A Structured Literature Review on Obsolete Electric Vehicles Management Practices

Abstract

:1. Introduction

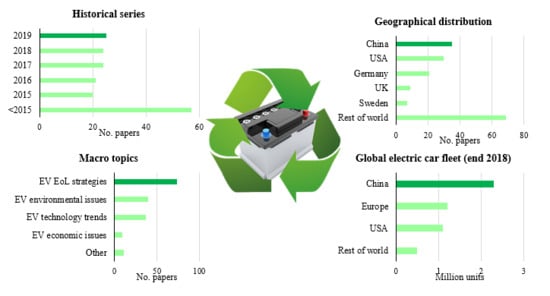

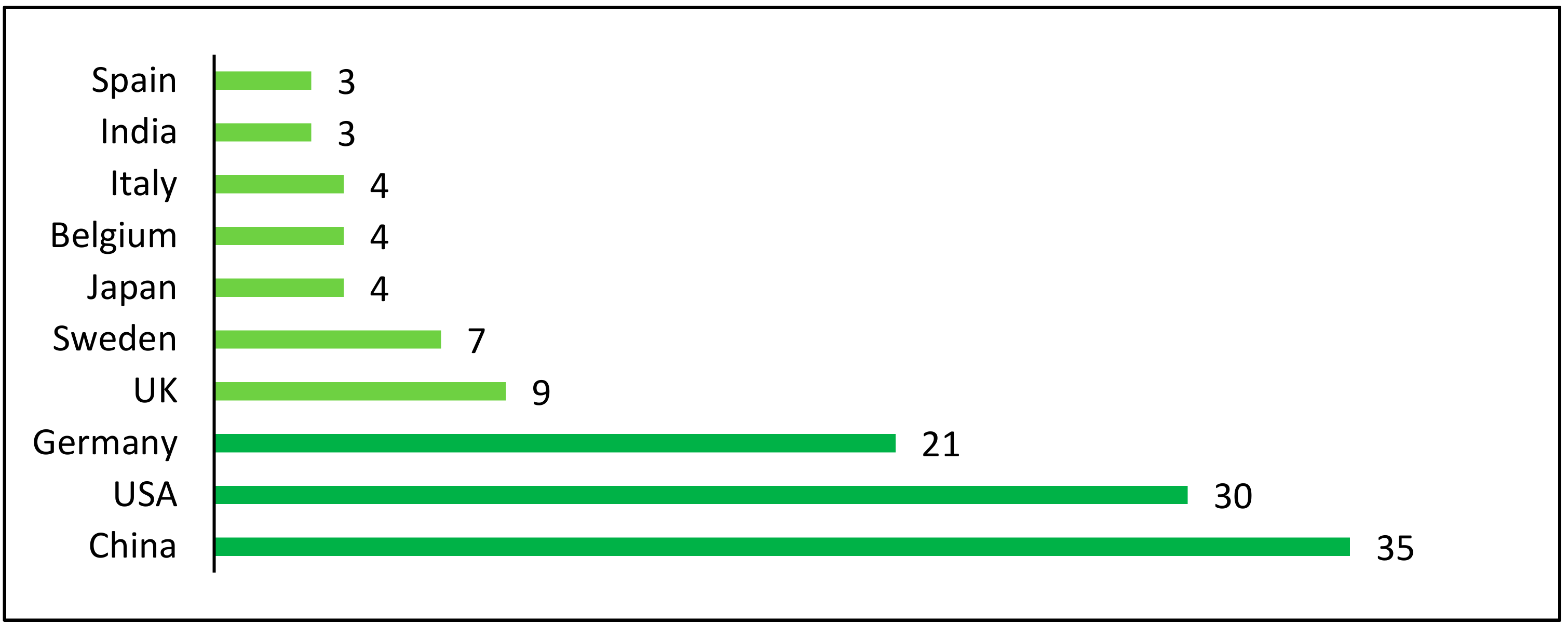

2. Materials and Methods

2.1. Topic Conceptualization and Classification

2.2. Research Methodology and Framework of Analysis

3. Results

- Works on EV disassembly (see Section 3.1);

- Works on EV recycling (and reuse, just for batteries)—(see Section 3.2);

- Works on EV remanufacturing (see Section 3.3).

- Works on EV recycling environmental issues (see Section 3.4);

- Works on EV recycling economic issues (see Section 3.5);

- Works on EV recycling social issues (see Section 3.6).

3.1. EV Disassembly

3.2. EV Recycling

3.2.1. EV Battery Recycling

3.2.2. EV Magnet Recycling

3.2.3. EV Power Electronics Recycling

3.2.4. Fuel Cells Recycling

3.3. EV Remanufacturing

3.4. EV Environmental Issues

3.5. EV Economic Issues

3.6. EV Social Issues

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Acronyms

| BEV | Battery Electric Vehicle | GHG | Greenhouse Gas |

| CE | Circular Economy | HEV | Hybrid Electric Vehicle |

| ELV | End of Life Vehicles | ICEV | Internal Combustion Engine Vehicle |

| EoL | End of Life | IEA | International Energy Association |

| ESS | Energy Storage System | LIB | Lithium Ion Battery |

| EU | European Union | PCB | Printed Circuit Board |

| EV | Electric Vehicle | PHEV | Plug-in Hybrid Electric Vehicle |

| EVI | Electric Vehicle Initiative | RE | Renewable Energy |

| FCEV | Fuel Cell Electric Vehicle | REE | Rare Earth Elements |

| FCHEV | Fuel Cell Hybrid Electric Vehicle | REEV | Range Extended Electric Vehicle |

References

- IRENA. Biogas for Road Vehicles Technologu Brief; IRENA: Abu Dhabi, UAE, 2018. [Google Scholar]

- Tan, X.; Zeng, Y.; Gu, B.; Wang, Y.; Xu, B. Scenario Analysis of Urban Road Transportation Energy Demand and GHG Emissions in China—A Case Study for Chongqing. Sustainability 2018, 10, 2033. [Google Scholar] [CrossRef] [Green Version]

- Lu, M.; Xie, R.; Chen, P.; Zou, Y.; Tang, J. Green Transportation and Logistics Performance: An Improved Composite Index. Sustainability 2019, 11, 2976. [Google Scholar] [CrossRef] [Green Version]

- Martin, M.; Røyne, F.; Ekvall, T.; Moberg, Å. Life cycle sustainability evaluations of bio-based value chains: Reviewing the indicators from a Swedish perspective. Sustainability 2018, 10, 547. [Google Scholar] [CrossRef] [Green Version]

- Sovacool, B.K.; Kester, J.; Heida, V. Cars and kids: Childhood perceptions of electric vehicles and sustainable transport in Denmark and the Netherlands. Technol. Forecast. Soc. Chang. 2019, 144, 182–192. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F. Heavy vehicles on the road towards the circular economy: Analysis and comparison with the automotive industry. Resour. Conserv. Recycl. 2018, 135, 108–122. [Google Scholar] [CrossRef]

- Fuso Nerini, F.; Slob, A.; Engström, R.E.; Trutnevyte, E. A Research and Innovation Agenda for Zero-Emission European Cities. Sustainability 2019, 11, 1692. [Google Scholar] [CrossRef] [Green Version]

- Álvarez Fernández, R. A more realistic approach to electric vehicle contribution to greenhouse gas emissions in the city. J. Clean. Prod. 2018, 172, 949–959. [Google Scholar] [CrossRef]

- Zhang, Y.; Han, Q. Development of electric vehicles for China’s power generation portfolio: A regional economic and environmental analysis. J. Clean. Prod. 2017, 162, 71–85. [Google Scholar] [CrossRef]

- IEA. Global EV Outlook 2019—Scaling-Up the Transition to Electric Mobility; IEA: London, UK, 2019. [Google Scholar]

- EEA. Electric Vehicles in Europe; EEA: Copenhagen, Denmark, 2016. [Google Scholar]

- Grandell, L.; Lehtilä, A.; Kivinen, M.; Koljonen, T.; Kihlman, S.; Lauri, L.S. Role of critical metals in the future markets of clean energy technologies. Renew. Energy 2016, 95, 53–62. [Google Scholar] [CrossRef]

- Wittstock, R.; Pehlken, A.; Wark, M. Challenges in Automotive Fuel Cells Recycling. Recycling 2016, 1, 343–364. [Google Scholar] [CrossRef] [Green Version]

- Lave, L.B.; MacLean, H.L. An environmental-economic evaluation of hybrid electric vehicles: Toyota’s Prius vs. its conventional internal combustion engine Corolla. Transp. Res. Part D Transp. Environ. 2002, 7, 155–162. [Google Scholar] [CrossRef]

- Offer, G.J.; Howey, D.; Contestabile, M.; Clague, R.; Brandon, N.P. Comparative analysis of battery electric, hydrogen fuel cell and hybrid vehicles in a future sustainable road transport system. Energy Policy 2010, 38, 24–29. [Google Scholar] [CrossRef] [Green Version]

- Correa, G.; Muñoz, P.; Falaguerra, T.; Rodriguez, C.R. Performance comparison of conventional, hybrid, hydrogen and electric urban buses using well to wheel analysis. Energy 2017, 141, 537–549. [Google Scholar] [CrossRef]

- Graditi, G.; Langella, G.; Laterza, C.; Valenti, M. Conventional and electric vehicles: A complete economic and environmental comparison. In Proceedings of the ICCEP 2015—5th International Conference on Clean Electrical Power: Renewable Energy Resources Impact, Taormina, Italy, 16–18 June 2015; pp. 660–665. [Google Scholar]

- Wang, W.; Wu, Y. An overview of recycling and treatment of spent LiFePO4 batteries in China. Resour. Conserv. Recycl. 2017, 127, 233–243. [Google Scholar] [CrossRef]

- Manzetti, S.; Mariasiu, F. Electric vehicle battery technologies: From present state to future systems. Renew. Sustain. Energy Rev. 2015, 51, 1004–1012. [Google Scholar] [CrossRef]

- Hao, H.; Qiao, Q.; Liu, Z.; Zhao, F. Impact of recycling on energy consumption and greenhouse gas emissions from electric vehicle production: The China 2025 case. Resour. Conserv. Recycl. 2017, 122, 114–125. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, Q.; Li, Y.; Wang, G.; Li, Y. Recycling Mechanisms and Policy Suggestions for Spent Electric Vehicles’ Power Battery -A Case of Beijing. J. Clean. Prod. 2018, 186, 388–406. [Google Scholar] [CrossRef]

- Larcher, D.; Tarascon, J.-M. Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 2015, 7, 19–29. [Google Scholar] [CrossRef]

- Mathur, N.; Deng, S.; Singh, S.; Yih, Y. Evaluating the environmental benefits of implementing Industrial Symbiosis to used electric vehicle batteries. Procedia CIRP 2019, 80, 661–666. [Google Scholar] [CrossRef]

- Qiao, Q.; Zhao, F.; Liu, Z.; He, X.; Hao, H. Life cycle greenhouse gas emissions of Electric Vehicles in China: Combining the vehicle cycle and fuel cycle. Energy 2019, 177, 222–233. [Google Scholar] [CrossRef]

- Rosa, P.; Terzi, S. Comparison of current practices for a combined management of printed circuit boards from different waste streams. J. Clean. Prod. 2016, 137, 300–312. [Google Scholar] [CrossRef]

- Singlitico, A.; Goggins, J.; Monaghan, R.F.D. The role of life cycle assessment in the sustainable transition to a decarbonised gas network through green gas production. Renew. Sustain. Energy Rev. 2019, 99, 16–28. [Google Scholar] [CrossRef]

- Zeng, X.; Li, J.; Liu, L. Solving spent lithium-ion battery problems in China: Opportunities and challenges. Renew. Sustain. Energy Rev. 2015, 52, 1759–1767. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Rosa, P.; Terzi, S. Automotive printed circuit boards recycling: An economic analysis. J. Clean. Prod. 2016, 121, 130–141. [Google Scholar] [CrossRef]

- D’Adamo, I.; Rosa, P.; Terzi, S. Challenges in waste electrical and electronic equipment management: A profitability assessment in three European countries. Sustainability 2016, 8, 633. [Google Scholar] [CrossRef] [Green Version]

- Amato, A.; Becci, A.; Birloaga, I.; De Michelis, I.; Ferella, F.; Innocenzi, V.; Ippolito, N.M.; Pillar Jimenez Gomez, C.; Vegliò, F.; Beolchini, F. Sustainability analysis of innovative technologies for the rare earth elements recovery. Renew. Sustain. Energy Rev. 2019, 106, 41–53. [Google Scholar] [CrossRef]

- Cheng, C.; Lin, C.; Wen, L.; Chang, T. Determining environmental costs: A challenge in a governmental e-waste recycling scheme. Sustainability 2019, 11, 5156. [Google Scholar] [CrossRef] [Green Version]

- Webster, J.; Watson, R.T. Analyzing the Past to Prepare for the Future: Writing a Literature Review. MIS Q. 2002, 26, xiii-xiii. [Google Scholar]

- Du, J.; Ouyang, M.; Chen, J. Prospects for Chinese electric vehicle technologies in 2016–2020: Ambition and rationality. Energy 2017, 120, 584–596. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, Y.; Yu, E.; Rao, R.; Xie, J. Review of electric vehicle policies in China: Content summary and effect analysis. Renew. Sustain. Energy Rev. 2017, 70, 698–714. [Google Scholar] [CrossRef]

- IEA. Global EV Outlook 2016—Beyond One Million Electric Cars; IEA: London, UK, 2016. [Google Scholar]

- IEA. Global EV Outlook 2017—Two Million and Counting; IEA: London, UK, 2017. [Google Scholar]

- Wolff, S.; Madlener, R. Driven by change: Commercial drivers’ acceptance and efficiency perceptions of light-duty electric vehicle usage in Germany. Transp. Res. Part C Emerg. Technol. 2019, 105, 262–282. [Google Scholar] [CrossRef]

- Zeng, X.; Duan, H.; Wang, F.; Li, J. Examining environmental management of e-waste: China’s experience and lessons. Renew. Sustain. Energy Rev. 2017, 72, 1076–1082. [Google Scholar] [CrossRef]

- Choma, E.F.; Ugaya, C.M.L. Environmental impact assessment of increasing electric vehicles in the Brazilian fleet. J. Clean. Prod. 2017, 152, 497–507. [Google Scholar] [CrossRef]

- Peters, J.F.; Baumann, M.; Zimmermann, B.; Braun, J.; Weil, M. The environmental impact of Li-Ion batteries and the role of key parameters—A review. Renew. Sustain. Energy Rev. 2017, 67, 491–506. [Google Scholar] [CrossRef]

- Wegener, K.; Andrew, S.; Raatz, A.; Dröder, K.; Herrmann, C. Disassembly of electric vehicle batteries using the example of the Audi Q5 hybrid system. Procedia CIRP 2014, 23, 155–160. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Li, B.; Garg, A.; Liu, Y. A generic framework for recycling of battery module for electric vehicle by combining the mechanical and chemical procedures. Int. J. Energy Res. 2018, 42, 3390–3399. [Google Scholar] [CrossRef]

- Bdiwi, M.; Rashid, A.; Putz, M. Autonomous disassembly of electric vehicle motors based on robot cognition. In Proceedings of the ICRA 2016—IEEE International Conference on Robotics and Automation; IEEE: Stockholm, Sweden, 2016; pp. 2500–2505. [Google Scholar]

- Li, J.; Barwood, M.; Rahimifard, S. Robotic disassembly for increased recovery of strategically important materials from electrical vehicles. Robot. Comput. Integr. Manuf. 2018, 50, 203–212. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Barwood, M.; Rahimifard, S. An automated approach for disassembly and recycling of Electric Vehicle components. In Proceedings of the IEVC 2014—IEEE International Electric Vehicle Conference, Florence, Italy, 17–19 December 2014; pp. 1–6. [Google Scholar]

- Elwert, T.; Goldmann, D.; Römer, F.; Buchert, M.; Merz, C.; Schüler, D.; Sutter, J. Current Developments and Challenges in the Recycling of Key Components of (Hybrid) Electric Vehicles. Recycling 2015, 1, 25–60. [Google Scholar] [CrossRef]

- Ciez, R.E.; Whitacre, J.F. Examining different recycling processes for lithium-ion batteries. Nat. Sustain. 2019, 2, 148–156. [Google Scholar] [CrossRef]

- Canals Casals, L.; Amante García, B.; Aguesse, F.; Iturrondobeitia, A. Second life of electric vehicle batteries: Relation between materials degradation and environmental impact. Int. J. Life Cycle Assess. 2017, 22, 82–93. [Google Scholar] [CrossRef]

- Bräuer, S. They Not Only Live Once—Towards Product- Service Systems for Repurposed Electric Vehicle Batteries. In Proceedings of the MKWI 2016—Multikonferenz Wirtschaftsinformatik; Nissen, V., Stelzer, D., Straßburger, S., Fischer, D., Eds.; Technische Universität Ilmenau: Ilmenau, Germany, 2016; Volume 4, pp. 1299–1310. [Google Scholar]

- Xie, Y.; Yu, H.; Ou, Y.; Li, C. Business Model for Recycling Traction Battery. In Proceedings of the MEITA 2015—International Conference on Materials Engineering and Information Technology Applications, Qingdao, China, 28–29 November 2015; pp. 176–180. [Google Scholar]

- Cusenza, M.A.; Guarino, F.; Longo, S.; Mistretta, M.; Cellura, M. Reuse of electric vehicle batteries in buildings: An integrated load match analysis and life cycle assessment approach. Energy Build. 2019, 186, 339–354. [Google Scholar] [CrossRef]

- Pagliaro, M.; Meneguzzo, F. Lithium battery reusing and recycling: A circular economy insight. Heliyon 2019, 5, 1–7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ioakimidis, C.S.; Murillo-Marrodán, A.; Bagheri, A.; Thomas, D.; Genikomsakis, K.N. Life Cycle Assessment of a Lithium Iron Phosphate (LFP) Electric Vehicle Battery in Second Life Application Scenarios. Sustainability 2019, 11, 2527. [Google Scholar] [CrossRef] [Green Version]

- Gaines, L. The future of automotive lithium-ion battery recycling: Charting a sustainable course. Sustain. Mater. Technol. 2014, 1, 2–7. [Google Scholar] [CrossRef] [Green Version]

- Sonoc, A.; Jeswiet, J.; Soo, V.K. Opportunities to improve recycling of automotive lithium ion batteries. Procedia CIRP 2015, 29, 752–757. [Google Scholar] [CrossRef]

- Sonoc, A.; Jeswiet, J. A review of lithium supply and demand and a preliminary investigation of a room temperature method to recycle lithium ion batteries to recover lithium and other materials. Procedia CIRP 2014, 15, 289–293. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Gong, D. Modelling and simulation on recycling of electric vehicle batteries—Using Agent approach. Int. J. Simul. Model. 2014, 13, 79–92. [Google Scholar] [CrossRef]

- Tytgat, J. The recycling efficiency of Li-ion EV batteries according to the European Commission Regulation, and the relation with the end-of-life vehicles directive recycling rate. In Proceedings of the EVS27—2013 World Electric Vehicle Symposium and Exhibition, Barcelona, Spain, 17–20 November 2013; Volume 6, pp. 1039–1047. [Google Scholar]

- Chagnes, A.; Pospiech, B. A brief review on hydrometallurgical technologies for recycling spent lithium-ion batteries. J. Chem. Technol. Biotechnol. 2013, 88, 1191–1199. [Google Scholar] [CrossRef]

- Zeng, X.; Li, J.; Singh, N. Recycling of spent lithium-ion battery: A critical review. Crit. Rev. Environ. Sci. Technol. 2014, 44, 1129–1165. [Google Scholar] [CrossRef]

- Chen, X.; Ma, H.; Luo, C.; Zhou, T. Recovery of valuable metals from waste cathode materials of spent lithium-ion batteries using mild phosphoric acid. J. Hazard. Mater. 2017, 326, 77–86. [Google Scholar] [CrossRef]

- Heelan, J.; Gratz, E.; Zheng, Z.; Wang, Q.; Chen, M.; Apelian, D.; Wang, Y. Current and Prospective Li-Ion Battery Recycling and Recovery Processes. JOM J. Miner. Met. Mater. Soc. 2016, 68, 2632–2638. [Google Scholar] [CrossRef] [Green Version]

- Ku, H.; Jung, Y.; Jo, M.; Park, S.; Kim, S.; Yang, D.; Rhee, K.; An, E.-M.; Sohn, J.; Kwon, K. Recycling of spent lithium-ion battery cathode materials by ammoniacal leaching. J. Hazard. Mater. 2016, 313, 138–146. [Google Scholar] [CrossRef] [PubMed]

- Moradi, B.; Botte, G.G. Recycling of graphite anodes for the next generation of lithium ion batteries. J. Appl. Electrochem. 2016, 46, 123–148. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, Z.; Xia, J.; Li, F.; He, W.; Li, G.; Huang, J. Preparing graphene from anode graphite of spent lithium-ion batteries. Front. Environ. Sci. Eng. 2017, 11, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Xue, Q.; Li, L.; Fan, E.; Wu, F.; Chen, R. Sustainable Recycling and Regeneration of Cathode Scraps from Industrial Production of Lithium-Ion Batteries. ACS Sustain. Chem. Eng. 2016, 4, 7041–7049. [Google Scholar] [CrossRef]

- Li, H.; Corneal, L.M.; Standridge, C.R. Effects of acid concentration, temperature, and time on recycling of post-vehicle-application lithium-ion batteries of varying chemistries. Mater. Renew. Sustain. Energy 2015, 4, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Zeng, X.; Li, J. Innovative application of ionic liquid to separate Al and cathode materials from spent high-power lithium-ion batteries. J. Hazard. Mater. 2014, 271, 50–56. [Google Scholar] [CrossRef]

- Raugei, M.; Winfield, P. Prospective LCA of the production and EoL recycling of a novel type of Li-ion battery for electric vehicles. J. Clean. Prod. 2019, 213, 926–932. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Fan, E.; Guan, Y.; Zhang, X.; Xue, Q.; Wei, L.; Wu, F.; Chen, R. Sustainable Recovery of Cathode Materials from Spent Lithium-Ion Batteries Using Lactic Acid Leaching System. ACS Sustain. Chem. Eng. 2017, 5, 5224–5233. [Google Scholar] [CrossRef]

- Xin, Y.; Guo, X.; Chen, S.; Wang, J.; Wu, F.; Xin, B. Bioleaching of valuable metals Li, Co, Ni and Mn from spent electric vehicle Li-ion batteries for the purpose of recovery. J. Clean. Prod. 2016, 116, 249–258. [Google Scholar] [CrossRef]

- Cheng, Y.-P.; Li, Y.; Jiang, S.; Xie, H.-Q. The recovery of lithium cobalt oxides from spent Li-ion batteries and its electrochemical performances. In Proceedings of the ICPRE 2016—2016 IEEE International Conference on Power and Renewable Energy, Shanghai, China, 21–23 October 2016; pp. 204–208. [Google Scholar]

- Diekmann, J.; Hanisch, C.; Froböse, L.; Schälicke, G.; Loellhoeffel, T.; Fölster, A.-S.; Kwade, A. Ecological Recycling of Lithium-Ion Batteries from Electric Vehicles with Focus on Mechanical Processes. J. Electrochem. Soc. 2017, 164, A6184–A6191. [Google Scholar] [CrossRef]

- Yun, L.; Linh, D.; Shui, L.; Peng, X.; Garg, A.; LE, M.L.P.; Asghari, S.; Sandoval, J. Metallurgical and mechanical methods for recycling of lithium-ion battery pack for electric vehicles. Resour. Conserv. Recycl. 2018, 136, 198–208. [Google Scholar] [CrossRef]

- Lixandru, A.; Venkatesan, P.; Jönsson, C.; Poenaru, I.; Hall, B.; Yang, Y.; Walton, A.; Güth, K.; Gauß, R.; Gutfleisch, O. Identification and recovery of rare-earth permanent magnets from waste electrical and electronic equipment. Waste Manag. 2017, 68, 482–489. [Google Scholar] [CrossRef] [PubMed]

- Bandara, H.M.D.; Mantell, M.A.; Darcy, J.W.; Emmert, M.H. Rare Earth Recycling: Forecast of Recoverable Nd from Shredder Scrap and Influence of Recycling Rates on Price Volatility. J. Sustain. Metall. 2015, 1, 179–188. [Google Scholar] [CrossRef] [Green Version]

- Bandara, H.M.D.; Darcy, J.W.; Apelian, D.; Emmert, M.H. Value analysis of neodymium content in shredder feed: Toward enabling the feasibility of rare earth magnet recycling. Environ. Sci. Technol. 2014, 48, 6553–6560. [Google Scholar] [CrossRef]

- Rademaker, J.H.; Kleijn, R.; Yang, Y. Recycling as a strategy against rare earth element criticality: A systemic evaluation of the potential yield of NdFeB magnet recycling. Environ. Sci. Technol. 2013, 47, 10129–10136. [Google Scholar] [CrossRef]

- Yano, J.; Muroi, T.; Sakai, S. Rare earth element recovery potentials from end-of-life hybrid electric vehicle components in 2010-2030. J. Mater. Cycles Waste Manag. 2015, 18, 655–664. [Google Scholar] [CrossRef]

- Elwert, T.; Goldmann, D.; Roemer, F.; Schwarz, S. Recycling of NdFeB Magnets from Electric Drive Motors of (Hybrid) Electric Vehicles. J. Sustain. Metall. 2016, 3, 108–121. [Google Scholar] [CrossRef]

- Bulach, W.; Schüler, D.; Sellin, G.; Elwert, T.; Schmid, D.; Goldmann, D.; Buchert, M.; Kammer, U. Electric vehicle recycling 2020: Key component power electronics. Waste Manag. Res. 2018, 36, 311–320. [Google Scholar] [CrossRef]

- Handley, C.; Brandon, N.P.; van der Vorst, R. Impact of the European Union vehicle waste directive on end-of-life options for polymer electrolyte fuel cells. J. Power Sources 2002, 106, 344–352. [Google Scholar] [CrossRef]

- Kaushal, R.K.; Nema, A.K.; Chaudhary, J. Strategic exploration of battery waste management: A game-theoretic approach. Waste Manag. Res. 2015, 33, 681–689. [Google Scholar] [CrossRef] [PubMed]

- Xing, Y.; Ma, E.W.M.; Tsui, K.L.; Pecht, M. Battery Management Systems in Electric and Hybrid Vehicles. Energies 2011, 4, 1840–1857. [Google Scholar] [CrossRef]

- Hu, Y.; Cheng, H.; Tao, S. Retired Electric Vehicle (EV) Batteries: Integrated Waste Management and Research Needs. Environ. Sci. Technol. 2017, 51, 10927–10929. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Song, Y.; Li, L.; Liao, H.; Peng, Y. On-line life cycle health assessment for lithium-ion battery in electric vehicles. J. Clean. Prod. 2018, 199, 1050–1065. [Google Scholar] [CrossRef]

- Richa, K.; Babbitt, C.W.; Gaustad, G. Eco-Efficiency Analysis of a Lithium-Ion Battery Waste Hierarchy Inspired by Circular Economy. J. Ind. Ecol. 2017, 21, 715–730. [Google Scholar] [CrossRef]

- Richa, K.; Babbitt, C.W.; Gaustad, G.; Wang, X. A future perspective on lithium-ion battery waste flows from electric vehicles. Resour. Conserv. Recycl. 2014, 83, 63–76. [Google Scholar] [CrossRef]

- Soo, V.K.; Peeters, J.R.; Paraskevas, D.; Compston, P.; Doolan, M.; Duflou, J.R. Sustainable aluminium recycling of end-of-life products: A joining techniques perspective. J. Clean. Prod. 2018, 178, 119–132. [Google Scholar] [CrossRef] [Green Version]

- Xu, C.J.; Zhang, W.; He, W.; Li, G.; Huang, J.; Zhu, H. Generation and management of waste electric vehicle batteries in China. Environ. Sci. Pollut. Res. 2017, 24, 20825–20830. [Google Scholar] [CrossRef]

- Ramoni, M.O.; Zhang, H.-C. End-of-life (EOL) issues and options for electric vehicle batteries. Clean Technol. Environ. Policy 2013, 15, 881–891. [Google Scholar] [CrossRef]

- Foster, M.; Isely, P.; Standridge, C.R.; Hasan, M.M. Feasibility assessment of remanufacturing, repurposing, and recycling of end of vehicle application lithium-ion batteries. J. Ind. Eng. Manag. 2014, 7, 698–715. [Google Scholar] [CrossRef] [Green Version]

- Kampker, A.; Heimes, H.H.; Ordung, M.; Lienemann, C.; Hollah, A.; Sarovic, N. Evaluation of a Remanufacturing for Lithium Ion Batteries from Electric Cars. Int. J. Mech. Mechatron. Eng. 2016, 10, 1922–1928. [Google Scholar]

- Liu, W.-W.; Zhang, H.; Liu, L.-H.; Qing, X.-C.; Tang, Z.-J.; Li, M.-Z.; Yin, J.-S.; Zhang, H.-C. Remanufacturing cathode from end-of-life of lithium-ion secondary batteries by Nd:YAG laser radiation. Clean Technol. Environ. Policy 2016, 18, 231–243. [Google Scholar] [CrossRef]

- Hannan, M.A.; Hoque, M.M.; Mohamed, A.; Ayob, A. Review of energy storage systems for electric vehicle applications: Issues and challenges. Renew. Sustain. Energy Rev. 2017, 69, 771–789. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, M.; Zheng, J.; Sun, X.; Zhao, M.; Wang, X. Life cycle greenhouse gas emission reduction potential of battery electric vehicle. J. Clean. Prod. 2018, 190, 462–470. [Google Scholar] [CrossRef]

- Riba, J.R.; López-Torres, C.; Romeral, L.; Garcia, A. Rare-earth-free propulsion motors for electric vehicles: A technology review. Renew. Sustain. Energy Rev. 2016, 57, 367–379. [Google Scholar] [CrossRef] [Green Version]

- Ziemann, S.; Müller, D.B.; Schebek, L.; Weil, M. Modeling the potential impact of lithium recycling from EV batteries on lithium demand: A dynamic MFA approach. Resour. Conserv. Recycl. 2018, 133, 76–85. [Google Scholar] [CrossRef]

- Wang, X.; Gaustad, G.; Babbitt, C.W.; Bailey, C.; Ganter, M.J.; Landi, B.J. Economic and environmental characterization of an evolving Li-ion battery waste stream. J. Environ. Manag. 2014, 135, 126–134. [Google Scholar] [CrossRef]

- Wang, X.; Gaustad, G.; Babbitt, C.W.; Richa, K. Economies of scale for future lithium-ion battery recycling infrastructure. Resour. Conserv. Recycl. 2014, 83, 53–62. [Google Scholar] [CrossRef]

- Price, B.; Dietz, E.; Richardson, J. Life cycle costs of electric and hybrid electric vehicle batteries and End-of-Life uses. In Proceedings of the EIT 2012—IEEE International Conference on Electro/Information Technology, Indianapolis, IN, USA, 6–8 May 2012; pp. 1–7. [Google Scholar]

- Kibira, D.; Jain, S. Impact of Hybrid and Electric Vehicles on Automobile Recycling Infrastructure. In Proceedings of the WSC’11—2011 IEEE Winter Simulation Conference, Phoenix, AZ, USA, 11–14 December 2011; pp. 1072–1083. [Google Scholar]

- Huth, C.; Kieckhäfer, K.; Spengler, T.S. Make-or-buy strategies for electric vehicle batteries-a simulation-based analysis. Technol. Forecast. Soc. Chang. 2015, 99, 22–34. [Google Scholar] [CrossRef]

- Jansson, J.; Nordlund, A.; Westin, K. Examining drivers of sustainable consumption: The influence of norms and opinion leadership on electric vehicle adoption in Sweden. J. Clean. Prod. 2017, 154, 176–187. [Google Scholar] [CrossRef]

- Garcia-Muiña, F.; González-Sánchez, R.; Ferrari, A.; Settembre-Blundo, D. The Paradigms of Industry 4.0 and Circular Economy as Enabling Drivers for the Competitiveness of Businesses and Territories: The Case of an Italian Ceramic Tiles Manufacturing Company. Soc. Sci. 2018, 7, 255. [Google Scholar] [CrossRef] [Green Version]

- D’Adamo, I.; Falcone, P.M.; Ferella, F. A socio-economic analysis of biomethane in the transport sector: The case of Italy. Waste Manag. 2019, 95, 102–115. [Google Scholar] [CrossRef]

- Garcia-Muiña, F.E.; González-Sánchez, R.; Ferrari, A.M.; Volpi, L.; Pini, M.; Settembre-Blundo, C.; Settembre-Blundo, D. Identifying the Equilibrium Point between Sustainability Goals and Circular Economy Practices in an Industry 4.0 Manufacturing Context Using Eco-Design. Soc. Sci. 2019, 8, 241. [Google Scholar] [CrossRef] [Green Version]

- Un-Noor, F.; Padmanaban, S.; Mihet-Popa, L.; Mollah, M.N.; Hossain, E. A comprehensive study of key electric vehicle (EV) components, technologies, challenges, impacts, and future direction of development. Energies 2017, 10, 1217. [Google Scholar] [CrossRef] [Green Version]

- Kawamoto, R.; Mochizuki, H.; Moriguchi, Y.; Nakano, T.; Motohashi, M.; Sakai, Y.; Inaba, A. Estimation of CO2 Emissions of Internal Combustion Engine Vehicle and Battery Electric Vehicle Using LCA. Sustainability 2019, 11, 2690. [Google Scholar] [CrossRef] [Green Version]

- Ferrão, P.; Amaral, J. Assessing the economics of auto recycling activities in relation to European Union Directive on end of life vehicles. Technol. Forecast. Soc. Chang. 2006, 73, 277–289. [Google Scholar] [CrossRef]

- Li, Y.; Lim, M.K.; Tan, Y.; Lee, S.Y.; Tseng, M.-L. Sharing economy to improve routing for urban logistics distribution using electric vehicles. Resour. Conserv. Recycl. 2019, 153, 1–13. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Gaustad, G.; Krystofik, M.; Bustamante, M.; Badami, K. Circular economy strategies for mitigating critical material supply issues. Resour. Conserv. Recycl. 2018, 135, 24–33. [Google Scholar] [CrossRef]

- Zubi, G.; Dufo-López, R.; Carvalho, M.; Pasaoglu, G. The lithium-ion battery: State of the art and future perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308. [Google Scholar] [CrossRef]

- Stoycheva, S.; Marchese, D.; Paul, C.; Padoan, S.; Juhmani, A.; Linkov, I. Multi-criteria decision analysis framework for sustainable manufacturing in automotive industry. J. Clean. Prod. 2018, 187, 257–272. [Google Scholar] [CrossRef]

- Krishna Mohan, T.V.; Amit, R.K. Dismantlers’ dilemma in end-of-life vehicle recycling markets: A system dynamics model. Ann. Oper. Res. 2018, 1–29. [Google Scholar] [CrossRef]

- Rosa, P.; Terzi, S. Improving end of life vehicle’s management practices: An economic assessment through system dynamics. J. Clean. Prod. 2018, 184, 520–536. [Google Scholar] [CrossRef]

- Gu, H.; Liu, Z.; Qing, Q. Optimal electric vehicle production strategy under subsidy and battery recycling. Energy Policy 2017, 109, 579–589. [Google Scholar] [CrossRef]

- Hoyer, C.; Kieckhäfer, K.; Spengler, T.S. Impact of Mandatory Rates on the Recycling of Lithium-Ion Batteries from Electric Vehicles in Germany. In Proceedings of the LCE 2013—20th CIRP International Conference on Life Cycle Engineering, Singapore, 17–19 April 2013; pp. 543–548. [Google Scholar]

- Khodier, A.; Williams, K.S.; Dallison, N. Challenges around automotive shredder residue production and disposal. Waste Manag. 2018, 73, 566–573. [Google Scholar] [CrossRef] [Green Version]

- Cucchiella, F.; D’Adamo, I.; Rosa, P.; Terzi, S. Scrap automotive electronics: A mini-review of current management practices. Waste Manag. Res. 2016, 34, 3–10. [Google Scholar] [CrossRef] [PubMed]

- Hoyer, C.; Kieckhäfer, K.; Spengler, T.S. Technology and capacity planning for the recycling of lithium-ion electric vehicle batteries in Germany. J. Bus. Econ. 2015, 85, 505–544. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, X.; Lim, M.K.; He, Y.; Li, L. Sustainable recycling partner selection using fuzzy DEMATEL-AEW-FVIKOR: A case study in small-and-medium enterprises (SMEs). J. Clean. Prod. 2018, 196, 489–504. [Google Scholar] [CrossRef]

- Ai, N.; Zheng, J.; Chen, W.-Q. US end-of-life electric vehicle batteries: Dynamic inventory modeling and spatial analysis for regional solutions. Resour. Conserv. Recycl. 2019, 145, 208–219. [Google Scholar] [CrossRef]

- Reinhardt, R.; Christodoulou, I.; Gassó-Domingo, S.; Amante García, B. Towards sustainable business models for electric vehicle battery second use: A critical review. J. Environ. Manag. 2019, 245, 432–446. [Google Scholar] [CrossRef]

- Mayyas, A.; Steward, D.; Mann, M. The case for recycling: Overview and challenges in the material supply chain for automotive li-ion batteries. Sustain. Mater. Technol. 2018, 17, 1–13. [Google Scholar] [CrossRef]

- Qiao, Q.; Zhao, F.; Liu, Z.; Hao, H. Electric vehicle recycling in China: Economic and environmental benefits. Resour. Conserv. Recycl. 2019, 140, 45–53. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, Q.; Li, Y.; Li, H.; Pan, X.; Mclellan, B. The social-economic-environmental impacts of recycling retired EV batteries under reward-penalty mechanism. Appl. Energy 2019, 251, 1–16. [Google Scholar] [CrossRef]

- Hendrickson, T.P.; Kavvada, O.; Shah, N.; Sathre, R.; Scown, C.D. Life-cycle implications and supply chain logistics of electric vehicle battery recycling in California. Environ. Res. Lett. 2015, 10, 1–10. [Google Scholar] [CrossRef]

| Author | Battery | Engine | Electronics |

|---|---|---|---|

| [41] | x | ||

| [42] | x | ||

| [43] | x | ||

| [44] | x | ||

| [45] | x |

| Author | Battery (Reuse/Recycle) | Magnets | Electronics | Fuel Cells |

|---|---|---|---|---|

| [48] | x | |||

| [49] | x | |||

| [50] | x | |||

| [51] | x | |||

| [52] | x | |||

| [53] | x | |||

| [54] | x | |||

| [55] | x | |||

| [18] | x | |||

| [42] | x | |||

| [56] | x | |||

| [57] | x | |||

| [21] | x | |||

| [58] | x | |||

| [50] | x | |||

| [59] | x | |||

| [60] | x | |||

| [61] | x | |||

| [62] | x | |||

| [63] | x | |||

| [64] | x | |||

| [65] | x | |||

| [66] | x | |||

| [67] | x | |||

| [68] | x | |||

| [69] | x | |||

| [70] | x | |||

| [71] | x | |||

| [72] | x | |||

| [73] | x | |||

| [42] | x | |||

| [74] | x | |||

| [75] | x | |||

| [76] | x | |||

| [77] | x | |||

| [78] | x | |||

| [79] | x | |||

| [80] | x | |||

| [46] | x | |||

| [81] | x | |||

| [82] | x | |||

| [13] | x |

| Author | Environmental | Economic | Technical |

|---|---|---|---|

| [48] | x | ||

| [49] | x | ||

| [50] | x | ||

| [51] | x | ||

| [52] | x | ||

| [53] | x |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Adamo, I.; Rosa, P. A Structured Literature Review on Obsolete Electric Vehicles Management Practices. Sustainability 2019, 11, 6876. https://0-doi-org.brum.beds.ac.uk/10.3390/su11236876

D’Adamo I, Rosa P. A Structured Literature Review on Obsolete Electric Vehicles Management Practices. Sustainability. 2019; 11(23):6876. https://0-doi-org.brum.beds.ac.uk/10.3390/su11236876

Chicago/Turabian StyleD’Adamo, Idiano, and Paolo Rosa. 2019. "A Structured Literature Review on Obsolete Electric Vehicles Management Practices" Sustainability 11, no. 23: 6876. https://0-doi-org.brum.beds.ac.uk/10.3390/su11236876