Detail Engineering Completion Rating Index System (DECRIS) for Optimal Initiation of Construction Works to Improve Contractors’ Schedule-Cost Performance for Offshore Oil and Gas EPC Projects

Abstract

:1. Introduction

- Lack of EPC Contractor’s capability of FEED verification to justify complex owner requirements;

- Lack of experience in the use of exotic materials, and installation of special equipment;

- Lack of experience in performing a fast-track process with a limited schedule;

- Sub-order items including local content requirements in the host country that may impact on project schedule;

- Mandatory requirements to procure equipment from approved vendor list (AVL);

- Owner requirements of single-point responsibility for various contractual liabilities;

- Delay liquidated damages (so-called penalties) following schedule delay on EPC contractor are unrealistically high (as much as US$ 1–2 million/day); and

- Re-order for major equipment and critical bulk materials and reconstruction (re-work) due to early fabrication start with incomplete detail design to comply with the completion date and milestones [6].

2. Literature Review

3. Research Objectives and Contributions

- Research Goal 1—modeling of DECRIS by adjusting previous assessment tools such as PDRI can be developed to measure the optimal progress of detail engineering to initiate the fabrication of initial modules in the scheduling critical path.

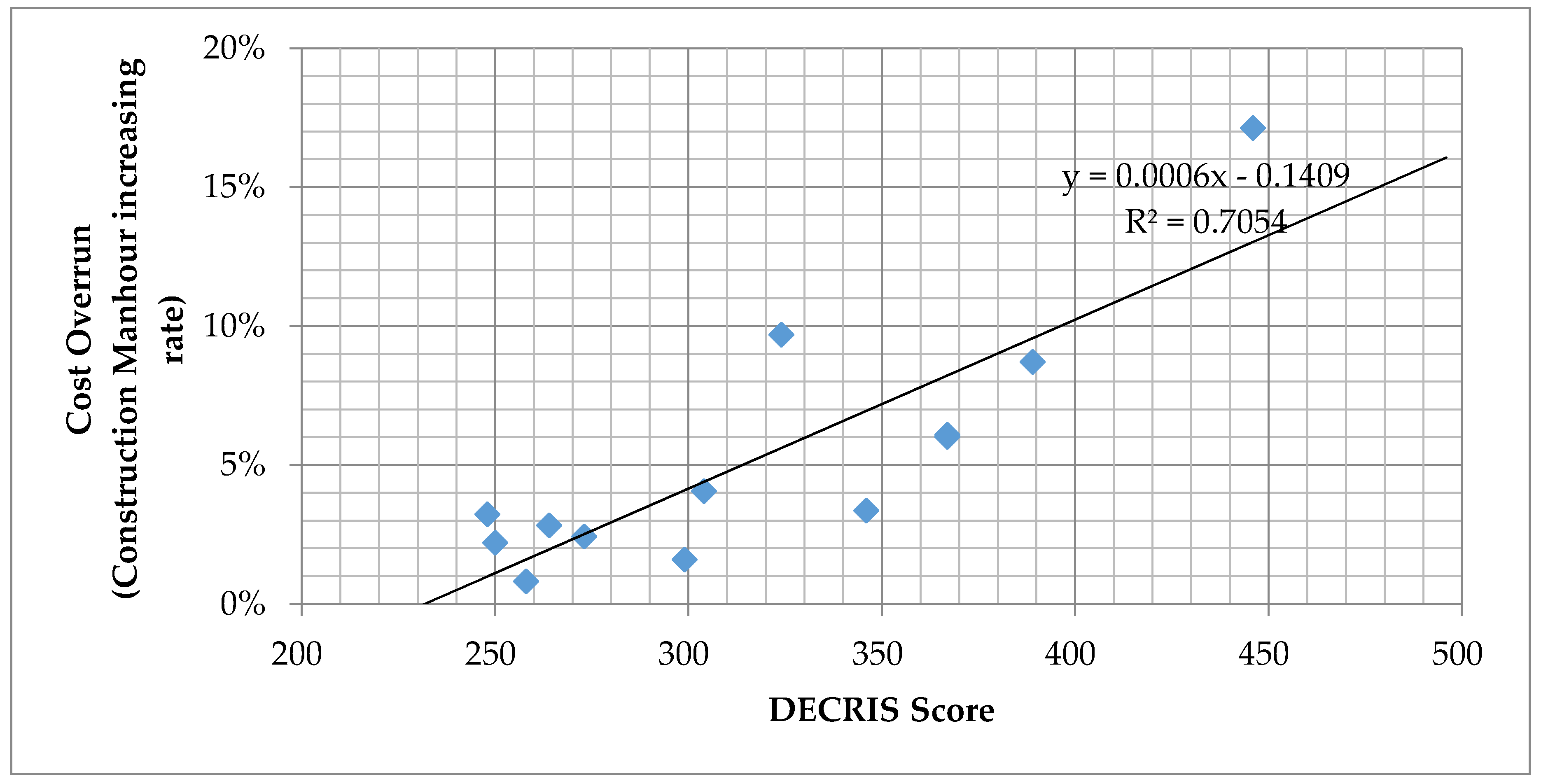

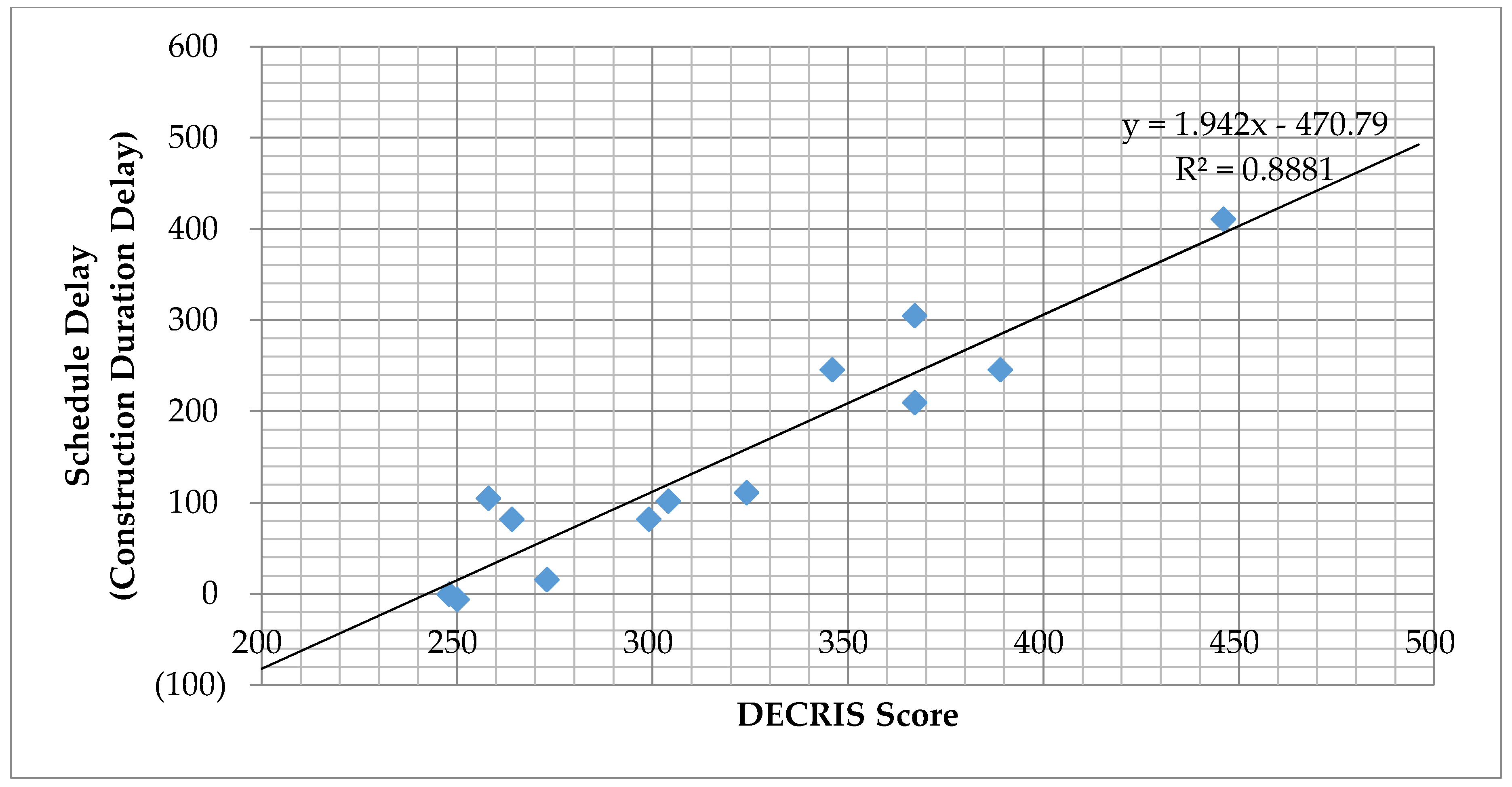

- Research Goal 2—the correlation between the developed DECRIS score and the construction cost and schedule performance.

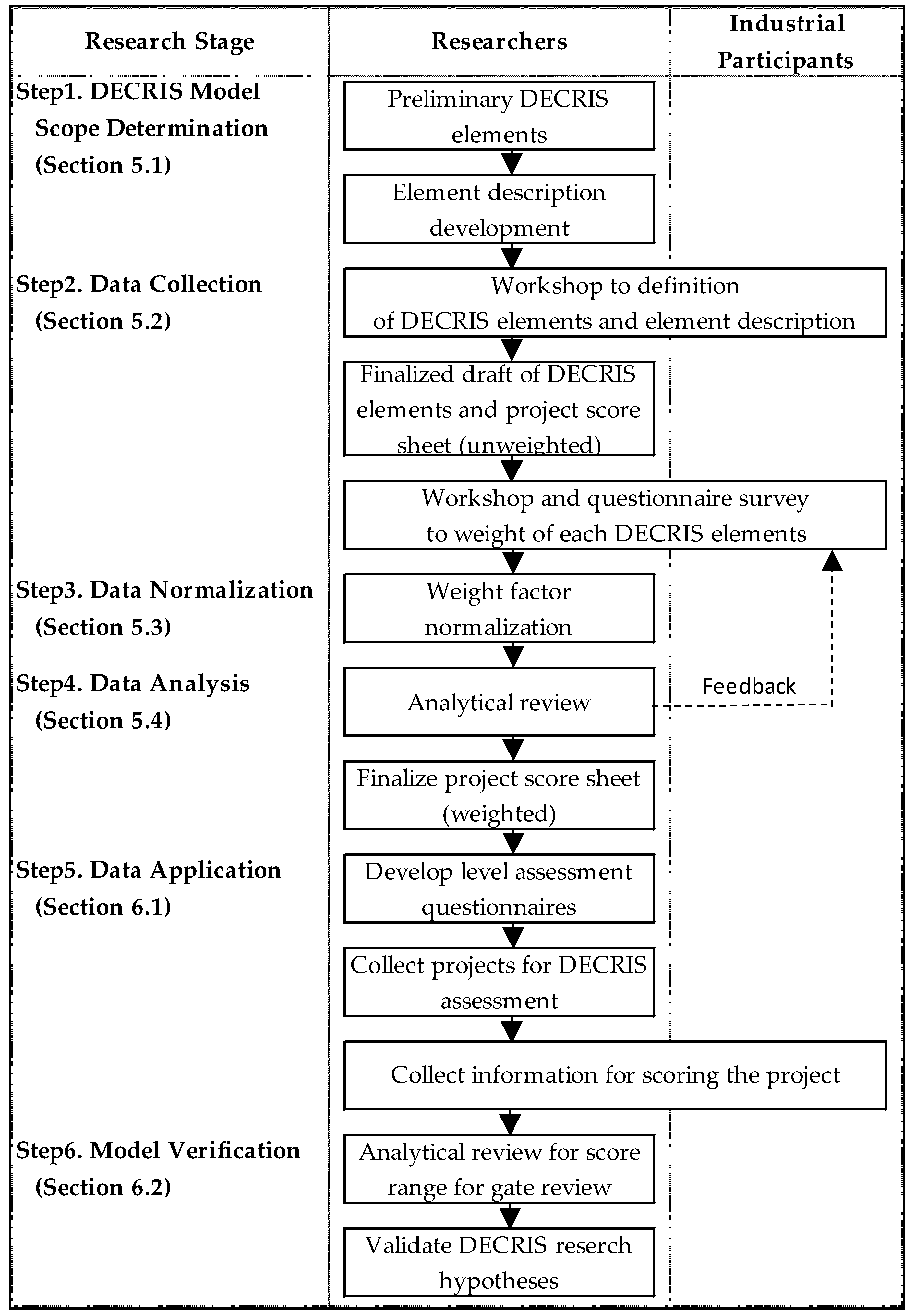

4. Research Methodology for the DECRIS Model

- (1)

- DECRIS model scope determination: collect the preliminary elements from the existing literature and develop the element description

- (2)

- Data collection: a workshop was performed with industry experts to determine elements that affect the calculation of the detail engineering completion rating and to organize the identified elements in proper sections and categories. The expert survey was also used for data collection to calculate the relative importance of each element to engineering completion.

- (3)

- Data normalization: to determine the weight factor for each of the DECRIS elements using the data from the expert survey, data normalization, preliminary estimate, validation process, element average weight calculation, and interpolation were carried out.

- (4)

- Data analysis: one sample t-test is used to finalize the weight factor of each element. The weight factor of each element indicates the level of importance of the element’s contribution to the detail engineering completion rating index.

- (5)

- Data application: the DECRIS model developed through the previous research stages is verified by applying it to the 13 sample projects. Each project was assessed using the DECRIS level assessments.

- (6)

- Model verification: the score outputs were then compared with the project performances of each project (using statistical analyses) to see the level at which the model could predict project performance. A cutoff score was then developed based on the model and sample projects.

5. DECRIS Model Development

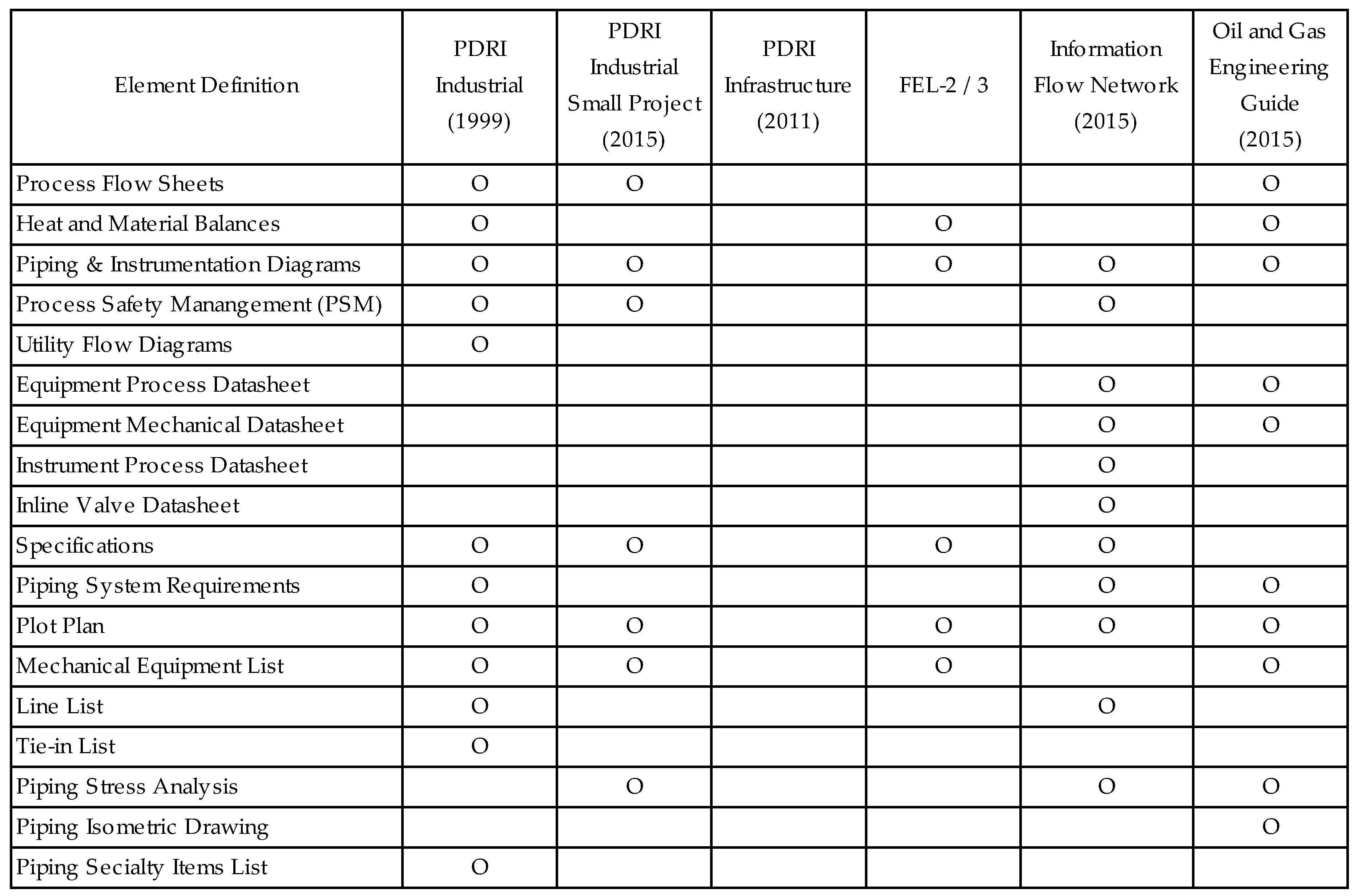

5.1. Step 1: DECRIS Model Scope Determination: Preliminary Elements

5.2. Step 2: DECRIS Element Finalization

5.3. Step 3: Data Normalization

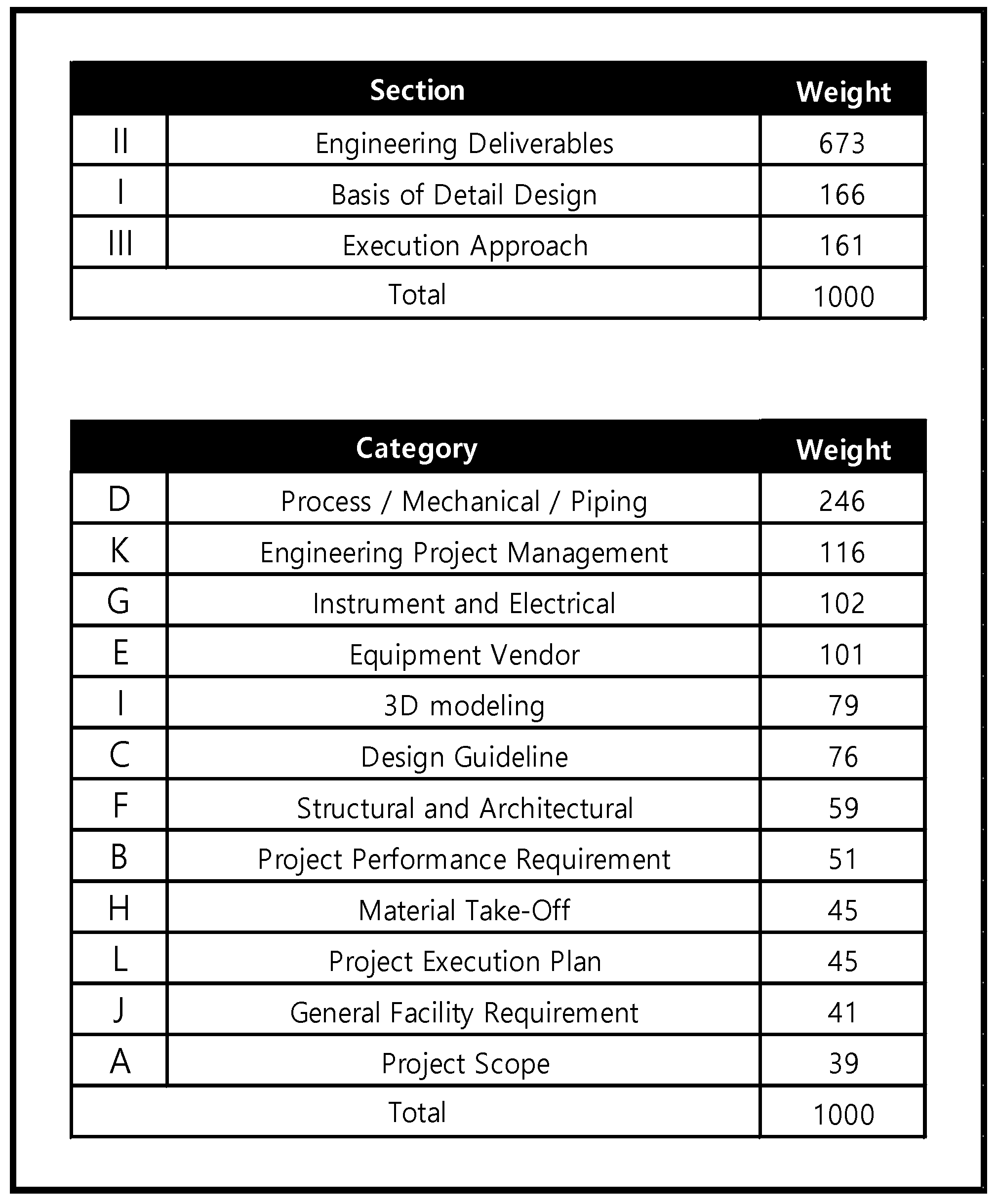

5.4. Step 4: Data Analysis

5.5. Comparison of DECRIS vs. Previous Engineering Assessment Tools Layout and Use

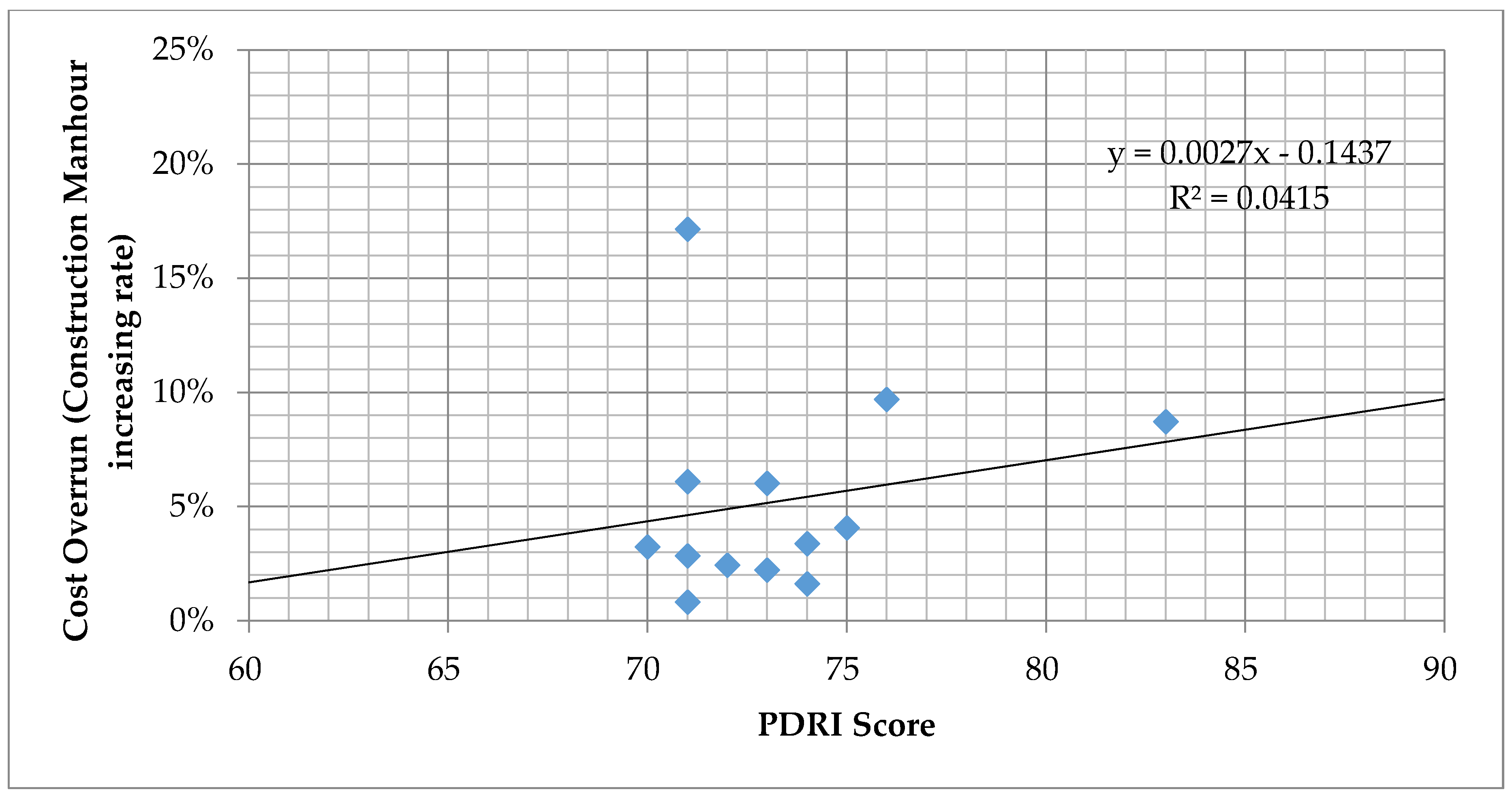

- The sections, based on project decision and front-end definition, are thus major components of PDRI-Industrial (given a 922 score) [7] and PDRI-Infrastructure (given a 730 score) [8]. PDRI focuses on front-end planning and does not represent work packages in the detail engineering stage. The hierarchy overview of the PDRI-Industrial model is briefly outlined in Appendix D for reference purposes. As described in the introduction, the major target of DECRIS is the detail design conducted by the EPC contractor; it is thus reasonable that the engineering deliverables of detail engineering is the most important section.

- From the project size point of view, PDRI-Industrial is for midsize industrial projects whereas the DECRIS is for oil and gas EPC megaprojects over US$ 500 m.

- The Scope of detail engineering in PDRI-Infrastructure is basically the owner’s responsibility (whereas in case of EPC, it belongs to the EPC contractor, therefore the completion of the impact of detail engineering completion to the schedule and cost performance is less severe than the EPC case).

6. Applications and Verifications

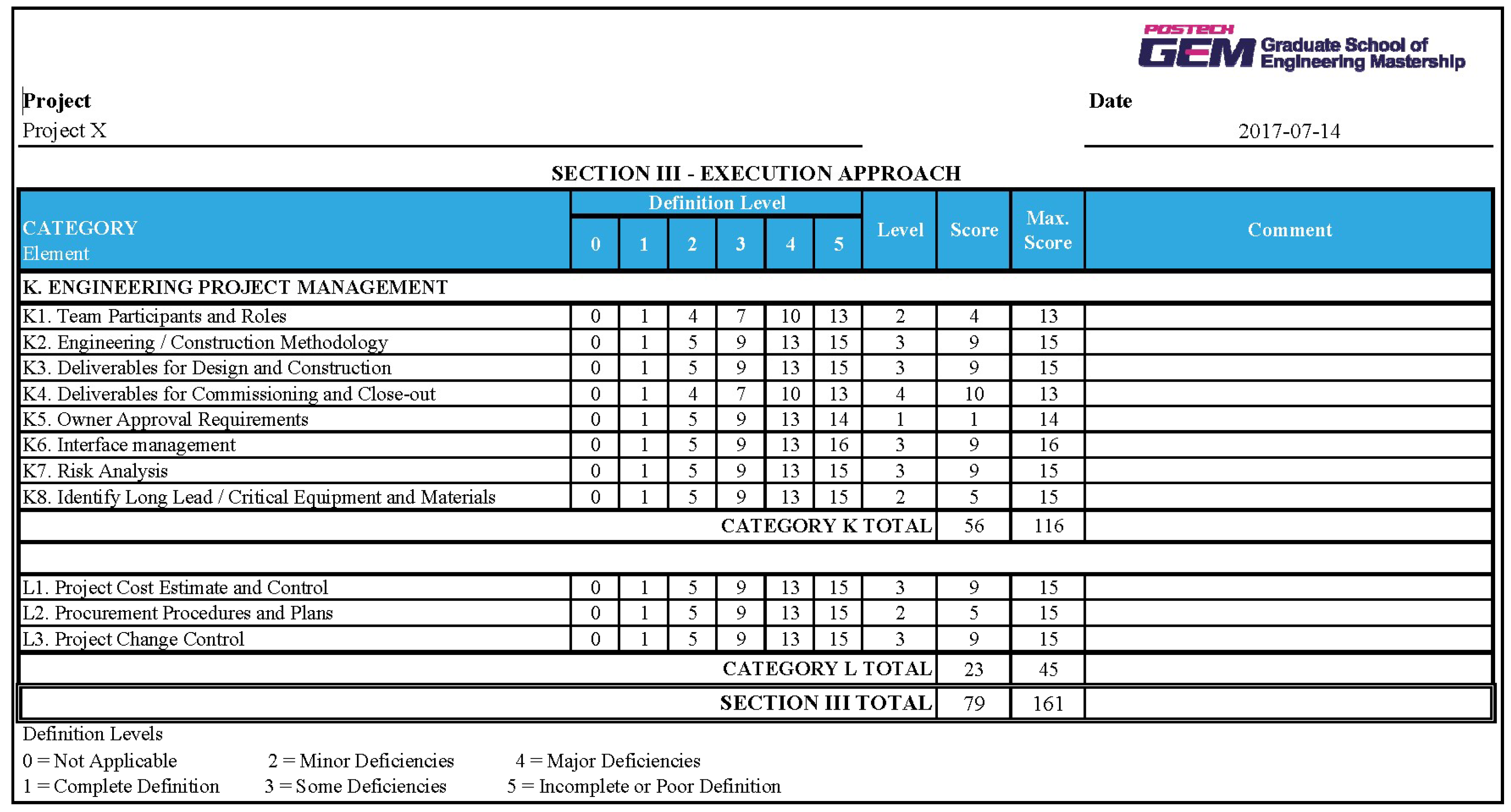

6.1. Step 5: Data Application through Sample Projects

6.2. Step 6: Model Verification with a Case Study

- x = DECRIS score at steel cutting session in Project X = 368

- y = Construction labor hours increase rate (cost overrun) as per design changes

- z = Construction duration delay

6.3. Comparison of DECRIS and PDRI (Existing Assessment Tool) Performance

7. Conclusions and Discussion

7.1. Summary and Contributions

7.2. Future Directions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AFC | Approval for Construction |

| CDD | Construction Duration Delay |

| CLIR | Construction Labor hours Increase Rate |

| DECRIS | Detail engineering Completion Rating Index System |

| EDMS | Electronic Document Management System |

| EPC | Engineering, Procurement and Construction |

| FEED | Front-End Engineering and Design |

| FEL | Front-End Loading |

| FPSO | Floating Production, Storage and Offloading |

| FLNG | Floating LNG |

| PDRI | Project Definition Rating Index |

| fsQCA | Fuzzy Set Qualitative Comparative Analysis |

| PCA | Principal Component Analysis |

Appendix A. Boxplot of Weight Factor by Elements

Appendix B. Weighted Scoresheet

| SECTION I-BASIS OF DETAIL DESIGN | |||||||

| CATEGORY Element | Definition Level | Score | |||||

| 0 | 1 | 2 | 3 | 4 | 5 | ||

| A. PROJECT SCOPE | |||||||

| A1. Project Objectives Statement | 0 | 1 | 3 | 5 | 7 | 9 | |

| A2. Project Scope of Work | 0 | 1 | 5 | 9 | 13 | 17 | |

| A3. Project Philosophies | 0 | 1 | 4 | 7 | 10 | 13 | |

| B. PROJECT PERFORMANCE REQUIREMENT | |||||||

| B1. Products | 0 | 1 | 4 | 7 | 10 | 12 | |

| B2. Capacities | 0 | 1 | 4 | 7 | 10 | 13 | |

| B3. Technology | 0 | 1 | 4 | 7 | 10 | 12 | |

| B4. Processes | 0 | 1 | 5 | 9 | 13 | 14 | |

| C. DESIGN GUIDELINE | |||||||

| C1. Process Design Criteria | 0 | 1 | 5 | 9 | 13 | 16 | |

| C2. Project Site Assessment | 0 | 1 | 5 | 9 | 13 | 14 | |

| C3. Lead Discipline Scope of Work | 0 | 1 | 5 | 9 | 13 | 14 | |

| C4. Project Schedule | 0 | 1 | 5 | 9 | 13 | 17 | |

| C5. Constructability Analysis | 0 | 1 | 5 | 9 | 13 | 15 | |

| SECTION II-ENGINEERING DELIVEABLES | |||||||

| D. PROCESS/MECHANICAL/PIPING | |||||||

| D1. Process Flow Diagrams | 0 | 1 | 5 | 9 | 13 | 15 | |

| D2. Heat and Material Balance | 0 | 1 | 5 | 9 | 13 | 15 | |

| D3. Piping & Instrumentation Diagrams | 0 | 2 | 7 | 12 | 17 | 18 | |

| D4. Process Safety Management (PSM) | 0 | 1 | 5 | 9 | 13 | 15 | |

| D5. Utility Flow Diagram | 0 | 1 | 5 | 9 | 13 | 14 | |

| D6. Process Datasheets | 0 | 1 | 5 | 9 | 13 | 15 | |

| D7. Equipment Mechanical Datasheets | 0 | 1 | 5 | 9 | 13 | 15 | |

| D8. Specifications | 0 | 1 | 5 | 9 | 13 | 16 | |

| D9. Piping System Requirements | 0 | 1 | 5 | 9 | 13 | 15 | |

| D10. Plot Plan | 0 | 1 | 5 | 9 | 13 | 16 | |

| D11. Project Equipment List | 0 | 1 | 4 | 7 | 10 | 13 | |

| D12. Line Lists | 0 | 1 | 4 | 7 | 10 | 13 | |

| D13. Tie-in Lists | 0 | 1 | 4 | 7 | 10 | 13 | |

| D14. Piping Stress Analysis | 0 | 1 | 5 | 9 | 13 | 15 | |

| D15. Piping Isometric Drawings | 0 | 1 | 4 | 7 | 10 | 13 | |

| D16. Piping Specialty Items Lists | 0 | 1 | 4 | 7 | 10 | 12 | |

| D17. Instrument Index | 0 | 1 | 4 | 7 | 10 | 13 | |

| E. EQUIPMENT VENDOR | |||||||

| E1. Equipment Procurement Status | 0 | 1 | 5 | 9 | 13 | 15 | |

| E2. In-line and Instrument Procurement Status | 0 | 1 | 5 | 9 | 13 | 14 | |

| E3. Equipment General Arrangement Drawings | 0 | 1 | 5 | 9 | 13 | 17 | |

| E4. Process and Mechanical Documents | 0 | 1 | 5 | 9 | 13 | 14 | |

| E5. Instrument and Electrical Documents | 0 | 1 | 5 | 9 | 13 | 14 | |

| E6. Structural and Architectural Documents | 0 | 1 | 4 | 7 | 10 | 13 | |

| E7. Equipment Utility Requirements | 0 | 1 | 5 | 9 | 13 | 14 | |

| F. STRUCTURAL AND ARCHITECTURAL | |||||||

| F1. Structural Specifications | 0 | 1 | 5 | 9 | 13 | 15 | |

| F2. Structural Analysis | 0 | 1 | 5 | 9 | 13 | 16 | |

| F3. Architectural Arrangement Drawing | 0 | 1 | 4 | 7 | 10 | 13 | |

| F4. Weight Control Report | 0 | 1 | 5 | 9 | 13 | 15 | |

| G. INSTRUMENT AND ELECTRICAL | |||||||

| G1. Control Philosophy | 0 | 1 | 5 | 9 | 13 | 15 | |

| G2. Logic Diagrams | 0 | 1 | 5 | 9 | 13 | 15 | |

| G3. Cable Schedule | 0 | 1 | 5 | 9 | 13 | 14 | |

| G4. Hook-up Diagram | 0 | 1 | 5 | 9 | 13 | 14 | |

| G5. Critical Electrical Item List | 0 | 1 | 5 | 9 | 13 | 14 | |

| G6. Electrical Single Line Diagrams | 0 | 1 | 5 | 9 | 13 | 15 | |

| G7. Instrument and Electrical Specifications | 0 | 1 | 5 | 9 | 13 | 15 | |

| H. MATERIAL TAKE-OFF | |||||||

| H1. Piping MTO | 0 | 1 | 5 | 9 | 13 | 15 | |

| H2. Structural and Architectural MTO | 0 | 1 | 5 | 9 | 13 | 15 | |

| H3. Instrument and Electrical Bulk Item MTO | 0 | 1 | 5 | 9 | 13 | 15 | |

| I. 3D MODELING | |||||||

| I1. 3D Modeling Review | 0 | 1 | 5 | 9 | 13 | 17 | |

| I2. 3D Modeling (Equipment/Piping) | 0 | 1 | 5 | 9 | 13 | 17 | |

| I3. 3D Modeling (Structural) | 0 | 1 | 5 | 9 | 13 | 15 | |

| I4. 3D Modeling (Architectural) | 0 | 1 | 5 | 9 | 13 | 15 | |

| I5. 3D Modeling (Instrument and Electrical) | 0 | 1 | 5 | 9 | 13 | 15 | |

| J. GENERAL FACILITY REQUIREMENT | |||||||

| J1. Preservation and Storage Requirement | 0 | 1 | 4 | 7 | 10 | 12 | |

| J2. Transportation Requirements | 0 | 1 | 4 | 7 | 10 | 13 | |

| J3. Welding Procedure Specification | 0 | 1 | 5 | 9 | 13 | 16 | |

| SECTION III-EXECUTION APPROACH | |||||||

| K. ENGINEERING PROJECT MANAGEMENT | |||||||

| K1. Team Participants and Roles | 0 | 1 | 4 | 7 | 10 | 13 | |

| K2. Engineering/Construction Methodology | 0 | 1 | 5 | 9 | 13 | 15 | |

| K3. Deliverables for Design and Construction | 0 | 1 | 5 | 9 | 13 | 15 | |

| K4. Deliverables for Commissioning and Close-out | 0 | 1 | 4 | 7 | 10 | 13 | |

| K5. Owner Approval Requirements | 0 | 1 | 5 | 9 | 13 | 14 | |

| K6. Interface Management | 0 | 1 | 5 | 9 | 13 | 16 | |

| K7. Risk Analysis | 0 | 1 | 5 | 9 | 13 | 15 | |

| K8. Identify Long Lead/Critical Equipment and Materials | 0 | 1 | 5 | 9 | 13 | 15 | |

| L. PROJECT EXECUTION PLAN | |||||||

| L1. Project Cost Estimate and Control | 0 | 1 | 5 | 9 | 13 | 15 | |

| L2. Procurement Procedures and Plans | 0 | 1 | 5 | 9 | 13 | 15 | |

| L3. Project Change Control | 0 | 1 | 5 | 9 | 13 | 15 | |

Appendix C. DECSIS Level Assessment Questionnaires (Selected Samples)

- Section II: Engineering Deliverables

- Category D. Process/Mechanical/PipingD1. Process Flow Diagrams

Level Description 1 Final Process Simulation was carried out and AFC stage Process Flow Diagram (PFD) was approved without comment. No further design change in Process Flow Diagram is foreseen. 2 Updated Process Simulation in detail engineering was performed according to project requirements, as well as Client comments from PFD and major design changes. Revised PFD (AFD) was issued. No further major design change in Process flow diagram is foreseen. 3 Process simulation in detail engineering was performed in line with Project Requirements, and its result including PFD (IFA, first revision) was updated and submitted to the Client. 4 There is no discrepancy between process simulation, PFD, and Heat and Material Balance in FEED. In addition, they comply with Basis of Design. No process simulation in detail engineering stage was performed. 5 There is no process simulation performed in FEED, or many discrepancies between process simulation, PFD and Heat and Material Balance were found. No process simulation in detail engineering was performed. D2. Heat and Material BalancesLevel Description 1 AFC Heat and Material Balance and Process Description were approved without comment. No further design change in Heat and Material Balance is foreseen. 2 Updated Heat and Material Balance and Process description in detail engineering were developed according to Project requirements, as well as Client comments from previous documents and major design changes. Revised Heat and Material Balance and Process description (AFD) were issued. No further major design change in Heat and Material Balance and Process Description is foreseen. 3 Heat and Material Balance and Process Description in detail engineering were developed in line with Project Requirements, and issued with IFA (first revision). 4 There is no discrepancy between PFD, Heat and Mass Balance and Process description in FEED. In addition, they comply with Basis of Design and design capacity margin. No Heat and Material Balance in detail engineering was developed. 5 Many discrepancies between PFD, Process Description and Heat and Material Balance were found. No PFD and Heat and Material Balance in detail engineering were issued. D3. Piping and Instrumentation DiagramsLevel Description 1 AFC Piping and Instrumentation Diagram (P&ID) was issued with incorporated Final Equipment P&ID (Vendor) and In-line instrument Vendor data, and approved without comment. All Hazard and operability (HAZOP) recommendations were closed and incorporated in P&ID. No further design change in P&ID is foreseen. 2 Updated P&ID in detail engineering were developed according to Project Requirements, Client comments from previous P&ID and 30% Modeling Punch, and major design changes. Revised P&ID (AFD) was issued. Process HAZOP and Package Unit HAZOP were performed and Process Line List and Line diagram was issued. No further major change in P&ID is foreseen. 3 P&ID in detail engineering was developed in line with Project Requirements, and issued with IFA (first revision). Preliminary Vendor Documents or Value Improving Practices for major equipment was incorporated in IFA P&ID. Hazardous Identification (HAZID) recommendation was incorporated. 4 There is no discrepancy between PFD, Process description, Utility Flow Diagram (UFD), P&ID in FEED. In addition, it complies with Basis of Design and design capacity margin. No P&ID in detail engineering was developed. 5 Many discrepancies between PFD, Process Description, UFD and P&ID were found. No P&ID in detail engineering was issued. D4. Process Safety ManagementLevel Description 1 All HAZOP/HAZID recommendations were concluded and approved by the client. In addition, the relevant engineering deliverables were properly documented and approved. 2 HAZOP for Vendor packaged unit and Contractor’s system were finished based on updated P&IDs. Major HAZOP/HAZID recommendations were concluded and approved by the client. 3 HAZOP has been performed for the Contractor’s system based on P&ID issued by Contractor. Major HAZID recommendations were concluded and approved by the client. 4 HAZID was performed during FEED stage. Environmental/Human/Process/Facility Operation hazards have been defined. HAZOP was not performed. 5 No HAZID was performed during FEED stage. Environmental/Human/Process/Facility Operation hazards have not been defined yet. D5. Utility Flow DiagramsLevel Description 1 AFC stage UFD was approved without comment. No further design change in the UFD is foreseen. 2 From incorporating Client comments in UFD, Vendor information for utility consumption and major design changes, revised UFD (AFD) was issued. No further major design change in UFD is foreseen. 3 Heat and Material Balance and UFD in detail engineering were developed in line with Project Requirements, and issued with IFA (first revision). 4 There is no discrepancy between UFD and Heat and Material Balance in FEED. In addition, they comply with Basis of Design. Utility requirements for major consumer were defined through equipment information. 5 Many discrepancies between UFD and Heat and Material Balance in FEED were found. Utility requirements for consumer were estimated only with historical data and no equipment information was developed. D6. Process DatasheetsLevel Description 1 Final Process datasheets were approved without comment. No further design change in the process datasheet is foreseen. 2 From incorporating Client comments in process datasheet, Selected Vendor’s information and major design changes, the revised process datasheets were issued. No further major design change in process datasheet is foreseen. 3 Process datasheets in detail engineering were developed in line with Project Requirements, and issued with IFA (first revision). Value Improving Practices for major equipment were incorporated in the process datasheet. 4 All process datasheets for major equipment were developed during FEED stage. There is no major discrepancy between FEED P&ID and process datasheets. No process datasheet in detail engineering was developed. 5 No process datasheet was included in FEED packages, or process datasheets were developed for Long Lead Items (LLI) only during FEED stage. There are many discrepancies in FEED P&ID and process datasheets. D7. Equipment Mechanical DatasheetsLevel Description 1 AFC stage equipment mechanical datasheets were completed with Vendor’s firm information and approved without comment. No further design change in the equipment mechanical datasheet is foreseen. 2 From incorporating Client comments in equipment mechanical datasheet, Selected Vendor’s information and major design changes, the revised equipment mechanical datasheets were issued. No further major design change in equipment mechanical datasheet is foreseen. 3 Equipment mechanical datasheets in detail engineering were developed in line with Project Requirements, and issued with IFA (first revision). Value Improving Practices and applicable Code/Standard requirements for major equipment were incorporated in the equipment mechanical datasheet. 4 All equipment mechanical datasheets for major equipment were developed during FEED stage. There is no major discrepancy between FEED P&ID and equipment mechanical datasheets. No equipment mechanical datasheet in detail engineering was developed. 5 No equipment mechanical datasheet was included in FEED packages, or equipment mechanical datasheets were developed for LLI only during FEED stage. There are many discrepancies in FEED P&ID and equipment mechanical datasheets. D8. SpecificationsLevel Description 1 AFC stage process, mechanical and piping specifications were approved without comment. No further design change in the specification is foreseen. 2 From incorporating Client comments in specification and major design changes, the revised specifications were issued. No further major design change in specification is foreseen. 3 Specifications in detail engineering were developed in line with Project Requirements, and issued with IFA (first revision). The specification includes equipment type, packaged units, piping specifications, protective coating and insulation. 4 All major specifications were developed during FEED stage. There is no major discrepancy between specifications. No specification in detail engineering was developed. 5 No specification was included in FEED packages, or there are many discrepancies in FEED specifications. D9. Piping System RequirementsLevel Description 1 AFC stage piping material classes were completed with Vendor’s firm information and approved without comment. No further design change in the piping material class is foreseen. 2 From incorporating Client comments in piping material class, additional piping materials and major design changes, the revised piping material class was issued. No further major design change in equipment mechanical datasheet is foreseen. 3 Piping material classes in detail engineering were developed in line with Project Requirements, and issued with IFA (first revision). Value Improving Practices and applicable Code/Standard requirements were incorporated in the piping material class. 4 All piping material classes were developed in line with material selection in FEED stage. All relevant devices including straight runs, elbows, tees, flanges, reducers, manual valves, gaskets, bolts and nuts were defined in the piping material classes. 5 No piping material class was developed during FEED stage, or piping material class was partially developed. D10. Plot PlanLevel Description 1 AFC stage plot plan was completed with Vendor’s firm information, 60% and 90% modeling review punch and approved without comment. No further design change in the plot plan is foreseen. 2 From incorporating Client comments in plot plan, 30% modeling review punch and major design changes, the revised plot plan (AFD stage) was issued. No further major design change in plot plan is foreseen. 3 Plot plan in detail engineering was developed in line with Project Requirements and preliminary equipment Vendor documents, and issued with IFA (first revision). Value Improving Practices including process function group and interconnection optimization were incorporated in the plot plan. 4 Plot plan was developed with all equipment, evacuation path, access/handling volume, large diameter pipe (including flexibility requirement), and access way and hazard area risks. 5 Plot plan was developed with limited equipment and device information during FEED stage. D11. Project Equipment ListsLevel Description 1 AFC stage project equipment list was completed with Vendor’s firm information and approved without comment. 2 From incorporating Client comments in project equipment datasheet, Vendor information and major design changes, the revised project equipment list was issued. All disciplines’ input was incorporated and no additional equipment in project equipment list is foreseen. 3 Project equipment list in detail engineering was developed in line with Project Requirements, and issued with IFA (first revision). Value Improving Practices and potential Vendor’s information for equipment were incorporated in the package equipment list. Additionally, equipment list includes Vendor name, equipment model, insulation and fire proofing requirements. 4 Project equipment list for all major equipment was developed during FEED stage. There is no major discrepancy between FEED P&ID and equipment list. Equipment list includes tag number, equipment description, equipment type, capacity/quantity, position/module/deck, assumed dimension/weight. 5 Project equipment list was developed for major equipment only during FEED stage. No auxiliary equipment was considered in the project equipment list. There are many discrepancies in project equipment list and P&ID. D12. Line ListsLevel Description 1 AFC stage line list was completed with all pipelines and approved without comment. 2 From incorporating Client comments in line list and major design changes in P&IDs, the revised line list (AFD) was issued. All lines over 2” with insulation and Passive Fire Protection (PFP) requirements shall be included in the line list. 3 Line list in detail engineering was developed in line with IFA P&IDs, and issued with IFA (first revision). Line list should include large bore and exotic material lines for 1st MTO for piping materials. 4 Line list for all major pipe route was developed during FEED stage. There is no major discrepancy between FEED P&ID and line list. Line list includes tag number, operating and design condition, pipe specification, insulation/tracing and painting requirement. 5 No line list was developed during FEED stage. D13. Tie-in ListsLevel Description 1 AFC stage tie-in list was completed with AFC P&ID, verified with Vendor documents and/or confirmations, and approved without comment. 2 From incorporating Client comments in tie-in list, Vendor documents (General Arrangement Drawing for Equipment) and major design change in P&IDs, the revised tie-in list (AFD) was issued. All lines over 2” with insulation and PFP requirements shall be included in the tie-in list. 3 Tie-in list in detail engineering were developed in line with IFA P&IDs, and issued with IFA (first revision). Tie-in list should crosscheck with preliminary Vendor information for major equipment. Structured process to validate tie-ins and tie-in strategy was documented. 4 Tie-in list for major pipe connections was developed during FEED stage. There is no major discrepancy between FEED P&ID and tie-in list. The tie-in list includes line tag number, reference drawings, pipe specification, and type and size of tie-in. 5 No tie-in list was developed during FEED stage. D14. Pipe Stress AnalysisLevel Description 1 AFC stage piping stress analysis was completed with AFC P&ID, verified with Vendor documents and/or confirmations, and approved without comment. All support and anchor locations were settled, and no further design change is expected. 2 From incorporating Client comments in piping stress analysis, Vendor information for boundary condition (allowable nozzle load) and major design changes in P&IDs, the revised piping stress analysis (AFD) was performed. 3 Piping stress analysis in detail engineering was conducted in line with IFA P&IDs, and issued with IFA (first revision). Support and anchor locations, and pipe wall thickness were updated as per the piping stress analysis. 4 Guidelines for piping stress analysis were developed in FEED package. Applications for high temperature, large diameter, and heavy wall thickness, upstream and downstream of rotating equipment were well defined. 5 No guidelines for piping stress analysis were developed during FEED stage. FEED package does not specify the extent of piping stress analysis. D15. Piping Isometric DrawingsLevel Description 1 AFC stage piping isometric drawings were completed with AFC P&ID, and approved without comment. All support and anchor locations were settled, and no further design change is expected. 2 From incorporating Client comments in piping isometric drawings and major design changes in P&IDs, the revised piping isometric drawing (AFD) was generated and submitted. 3 Methodology to generate piping isometric drawing was settled. Piping isometric drawings in detail engineering were generated from 3D modeling, and issued with IFA (first revision). Support and anchor locations, and pipe wall thickness were updated as per the piping stress analysis. 4 Guidelines for piping isometric drawing were developed in FEED package. Requirements for piping isometric drawings were well defined. 5 No guidelines for piping isometric drawing were developed during FEED stage. D16. Piping Specialty Items ListsLevel Description 1 AFC stage piping specialty items list was completed with AFC P&ID, and approved without comment. Catalog for 3D modeling was settled, and no further design change is expected. 2 From incorporating Client comments in piping specialty items list and major design changes in P&IDs, the revised piping specialty items list (AFD) was generated and submitted. 3 Piping specialty items list in detail engineering was developed in line with IFA P&IDs, and issued with IFA (first revision). Scope of supply was defined and preliminary Vendor information was given. 4 Guidelines for piping specialty items were developed in FEED package. Types of piping specialty items including strainers, steam traps, flexible hoses, and expansion joints were defined. 5 No guidelines for piping specialty items were developed during FEED stage. D17. Instrument IndexLevel Description 1 AFC stage instrument index was completed with approved AFC P&ID, and approved without comment. All information on instrument index was settled, and no further design change is expected. 2 From incorporating Client comments in instrument index and major design changes in P&IDs, the revised instrument index (AFD) was generated and submitted. No major change on instrument index is foreseen. 3 Instrument index in detail engineering was developed in line with IFA P&IDs, and issued with IFA (first revision). Information of tag numbers, service conditions, instrument type, and signal output, material of construction, range and set point was provided. 4 Guidelines for instrument index were developed in FEED package. Requirement for instrument index was defined. 5 No guidelines for instrument index were developed during FEED stage.

Appendix D. PDRI-Industrial Hierarchy

- Section I—Basis of Project Decision

- Section II—Front-End Definition

- Section III—Execution Approach

- Section I—Basis of Project Decision (5 sub-sections and 22 elements-max score 499)

A Manufacturing Objectives Criteria (3 elements—max score 45) B Business Objectives (8 elements—max score 213) C Basic data research & development (2 elements—max score 94) D Project scope (6 elements—max score 120) E Value engineering (3 elements—max score 27) - Section II—Front-End Definition (6 sub-sections and 33 elements—max score 423)

F Site Information (6 elements—max score 104) G Process/Mechanical (13 elements—max score 196) H Equipment Scope (3 elements—max score 33) I Civil, Structural, & Architectural (2 elements—max score 19) J Infrastructure (3 elements—max score 25) K Instrument & Electrical (6 elements—max score 46) - Section III—Execution Approach (4 sub-sections and 15 elements—max score 78)

L Procurement strategy (3 elements—max score 16) M Deliverables (3 elements—max score 9) N Project Control (3 elements—max score 17) P Project Execution Plan (6 elements—max score 36)

References

- Leffler, W.L.; Pattarozzi, R.; Sterling, G. Deepwater Petroleum Exploration & Production: A Nontechnical Guide; PennWell Books: Houston, TX, USA, 2011. [Google Scholar]

- Tanmay. Oil & Gas EPC Market Perspective and Comprehensive Analysis to 2023. 2018. Available online: https://theexpertconsulting.com/oil-gas-epc-market-perspective-and-comprehensive-analysis-to-2023/ (accessed on 20 May 2018).

- Rijtema, S.; de Haas, R. Creating Sustainable Offshore Developments in the Ultra-Deep Water. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 2015. [Google Scholar]

- Merrow, E.W. Industrial Megaprojects: Concepts, Strategies, and Practices for Success; Wiley: Hoboken, NJ, USA, 2011; Volume 8. [Google Scholar]

- Edaily. Available online: http://www.edaily.co.kr/news/news_detail.asp?newsId=03332486612810296&mediaCodeNo=257 (accessed on 10 March 2018).

- Ahn, B. Managing the Efficiency of Foreign Engineering Contracts: A Study of a Norwegian and South Korean Project Interface; University of Stavanger: Stavanger, Norway, 2015. [Google Scholar]

- Gibson, G.; Dumont, P.R. Project Definition Rating Index (PDRI) for Industrial Projects; Construction Industry Institute Implementation Resource: Texas, Austin, 1996. [Google Scholar]

- Bingham, E. Development of the Project Definition Rating Index (PDRI) for Infrastructure Projects; Arizona State University: Tempe, AZ, USA, 2010. [Google Scholar]

- Collins, W.A. Development of the Project Definition Rating Index (PDRI) for Small Industrial Projects; Arizona State University: Tempe, AZ, USA, 2015. [Google Scholar]

- Collins, W.; Parrish, K.; Gibson, G.E., Jr. Development of a Project Scope Definition and Assessment Tool for Small Industrial Construction Projects. J. Manag. Eng. 2017, 33, 04017015. [Google Scholar] [CrossRef]

- Zaheer, S.H.; Fallows, C. Document Project Readiness by Estimate Class Using PDRI; EST. 604; AACE International Transactions: Morgantown, WV, USA, 2011. [Google Scholar]

- Bingham, E.; Gibson, G.E., Jr. Infrastructure project scope definition using project definition rating index. J. Manag. Eng. 2016, 33, 04016037. [Google Scholar] [CrossRef]

- Dumont, P.R.; Gibson, G.E., Jr.; Fish, J.R. Scope management using project definition rating index. J. Manag. Eng. 1997, 13, 54–60. [Google Scholar] [CrossRef]

- Tih-Ju, C.; An-Pi, C.; Chao-Lung, H.; Jyh-Dong, L. Intelligent Green Buildings Project Scope Definition Using Project Definition Rating Index (PDRI). Procedia Econ. Financ. 2014, 18, 17–24. [Google Scholar] [CrossRef]

- George, R.; Bell, L.C.; Back, W.E. Critical activities in the front-end planning process. J. Manag. Eng. 2008, 24, 66–74. [Google Scholar] [CrossRef]

- Pheng, L.S.; Chuan, Q.T. Environmental factors and work performance of project managers in the construction industry. Int. J. Proj. Manag. 2006, 24, 24–37. [Google Scholar] [CrossRef]

- Stenhouse, L. The study of samples and the study of cases. Br. Educ. Res. J. 1980, 6. [Google Scholar] [CrossRef]

- Thomson, S.B. Sample size and grounded theory. J. Adm. Gov. 2010, 5, 45–52. [Google Scholar]

- Kline, R.B. Principles and Practice of Structural Equation Modeling; Guilford Publications: New York, NY, USA, 2015. [Google Scholar]

| Code | Description | Code | Description |

|---|---|---|---|

| I | Basis of Detail design | F | Structural and Architectural |

| A | Project Scope | F1 | Structural Requirements |

| A1 | Project Objectives Statement | F2 | Structural Analysis |

| A2 | Project Scope of Work | F3 | Structural and Architectural Arrangement Drawing |

| A3 | Project Philosophies | F4 | Weight Control Report |

| B | Project Performance Requirement | G | Instrument and Electrical |

| B1 | Products | G1 | Control Philosophy |

| B2 | Capacities | G2 | Logic Diagrams |

| B3 | Technology | G3 | Cable Schedule |

| B4 | Processes | G4 | Hook-up Diagram |

| C | Design Guideline | G5 | Critical Electrical Item lists |

| C1 | Process Design Criteria | G6 | Electrical Single Line Diagrams |

| C2 | Project Site Assessment | G7 | Instrument and electrical Specifications |

| C3 | Lead discipline Scope of Work | H | Material Take-Off |

| C4 | Project Schedule | H1 | Piping MTO (Material Take Off) |

| C5 | Constructability Analysis | H2 | Structural and Architectural MTO |

| II | Engineering Deliverables | H3 | Instrument and Electrical Bulk Item MTO |

| D | Process/Mechanical/Piping | I | 3D modeling |

| D1 | Process Flow Diagrams | I1 | 3D Modeling Review |

| D2 | Heat and Material Balances | I2 | 3D Modeling Input (Equipment/Piping) |

| D3 | Piping and Instrumentation Diagrams | I3 | 3D Modeling Input (Structural) |

| D4 | Process Safety Management (PSM) | I4 | 3D Modeling Input (Architectural) |

| D5 | Utility Flow Diagrams | I5 | 3D Modeling Input (Instrument and Electrical) |

| D6 | Process Datasheets | J | General Facility Requirement |

| D7 | Equipment Mechanical Datasheets | J1 | Preservation and Storage Requirement |

| D8 | Specifications | J2 | Transportation Requirement |

| D9 | Piping System Requirements | J3 | Welding Procedure Specification |

| D10 | Plot Plan | III | Execution Approach |

| D11 | Mechanical Equipment List | K | Engineering Project Management |

| D12 | Line Lists | K1 | Team Participants and Roles |

| D13 | Tie-in Lists | K2 | Engineering/Construction Methodology |

| D14 | Piping Stress Analysis | K3 | Deliverables for Design and Construction |

| D15 | Piping Isometric Drawings | K4 | Deliverables for Commissioning and Close-out |

| D16 | Piping Specialty Items Lists | K5 | Owner Approval Requirements |

| D17 | Instrument Index | K6 | Interface Management and Communication Plan |

| E | Equipment Vendor | K7 | Risk Analysis |

| E1 | Equipment Procurement Status | K8 | Identify Long Lead/Critical Equipment and Materials |

| E2 | In-line and Instrument Procurement Status | L | Project Execution Plan |

| E3 | Equipment General Arrangement Drawings | L1 | Project Cost Estimate and Control |

| E4 | Process and Mechanical Documents | L2 | Procurement Procedures and Plans |

| E5 | Instrument and Electrical Documents | L3 | Project Change Control |

| E6 | Structural and Architectural Documents | ||

| E7 | Equipment Utility Requirements |

| Section | No of Category | No of Element |

|---|---|---|

| Basis of Detail Design | 3 | 12 |

| Engineering Deliverables | 7 | 46 |

| Execution Approach | 2 | 11 |

| Total | 12 | 69 |

| Details | Number |

|---|---|

| Participant | 32 people |

| Overall Experience | 425 years |

| Over 10 years of Experience | 25 people |

| Director | 2 people |

| Team Leader/Department Head | 9 people |

| Project Management Professionals (PMPs) | 5 people |

| DECRIS | PDRI-Industrial | PDRI Infrastructure | ||||

|---|---|---|---|---|---|---|

| Sector | Offshore Oil and Gas (>500M USD) | General Industrial (>10M USD) | Infrastructure | |||

| Project phase | Detail Design | Front-End Planning | Planning | |||

| No of section | 3 | 3 | 3 | |||

| Section #1 a | Basis of Detail Design | (16.6%) | Basis of Project Decision | (49.9%) | Basis of Project Decision | (43.7%) |

| Section #2 a | Engineering Deliverable | (67.3%) | Front-End Definition | (42.3%) | Basis of Design | (29.3%) |

| Section #3 a | Execution Approach | (16.1%) | Execution Approach | (7.8%) | Execution Approach | (27.0%) |

| No of category | 12 | 14 | 13 | |||

| No of element | 69 | 70 | 67 | |||

| Project | Type | Steel Cutting | Hand-Over | DECRIS Score |

|---|---|---|---|---|

| A | Fixed | 2012-07-13 | 2015-07-15 | 346 |

| B | Floater | 2011-07-01 | 2015-02-14 | 446 |

| C | Fixed | 2012-04-02 | 2013-08-27 | 250 |

| D | Floater | 2012-09-07 | 2015-12-17 | 304 |

| E | Fixed | 2013-09-16 | 2015-06-30 | 299 |

| F | Floater | 2014-06-13 | 2017-07-15 | 367 |

| G | Floater | 2013-10-04 | 2015-11-30 | 367 |

| H | Floater | 2014-05-02 | 2016-10-03 | 389 |

| I | Fixed | 2015-03-03 | 2017-02-20 | 264 |

| J | Fixed | 2015-09-15 | 2016-11-28 | 248 |

| K | Fixed | 2016-01-25 | 2017-05-12 | 273 |

| L | Fixed | 2008-09-23 | 2013-11-14 | 258 |

| M | Fixed | 2011-03-04 | 2012-11-21 | 324 |

| X | Fixed | 2016-07-01 | 2020-05-08 | 368 |

| Project | CLIR 1 (%) | CDD 2 (days) | Project | CLIR (%) | CDD (days) |

|---|---|---|---|---|---|

| B | 17.14% | 411 | L | 0.82% | 105 |

| H | 8.71% | 246 | E | 1.61% | 82 |

| F | 6.09% | 305 | K | 2.44% | 16 |

| G | 6.02% | 210 | I | 2.84% | 82 |

| A | 3.37% | 246 | C | 2.22% | -6 |

| D | 4.06% | 102 | J | 3.24% | 0 |

| M | 9.70% | 111 |

| Project | Group | DECRIS Score | CLIR (%) | CDD (days) | Project | Group | DECRIS Score | CLIR (%) | CDD (days) |

|---|---|---|---|---|---|---|---|---|---|

| B | High | 446 | 17.14 | 411 | E | low | 299 | 1.61 | 82 |

| H | High | 389 | 8.71 | 246 | K | low | 273 | 2.44 | 16 |

| F | High | 367 | 6.09 | 305 | I | low | 264 | 2.84 | 82 |

| G | High | 367 | 6.02 | 210 | C | low | 250 | 2.22 | −6 |

| A | High | 346 | 3.37 | 246 | J | low | 248 | 3.24 | 0 |

| D | High | 304 | 4.06 | 102 | L | Low | 258 | 0.82 | 105 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.-H.; Lee, E.-B.; Choi, H.-S. Detail Engineering Completion Rating Index System (DECRIS) for Optimal Initiation of Construction Works to Improve Contractors’ Schedule-Cost Performance for Offshore Oil and Gas EPC Projects. Sustainability 2018, 10, 2469. https://0-doi-org.brum.beds.ac.uk/10.3390/su10072469

Kim M-H, Lee E-B, Choi H-S. Detail Engineering Completion Rating Index System (DECRIS) for Optimal Initiation of Construction Works to Improve Contractors’ Schedule-Cost Performance for Offshore Oil and Gas EPC Projects. Sustainability. 2018; 10(7):2469. https://0-doi-org.brum.beds.ac.uk/10.3390/su10072469

Chicago/Turabian StyleKim, Myung-Hun, Eul-Bum Lee, and Han-Suk Choi. 2018. "Detail Engineering Completion Rating Index System (DECRIS) for Optimal Initiation of Construction Works to Improve Contractors’ Schedule-Cost Performance for Offshore Oil and Gas EPC Projects" Sustainability 10, no. 7: 2469. https://0-doi-org.brum.beds.ac.uk/10.3390/su10072469