A Product/Service System Design Schema: Application to Big Data Analytics

Abstract

:1. Introduction

- What relationships exist between PSS design and BDA?

- What are the achievements thus far and development opportunities in PSS design through applying BDA?

- What does the literature report on the environmental implications of applying BDA in PSS design?

2. Theoretical Background

2.1. PSS Design

2.2. BDA (Big Data Analytics)

2.3. Systematic Literature Review and Literature Synthesis

3. Research Method

3.1. Overview

3.2. Intra-Disciplinary Meta-Synthesis and Consolidation of Prescriptive PSS Design Insights

- Abstract to identify the essential problems;

- Establish function structures: overall function—subfunctions;

- Search for working principles that fulfil the sub-functions;

- Combine working principles into working structures;

- Select suitable combinations;

- Firm up into principle solution variants;

- Evaluate variants against technical and economic criteria.

3.3. Systematic Literature Review and Inter-Disciplinary Meta Synthesis of BDA Literature with the PSS Design Schema

4. Results

4.1. Intra-Disciplinary Meta-Synthesis of the PSS Design Insights

4.1.1. Meta-Analysis and Synthesis

4.1.2. Consolidation of Synthesized PSS Design Insights

4.1.3. PSS Design Benefiting from BDA

4.2. Systematic Review and Inter-Disciplinary Meta-Synthesis of BDA Literature with PSS Design Schema

4.2.1. Overview of the Results of the Literature Search

4.2.2. Descriptive Results of Design in Industry Enhanced by BDA with Industrial Cases

4.2.3. Discovering Research Opportunities in PSS Conceptual Design Enhanced by BDA

5. Discussion

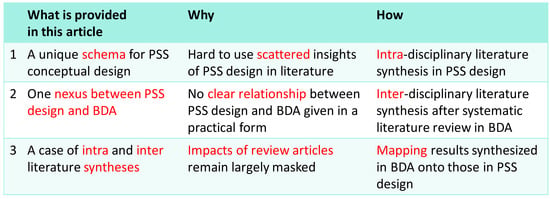

5.1. Scientific Contributions

5.2. Environmental Implications

5.3. Implications of BDA on Customization

5.4. Practical Contributions

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

A List of Acronyms

| BDA | big data analytics |

| ISI | Institute for Scientific Information |

| MTBF | mean time between failures |

| MTTF | mean time to failure |

| NPD | new product development |

| PBSA | Pahl’s and Beitz’ systematic approach |

| PSS | product/service system |

| R&D | research and development |

| RQ | research question |

| SCI | Science Citation Index |

| SCM | supply chain management |

| SSCI | Social Sciences Citation Index |

Appendix A

Appendix B

References

- Vasantha, G.V.A.; Roy, R.; Lelah, A.; Brissaud, D. A review of product–service systems design methodologies. J. Eng. Des. 2012, 23, 635–659. [Google Scholar] [CrossRef]

- Qu, M.; Yu, S.; Chen, D.; Chu, J.; Tian, B. State-of-the-art of design, evaluation, and operation methodologies in product service systems. Comput. Ind. 2016, 77, 1–14. [Google Scholar] [CrossRef]

- Brambila-Macias, S.; Sakao, T.; Kowalkowski, C. Bridging the Gap between Engineering Design and Marketing: Insights for Research and Practice in Product/Service System Design. Des. Sci. 2018, 4. [Google Scholar] [CrossRef] [Green Version]

- Tischner, U.; Verkuijl, M.; Tukker, A. First Draft PSS Review; Econcept: Cologne, Germany, 2002. [Google Scholar]

- Tukker, A. Eight Types of Product-Service System: Eight Ways to Sustainability? Experiences from Suspronet. Bus. Strategy Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Sakao, T.; Shimomura, Y.; Sundin, E.; Comstock, M. Modeling Design Objects in CAD System for Service/Product Engineering. Comput. Aided Des. 2009, 41, 197–213. [Google Scholar] [CrossRef] [Green Version]

- McKay, A.; Kundu, S. A representation scheme for digital product service system definitions. Adv. Eng. Inform. 2014, 28, 479–498. [Google Scholar] [CrossRef] [Green Version]

- Aurich, J.C.; Fuchs, C.; Wagenknecht, C. Life cycle oriented design of technical Product-Service Systems. J. Clean. Prod. 2006, 14, 1480–1494. [Google Scholar] [CrossRef]

- Kimita, K.; Sakao, T.; Shimomura, Y. A failure analysis method for designing highly reliable product-service systems. Res. Eng. Des. 2018, 29, 143–160. [Google Scholar] [CrossRef]

- Arai, T.; Shimomura, Y. Proposal of Service CAD System—A Tool for Service Engineering. CIRP Ann. Manuf. Technol. 2004, 53, 397–400. [Google Scholar] [CrossRef]

- Komoto, H.; Tomiyama, T. Integration of a service CAD and a life cycle simulator. CIRP Ann. Manuf. Technol. 2008, 57, 9–12. [Google Scholar] [CrossRef]

- Stahel, W.R. The Utilization-Focused Service Economy: Resource Efficiency and Product-Life Extension. In The Greening of Industrial Ecosystems; National Academy Press: Washinton, DC, USA, 1994; pp. 178–190. [Google Scholar]

- Goedkoop, M.J.; Van Halen, C.J.; Te Riele, H.R.; Rommens, P.J. Product Service Systems, Ecological and Economic Basics; VROM 990570; Dutch Ministry of Housing, Spatial Planning and the Environment: Hague, The Netherlands, 1999.

- Sakao, T.; Napolitano, N.; Tronci, M.; Sundin, E.; Lindahl, M. How Are Product-Service Combined Offers Provided in Germany and Italy?—Analysis with Company Sizes and Countries. J. Syst. Sci. Syst. Eng. 2008, 17, 367–381. [Google Scholar] [CrossRef] [Green Version]

- Matschewsky, J.; Kambanou, M.L.; Sakao, T. Designing and providing integrated productservice systems—Challenges, opportunities and solutions resulting from prescriptive approaches in two industrial companies. Int. J. Prod. Res. 2018, 56, 2150–2168. [Google Scholar] [CrossRef] [Green Version]

- Cui, Y.; Kara, S.; Chan, K.C. Manufacturing big data ecosystem: A systematic literature review. Robot. Comput. Integr. Manuf. 2020, 62. [Google Scholar] [CrossRef]

- Dinges, V.; Urmetzer, F.; Martinez, V.; Zaki, M.; Neely, A. The Future of Servitization: Technologies that will Make a Difference; Cambridge Service Alliance, University of Cambridge: Cambridge, UK, 2015; p. 15. [Google Scholar]

- Braune, A.; Hüttemann, G.; Klein, M.; Löwen, U.; Thron, M. Usage Viewpoint of Application Scenario Value-Based Service; Federal Ministry for Economic Affairs and Energy (BMWi): Berlin, Germany, 2018; p. 28.

- Baines, T.S.; Bigdeli, A.Z.; Bustinza, O.F.; Ridgway, K. Servitization: Revisiting the State-of-the-art and Research Priorities. Int. J. Oper. Prod. Manag. 2017, 37, 256–278. [Google Scholar] [CrossRef]

- Lerch, C.; Gotsch, M. Digitalized Product-Service Systems in Manufacturing Firms: A Case Study Analysis. Res. Technol. Manag. 2015, 58, 45–52. [Google Scholar] [CrossRef]

- Rymaszewska, A.; Helo, P.; Gunasekaran, A. IoT powered servitization of manufacturing—An exploratory case study. Int. J. Prod. Econ. 2017. [Google Scholar] [CrossRef]

- Ardolino, M.; Rapaccini, M.; Saccani, N.; Gaiardelli, P.; Crespi, G.; Ruggeri, C. The role of digital technologies for the service transformation of industrial companies. Int. J. Prod. Res. 2018, 56, 2116–2132. [Google Scholar] [CrossRef]

- Sakao, T.; Brambila-Macias, S.A. Do we share an understanding of transdisciplinarity in environmental sustainability research? J. Clean. Prod. 2018, 170, 1399–1403. [Google Scholar] [CrossRef]

- Geum, Y.; Park, Y. Designing the sustainable product-service integration: A product-service blueprint approach. J. Clean. Prod. 2011, 19, 1601–1614. [Google Scholar] [CrossRef]

- Akasaka, F.; Nemoto, Y.; Kimita, K.; Shimomura, Y. Development of a knowledge-based design support system for Product-Service Systems. Comput. Ind. 2012, 63, 309–318. [Google Scholar] [CrossRef]

- Meier, H.; Roy, R.; Seliger, G. Industrial Product-Service Systems-IPS². CIRP Ann. Manuf. Technol. 2010, 59, 607–627. [Google Scholar] [CrossRef]

- Clayton, R.J.; Backhouse, C.J.; Dani, S. Evaluating existing approaches to product-service system design: A comparison with industrial practice. J. Manuf. Technol. Manag. 2012, 23, 272–298. [Google Scholar] [CrossRef] [Green Version]

- Morelli, N. Designing product/service systems: A methodological exploration. Des. Issues 2002, 18, 3–18. [Google Scholar] [CrossRef]

- Isaksson, O.; Larsson, T.C.; Öhrwall Rönnbäck, A. Development of product-service systems: Challenges and opportunities for the manufacturing firm. J. Eng. Des. 2009, 20, 329–348. [Google Scholar] [CrossRef]

- Fargnoli, M.; Costantino, F.; Di Gravio, G.; Tronci, M. Product service-systems implementation: A customized framework to enhance sustainability and customer satisfaction. J. Clean. Prod. 2018, 188, 387–401. [Google Scholar] [CrossRef]

- Yazdani, B.; Holmes, C. Four Models of Design Definition: Sequential, Design Centered, Concurrent and Dynamic. J. Eng. Des. 1999, 10, 25–37. [Google Scholar] [CrossRef]

- Andreasen, M.M. 45 Years with design methodology. J. Eng. Des. 2011, 22, 293–332. [Google Scholar] [CrossRef]

- Hara, T.; Arai, T.; Shimomura, Y.; Sakao, T. Service CAD System to Integrate Product Behavior and Service Activity for Total Value. CIRP J. Manuf. Sci. Technol. 2009, 1, 262–271. [Google Scholar] [CrossRef]

- Vasantha, G.V.A.; Roy, R.; Corney, J.R. Advances in Designing Product-Service Systems. J. Indian Inst. Sci. 2015, 95, 429–447. [Google Scholar]

- Cavalieri, S.; Pezzotta, G. Product–Service Systems Engineering: State of the art and research challenges. Comput. Ind. 2012, 63, 278–288. [Google Scholar] [CrossRef]

- Sandelowski, M.; Docherty, S.; Emden, C. Qualitative metasynthesis: Issues and techniques. Res. Nurs. Health 1997, 20, 365–371. [Google Scholar] [CrossRef]

- Laney, D. 3D Data Management: Controlling Data Volume, Velocity, and Variety; META Group: Stamford, CT, USA, 2011. [Google Scholar]

- Gandomi, A.; Haider, M. Beyond the hype: Big data concepts, methods, and analytics. Int. J. Inf. Manag. 2015, 35, 137–144. [Google Scholar] [CrossRef] [Green Version]

- Akter, S.; Fosso Wamba, S. Big data analytics in E-commerce: A systematic review and agenda for future research. Electron. Mark. 2016, 26, 173–194. [Google Scholar] [CrossRef] [Green Version]

- Khakifirooz, M.; Chien, C.F.; Chen, Y.J. Bayesian inference for mining semiconductor manufacturing big data for yield enhancement and smart production to empower industry 4.0. Appl. Soft Comput. 2018, 68, 990–999. [Google Scholar] [CrossRef]

- Lau, R.Y.K.; Zhang, W.P.; Xu, W. Parallel Aspect-Oriented Sentiment Analysis for Sales Forecasting with Big Data. Prod. Oper. Manag. 2018, 27, 1775–1794. [Google Scholar] [CrossRef]

- Akter, S.; Bandara, R.; Hani, U.; Wamba, S.F.; Foropon, C.; Papadopoulos, T. Analytics-based decision-making for service systems: A qualitative study and agenda for future research. Int. J. Inf. Manag. 2019, 48, 85–95. [Google Scholar] [CrossRef]

- Park, H.; Yoon, J. A chance discovery-based approach for new product–service system (PSS) concepts. Serv. Bus. 2015, 9, 115–135. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef] [Green Version]

- Erkoyuncu, J.A.; Roy, R.; Shehab, E.; Cheruvu, K. Understanding service uncertainties in Industrial Product-Service System cost estimation. Int. J. Adv. Manuf. Technol. 2011, 52, 1223–1238. [Google Scholar] [CrossRef]

- Fargnoli, M.; Haber, N.; Sakao, T. PSS modularisation: A customer-driven integrated approach. Int. J. Prod. Res. 2018. [Google Scholar] [CrossRef] [Green Version]

- Sakao, T.; Song, W.; Matschewsky, J. Creating service modules for customising product/service systems by extending DSM. CIRP Ann. Manuf. Technol. 2017, 66, 21–24. [Google Scholar] [CrossRef] [Green Version]

- Motamarri, S.; Akter, S.; Yanamandram, V. Does big data analytics influence frontline employees in services marketing? Bus. Process Manag. J. 2017, 23, 623–644. [Google Scholar] [CrossRef] [Green Version]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.-I. Sustainable industrial value creation: Benefits and challenges of industry 4.0. Int. J. Innov. Manag. 2017, 21. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Bem, D.J. Writinga Review Article for Psychological Bulletin. Psychol. Bull. 1995, 118, 172–177. [Google Scholar] [CrossRef]

- Webster, J.; Watson, R.T. Analyzing the Past to Prepare for the Future: Wrting a Literature Review. MIS Q. 2002, 26, 11–19. [Google Scholar]

- Short, J. The Art of Writing a Review Article. J. Manag. 2009, 35, 1312–1317. [Google Scholar] [CrossRef]

- Milne, R.; Chambers, L. Assessing the Scientific Quality of Review Articles. J. Epidemiol. Community Health 1993, 47, 169–170. [Google Scholar] [CrossRef] [Green Version]

- Ioannidis, J.P.A. The Mass Production of Redundant, Misleading, and Conflicted Systematic Reviews and Meta-analyses. Milbank Q. 2016, 94, 485–514. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sakao, T. Research Series Review for Transdisciplinarity Assessment—Validation with Sustainable Consumption and Production Research. Sustainability 2019, 11, 5250. [Google Scholar] [CrossRef] [Green Version]

- Martin Ginis, K.A.; Ma, J.K.; Latimer-Cheung, A.E.; Rimmer, J.H. A systematic review of review articles addressing factors related to physical activity participation among children and adults with physical disabilities. Health Psychol. Rev. 2016, 10, 478–494. [Google Scholar] [CrossRef] [PubMed]

- Sweller, J.; van Merrienboer, J.J.G.; Paas, F.G.W.C. Cognitive Architecture and Instructional Design. Educ. Psychol. Rev. 1998, 10, 251–296. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W. Engineering Design: A Systematic Approach; Springer-Verlag: London, UK, 2007. [Google Scholar]

- Kannengiesser, U.; Gero, J.S. Is Designing Independent of Domain? Comparing Models of Engineering, Software and Service Design. Res. Eng. Des. 2015, 26, 253–275. [Google Scholar] [CrossRef]

- Eisenbart, B.; Gericke, K.; Blessing, L.T.M. An analysis of functional modeling approaches across disciplines. Artif. Intell. Eng. Des. Anal. Manuf. 2013, 27, 281–289. [Google Scholar] [CrossRef]

- Eisenbart, B.; Gericke, K.; Blessing, L.T.M. Taking a look at the utilisation of function models in interdisciplinary design: Insights from ten engineering companies. Res. Eng. Des. 2017, 28, 299–331. [Google Scholar] [CrossRef]

- Baines, T.S.; Lightfoot, H.W.; Evans, S.; Neely, A.; Greenough, R.; Peppard, J.; Roy, R.; Shehab, E.; Braganza, A.; Tiwari, A.; et al. State-of-the-art in product-service systems. Proc. Inst. Mech. Eng. B 2007, 221, 1543–1552. [Google Scholar] [CrossRef] [Green Version]

- Beuren, F.H.; Ferreira, M.G.G.; Miguel, P.A.C. Product-service systems: A literature review on integrated products and services. J. Clean. Prod. 2013, 47, 222–231. [Google Scholar] [CrossRef]

- Annarelli, A.; Battistella, C.; Nonino, F. Product service system: A conceptual framework from a systematic review. J. Clean. Prod. 2016, 139, 1011–1032. [Google Scholar] [CrossRef]

- Mahut, F.; Daaboul, J.; Bricogne, M.; Eynard, B. Product-Service Systems for servitization of the automotive industry: A literature review. Int. J. Prod. Res. 2017, 55, 2102–2120. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Tukker, A.; Tischner, U. Product-services as a research field: Past, present and future. Reflections from a decade of research. J. Clean. Prod. 2006, 14, 1552–1556. [Google Scholar] [CrossRef]

- Alonso-Rasgado, T.; Thompson, G.; Elfstrom, B. The design of functional (total care) products. J. Eng. Des. 2004, 15, 515–540. [Google Scholar] [CrossRef]

- Maxwell, D.; Sheate, W.; Vorst, R.v.d. Functional and systems aspects of the sustainable product and service development approach for industry. J. Clean. Prod. 2006, 14, 1466–1479. [Google Scholar] [CrossRef]

- Morelli, N. Product-service systems, a perspective shift for designers: A case study: The design of a telecentre. Des. Stud. 2003, 24, 73–99. [Google Scholar] [CrossRef]

- Roy, R. Sustainable product-service systems. Futures 2000, 32, 289–299. [Google Scholar] [CrossRef]

- Morelli, N. Developing new product service systems (PSS): Methodologies and operational tools. J. Clean. Prod. 2006, 14, 1495–1501. [Google Scholar] [CrossRef]

- Mont, O.K. Clarifying the concept of product–service system. J. Clean. Prod. 2002, 10, 237–245. [Google Scholar] [CrossRef]

- Doultsinou, A.; Roy, R.; Baxter, D.; Gao, J.; Mann, A. Developing a service knowledge reuse framework for engineering design. J. Eng. Des. 2009, 20, 389–411. [Google Scholar] [CrossRef]

- Maussang, N.; Zwolinski, P.; Brissaud, D. Product-service system design methodology: From the PSS architecture design to the products specifications. J. Eng. Des. 2009, 20, 349–366. [Google Scholar] [CrossRef]

- Sakao, T.; Shimomura, Y. Service Engineering: A novel engineering discipline for producers to increase value combining service and product. J. Clean. Prod. 2007, 15, 590–604. [Google Scholar] [CrossRef] [Green Version]

- McAloone, T.C.; Andreason, M.M. Design for Utility, Sustainability and Social Virtues, Developing Product Service Systems. In Proceedings of the International Design Conference, Dubrovnik, Croatia, 17–20 May 2004; pp. 1545–1552. [Google Scholar]

- Meier, H. Life Cycle-Based Service Design for Innovative Business Models. CIRP Ann. Manuf. Technol. 2004, 53, 393–396. [Google Scholar] [CrossRef]

- Pezzotta, G.; Pinto, R.; Pirola, F.; Ouertani, M.Z. Balancing product-service provider’s performance and customer’s value: The SErvice Engineering Methodology (SEEM). Procedia CIRP 2014, 16, 50–55. [Google Scholar] [CrossRef] [Green Version]

- Sakao, T.; Lindahl, M. A method to improve integrated product service offerings based on life cycle costing. Cirp Ann. Manuf. Technol. 2015, 64, 33–36. [Google Scholar] [CrossRef] [Green Version]

- Pezzotta, G.; Pirola, F.; Rondini, A.; Pinto, R.; Ouertani, M.-Z. Towards a methodology to engineer industrial product-service system—Evidence from power and automation industry. CIRP J. Manuf. Sci. Technol. 2016, 15, 19–32. [Google Scholar] [CrossRef]

- Webster, K. The Circular Economy: A Wealth of Flows; Ellen MacArthur Foundation: Isle of Wight, UK, 2015. [Google Scholar]

- ISO. ISO 14040-Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Ulaga, W.; Chacour, S. Measuring Customer Perceived Value in Business Markets. Ind. Mark. Manag. 2001, 30, 525–540. [Google Scholar] [CrossRef]

- Lay, G.; Schroeter, M.; Biege, S. Service-Based Business Concepts: A Typology for Business-to-Business Markets. Eur. Manag. J. 2009, 27, 442–455. [Google Scholar] [CrossRef]

- Regan, W.J. The Service Revolution. J. Mark. 1963, 47, 57–62. [Google Scholar] [CrossRef] [Green Version]

- Byers, S.; Groth, J.; Sakao, T. Using Portfolio Theory to Improve Resource Efficiency of Invested Capital. J. Clean. Prod. 2015, 98, 156–165. [Google Scholar] [CrossRef] [Green Version]

- Niebel, T.; Rasel, F.; Viete, S. BIG data - BIG gains? Understanding the link between big data analytics and innovation. Econ. Innov. New Technol. 2019, 28, 296–316. [Google Scholar] [CrossRef] [Green Version]

- Bag, S.; Wood, L.C.; Xu, L.; Dhamija, P.; Kayikci, Y. Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resour. Conserv. Recycl. 2020, 153. [Google Scholar] [CrossRef]

- Woo, J.; Shin, S.J.; Seo, W.; Meilanitasari, P. Developing a big data analytics platform for manufacturing systems: Architecture, method, and implementation. Int. J. Adv. Manuf. Technol. 2018, 99, 2193–2217. [Google Scholar] [CrossRef]

- Chan, S.L.; Lu, Y.L.; Wang, Y. Data-driven cost estimation for additive manufacturing in cybermanufacturing. J. Manuf. Syst. 2018, 46, 115–126. [Google Scholar] [CrossRef]

- Engelseth, P.; Molka-Danielsen, J.; White, B.E. On data and connectivity in complete supply chains. Bus. Process Manag. J. 2019, 25, 1145–1163. [Google Scholar] [CrossRef]

- Teng, S.Y.; How, B.S.; Leong, W.D.; Teoh, J.H.; Cheah, A.C.S.; Motavasel, Z.; Lam, H.L. Principal component analysis-aided statistical process optimisation (PASPO) for process improvement in industrial refineries. J. Clean. Prod. 2019, 225, 359–375. [Google Scholar] [CrossRef] [Green Version]

- Zhan, Y.Z.; Tan, K.H.; Li, Y.N.; Tse, Y.K. Unlocking the power of big data in new product development. Ann. Oper. Res. 2018, 270, 577–595. [Google Scholar] [CrossRef] [Green Version]

- Jagtap, S.; Duong, L.N.K. Improving the new product development using big data: A case study of a food company. Br. Food J. 2019, 121, 2835–2848. [Google Scholar] [CrossRef] [Green Version]

- Zhan, Y.Z.; Tan, K.H. An analytic infrastructure for harvesting big data to enhance supply chain performance. Eur. J. Oper. Res. 2020, 281, 559–574. [Google Scholar] [CrossRef]

- Guo, L.A.; Sharma, R.; Yin, L.; Lu, R.D.; Rong, K. Automated competitor analysis using big data analytics Evidence from the fitness mobile app business. Bus. Process Manag. J. 2017, 23, 735–762. [Google Scholar] [CrossRef]

- Kim, Y.J.; Queiroz, L.B. Big Data for condition evaluation of constructed bridges. Eng. Struct. 2017, 141, 217–227. [Google Scholar] [CrossRef]

- Wong, E.; Wei, Y. Customer online shopping experience data analytics Integrated customer segmentation and customised services prediction model. Int. J. Retail Distrib. Manag. 2018, 46, 406–420. [Google Scholar] [CrossRef]

- Nashaat, M.; Ghosh, A.; Miller, J.; Quader, S.; Marston, C. M-Lean: An end-to-end development framework for predictive models in B2B scenarios. Inf. Softw. Technol. 2019, 113, 131–145. [Google Scholar] [CrossRef]

- Majumdar, A.; Bose, I. Do tweets create value? A multi-period analysis of Twitter use and content of tweets for manufacturing firms. Int. J. Prod. Econ. 2019, 216, 1–11. [Google Scholar] [CrossRef]

- Ahani, A.; Nilashi, M.; Ibrahim, O.; Sanzogni, L.; Weaven, S. Market segmentation and travel choice prediction in Spa hotels through TripAdvisor’s online reviews. Int. J. Hosp. Manag. 2019, 80, 52–77. [Google Scholar] [CrossRef]

- Chen, M.C.; Hsiao, Y.H.; Chang, K.C.; Lin, M.K. Applying big data analytics to support Kansei engineering for hotel service development. Data Technol. Appl. 2019, 53, 33–57. [Google Scholar] [CrossRef]

- Hussain, R.; Lockett, H.; Vasantha, G.V.A. A framework to inform PSS Conceptual Design by using system-in-use data. Comput. Ind. 2012, 63, 319–327. [Google Scholar] [CrossRef] [Green Version]

- Belkadi, F.; Boli, N.; Usatorre, L.; Maleki, E.; Alexopoulos, K.; Bernard, A.; Mourtzis, D. A knowledge-based collaborative platform for PSS design and production. CIRP J. Manuf. Sci. Technol. 2018. [Google Scholar] [CrossRef]

- Tomiyama, T.; Lutters, E.; Stark, R.; Abramovici, M. Development capabilities for smart products. CIRP Ann. Manuf. Technol. 2019, 68, 727–750. [Google Scholar] [CrossRef]

- Neramballi, A.; Sakao, T.; Gero, J.S. Effects of a design support on practitioners designing a Product/Service System—A case study. In Human Behaviour in Design; Eriksson, Y., Paetzold, K., Eds.; Universität der Bundeswehr München: Tutzing, Germany, 2019; pp. 11–22. [Google Scholar]

- EMF. Artificial Intelligence and the Circular Economy—AI As a Tool to Accelerate the Transition; Ellen MacArthur Foundation: Cowes, UK, 2019. [Google Scholar]

- Hara, T.; Sakao, T.; Fukushima, R. Customization of product, service, and product/service system: What and how to design. Mech. Eng. Rev. 2019, 6, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Fogliatto, F.S.; da Silveira, G.J.C. Mass customization: A method for market segmentation and choice menu design. Int. J. Prod. Econ. 2008, 111, 606–622. [Google Scholar] [CrossRef]

- Sakao, T.; Shimomura, Y.; Comstock, M.; Sundin, E. A Method of Value Customization. J. Theory Appl. Mech. Eng. 2007, 49, 99–108. [Google Scholar]

- Sakao, T.; Fargnoli, M. Customization in Ecodesign: A Demand-side Approach Bringing New Opportunities? J. Ind. Ecol. 2010, 14, 529–532. [Google Scholar] [CrossRef]

- Song, W.; Sakao, T. A customization-oriented framework for design of sustainable product/service system. J. Clean. Prod. 2017, 140, 1672–1685. [Google Scholar] [CrossRef]

- DIN. Product-Service Systems—Value Creation by Integrating Goods and Services. Public Available Specification 1094, DIN PAS 1094; Beuth Verlag: Berlin, Germany, 2009. [Google Scholar]

| Facet of PSS design | [1] | [2] | [26] | [34] | [35] | [63] | [64] | [65] | [66] | [67] |

|---|---|---|---|---|---|---|---|---|---|---|

| 1. Functionality-oriented designing | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| 2. Identification of relevant actors along PSS lifecycle | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 3. Value propositions | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| 4. Development and integration of system elements | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| 5. Examination of the balance of the integration | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| PBSA Framework for Conceptual Design | Distilled Essence of PSS Design | Consolidated Schema for Conceptual PSS Design |

|---|---|---|

| 1. Abstract to identify the essential problems | 1. Functionality-oriented designing 2. Identification of relevant actors along the PSS lifecycle | 1. Functional unit definition 2. Stakeholder identification 3. Requirement consolidation |

| 2. Establish function structures: overall function—subfunctions | ||

| 3. Search for working principles that fulfil the sub-functions | 3. Value proposition 4. Development and integration of system elements | 4. Value proposition 5. Criterion identification 6. Element integration |

| 4. Combine working principles into working structures | ||

| 5. Select suitable combinations | 5. Examination of the balance of the integration | 7. Balance examination 8. Selecting combinations |

| 6. Firm up into principle solution variants | ||

| 7. Evaluate variants against technical and economic criteria | No essence applicable | 9. Evaluating combinations 10. Solution selection |

| Type | Data Source | Design Object |

|---|---|---|

| PP | Use of products | Product |

| PS | Use of products | Service |

| SP | Production and use of services | Product |

| SS | Production and use of services | Service |

| PP (Product to Product) and PS (Product to Service) | SP (Service to Product) and SS (Service to Service) | |

|---|---|---|

| Step 1: Functional unit definition | T | T |

| Step 2: Stakeholder identification | T | |

| Step 3: Requirement consolidation | T | T |

| Step 4: Value proposition | T | T |

| Step 5: Criterion identification | ||

| Step 6: Element integration | T | T |

| Step 7: Balance examination | T | T |

| Step 8: Selecting combinations | ||

| Step 9: Evaluating combinations | T | T |

| Step 10: Solution selection |

| Ref. | Type | Data used | Aim | Method Used | Result | Aspects 1 | |||

|---|---|---|---|---|---|---|---|---|---|

| [94] | PP | Operating conditions and the responses (e.g., a steady-state condition for 120 minutes with 5-minute interval) | Optimize operations in oil re-refining processes | Principal component analysis | Fewer experiment sets for design of experiment: eventual improvements were quantified in terms of product yield (e.g., 84% increased), process quality (e.g., 47% increased), environmental impacts (e.g., 91% improved in acidification potential), etc. | Q | C | T | E |

| [95] | PP | 26,000 customers involved: Social media data (130,000 comments) and machine-generated/sensor data | Better understand customers in NPD at a wearable medical equipment manufacturer | Data (including text) mining and clustering analysis | More precise insights of customer perceptions (trends, expectations, preferences, etc.), leading to NPD with <5 months, that is, less than half in time and 2 million USD (a fraction of economic cost) compared to a traditional NPD project | Q | C | T | |

| [96] | PP | Seven peer brands’ sugar levels and prices, and consumer feedbacks on lemonade quality | Support NPD for a lemonade with a reduced sugar level | Text mining | Reducing the NPD costs by 33% and time by 10% without compromising the quality | Q | C | T | e |

| [97] | PP | Customers’ preferences registered via the official company website, product information (including videos), social media (10 million threads), and customer locations. | Better manage competences for NPD in a Chinese manufacturer of athletics goods owning three main manufacturing facilities. | Data mining | Strategies such as an optimal expansion on the company’s existing competences by considering internal and external competences: seven golf clubs (e.g., 3-iron and 460cc 10.5° driver) were analyzed with 14 competences (e.g., wood manufacturing and stamping technologies). | Q | C | T | |

| [98] | PP | 100,000 user evaluations of fitness mobile apps on social media | Analyze competing products | Natural language processing and machine learning | Four clusters of ca 500 apps and an app’s position in relation to peers, including the product functionality similarity, contributing to making strategies on pricing models, product differentiation, and faster adaptation | Q | C | T | |

| [99] | PP PS | Data of one million bridges in the USA; e.g., structural types, condition ratings, geographical zones, and traffic volumes | Analyze and evaluate conditions (incl. degradation) of constructed bridges | ANOVA (analysis of variance) | Insights such as the adequate selection of structural types (e.g., concrete cast-in-place) dependent on the use environments, enhancing the performance and longevity of the bridges, and planning better inspection/maintenance based on deterioration | Q | e | ||

| [100] | SS | Purchase transactions by 110,000 customers at this agency and its competitors’ pricing data | Analyze customer behaviors and predict their next purchases of flight tickets at an online travel agency | Data mining and customer segmentation | Patterns and correlations in customer purchasing behaviors, contributing to better customer relationship management, such as targeted promotion | Q | c | t | |

| [101] | SS | Data about the software, such as purchase, 330,000 renewals, 120,000 non-renewals, download, problems, and evolution | Predict the risks of software license cancellation in combination with domain knowledge | Machine learning | The framework for prediction tested at IBM, attesting the usefulness of the framework in industry | q | c | t | |

| [102] | SS | Three million tweets on Twitter by 1200 companies and their financial data | Examine the relationships of product-related communication and the financial performance of manufacturing firms | Text mining | Positive association between divulging product-related information and the firm value on the market | c | |||

| [103] | SS | 4900 online reviews on TripAdvisor for 200 Spa hotels | Segment hotel customers and the prediction of their choices | Machine learning and clustering | Accurate prediction of user choices per segment, which is expected to contribute to optimal marketing expenditures | Q | c | T | |

| [104] | SS SP | 2600 online reviews on TripAdvisor for 20 hotels in Taipei | Understand hotel guests’ perceptions | Text mining | Through extracting Kansei words (e.g., excellent and friendly) and hotel service characteristics (e.g., facilities and service delivery) as well as their relationships, a guideline for hotel service development was proposed | Q | C | T | |

| PP (Product to Product) and PS (Product to Service) | SP (Service to Product) and SS (Service to Service) | |

|---|---|---|

| Step 1: Functional unit definition | O | O |

| Step 2: Stakeholder identification | [103] | |

| Step 3: Requirement consolidation | [95,96] | [100,104] |

| Step 4: Value proposition | [96,98] | [100] |

| Step 5: Criterion identification | ||

| Step 6: Element integration | [99] 1 | O |

| Step 7: Balance examination | O | O |

| Step 8: Selecting combinations | ||

| Step 9: Evaluating combinations | O | O |

| Step 10: Solution selection |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sakao, T.; Neramballi, A. A Product/Service System Design Schema: Application to Big Data Analytics. Sustainability 2020, 12, 3484. https://0-doi-org.brum.beds.ac.uk/10.3390/su12083484

Sakao T, Neramballi A. A Product/Service System Design Schema: Application to Big Data Analytics. Sustainability. 2020; 12(8):3484. https://0-doi-org.brum.beds.ac.uk/10.3390/su12083484

Chicago/Turabian StyleSakao, Tomohiko, and Abhijna Neramballi. 2020. "A Product/Service System Design Schema: Application to Big Data Analytics" Sustainability 12, no. 8: 3484. https://0-doi-org.brum.beds.ac.uk/10.3390/su12083484