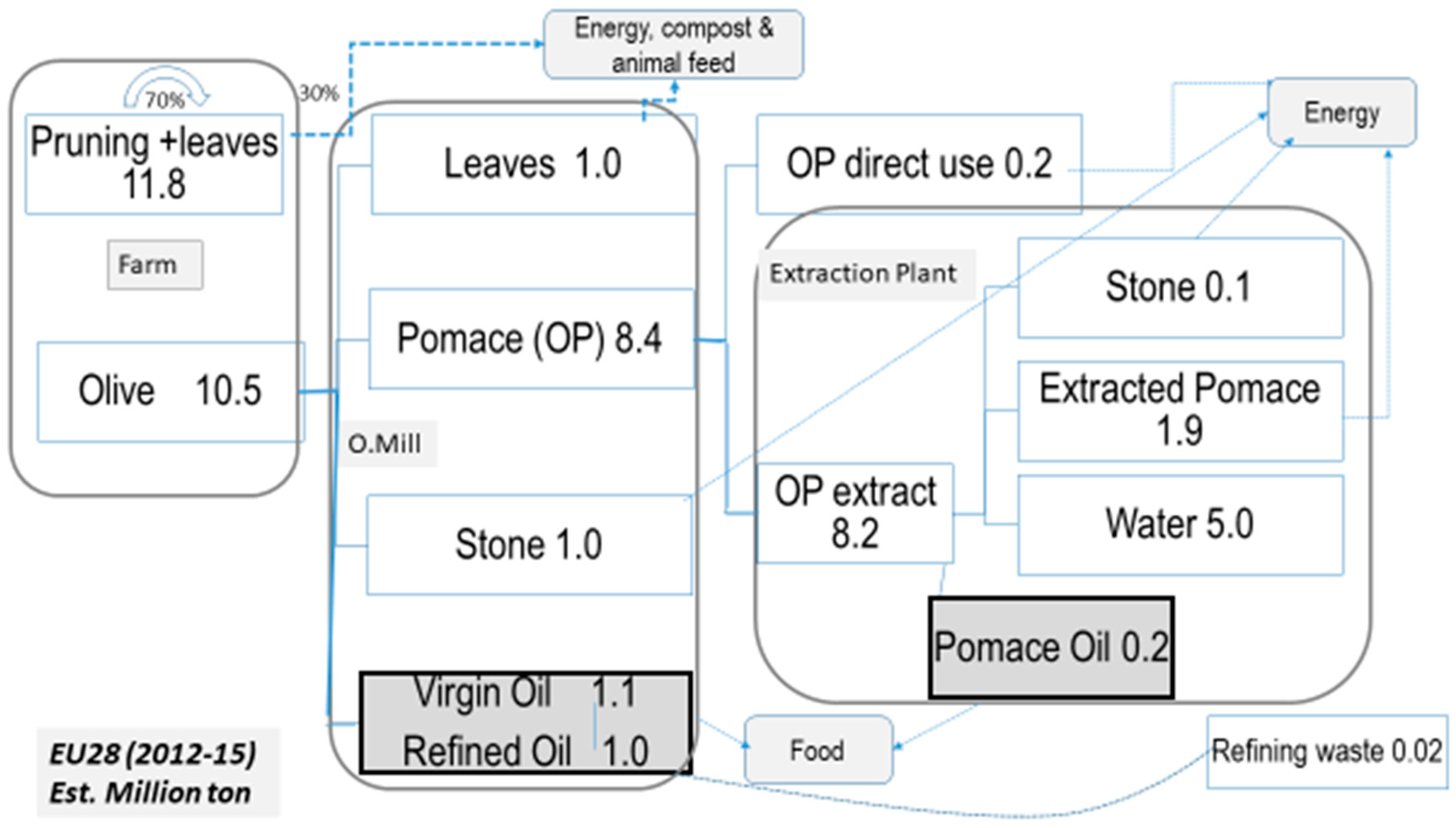

Figure 2 illustrates the biomass along the olive oil chain. Estimation of by-product generation is based on an analysis of the Andalusian olive oil industry, which represents around 50% of the total EU production [

7].

In the EU-28, olive mills generate 9.6 million tonnes/year of by-products subject to valorisation (olive pomace, leaves and stone), while the olive tree pruning biomass (OTPB) accounts for an additional 11.8 million tonnes of biomass. Nevertheless, only a fraction of the OTPB can be economically recovered because part of the production takes place in remote mountainous farms: according to some estimates [

8], only 30% can be used. This gives an estimate for the EU-28 of 13.1 million tonnes (9.6 tonnes of waste from mills +30% of the OTPB). The valorisation of this amount of biomass is already generating jobs and economic activity, but the application of the bioeconomy paradigm opens up some new opportunities.

Olive leaves (OLs) are a mixture of leaves and small branches generated both at the farm during the pruning of the olive trees, as well as during the harvesting and cleaning of olives prior to oil extraction in the processing plant. OLs are generally used for direct combustion, animal feed (fresh) and as feedstock for direct combustion or pellet manufacturing.

Olive pomace (OP) consists of olive pulp, skin, stone and water, although the specific characteristics of OP may differ according to the type of oil extraction, whether it is fresh or dry, and whether it is produced before oil extraction (OP) or after (XOP). Olive stones (OSs) can also be a single by-product when they are well separated from the pulp either before or after oil extraction; they are used mainly for energy production. Finally, olive cake ash is the product that results after OP has been used as feedstock in a biomass energy plant, but it is not included in this review.

4. Use of Olive Biomass from the Olive Oil Industry

In this section, we review the current uses of olive biomass—primarily energy, followed by composting and direct field application. Research has been focused on supporting its use for energy and looking for high-value components, neglecting the ‘middle way’, which is its use as animal feed. The current use of by-products derived from olive cultivation and oil extraction is briefly described below.

4.1. Low-Value Uses of Olive Biomass

The use of olive by-products for energy is well established. The analysis of Andalusian (50% of EU-28 olive oil) by-product use [

7] shows that biomass for energy generation accounts for 80% of olive by-products (47% for electricity generation and 33% for thermal energy). Composting or direct field application represents 14.3% and landfill 0.7%. Hence, 95% of all by-products are devoted to low-value uses, with the remaining 5% consumed as animal feed.

The abovementioned parameters probably represent an optimistic version of the European sector as a whole, since the agro-industrial complex in the olive sector in Andalusia is the most highly developed in the EU. The rest of the EU countries may use relatively less olive waste for energy generation (electricity) and relatively more for composting, field application and waste destinations, but as Andalusia represents 50% of the EU production, we believe that the above data can be taken as representative of EU olive by-product utilisation.

The dominant energy use is electricity generation, with part of the residual heat used to dry the olive pomace, resulting in the high economic efficiency of the system. Regarding thermal energy use, the main consumer is the olive industry itself for oil extraction in the olive mill (virgin oil) and OP extraction plant, followed by heating in the ‘non-olive’ agro-industrial sector. Lastly, a small percentage of OS is treated (cleaned and dried) for domestic use as a substitute for wood pellets.

In addition to the by-products of the industrial phase, olive tree cultivation generates a large amount of biomass from the pruning that is needed to remove old branches and increase crop productivity. OTPB comprises leaves (25% dry weight basis), thin branches (ø < 1 cm) (50%) and branches of different thicknesses (ø > 1 cm) (25%) [

8]. Only a small amount of OTPB is directly used as a raw material in power generation plants (electricity or thermal generation). In terms of indirect uses, there are a number of plants that transform this material into pellets for industrial or domestic heating.

Olive mill waste is characterised as phytotoxic and so direct release into the environment is not recommended [

9]. Two-phase olive mill waste (referred to as ‘olive wet husk’, ‘olive wet pomace’ or ‘olive wet cake’), is a solid waste with a strong odour and a doughy texture, which makes it difficult to manage and transport. The composting of olive mill waste has received a great deal of attention [

10].

The direct combustion of biomass for electricity generation or thermal use has not prompted many research papers as it is already a well-established industry. The use of OS as a biofuel for heating is quite widespread in olive oil producing regions, especially in agro-industries, livestock farms, greenhouses, and domestic heating systems. The research on energy use has focused on improving methane generation in anaerobic digestion processes [

11].

The conversion of waste to solid (pellets) or liquid (biodiesel) biofuel incorporates more value than direct energy use or composting. Other research papers have examined the conversion of by-products to biodiesel with the use of lipase enzymes [

12,

13] or by other means [

14].

The use of olive waste and by-products is a positive solution in terms of employment and value generation. Moreover, the savings in GHG emissions for Andalusia (≈50% of olive oil EU production) are estimated at 1.6 million tonnes/year of CO

2-eq [

7].

4.2. High-Value Uses of Olive Biomass (Functional Components)

Olive biomass as a source of bioactive compounds is a priority in the applied research in this field. Regarding the extraction of valuable compounds that may be marketable in the pharmaceutical and cosmetic industries, Galanakis et al. [

15] describe the different technologies for the recovery of bioactive compounds from olive oil processing by-products and suggest an integrated method that ensures the sustainability of the process. The most widely-used technique is to pre-treat the initial material and convert oleuropein to hydroxytyrosol, prior to extracting phenols with solvent and/or other technologies. Fernández-Bolaños et al. [

16] summarise the current knowledge on the utilisation of residual products, with more than 90 references including articles and patents, and highlight promising future applications. They classify all these studies into two options for use: the recovery of valuable natural components, and bioconversion into useful products.

Olive mill wastewater is a rich source of bioactive compounds and natural phenols such as hydroxytyrosol (a natural phenolic phytochemical with remarkable antioxidant properties that potentially affect blood lipid levels). Phenols (such as hydroxytyrosol, tyrosol, oleuropein) recovered from olive mill wastewater are also active UV filters [

17] used in cosmetics. An interesting possibility is the application of the ‘cascading use’ principle, whereby energy use is allowed only after valuable compounds have been extracted. The separation and purification of these value-added compounds could open the door to further investigation, given the inhibitory effect that phenolic compounds can exert on sugar fermentation. Removal of these compounds from the aqueous extract could also facilitate the production of ethanol from the glucose present in the extractive fraction, enhancing biogas or bioethanol production [

8].

4.3. Medium-Value Use of Olive Biomass (Animal Feed)

As we mentioned above, both high-value and low-value uses of olive by-products have been addressed in numerous publications and patents, whereas their use as animal feed has received less attention. The use of food waste for animal feed is already well established in some industries but olive by-products generally need some processing and are more complex to use than, say, beet pulp or potato peels; these feedstuffs are provided by their respective industries, which are already well integrated with the livestock industry.

Olive by-products have traditionally been used by farmers in Mediterranean areas but there are three barriers to wider use: (a) olive biomass has very little available protein; (b) it contains some phytosterols that may have counterproductive results; and (c) olive mill by-products are a good source of energy, but high energy content may in fact reduce the animals’ total feed intake and thus may also be counterproductive. These characteristics make olive by-products a good supplement for a balanced diet, but fat-rich by-products should be limited to a certain percentage (10% of total diet at most, although 5% is usually recommended).

The most frequently used by-product is OP, which is one of two major by-products of the olive oil extraction industry; for every 100 kg of olives, 40–80 kg of OP (highly variable depending on the technology) is produced. OP has been used directly in low doses (5% of total feed intake) with satisfactory results. Nasopoulou et al. [

18] review the evidence of olive by-products as feed for aquaculture and livestock, concluding for both that moderate consumption does not affect growth and improves the FA profile of animal products by reducing saturated acids and increasing unsaturated components both in meat and milk [

19]. When ruminants are fed a diet with levels of OP below 10%, it results in a reduction in feeding costs and an improvement in milk composition without impacting milk yield [

20].

The use of other olive by-products has been reported in the literature, such as OS for rabbits and birds [

21,

22,

23], as well as olive soap stocks given to ewes and [

24] for rearing crossbred Iberian pigs. All these studies report changes in the FA profile with a relative increase in unsaturated components.

4.4. Olive Oil Chain By-Products as a Functional Feed to Improve Human Food

It is well known that a reduction in dietary saturated fat has generally been thought to improve cardiovascular health. Dietary and policy recommendations frequently focus on reducing saturated FA consumption to improve cardio-metabolic health. Milk and dairy foods contain saturated fats, and their consumption often leads to a rise in the plasma cholesterol level. According to the USDA recommendations for a healthy diet, saturated fat should be avoided, including the fat contained in dairy products [

25]. Meta-analyses point to a reduction in risk in the subjects with the highest dairy consumption relative to those with the lowest intake [

26].

The concept of the bioeconomy and the use of olive oil by-products offer the possibility to improve the FA profile of milk fat by including appropriate fat sources in dairy ruminant diets [

27]. More specifically, the aim is to reduce the content of medium-chain saturated fatty acids (MCSFAs), which have a hypercholesterolemic effect, and increase the FAs considered beneficial, such as polyunsaturated FAs of the n-3 series and rumenic acid (

cis-9,

trans-11 18:2) [

28,

29]. Sources of polyunsaturated FAs include oilseeds and also low-quality olive oil (‘lampante’ oil) [

30]. As the previous section describes, olive by-products can provide an alternative to primary feed (grains or fodder), in line with the guiding principles of the circular economy and bioeconomy.

Regarding feed for ruminants, olive leaves are fibrous with low digestibility, especially of crude protein, and they promote very poor rumen fermentation. It has also been observed that for lactating animals, olive leaves result in an improvement in milk fat quality compared to diets based on conventional forages [

31].

A number of studies show that the knowledge regarding the use of olive cake (OC) is also in line with the evidence for OLs. A significant change is shown in the composition of goat milk with increased levels of OC in the diet. A commonly reported finding is that contents of milk fat and milk total solids, as well as milk yields, increase under an OC diet, with a reduction in saturated FAs and an increase in monounsaturated FAs compared to the control [

20,

30,

32]. These authors agree that the addition of moderate amounts of oil by-products to the diets of dairy goats has favourable effects on milk FA composition from the point of view of the human consumer, without negative effects on animal performance. Research also demonstrates a change in fat profile in meat similar to that mentioned in milk, both in ruminants [

18,

30,

31] and Iberian crossbred pigs [

24] and also in fish [

18].

5. Discussion and Concluding Remarks

Intensive dairy production (cows as well as ewes and goats) in the Mediterranean basin is based on imported conventional ingredients included in concentrates. The use of olive by-products in animal feed is growing and the evidence is positive, as the previous section has illustrated [

33]. Nevertheless, such uses are still limited in comparison to low-value uses (energy and compost). According to EUROSTAT, milk production in the EU-28 is around 160 million tonnes, 37% of which goes to produce 9.3 million tonnes of cheese (EU consumption is 18.3 kg/cap). Feeding stuffs and veterinary expenses together accounted for 94.5 million EUR and the EU-28 has an overall self-sufficiency rate of between 58% and 71% for feeding livestock. This could be improved by reducing the EU feedstock dependence and increasing the quality of the animal products (mainly dairy) through the use of olive by-products in ruminant diets.

The compound feed manufacturing industry is an essential element of the production chain for animal products. An aim of the bioeconomy and the circular economy is for operators in the food industry to increase resource-use efficiency (reducing losses) as much as possible. Food manufacturers are encouraged to prioritise animal feed use, although the olive industry has favoured energy use. In the EU-28, the value of meat and other animal products was 170 billion EUR in 2014 (42% of the total value of farm production). Animal feed is the most important livestock production cost factor. Farm animals in the EU-28 are fed 475 million tonnes of feedstuffs. The use of EU-28 olive by-products—which we have estimated (see

Figure 2) at around 13.1 million tonnes (OTPB, OL, OP and OS)—for animal feed can help reduce feeding costs and improve the quality of the resulting animal products (meat and dairy).

Regarding the environmental impact, we have conducted a preliminary estimation based on the ‘Global Livestock Environmental Assessment Model (GLEAM_v2)’ tool [

34]. Assuming that, at a conservative estimate, olive by-products currently make up only 10% of dairy ewes’ diet, the model estimates an 8% saving in GHG emissions. This is only an initial estimation (for ewes in a southern European context) and requires further verification, but the provisional results indicate that the proposed use of olive by-products to feed dairy animals could help combat climate change.

Intensive goat, sheep and cow milk production in the Mediterranean basin is based on imported conventional ingredients included in concentrates. There is an opportunity to apply circular economy and bioeconomy principles in order to produce milk with a lower saturated fat content by using by-products of the olive oil chain to replace conventional ingredients. This would have the double effect of reducing feed costs and improving the quality of milk (and other dairy products) with respect to human health.

We hope that our review supports the design of a strategic approach to implementing bioeconomy principles, based on the biomass value pyramid. In our opinion and as McCormick and Kautto [

35] conclude, “emphasis on an economic perspective and creating public welfare; realising the latent value in biological resources; and a broad, cross-sectoral focus that allows flexible interpretations and enables (possibly) far-reaching impacts”.

This paper takes into consideration the fact that what is fed to animals ultimately determines what humans eat, and that low biomass value uses should be the last resort once the higher values of biomass have been obtained. This would represent an improvement over the present situation in the olive sector. Further research should be carried out for the table olives sector and an additional global economic and environmental analysis of the olive by-products valorisation strategy should be conducted.