Optimization of Green Fresh Food Logistics with Heterogeneous Fleet Vehicle Route Problem by Improved Genetic Algorithm

Abstract

:1. Introduction

2. Literature Review

2.1. Green Logistics

2.2. VRP Models Considering the Damage to the Environment

2.3. VRP Models for Fresh Food Logistics

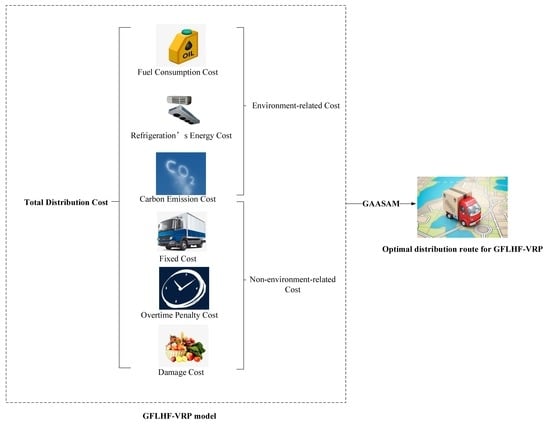

3. Model Formulation

3.1. Model Description

- There is only one distribution center, and the distribution center has vehicles of different types;

- Each type of vehicle has its own maximum load, fixed cost, fuel consumption, refrigeration energy consumption and the coefficient of carbon emission;

- The salary of the driver is included in the fixed cost of the distribution vehicle;

- The quality of fresh food is related to delivery time and temperature;

- The delivery vehicle shall arrive at the customer point within the time window specified by the customer. If it arrives at the customer point after the time window, it shall bear the cost of overtime punishment;

- The demand of any customer is not greater than the maximum load of any vehicle;

- The battery supplies the refrigeration equipment of the vehicle; and capacity of batteries is set to be enough for distribution, the situation that the vehicle runs without power will not be considered;

- All vehicles should depart from the distribution center and finally return to the distribution center;

- Vehicles shall not be overloaded;

- All vehicles run at a uniform speed.

3.2. Parameters and Variable Definition

3.3. Cost Analysis in GFLHF-VRP Model

3.3.1. Fixed Cost

3.3.2. Damage Cost

3.3.3. Overtime Penalty Cost

3.3.4. Fuel Consumption Cost

3.3.5. Refrigeration’s Energy Cost

3.3.6. Carbon Emission Cost

3.4. Objective Function of the Model

4. Adaptive Simulated Annealing Mutation Genetic Algorithm

4.1. Algorithm Introduction

4.2. Algorithm Composition

4.2.1. Encoding Operation

4.2.2. Population Initialization

4.2.3. Fitness Calculation

4.2.4. Individual Selection

4.2.5. Crossover Operation

4.2.6. Adaptive Simulated Annealing Mutation Operation

4.3. Algorithm Flows

5. Case Study

5.1. Experimental Data and Parameter Setting

5.2. Algorithm Performance Tests

6. Discussion

- More distribution vehicles that are suitable for fresh logistics with lower carbon emissions, lower fuel consumption and battery that can efficiently supply the energy for refrigerators should be used in fresh food logistics.

- Fresh food logistics enterprises should analyze their own logistics business with actual data to establish a complete mathematical model where experimental factors should be focused, and solve the model’s vehicle route problems through scientific algorithms; e.g., those enterprises can utilize the GFLHF-VRP model and GAASAM proposed in this paper to establish a greener and environmentally friendly distribution route for their own logistics business.

- The government should introduce concepts for fresh logistics companies to reduce carbon emissions, fuel consumption, and power consumption in the distribution process, and increase their environmental responsibility.

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| VRP | Vehicle Route Problem |

| G-VRP | Greem Vehicle Route Problem |

| GFLHF-VRP | Green Fresh Food Logistics with Heterogeneous Fleet Vehicle Route Problem |

| GA | Genetic Algorithm |

| GAASAM | Genetic Algorithm with Adaptive Simulated Annealing Mutation |

References

- Wang, X. Changes in CO2 Emissions induced by agricultural inputs in China over 1991–2014. Sustainability 2016, 8, 414. [Google Scholar] [CrossRef] [Green Version]

- Gregg, J.S.; Andres, R.J.; Marland, G. China: Emissions pattern of the world leader in CO2 emissions from fossil fuel consumption and cement production. Geophys. Res. Lett. 2008, 35. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, Y.; Xue, W.; Jin, L. Vehicle routing problem with fuel consumption and carbon emission. Int. J. Prod. Econ. 2015, 170, 234–242. [Google Scholar] [CrossRef]

- Montanari, R. Cold chain tracking: A managerial perspective. Trends Food Sci. Technol. 2008, 19, 425–431. [Google Scholar] [CrossRef]

- Mercier, S.; Villeneuve, S.; Mondor, M.; Uysal, I. Time–temperature management along the food cold chain: A review of recent developments. Compr. Rev. Food Sci. Food Saf. 2017, 16, 647–667. [Google Scholar] [CrossRef]

- Kuo, J.C.; Chen, M.C. Developing an advanced multi-temperature joint distribution system for the food cold chain. Food Control 2010, 21, 559–566. [Google Scholar] [CrossRef]

- Chen, J.; Gui, P.; Ding, T.; Na, S.; Zhou, Y. Optimization of Transportation Routing Problem for Fresh Food by Improved Ant Colony Algorithm Based on Tabu Search. Sustainability 2019, 11, 6584. [Google Scholar] [CrossRef] [Green Version]

- James, S.J.; James, C. The food cold-chain and climate change. Food Res. Int. 2010, 43, 1944–1956. [Google Scholar] [CrossRef]

- Wang, S.; Tao, F.; Shi, Y.; Wen, H. Optimization of vehicle routing problem with time windows for cold chain logistics based on carbon tax. Sustainability 2017, 9, 694. [Google Scholar] [CrossRef] [Green Version]

- Qiao, J. Research on optimizing the distribution route of food cold chain logistics based on modern biotechnology. AIP Conf. Proc. AIP Publ. 2019, 2110, 020070. [Google Scholar]

- Strandhagen, J.O.; Vallandingham, L.R.; Fragapane, G.; Strandhagen, J.W.; Stangeland, A.B.H.; Sharma, N. Logistics 4.0 and emerging sustainable business models. Adv. Manuf. 2017, 5, 359–369. [Google Scholar] [CrossRef]

- Facchini, F.; Oleśków-Szłapka, J.; Ranieri, L.; Urbinati, A. A Maturity Model for Logistics 4.0: An Empirical Analysis and a Roadmap for Future Research. Sustainability 2019, 12, 86. [Google Scholar] [CrossRef] [Green Version]

- Boenzi, F.; Digiesi, S.; Facchini, F.; Mossa, G. Greening Activities in Warehouses: A Model for Identifying Sustainable Strategies in Material Handling. Ann. DAAAM Proc. 2015, 26, 980–988. [Google Scholar]

- Facchini, F.; Pascale, G.D.; Faccilongo, N. Pallet picking strategy in food collecting center. Appl. Sci. 2018, 8, 1503. [Google Scholar] [CrossRef] [Green Version]

- Kuo, Y.; Wang, C.C. Optimizing the VRP by minimizing fuel consumption. Manag. Environ. Q. Int. J. 2011, 22, 440–450. [Google Scholar] [CrossRef]

- Bektaş, T.; Laporte, G. The pollution-routing problem. Transp. Res. Part B Methodol. 2011, 45, 1232–1250. [Google Scholar] [CrossRef]

- Erdoğan, S.; Miller-Hooks, E. A green vehicle routing problem. Transp. Res. Part E: Logist. Transp. Rev. 2012, 48, 100–114. [Google Scholar] [CrossRef]

- Koç, Ç.; Karaoglan, I. The green vehicle routing problem: A heuristic based exact solution approach. Appl. Soft Comput. 2016, 39, 154–164. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhao, Q.; Kaku, I.; Xu, Y. Development of a fuel consumption optimization model for the capacitated vehicle routing problem. Comput. Oper. Res. 2012, 39, 1419–1431. [Google Scholar] [CrossRef]

- Kwon, Y.J.; Choi, Y.J.; Lee, D.H. Heterogeneous fixed fleet vehicle routing considering carbon emission. Transp. Res. Part D Transp. Environ. 2013, 23, 81–89. [Google Scholar] [CrossRef]

- Bortolini, M.; Faccio, M.; Ferrari, E.; Gamberi, M.; Pilati, F. Fresh food sustainable distribution: Cost, delivery time and carbon footprint three-objective optimization. J. Food Eng. 2016, 174, 56–67. [Google Scholar] [CrossRef]

- Niu, Y.; Yang, Z.; Chen, P.; Xiao, J. Optimizing the green open vehicle routing problem with time windows by minimizing comprehensive routing cost. J. Clean. Prod. 2018, 171, 962–971. [Google Scholar] [CrossRef]

- Naderipour, M.; Alinaghian, M. Measurement, evaluation and minimization of CO2, NOx, and CO emissions in the open time dependent vehicle routing problem. Measurement 2016, 90, 443–452. [Google Scholar] [CrossRef] [Green Version]

- Hsu, C.I.; Hung, S.F.; Li, H.C. Vehicle routing problem with time-windows for perishable food delivery. J. Food Eng. 2007, 80, 465–475. [Google Scholar] [CrossRef]

- Osvald, A.; Stirn, L.Z. A vehicle routing algorithm for the distribution of fresh vegetables and similar perishable food. J. Food Eng. 2008, 85, 285–295. [Google Scholar] [CrossRef]

- Wu, Y.; Meng, Z.B.; Peng, M. The Research on the Optimization of Transportation Routing for Fresh Food by Improved Genetic Algorithm. Appl. Mech. Mater. Trans. Tech. Publ. 2012, 178, 1790–1796. [Google Scholar] [CrossRef]

- Amorim, P.; Parragh, S.N.; Sperandio, F.; Almada-Lobo, B. A rich vehicle routing problem dealing with perishable food: A case study. Top 2014, 22, 489–508. [Google Scholar] [CrossRef]

- Li, Y.; Chu, F.; Yang, Z.; Calvo, R.W. A production inventory routing planning for perishable food with quality consideration. IFAC-PapersOnLine 2016, 49, 407–412. [Google Scholar] [CrossRef]

- Wang, S.; Tao, F.; Shi, Y. Optimization of location–routing problem for cold chain logistics considering carbon footprint. Int. J. Environ. Res. 2018, 15, 86. [Google Scholar] [CrossRef] [Green Version]

- Shukla, M.; Jharkharia, S. Artificial Immune System-based algorithm for vehicle routing problem with time window constraint for the delivery of agri-fresh produce. J. Decis. Syst. 2013, 22, 224–247. [Google Scholar] [CrossRef]

- Wang, X.; Wang, M.; Ruan, J.; Zhan, H. The multi-objective optimization for perishable food distribution route considering temporal-spatial distance. Procedia Comput. Sci. 2016, 96, 1211–1220. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.K.; Hsueh, C.F.; Chang, M.S. Production scheduling and vehicle routing with time windows for perishable food products. Comput. Oper. Res. 2009, 36, 2311–2319. [Google Scholar] [CrossRef]

- Norouzi, N.; Sadegh-Amalnick, M.; Tavakkoli-Moghaddam, R. Modified particle swarm optimization in a time-dependent vehicle routing problem: Minimizing fuel consumption. Optim. Lett. 2017, 11, 121–134. [Google Scholar] [CrossRef]

- Park, J.B.; Park, Y.M.; Won, J.R.; Lee, K.Y. An improved genetic algorithm for generation expansion planning. IEEE Trans. Power Syst. 2000, 15, 916–922. [Google Scholar] [CrossRef] [Green Version]

- Andre, J.; Siarry, P.; Dognon, T. An improvement of the standard genetic algorithm fighting premature convergence in continuous optimization. Adv. Eng. Softw. 2001, 32, 49–60. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Kianfar, K.; Karimi, B. Reverse logistics network design using simulated annealing. Int. J. Adv. Manuf. Technol. 2010, 47, 269–281. [Google Scholar] [CrossRef]

- Lipowski, A.; Lipowska, D. Roulette-wheel selection via stochastic acceptance. Phys. A 2012, 391, 2193–2196. [Google Scholar] [CrossRef] [Green Version]

- Goldberg, D.E.; Lingle, R. Alleles, loci, and the traveling salesman problem. In Proceedings of the Internationa l Conference on Genetic Algorithms and Their Applications; Lawrence Erlbaum: Hillsdale, NJ, USA, 1985; pp. 154–159. [Google Scholar]

- Santos, J.; Ferreira, A.; Flintsch, G. An adaptive hybrid genetic algorithm for pavement management. Int. J. Pavement Eng. 2019, 20, 266–286. [Google Scholar] [CrossRef]

- Wang, C.; Lin, J.; Lin, M.; Zhong, Y. Evolutionary harmony search algorithm with metropolis acceptance criterion for travelling salesman problem. Int. J. Wirel. Mob. Comput. 2016, 10, 166–173. [Google Scholar] [CrossRef]

- Tavakkoli-Moghaddam, R.; Safaei, N.; Gholipour, Y. A hybrid simulated annealing for capacitated vehicle routing problems with the independent route length. Appl. Math. Comput. 2006, 176, 445–454. [Google Scholar] [CrossRef]

- Ombuki, B.; Ross, B.J.; Hanshar, F. Multi-objective genetic algorithms for vehicle routing problem with time windows. Appl. Intell. 2006, 24, 17–30. [Google Scholar] [CrossRef]

| Studies | Fuel Consumption | Refrigeration’s Energy Consumption | Carbon Emission | Time Windows | Product Damage | Hetero- geneous Fleets |

|---|---|---|---|---|---|---|

| Hsu et al. [24] | - | - | - | ✓ | - | - |

| Osvald et al. [25] | - | - | - | ✓ | ✓ | - |

| Wu et al. [26] | - | - | - | ✓ | - | - |

| Amorim et al. [27] | - | - | - | ✓ | - | ✓ |

| Yantong et al. [28] | - | - | - | - | ✓ | - |

| Shukla et al. [30] | - | - | - | ✓ | ✓ | - |

| Chen et al. [7] | ✓ | ✓ | - | ✓ | ✓ | - |

| Wang et al. [29] | ✓ | ✓ | ✓ | ✓ | ✓ | - |

| This study | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Notations | Description |

|---|---|

| Penalty cost per unit overtime | |

| Sensitivity of fresh food quality to delivery time | |

| Maximum load of the m-type distribution vehicle, | |

| Quantity of m-type vehicles available in the distribution center, | |

| Fixed cost of m-type distribution vehicles, | |

| Fuel consumption per unit distance of the m-type vehicle, | |

| Travel distance from point i to point j, | |

| Travel time from point i to point j, | |

| Demand of customer i, | |

| Service time of the customer point i, | |

| Energy consumption in refrigeration per unit time, when the door of freezing chamber of m-type vehicle is opened, | |

| Energy consumption in refrigeration per unit time, when the door of freezing chamber of m-type vehicle is closed, | |

| Carbon emission coefficient for unit fuel consumption of m-type vehicle, | |

| Cost per unit damaged fresh food | |

| Cost per unit fuel | |

| Cost per unit energy consumption in refrigeration | |

| Environmental cost of unit carbon emission | |

| Arrival time for distribution vehicle to customer point i, | |

| Time window of the customer point i in which is the early-arrival time, is the late-arrival time | |

| Route selection variable; , if the m-type vehicle k travel from point i to point j, , otherwise; |

| No. | X Axis/m | Y Axis/m | Demanded/t | Time Window/h | Service Time/h |

|---|---|---|---|---|---|

| 0 | 1133 | 200 | - | [0,-] | - |

| 1 | 1521 | 1742 | 1 | [1,1.17] | 0.25 |

| 2 | 1435 | 1303 | 1.3 | [0.67,2] | 0.17 |

| 3 | 1519 | 1602 | 2 | [0.75,1] | 0.17 |

| 4 | 507 | 1569 | 2.1 | [0.5,0.83] | 0.13 |

| 5 | 1012 | 1726 | 1.7 | [0.5,0.83] | 0.25 |

| 6 | 917 | 1734 | 1.2 | [0.5,1] | 0.17 |

| 7 | 1003 | 1932 | 1.5 | [0.67,1] | 0.13 |

| 8 | 1220 | 2127 | 2 | [1.17,1.67] | 0.13 |

| 9 | 997 | 1341 | 1.4 | [0.5,1] | 0.17 |

| 10 | 1872 | 952 | 0.9 | [0.5,0.83] | 0.25 |

| 11 | 1989 | 1707 | 0.8 | [0.67.1.17] | 0.25 |

| 12 | 2048 | 1099 | 1.3 | [1.17,1.5] | 0.17 |

| 13 | 200 | 1978 | 1.9 | [0.5,1] | 0.13 |

| 14 | 401 | 782 | 2.2 | [1,1.5] | 0.17 |

| 15 | 2008 | 952 | 1.3 | [0.5,0.83] | 0.13 |

| 16 | 1740 | 1189 | 0.7 | [0.5,1.17] | 0.17 |

| 17 | 550 | 676 | 1.6 | [0.5,1.5] | 0.25 |

| 18 | 2046 | 1626 | 1.8 | [0.67,1] | 0.17 |

| 19 | 2083 | 891 | 2.2 | [1.17,1.5] | 0.17 |

| 20 | 2194 | 539 | 1.1 | [0.5,0.83] | 0.17 |

| Vehicle Type | Vehicle Quantity | Maximum Load /t | Refrigeration Cost when the Door Closed/kw | Refrigeration Cost when the Door Opened/kw | Fuel Consumption per Unit Distance /(L∗km) | Carbon Emission Coefficient /(kg∗L) | Fixed Cost /CNY |

|---|---|---|---|---|---|---|---|

| 1 | 6 | 2.5 | 4.5 | 5 | 0.2 | 2.75 | 100 |

| 2 | 4 | 3 | 5 | 5.5 | 0.25 | 2.8 | 150 |

| 3 | 3 | 3.5 | 6 | 6.5 | 0.3 | 2.9 | 200 |

| Algorithms | Total Distribution Cost/CNY | Refrigeration’s Energy Cost/CNY | Fuel Consumption Cost/CNY | Carbon Emission Cost/CNY |

|---|---|---|---|---|

| GAASAM | 2842.1 | 341.1 | 658.6 | 138.6 |

| GA | 2961.3 | 440.1 | 700.3 | 147.1 |

| Algorithms | Fix Cost/CNY | Damage Cost/CNY | Overtime Penalty Cost/CNY |

|---|---|---|---|

| GAASAM | 1500 | 170.1 | 33.7 |

| GA | 1500 | 150.7 | 23.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Cao, Q.; Zuo, M.; Xu, F. Optimization of Green Fresh Food Logistics with Heterogeneous Fleet Vehicle Route Problem by Improved Genetic Algorithm. Sustainability 2020, 12, 1946. https://0-doi-org.brum.beds.ac.uk/10.3390/su12051946

Li D, Cao Q, Zuo M, Xu F. Optimization of Green Fresh Food Logistics with Heterogeneous Fleet Vehicle Route Problem by Improved Genetic Algorithm. Sustainability. 2020; 12(5):1946. https://0-doi-org.brum.beds.ac.uk/10.3390/su12051946

Chicago/Turabian StyleLi, Danlian, Qian Cao, Min Zuo, and Fei Xu. 2020. "Optimization of Green Fresh Food Logistics with Heterogeneous Fleet Vehicle Route Problem by Improved Genetic Algorithm" Sustainability 12, no. 5: 1946. https://0-doi-org.brum.beds.ac.uk/10.3390/su12051946