1. Introduction

Market development, internationalization, and growing competitiveness have led to the emergence of the so-called Fourth Industrial Revolution and to the parallel development of both the concept of Industry 4.0 and its domain of studies. Industry 4.0 follows three preceding technological transformations: steam power, which was the transformative force of the nineteenth century; electricity, which transformed much of the twentieth century, and the era of the computer beginning in the 1970s [

1].

The so-called Fourth Industrial Revolution is based on the development of a completely automated and intelligent production, capable of communicating autonomously with the main corporate players.

Industry 4.0 is based on the horizontal and vertical integration of production systems driven by real-time data interchange and flexible manufacturing to enable customized production [

2,

3].

The Fourth Industrial Revolution will lead to full automation and digitalization processes, and the use of electronics and information technologies (IT) in manufacturing and services in a private environment [

4].

The McKinsey Global Institute identifies the Fourth Industrial Revolution as the age of “cyber–physical systems”—systems that integrate computation, networking, and physical processes and include a myriad of technologies that span mobile devices, the Internet of Things (IoT), artificial intelligence (AI), robotics, cyber security, and 3D printing [

5].

So “the consequences of the development of technologies such as 3D printing, the online sales services such as car services, medical examinations from home, ordering food directly sent from the store to the refrigerator, and so on, will have a significant impact on changes in small and medium-sized enterprises (SME)” [

4] (p. 2).

According to the visionary work of Schwab [

6], the Fourth Industrial Revolution is evolving at an exponential rather than linear pace that not only changes the “what” and the “how” of doing things, but also “who” we are.

The introduction of Industry 4.0 has brought, and will continue to bring, profound changes in the global economy on variables such as investment, consumption, growth, employment, trade and so on.

Growth and employment are certainly the areas most affected by the introduction of innovations pertaining to the Industry 4.0 domain [

6].

Interestingly, Rüßmann et al. [

7], analyzing the German context, proposed estimated expected growth at various levels with the application of innovations pertaining to Industry 4.0. According to the authors, there will be improvements and important enhancements in productivity (manufacturing sectors by €90 billion to €150 billion), revenue growth (of about €30 billion a year), employment (6 percent increase during the next ten years) and investments (about €250 billion during the next ten years).

The term Industry 4.0 was coined in Germany and was first used in 2011 to identify the new proposal for the German economic policy to come; it was based on high-tech strategies [

8].

This is not surprising because the highest levels of Industry 4.0 implementation can be seen in Germany and especially in multinational technology corporations. Companies such as Siemens, General Electric, and Mitsubishi already possess a broad portfolio of production and automation solutions. “Manufacturing and automation technology developers such as DMG Mori, Wittenstein, Bosch, Rockwell, Omron, Schneider, Stäubli, Yaskawa, Krones, PSI and Software AG already market many technologies and solutions as Industry 4.0” [

9] (p. 195).

Since 2011, this term has been largely used not only in Germany and in the field of engineering where it was first introduced, but also in economic and management domains. Indeed, it radically changes the way firms are structured, and above all managed. However, even though there have been some papers published, above all in management literature, the academic discussion on Industry 4.0, the analysis of its content and its detailed description as well as the explanation of its possible future developments deserve more attention [

10]. Even though this paper will illustrate the definitions created by various authors, it seems appropriate at this stage to recall just two of them to create a shared understanding about the domain in which this study is grounded. Pan et al. [

10] (p. 1537), for example, state that “Industry 4.0 represents the ability of industrial components to communicate each other’s”, while Kovacs et al. [

11] (p. 122) affirm that “the essence of Industry 4.0 conception is the introduction of network-linked intelligent systems, which realize self-regulating production: people, machines, equipment and products will communicate to one another”.

To date, some papers have been published, above all in management literature, studying the main changes in business management models and firms’ main components. The academic discussion on Industry 4.0, the analysis of its content and its detailed description as well as the explanation of its possible future developments deserve more attention [

12]. The topic of Industry 4.0 is therefore still under-studied, although research in this domain has rapidly developed [

13,

14,

15], above all in the last three years (see

Section 3.1).

Two literature reviews [

16,

17] have also been published in this domain but neither of them focused on managerial aspects or on only the development of managerial topics, thus this subject still remains understudied.

As a consequence, the aim of this paper is to start filling this gap, focusing on the main contributions published on Industry 4.0 in management literature, seeking to give a unique definition from a managerial point of view, identifying the principal themes studied through a systematic review of the literature to identify future avenues of research.

Therefore, the following research questions can be put forward:

- –

How can Industry 4.0 be defined from a managerial point of view, based on definitions published so far?

- –

What are the main topics developed in management literature on Industry 4.0 so far? And which issues have been more developed within them?

- –

What are the main research gaps in management literature and how could future avenues of research be shaped?

The paper begins with a description of the methodology adopted for the systematic literature review. Then the evidence of the review will be outlined and the results will follow together with the discussion. The paper ends with the conclusion, which encompasses contributions and limitations of the study.

2. Methodology

The systematic literature review methodology evolved in the field of medicine in order to improve research performance and the quality of review processes; it could also inform government bodies more precisely in order to improve health system interventions [

18,

19]. For these reasons, the same method was selected and applied to managerial studies [

20,

21] and was chosen as the research methodology for the present paper which maintains the same principles and applies the three main steps of planning, execution and reporting suggested by Tranfield et al. [

22]. The systematic literature review was conducted between 4 April and 7 July 2018.

The analysis was articulated by a series of steps (described below) that allowed the construction of a database containing all the characteristics of the selected papers. From the database, it was possible to elaborate the information, using various points of view. This provided a complete picture of the characteristics of the international literature on Industry 4.0.

Figure 1 shows the entire review process.

The research began by identifying three scientific databases (Scopus-Elsevier, the Web of Science—WoS; JStor) and one search engine (Google Scholar) from which the papers were extracted, following a rigorous pre-established research scheme of subsequent analysis (see below). The databases were selected considering those mainly used internationally in management studies [

20] and also selected by online libraries of major universities. These databases proved to be the most complete in terms of the collection of scientific publications and provided a great combination of variables, useful to perform the systematic literature review. Many international publishers and journals index their contributions on these databases. The Google Scholar search engine was also added to the first three sources because it is the main free tool for academic research that has expanded its research equipment in recent years [

20].

In the case of the three databases considered, only one keyword (Industry 4.0) was chosen to select the papers, in order to keep the results of the research as broad as possible.

The filters in the various databases were then used to limit the research to the topic under analysis.

The research done through the Google Scholar search engine deserves a special mention.

In fact, Scholar is a search engine and not a database, so it does not allow precise identification and selection of research characteristics. To enable its use as a database, we used the Publish or Perish 12 software, which allows the use of Google Scholar resources in a form that allows the setting of specific filters and search options. In this way, it was possible to follow the steps of the research, subsequently described, also for Google Scholar, thus standardizing the methodology for all four sources.

The first search was performed using the keyword “Industry 4.0”. The results that emerged in the various databases are shown in

Table 1.

The second phase allowed the selection of only the themes on Industry 4.0 following a managerial approach or contributing in some way to firm literature. In particular, contributions were selected using the following filters:

- –

Scopus: business, management, accounting, social science, economics, econometric, and finance.

- –

WoS: business finance, operations, research management science, social sciences mathematical methods, management, behavioral sciences, economics, and business.

- –

JStore: business, economics, management, and organizational behavior.

- –

Google Scholar: business and management.

The results that emerged in the various databases are shown in

Table 2.

From the pre-selected papers, we decided to focus on contributions that responded to three characteristics:

- –

peer-review published papers;

- –

articles in international journals;

- –

papers written in English.

These characteristics excluded papers that could have less scientific rigor, such as monographs, book chapters, conference proceedings, etc. (See

Table 3).

The 495 papers, selected from all sources during the various phases of the above research, were then analyzed by reading the abstract according to the chosen “fit for purpose” method—all those articles whose abstract content was substantively relevant were included in the review. This phase allowed the final selection on which the results of the review presented in the next paragraph were then elaborated (n = 88).

Finally, any duplicate papers in multiple search engines were eliminated (see

Table 4).

The overall scheme of the research is shown in

Table 5.

The 68 selected papers were downloaded from the respective databases, archived and classified, creating a special Excel sheet to study their scientific characteristics. This was made possible by carefully reading all the papers, retrieving all useful information and also looking at their references to better understand the domain in which each study was grounded.

The final database includes information such as type of author (single author or collaboration); theme (see below); type of paper (conceptual or empirical); design; type of research performed (quantitative, qualitative); applied methodology (case study, survey, literature review, etc.); unit analyzed (firms, manager, others). Through this database, it was possible to classify the contributions analyzed and identify the main topics already covered in the field of Industry 4.0 from a managerial point of view.

3. Results

The analysis of the results was divided into four sections.

In the first, the characteristics of the papers were analyzed, while in the second the methodological aspects of the papers were studied. The third section focused on the analysis of the main definitions provided by the various authors on Industry 4.0. Finally, papers were classified, identifying the main themes studied in management literature, in order to understand the research orientation and the main observation lenses used by scholars. This indicates the existing gaps in literature and identifies future avenues of research in the Industry 4.0 domain.

3.1. Characteristics of the Papers

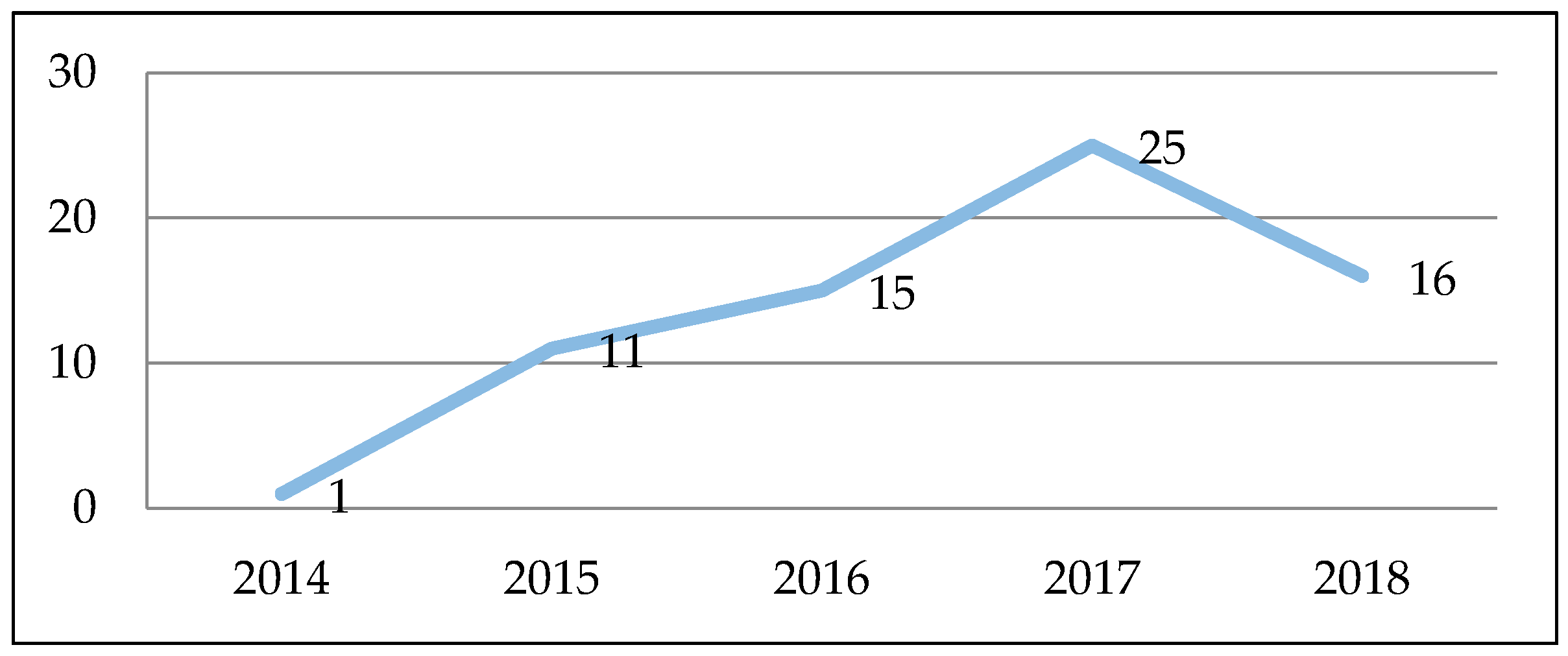

The database of results allowed the extrapolation of some interesting information, even at a general level. First of all, one notices that the topic of Industry 4.0 has very recently gained momentum and over recent years the interest of scholars concerning its different aspects has grown rapidly (see

Figure 2).

Obviously, the 2018 data is still incomplete, so a lower number of publications than the previous years does not seem so significant, because the research was carried out in the middle of the current year (see

Section 2).

Looking at journals in which papers were published, it is clear that they are numerous and more than one article was published in only some of them (selected in bold in

Table 6).

Table 6 shows the entire journal list hosting the 68 papers that make up the sample resulting from the literature review.

One can see that the journals with greater relevance to the aim of this paper, also containing a greater number of published papers, are the following:

- –

Entrepreneurship and Sustainability Issues;

- –

IFAC-PapersOnLine;

- –

International Journal of Innovation Management;

- –

International Journal of Production Research;

- –

Journal of Ambient Intelligence and Humanized Computing

- –

Journal of Industrial Engineering and Management;

- –

Journal of Security and Sustainability Issues;

- –

Sustainability;

- –

Technological Forecasting and Social Change;

- –

ZWF Zeitschrift Fuer Wirtschaftlichen Fabrikbetrieb (the title is in German language but in it papers are published in English).

Looking at the journals hosting the sample of the papers analyzed, it is possible to identify some main topics already studied in management literature concerning Industry 4.0.

In particular, a clear link between Industry 4.0 and the theme of sustainability emerges, highlighted by six papers in three journals dealing with this topic (Entrepreneurship and Sustainability Issues [

23,

24], Journal of Security and Sustainability Issues [

25,

26], Sustainability [

27,

28])—8.82% of the entire sample. Furthermore, the close link between management and engineering in papers focusing on Industry 4.0 appears to be relevant (i.e., Journal of Industrial Engineering and Management [

4,

29,

30]); this underlines the interdisciplinary nature of the topic.

Looking more in-depth at

Table 6, it is worth highlighting that International Journal of Production Research hosts eight papers representing more than 11% of the paper sample analyzed. Looking at the aim of the journal, it is clear that it hosts mostly papers on production methods, manufacturing strategy and processes, innovation management, etc. For this reason, it is clear that it is a perfect outlet for papers on Industry 4.0, especially focusing on production methods (4), supply chain (1), information systems supporting production processes (1), and two conceptual papers designing the state-of-the-art of this subject and peculiarity of Industry 4.0 in SMEs (Small Medium Enterprises). Indeed, Industry 4.0 was first associated to full production automation and full digitalization processes [

4].

Going into detail on the characteristics of the various papers, the first observation that emerges is that relating to the number of authors of each paper and their origin (

Table 7).

The greatest number of contributions derives from collaborations between two or three authors (56%) even if a good percentage of the sample is made up of papers written by just one author. Papers written by more than four authors (5, 6, or also 7 researchers) are common for research carried out in the engineering field, as emerged from a previous analysis of the journals in which papers where retrieved.

The total number of authors is 176, considering the 68 selected contributions.

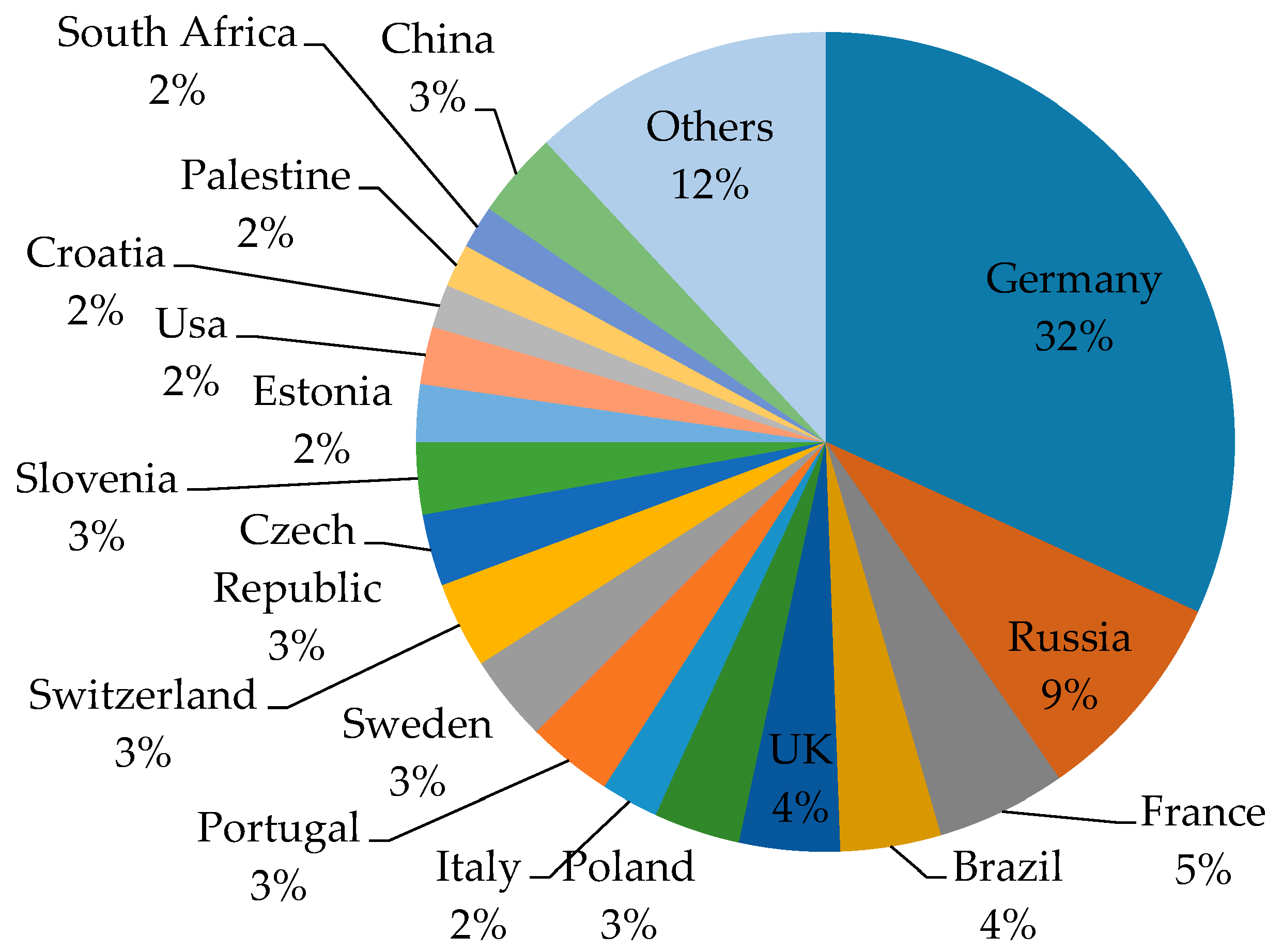

Considering their geographical origin, as shown in

Figure 3, there is a strong predominance of German authors (32%).

This aspect was expected since, as stated in the introduction, the theme of Industry 4.0 as well as its name initiated in Germany.

These data are also confirmed by the distribution of the authors not only on the basis of their geographical origin, but also in relation to the position taken in the paper. Supremacy always belongs to Germany, as is shown in

Table 8.

3.2. Methodological Aspects of the Papers

After looking at the general characteristics of the retrieved papers, the methodological approaches adopted in the papers will be analyzed. The first distinction that appeared important concerns the basic methodological approach adopted, which allows the separation of empirical contributions from purely conceptual ones.

Among the 68 contributions selected in this systematic literature review, 54% (37 papers) are conceptual papers, while the remainder are empirical papers (46%, 31 papers). It can be said that Industry 4.0, as a recent topic, was initially studied from a conceptual and/or theoretical point of view, while in more recent years empirical contributions have become quite numerous (see

Figure 4).

Looking at the conceptual papers in detail, one notes that they are based on various research designs:

- –

Literature review (20 papers, 54%);

- –

Construction of a model or a framework (15 papers, 41%);

- –

Systematic literature review (2 papers, 5%).

The two papers [

16,

17] presented as systematic literature reviews are of particular interest given the aim and methodology of this study which is,

per se, a systematic literature review on Industry 4.0 focused on management literature.

From this analysis, it emerges that in both papers the review settings are substantially different from the present research.

In both cases, contributions considered were published not only in journals, but in all kinds of sources, for example, conferences, workshops, online texts, etc. This means that papers of all quality are included and not only contributions which have passed a peer-review process. Even though with a new subject to study, it is convenient to consider all kinds of publications to really understand the domain and boundaries, today, a more structured and rigorous literature review appears necessary.

In addition, many research areas are included in the previously published reviews, unlike the present work which restricts analysis to a purely business and managerial vision, better defining its domain and boundaries.

Given these characteristics, this work can be considered original at least in the management field.

Looking at empirical papers more carefully, different research designs can be found:

- –

qualitative, found in 17 articles (55% of the sample);

- –

quantitative, present in 14 selected articles (45% of the sample).

Looking in greater depth at methodologies adopted in both approaches, it is possible to affirm that for qualitative approaches, case study methodology is applied in 16 papers (94%) while the remaining papers are based on interviews (6%).

In quantitative papers, various tools have been used by authors such as questionnaires, 11 contributions (79%) and descriptive statistics in the remaining three papers (21%). The main tool used is therefore the questionnaire, often sent by mail, which, in most cases, provides a good number of answers enabling rapid access to results. Moreover, looking more in-depth at empirical papers, even if most of them use questionnaires, only in two cases does their number exceed 200 and all of them use no-probabilistic and/or no significant samples. Most of these studies were carried out in single countries (i.e., Brazil, Turkey, Czech Republic, UK, Germany, and Belgium), while only three papers propose a study among several countries (i.e., Czech and Slovak Republic; USA, Japan, and Germany in the automotive industry; South African countries).

The targets of the questionnaires were as follows: firms (8 paper, 73%); managers (1 paper, 9%); SAP consultants (1 paper, 9%); and supply chain managers (1 paper, 9%).

3.3. The Definitions of Industry 4.0

Given the state-of-the-art of Industry 4.0 studies in management emerging from this literature review, it appears important to focus on the definition of this domain of analysis, starting with the study of definitions already published and retrieved.

Giving a clear definition of the research domain can be of help in circumscribing the management domain under analysis and avoiding the inclusion of inappropriate issues in the analysis. Indeed, in the papers retrieved, various terms, synonyms, and definitions have been proposed, without a consensus having been reached by scholars.

In fact, the existence of similar terms such as the “Internet of Things”, “Industrial Internet”, or related issues named as “Smart Factory” or “Human-Machine-Cooperation” did not facilitate finding a common understanding of what really constitutes the next level of the industrial revolution, i.e., Industry 4.0 [

31].

What is surprising is that in 54.4% of the sample papers no definition of the subject studied, Industry 4.0, is given. On the contrary, 31 out of 68 selected articles (46% of the sample) propose a precise definition of the topic and/or insert one or more definitions created and/or adopted by other scholars.

Carefully reading them, also considering the context in which these definitions were created and/or applied, it has been possible to classify them into different categories that highlight the main domain in which they are found (

Table 9).

The first category, the most numerous, includes all the definitions of Industry 4.0 examining in-depth the details of the components of Industry 4.0 and/or some technical peculiarities linked to this topic, sometimes also describing some key concepts related to Industry 4.0 (for example, IoT, ICT, Cyber–Physical Systems, etc.).

In this category, for example, Alekseev et al. [

37] (p. 3) provide a general definition of Industry 4.0 affirming that “Industry 4.0 is the totality of the spheres of economy in which the fully automatic production processes are based on the artificial intellect and the Internet create new machines without human participation”.

In the same way, Pan et al. [

10] (p. 1537) state that “Industry 4.0 represents the ability of industrial components to communicate each other’s” and Kovacs et al. [

11] (p. 122) affirm that “the essence of Industry 4.0 conception is the introduction of network-linked intelligent systems, which realize self-regulating production: people, machines, equipment and products will communicate to one another”.

Burritt and Christ, [

39] (p. 27) propose considering Industry 4.0 as “an umbrella term used to describe a group of connected technological advances that provide a foundation for increased digitization of the business”.

Sanders et al. [

29] (p. 816), on the other hand, introduce the theme of the impact of Industry 4.0 on production dynamics and state that “Industry 4.0 significantly influences the production environment with radical changes in the execution of operations. In contrast to conventional forecast based production planning, Industry 4.0 enables real-time planning of production plans, along with dynamic self-optimization”.

Other authors, embracing a different approach and going into more detail, deepen the concept of Industry 4.0 by introducing its tools and/or some related issues and/or concepts that are part of the Industry 4.0 general domain, seeking to improve the understanding of it and, above all, the links with other topics of interest, not only at a managerial level but also at both engineering and information technology levels. For example, Prause et al. [

24] (p. 423), in accordance with the previous definition proposed by Kagermann et al. [

53], confirm that “Industry 4.0 represents nothing less than the fourth industrial revolution, comprising 3D printing, Big data, Internet of Things, and Internet of Services, i.e., all the ingredients needed to facilitate smart manufacturing and logistics processes”.

Among the various issues and/or concepts and/or tools used in this kind of definition, the most retrieved concepts are those of Big Data [

32,

34,

36] and Cyber Physical Systems (CPS) [

30,

32,

39].

The second category of definitions focuses on value creation and the structure of the value chain. The value chain can be understood as the description of “the full range of activities which are required to bring a product or service from conception, through the different phases of production (involving a combination of physical transformation and the input of various producer services), delivery to final consumers, and final disposal after use” [

54] (p. 4).

The various definitions retrieved from the selected papers, thanks to this literature review, underline how innovations introduced by the fourth industrial revolution, i.e., Industry 4.0, globally influence all business processes and dynamics, not least the firm business model (which will be discussed later, see

Section 3.4). For example, Kinzel [

41] (p. 70) affirms that “Industry 4.0 is the new buzzword in the manufacturing industry. It comprises the entire value chain process in manufacturing goods and providing services”.

Moreover, Prause et al. [

24], embracing the view proposed by Koether [

55] (p. 583) on the impact of Industry 4.0 on the value chain and combining several definitions provided by other authors, affirm that “Industry 4.0 will deliver greater flexibility and robustness and Industry 4.0-related value chains will be built of flexible and adaptable business structures, possess the permanent ability for internal evolutionary developments in order to cope with a changing business environment”. Clearly, both authors consider the technical aspects of innovations introduced with the Fourth Industrial Revolution as suggested by Kagermann [

26] but also take into account the possible implications in terms of value creation suggested by Koether [

32].

The third category introduces the definition of Industry 4.0 as linked to the “Smart factory” concept, which is quite different from the previous category of definitions (see above) and which has been considered alone in this classification. Indeed, “a Smart Factory is a manufacturing solution that provides such flexible and adaptive production processes that will solve problems rising on a production facility with dynamic and rapidly changing boundary conditions in a world of increasing complexity” [

56] (p. 1197). Smart factories are strictly connected to production methods and industrial processes and can offer the opportunity, if considered separately from tools and/or other related issues and/or concepts falling in the previously recalled definition, for further considerations which will also be discussed in

Section 3.4.

Preuveneers et al.’s [

46] (p. 1) definition, falling within this category, underlines the potential and benefits of introducing innovations pertaining to Smart Factories, stating that “these technological revolutions will transform production and logistic processes into smart factory environments that will increase productivity and efficiency”. In the same vein, Weyer et al. focus their attention not only on tangible assets and/or manufacturing-related mechanical processes, but also on the role of consumers and competitors and state that Industry 4.0 “is a synonym for the transformation of today’s factories into smart factories, which are intended to address and overcome the current challenges of shorter product lifecycles, highly customized products and stiff global competition” [

48] (p. 579).

The fourth category of definitions introduces the concept of competitiveness, linking it to innovations and the evolution of Industry 4.0, but gives it different interpretations.

Navickas et al. [

49] define Industry 4.0 as a necessary tool to maintain the competitiveness of firms; they seem to suggest that Industry 4.0 is a must, just to maintain competitiveness.

Gerlitz [

23] on the contrary, considers Industry 4.0 an innovative tool to generate business competitiveness, pointing to its value as a critical success factor for the development and strength of firms as a whole.

Finally, Müller et al. [

43] explicitly add the temporal factor to this stream of definitions, stating that Industry 4.0 allows safeguarding the competitiveness of firms in the long term. This temporal perspective suggests embracing a strategic focus to study Industry 4.0. In any case, it is clear that for the authors, attention to Industry 4.0’s external context and its implications, is very relevant.

The fifth category is linked to the previous one, but explicitly puts the formulation of strategy, even if at a governmental level, at its core and not only considers the long-term perspective necessary to understand the implications of Industry 4.0.

According to the authors, before any other consideration, Industry 4.0 represents a managerial strategy. Indeed, Johansson et al. [

51] (p. 282) consider that “a current example of the technological development is presented in Industry 4.0, a strategy shaped by the German government in 2013” whereas Strange et al. [

50] (p. 174) propose an evolution of the definition of Industry 4.0, affirming that this “is a term reputedly first used to describe a high-technology strategy proposed by the German government, and is now commonly used to refer to the development of cyber–physical systems and dynamic data processes that use massive amounts of data to drive smart machines”.

The last category, the sixth, pays specific attention to single terms used as synonyms of Industry 4.0 and encompasses only papers on “Internet of Things”, the most frequently used synonym for Industry 4.0.

Kiel et al. [

57] (p. 2) in accordance with some previous definitions [

53,

57,

58] affirm that “Industry 4.0, which is internationally also known as the Industrial Internet of Things, refers to the integration of Internet of Things technologies into industrial value creation enabling manufacturers to harness entirely digitized, connected, smart, and decentralized value chains”. As a matter of fact, this definition seems to take into account not only the Internet of Things but also most concepts and/or issues considered in the previous categories of definitions, identifying the so-called “fil rouge”.

Kiel et al. [

40] are not the only authors to consider the Internet of Things and Industry 4.0 as synonyms, as highlighted by Müller et al. [

43], citing Hartmann and Halecker and also Hossain and Muhammad [

59,

60]. However, this does not really appear correct or fully representative of the complexity of Industry 4.0, even if it is true that Industry 4.0 is based, at least in part, on the Internet of Things.

Indeed, the Internet of Things “is a novel paradigm that is rapidly gaining ground in the scenario of modern wireless telecommunications. The basic idea of this concept is the pervasive presence around us of a variety of things or objects—such as Radio-Frequency IDentification (RFID) tags, sensors, actuators, mobile phones, etc.—which, through unique addressing schemes, are able to interact with each other and cooperate with their neighbors to reach common goals” [

61] (p. 2787).

The authors affirm also that “the very first definition of IoT derives from a Things oriented perspective”. Moreover, the Internet of Things term was attributed to “the Auto-ID Labs, a world-wide network of academic research laboratories in the field of networked RFID and emerging sensing technologies” [

61] (p. 2788).

More recently, Atzori et al. [

62] (p. 137) have proposed an updated definition of IoT, stating that this is “a conceptual framework that leverages on the availability of heterogeneous devices and interconnection solutions, as well as augmented physical objects providing a shared information base on global scale, to support the design of applications involving at the same virtual level both people and representations of objects”. Therefore, IoT can be considered an aspect of Industry 4.0 but not exactly a synonym.

3.4. The Main Topics Aready Studied in Industry 4.0 Managerial Literature

Analyzing in-depth the 68 papers of the sample, it was possible to track them back to 10 different areas on which contributions were focused to understand the managerial, strategic, business and/or organizational aspects already studied in management literature (see

Table 10).

The first theme that emerges from the papers analyzed is linked to production methods.

This result was quite expected given the already mentioned impact of Industry 4.0 on the manufacturing domain.

Indeed, Industry 4.0 stems from the interaction between physical reality and virtual reality and is intended to change the way today’s societies produce, consume, and live [

95].

Industry 4.0 (as emerged from the analysis of the definitions, see

Section 3.3) necessarily involves a radical change and innovation in manufacturing methods.

The most investigated implications in the field of manufacturing are, for example, details of the new production methods [

35,

57,

67,

69]; integration of companies, suppliers, and customers [

34,

46,

65]; lean production [

29,

42]; new qualification of workers [

48]; new managerial practices [

38]; and logistics processes [

11].

The second theme emerging from the literature review is the study of new business models.

The most significant contributions in this area investigated the impacts of the new technologies introduced by Industry 4.0 on the creation and/or adaptation of new or existing business models [

36,

37,

39,

40,

54,

55,

56,

57]. One of these contributions, interestingly, refers to SMEs [

43] for which Industry 4.0 represents an even greater challenge, due to the reduced size; SMEs are also considered in a different cluster of studies (see

infra).

Papers focusing on strategy are, in most cases, dedicated to investigating the existence and awareness in firms of the need for appropriate strategies for the development and application of Industry 4.0 tools and issues [

25,

36,

43,

73,

74,

75,

76,

77].

In this context, the paper proposes an already created framework for formulating a firm financial strategy [

37], linking its value to the assumption that the financial basis is necessary for the development of Industry 4.0 in developing countries.

Regarding the impacts and consequences of Industry 4.0, almost all papers remain at a general level of discussion [

9,

17,

79]. Only one paper explains the impact of Industry 4.0 in terms of value creation [

78], another focuses on product-service systems and finally an author [

80] investigates the consequences of Industry 4.0 in Turkey [

44]. In particular, Sener and Yuksel [

44] list the main benefits of the application of Industry 4.0. The most relevant are the following: digital individualization, firm flexibility, demand orientation, sustainability, consistent process, automated knowledge and learning, and productivity optimization. The authors also state that there is still no full firm awareness of the impacts of Industry 4.0, so it is necessary to spread awareness and knowledge of the great opportunities which it could introduce. What is interesting is that none of the papers analyzed in this systematic literature review, apart from the ones focusing on SMEs [

4,

31,

68,

69], identify strengths or weaknesses or the negative fall-outs of Industry 4.0, obviously overestimating the benefits of Industry 4.0, as commonly occurs with a new approach.

Human resources, the “soft” side of organizations, were also studied referring to the Industry 4.0 domain. In this context, all authors confirm the need to observe the role and changes of people. Indeed, although this aspect could even be considered secondary, it is of crucial importance for the correct implementation of Industry 4.0 and therefore the expected performance of firms. The retrieved papers focus on new skills required by enterprise personnel to operate in the new technological field [

82,

84,

86], not only staff but also managers [

85] and also focus on the important motivation of the staff involved [

41,

83]. Obviously, given the imprinting of the authors’ proposed definition (see

Section 4) which puts strategy at the very core of the Industry 4.0 definition, the different mind-set, orientation, openness and skills of top management are crucial and surely deserve more attention in literature.

As far as SMEs are concerned, papers are focused on two main topics.

Firstly, the management of Industry 4.0, as well as the introduction of the innovations and technologies to be included in it in SMEs to grasp potential opportunities are considered [

88,

89]. Secondly, papers focus on the main problems encountered by SMEs in relation to the introduction of Industry 4.0 [

4,

30,

87,

90], also questioning whether Industry 4.0 could victimize SMEs due to the difficulties SMEs could encounter in Industry 4.0 implementation, with poorer results than expected [

4].

Papers dealing with the supply chain in the context of Industry 4.0 can be classified into two different clusters. The first encompasses papers dealing with the main innovations and changes brought about by the advent of the Fourth Industrial Revolution, how these can contribute to solve typical agency problems within supply networks [

16,

32] or the need for Industry 4.0 innovations to be integrated into the business context, in order to guarantee its survival in the new digital era [

33].

The second cluster focuses on the influence and/or impact of Industry 4.0 on the firm supply chain, also looking at the main changes required to comply with Industry 4.0 requirements [

12,

91,

92].

In relation to the theme of sustainability, the identified papers report in-depth analyses concerning only two of the sustainability pillars found in literature: environmental and economic [

96,

97,

98].

Environmental sustainability must be carefully considered when innovations introduced by Industry 4.0 are studied. In this context, the retrieved papers underline, for example, that “the implementation of the industry and the development of a network of paradigms based on complex and intertwined manufacturing networks with changed roles of designers, physical product suppliers, clients and logistics service providers during their entire life-cycle” [

24] (p. 423) requires careful investigation of the relationships between networking, organizational development, structural frame conditions, and sustainability in the context of Industry 4.0.

In this same vein, Sousa [

93] (p. 18) identifies eleven critical success factors that should be carefully managed when introducing Industry 4.0 and environmentally-sustainable manufacturing (i.e., management leadership, readiness for organizational change, top management commitment, strategic alignment, training and capacity building, empowerment, teamwork, organizational culture, communication, project management, national culture, and regional differences). He then suggests that “productive synergy between Industry 4.0 and environmentally-sustainable manufacturing relies on understanding the role played by eleven critical success factors, which organizations should consider carefully when implementing Industry 4.0 and environmentally-sustainable manufacturing”.

Apart from environmental sustainability, economic sustainability has also been studied in the Industry 4.0 domain [

24,

39,

47]. In the three papers retrieved dealing with economic sustainability, all authors focus on the relationship between the implementation of Industry 4.0 and the related costs emerging from the firm’s adaptation to the new tools and/or processes and/or dynamics introduced seeking to understand their mutual influence and/or impact.

The last two topics considered by the papers of the sample extracted from the systematic literature review are Information Systems and Social Innovation.

Regarding the first, some authors [

94] focus on the need to model the business information systems and adapt them to the new data provided by Industry 4.0 (such as Big Data). In fact, it is fundamental to effectively integrate a large variety of devices and new services into existing systems to manage data, transform it into knowledge, and make smart automated decisions, hopefully rapidly.

In the Social Innovation domain, on the other hand, scholars proposed a framework able to facilitate the interaction between technological and social innovation. The perspective proposed in this research is very interesting because it combines the innovative and technological aspects of Industry 4.0 with the social perspective and at the same time takes into account sustainability issues. Morrar and Arman [

45] (p. 18) affirm that “the social revolution demonstrates the diffusion of social innovation, and vice versa. The technological revolution that accompanies the Industry 4.0 achieve its true potential in combination with social innovation in Industry 4.0 will be those that offer both social progress and economic benefits”—a topic surely deserving more attention in future studies.

4. Discussion

The first insight that appears clear from the present literature review is that Industry 4.0 is a cross-cutting theme of many disciplines that influence each other. From the analysis of the papers, it emerges that it is very difficult to find a research paper purely dedicated to the managerial and business aspects of Industry 4.0 because in every paper the business aspects blend with those pertaining to technical engineering, ICT, or sustainability. This, on the one hand, can be understood as the richness of the topic, but on the other leaves many aspects understudied or absolutely unexplored in the firm domain pertaining to the Fourth Industrial Revolution. Moreover, this seems quite expected in that Industry 4.0 is still a new subject of study and as such each discipline has yet to define its boundaries.

However, it can certainly be said that some aspects of Industry 4.0 that have already been studied, like the more technical ones, enjoy greater detail in literature, i.e., production methods, rather than other issues which still deserve more attention, for example, strategy, business models, sustainability, human resources, social innovation, etc., as will be discussed later in this section, answering the third research question which focuses on this issue.

The first research question put forward in the introduction of the paper was the following:

RQ1. How can Industry 4.0 be defined from a managerial point of view, based on definitions published so far?

As previously stated (see

Section 3.3), there is no consensus about the definition of Industry 4.0. In other words, quite a lot of definitions have appeared in literature focusing on various issues, but none of them put managerial aspects at their very core, nor is there consensus about tools and/or issues and/or processes necessary to clearly define the boundaries of Industry 4.0.

Indeed, in some cases, a misunderstanding may emerge about this industrial change domain and boundaries and/or a distorted representation of Industry 4.0 based on both different definitions and/or synonyms used. The latter is the case, as already mentioned, of “Internet of Things”, for example, used as a synonym of Industry 4.0 [

53,

57,

58]. Indeed, as already stated, IoT should instead be considered as an instrument of Industry 4.0, as suggested by most of the papers identified in this review (see

Section 3.3).

At the same time, in the authors’ opinion, given the complex puzzle of definitions emerging from the literature review, it is necessary to find a fairly broad definition of the concept able to encompass at least both the main aspects of Industry 4.0 and indicate how firms could benefit from it in terms not only of value creation—all this not forgetting that these positive fall-outs are the result of a correctly implemented purposely formulated strategy.

Therefore, in the authors’ opinion, a more comprehensive definition of Industry 4.0 can be formulated based on previous ones and focusing on the role of strategy:

“Industry 4.0 refers to the integration of Internet of Things technologies into industrial value creation enabling manufacturers to harness entirely digitized, connected, smart, and decentralized value chains” (Prause [24] (p. 423) able to “deliver greater flexibility and robustness to firm competitiveness and enable them to build flexible and adaptable business structures, [acquiring] the permanent ability for internal evolutionary developments in order to cope with a changing business environment” (Koether [55] (p. 583), “as the result of a purposely formulated strategy implemented over time”.

This definition combines some technical aspects with the positive fall-out of its implementation, but above all considers that the first must be purposely introduced and/or created within the firm and thoughtfully combined to produce the positive fall-out expected. This can only be produced if a correct strategy is formulated and implemented considering all aspects of the firm, not only the manufacturing or productive ones but also, for example, the financial ones as highlighted for SMEs [

37]. Considering Industry 4.0 as such clarifies why this term is synonymous with the Fourth Industrial Revolution. Indeed, previous industrial revolutions started by changing the way to produce goods, but to make firms efficient and effective again and enhance their performance it was necessary to entirely reshape the firm, from its very roots. Furthermore, new theories and business models emerged over time completely changing the focus of firms and the sources of their competitive advantages as well as their orientation to market. Therefore, Industry 4.0 is just at the very beginning in its role changing the way firms create value, gain competitiveness, become successful, formulate strategies and implement them. At the same time, firms will change relationships with the environment, completely modifying it and becoming modified by it; changing internally and externally together with the environment firms would give, once again, their innovative contribution to completely reshape societies, in that the innovation locus of societies relies on firms [

99,

100,

101].

This explains why a different definition of Industry 4.0, at least in management studies, is necessary to clarify that to contribute and make profit from it, firms should be ready to change from the very top down to their roots. This should begin with a different mind-set at board level, but should also include different skills and capabilities able to design strategies in a different and ever-changing frame, creating other capabilities, tools, processes, and combinations of them, to ensure good strategy implementation involving the entire firm, starting with people working within it—this is absolutely necessary.

Given the above, it is not surprising that among the eleven components identified by Sousa et al. [

93] for the successful implementation of Industry 4.0 and environmentally-sustainable manufacturing, the first is management leadership followed by readiness for organizational change, top management commitment, strategic alignment, training and capacity building, empowerment, teamwork, organizational culture, communication, project management, national culture, and regional differences. This confirms that Industry 4.0 will produce a profound change in firms and this change should consider sustainability issues, still understudied in literature. Indeed, the role of top management, leadership style, competences, and skills represents a domain in which more contributions are needed, together with the area of human resource management that is still an understudied topic; in this specific area, however, some studies can be retrieved in the management literature related to Industry 4.0 [

41,

82,

83,

84,

85,

86].

RQ2. What are the main topics developed in management literature on Industry 4.0 so far? And which issues have been more developed within them?

Regarding the second research question above, this review further investigated and classified the main topics dealing with Industry 4.0 (for details on the results, see

Section 3.4).

Given the results, it can be said that Industry 4.0 is still a recent topic, at least in management studies. As highlighted above, contributions only in very recent years used empirical methodologies, while the percentage of conceptual papers has diminished over the same period. Moreover, retrieved papers mostly focus on the more obvious aspects introduced by Industry 4.0 (i.e., changes in production methods), leaving great and interesting spaces to be further and/or better explored in this domain.

The state-of-the-art of management studies emerging from this systematic literature review highlights that at the present time the managerial literature on Industry 4.0 is still heavily affected by the influence of manufacturing also encompassing its technical and/or engineering aspects. Indeed, there are numerous technical studies found in the analysis of literature where the management side of the paper represents just a “small or null part” of the investigation or of the implications discussed. This appears quite predictable in that the topic is quite new and as in all previous Industrial Revolutions the starting point must be found in techniques, tools, processes, innovations, etc., all falling more within the engineering side of the firm.

Few contributions go into any detail on issues concerning the pure management and governance of firms, all without a comprehensive approach which is absolutely necessary in management studies (i.e., impact and changes in human resources [

41,

71,

82,

83], sustainability issues [

24,

39,

47,

93], social innovation lens [

45]), but again Industry 4.0 is a stream of literature taking its first steps in management literature.

Moreover, the empirical studies have been developed, in most cases, in a single country, analyzing small samples (see

Section 3.1). Therefore, further studies are also needed in these domains using representative and/or probabilistic samples, cross-country studies in specific industries—the automotive sector has been investigated in only three countries so far [

75]—and, after some years also with longitudinal studies to be started as soon as possible.

Given the above picture emerging from the systematic literature review, it is now possible to complete the answer to the third research question about the gaps in literature, proposing some future avenues of research.

RQ3. What are the main research gaps in management literature and how could future avenues of research could be shaped?

Apart from the gaps and future avenues of research that emerged from answering the previous research questions, some other areas from a management point of view are of particular interest in the Industry 4.0 domain.

In particular, strategy literature on Industry 4.0 is still at an early stage; until now, most of the papers have investigated the existence and awareness in firms of the need for appropriate strategies for the development and application of Industry 4.0 tools and issues (see

Section 3.4). Future studies should establish whether new approaches, skills, capabilities, etc., could be of help in formulating a successful strategy in firms embracing Industry 4.0. This could be studied not only at a general level but considering single sectors and also comparing them, seeking to identify common points and peculiarities able to support boards and also managers in their decisions. Obviously, this should probably also be reflected in different tactical and operational decision-making processes and outcomes at all levels within the firm, and not necessarily following a top-down path. As in previous revolutions, by starting this industrial revolution from the bottom, different organizational relationships could emerge, reshaping organizational structure and/or functioning. All of these aspects need to be studied more in-depth not only from a theoretical point of view, but above all using empirical methods in order to help discover the relationships between the different issues relevant to firm management, as well as their interplay and comprehensive impact on firm performances at all levels.

This area is linked two-fold with the business model stream of research, which certainly deserves further attention, even though some studies have started to identify some of its main issues. Future studies should consider more aspects and above all propose new business models able to help managers on their way to Industry 4.0 and its potential benefits. In this stream of literature, the transition processes to Industry 4.0 should also be studied more in-depth, in that a lot of issues must be managed to complete the transition and fully profit from it. In this domain, weaknesses or threats linked to and/or emerging from the implementation of Industry 4.0 should also be identified and potential solutions and/or ways to by-pass and/or mitigate them should be suggested. Indeed, in none of the papers selected in this systematic literature review have scholars focused on the “dark side” of Industry 4.0 but have just highlighted its advantages, positive fall-outs, and benefits. This picture appears quite partial in that each change, even though positive, when considered as a whole brings some problems, threats, issues to be solved, etc., that have still not been identified in Industry 4.0 management literature.

The transition to Industry 4.0 is very challenging and sustainability issues must be considered as a part of it, in that Industry 4.0 and sustainability are linked two-fold. This relationship could also be a very interesting topic for further investigation. As highlighted in the results section, only economic and environmental pillars have been investigated until now and not in a joint manner. Therefore, there is much scope for more contributions to further consider the two economic and environmental pillars that have already been taken into account, as well as the third pillar of sustainability, the social aspect of it. At the moment, the latter, as well as the mutual relationships between the three pillars of sustainability and Industry 4.0, have been totally neglected.

Moreover, the topic of social innovation also deserves more attention, although there was one paper considered by the present systematic literature review [

45]. Indeed, social innovation is also linked to sustainability [

102] and its consideration could help in identifying the relationship between Industry 4.0 and sustainability, given that some of its aspects could be achieved through Industry 4.0., for example, the quality of life or the protection of health. In this respect, the relationship between social innovation and sustainability also deserves further attention, i.e., [

90].

These suggested future research direction have emerged, in some way, thanks to this systematic literature review.

However, other topics that have been completely neglected by management scholars could also be of great interest, for example, quite surprisingly, open innovation.

Open innovation can be defined as “a distributed innovation process based on purposively managed knowledge flows across organizational boundaries, using pecuniary and non-pecuniary mechanisms in line with the organization’s business model” [

103] (p. 27). It appears clear that open innovation processes could be a very interesting topic to study in Industry 4.0 settings, also because the tools and processes of the latter are often the results of processes of open innovation, but until now no scholar has focused his/her research on this particular aspect of Industry 4.0.

Another topic of particular interest could be the value co-creation approach following a strategic perspective, seeking to identify the implications of Industry 4.0 in terms of value co-creation not only with customers, but all partners operating in the ecosystem of capabilities [

104].

All of these suggestions for future studies represent just a part of the possible avenues of research, but they clearly demonstrate that Industry 4.0 literature is still at an early stage and deserves further attention under different profiles in management studies.

5. Conclusions

This systematic literature review highlights that Industry 4.0 is still an emerging topic in management studies.

Moreover, this paper provides several contributions to the Industry 4.0 field from a theoretical point of view.

Firstly, by using well-structured and replicable methodology, previous reviews of the literature have been updated and extended, even if this is the first literature review of purely management literature. Both the systematic literature review method and the management approach adopted should be considered signs of originality of this paper in the Industry 4.0 literature.

This study also provides suggestions for future avenues of research in Industry 4.0 domains, spanning all aspects of firm management and taking into account the more recent models adopted by firms, such as open innovation and/or value co-creation; an issue still not explored at all in this domain.

Finally, this work suggests that Industry 4.0 deserves a dedicated strategy to be formulated ad hoc, taking into account different aspects and considering a transition period in which organizational changes are very important; a different firm should emerge as the result of the Fourth Industrial Revolution. This shed new light on the entire management literature on Industry 4.0.

Apart from the above-mentioned theoretical contributions, this paper also provides some managerial implications which could help firms to put it into practice, given that this paper is the first one focusing on managerial aspects of Industry 4.0.

Indeed, this systematic literature review can be useful to managers who intend to approach the innovations of Industry 4.0. It can help them to understand that this is a challenging transition which deserves attention and the careful implementation of a considered strategy, able to take into account the various firm aspects involved as well as their mutual relationships. Moreover, this paper also suggests that sustainability issues should be considered at the very core of the Industry 4.0 strategy and demonstrates that other issues related to the above should be considered, for example, social innovation.

In a very simple way, this paper, examining Industry 4.0 management literature, highlights that adopting Industry 4.0 is not just a matter of new technologies and/or tools and/or production methods, but implies changes in all management aspects, not only at an internal level but also in relationships with all partners and, more generally, actors of the ecosystems in which the firm operates. This should suggest to managers to carefully formulate their strategy as well as their transition to Industry 4.0, considering all issues—the only way to really profit from all the positive fall-out that Industry 4.0 seems to bring. Being aware of this could be of great help for managers on their way to Industry 4.0, while management scholars could certainly conduct further in-depth study of this topic to create a better support base for them.

From a social point of view the adoption of Industry 4.0 by firms, following a correct approach as the result of a purposely formulated strategy, could enhance the welfare and well-being of the whole society and contribute to enhance sustainability.

Some limitations of the paper must also be mentioned.

The main limitation is that the three databases and the search engine used do not cover all the accessible sources of management literature in which Industry 4.0 term was used. Therefore, other papers in management literature on Industry 4.0 may not have been included, but enlarging this systematic literature review could, per se, be an interesting avenue of future research.