Using Onboard-Produced Drinking Water to Achieve Ballast-Free Management

Abstract

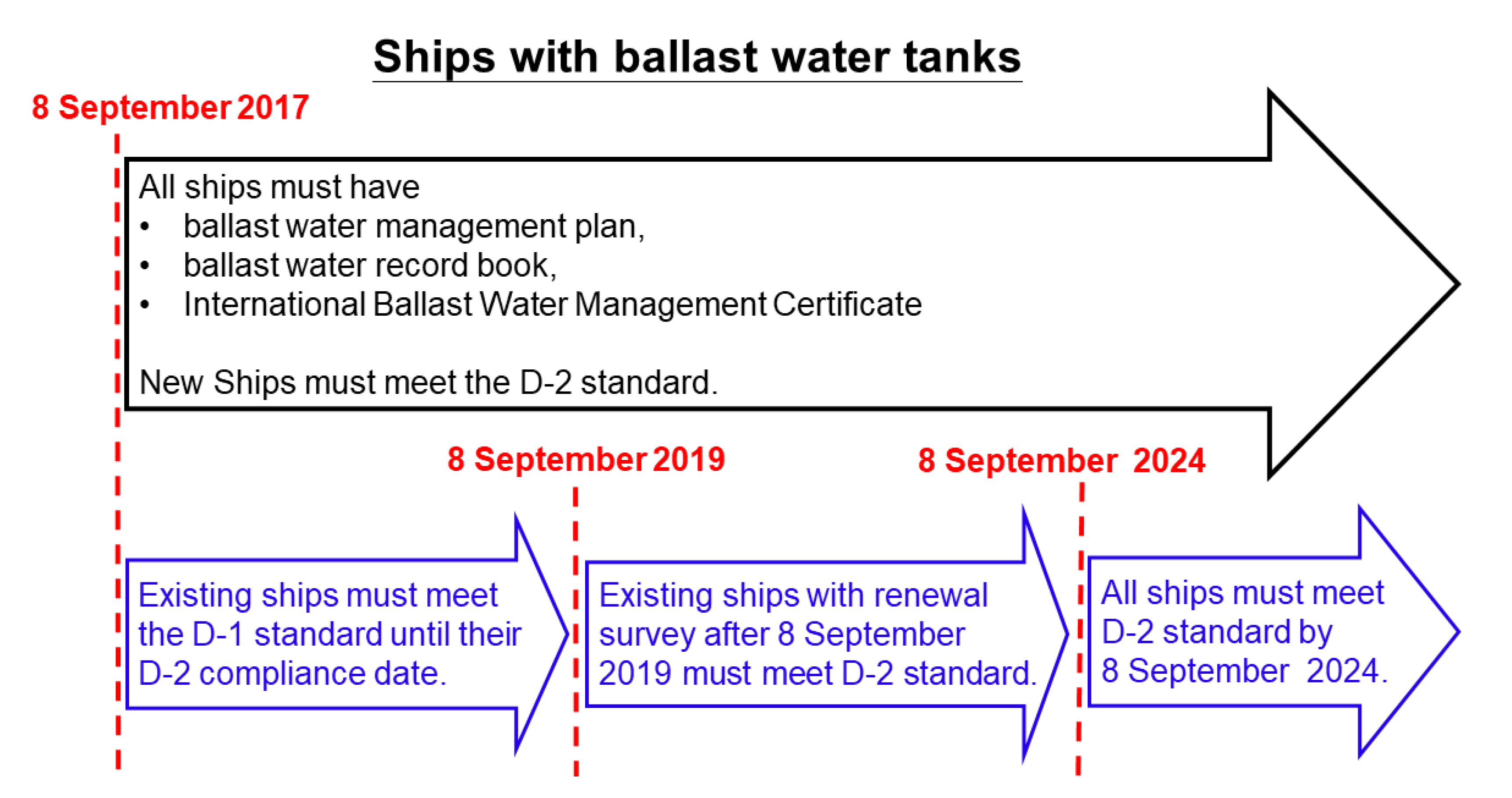

:1. Introduction

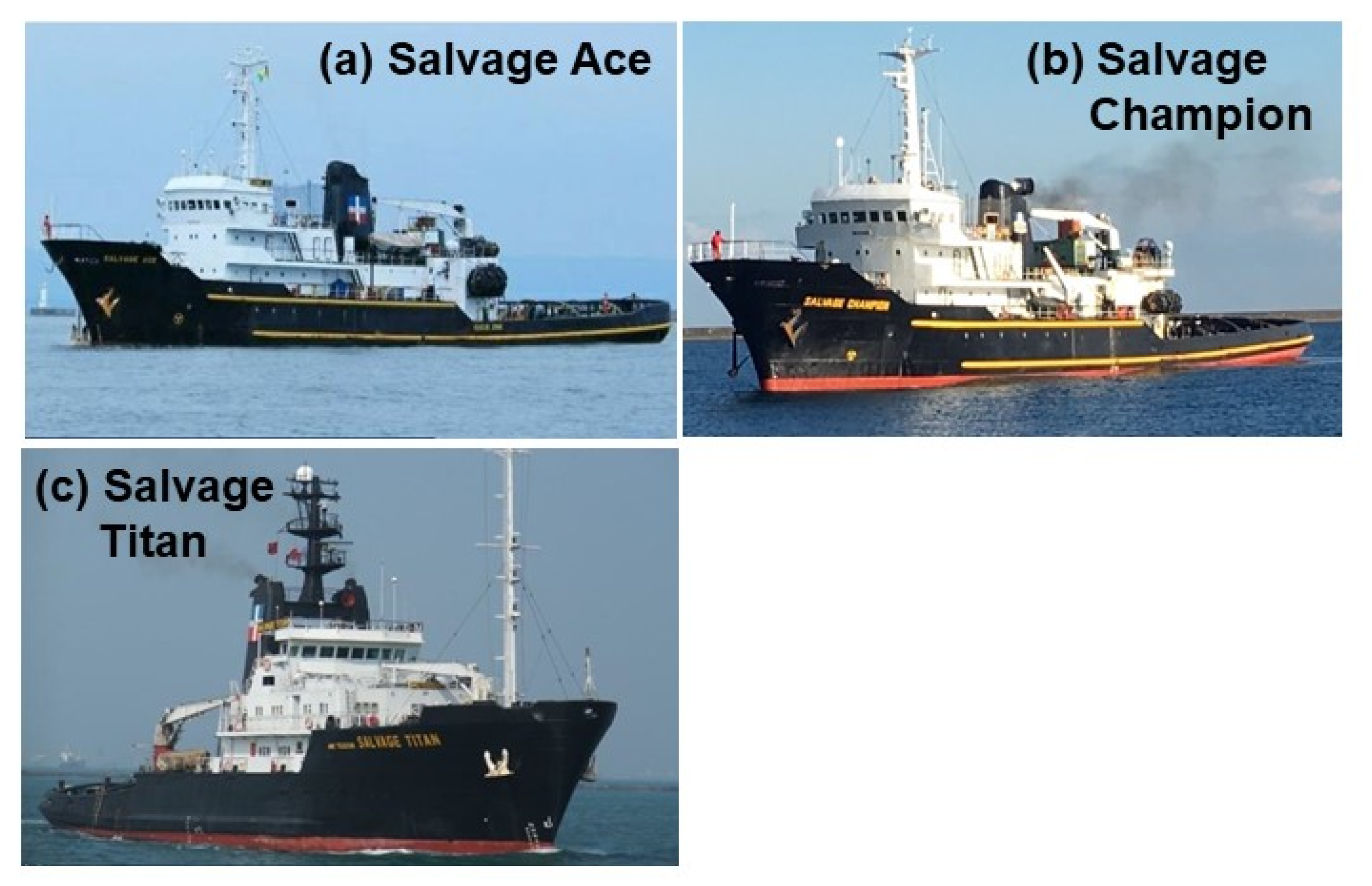

2. Materials and Methods

3. Results and Discussion

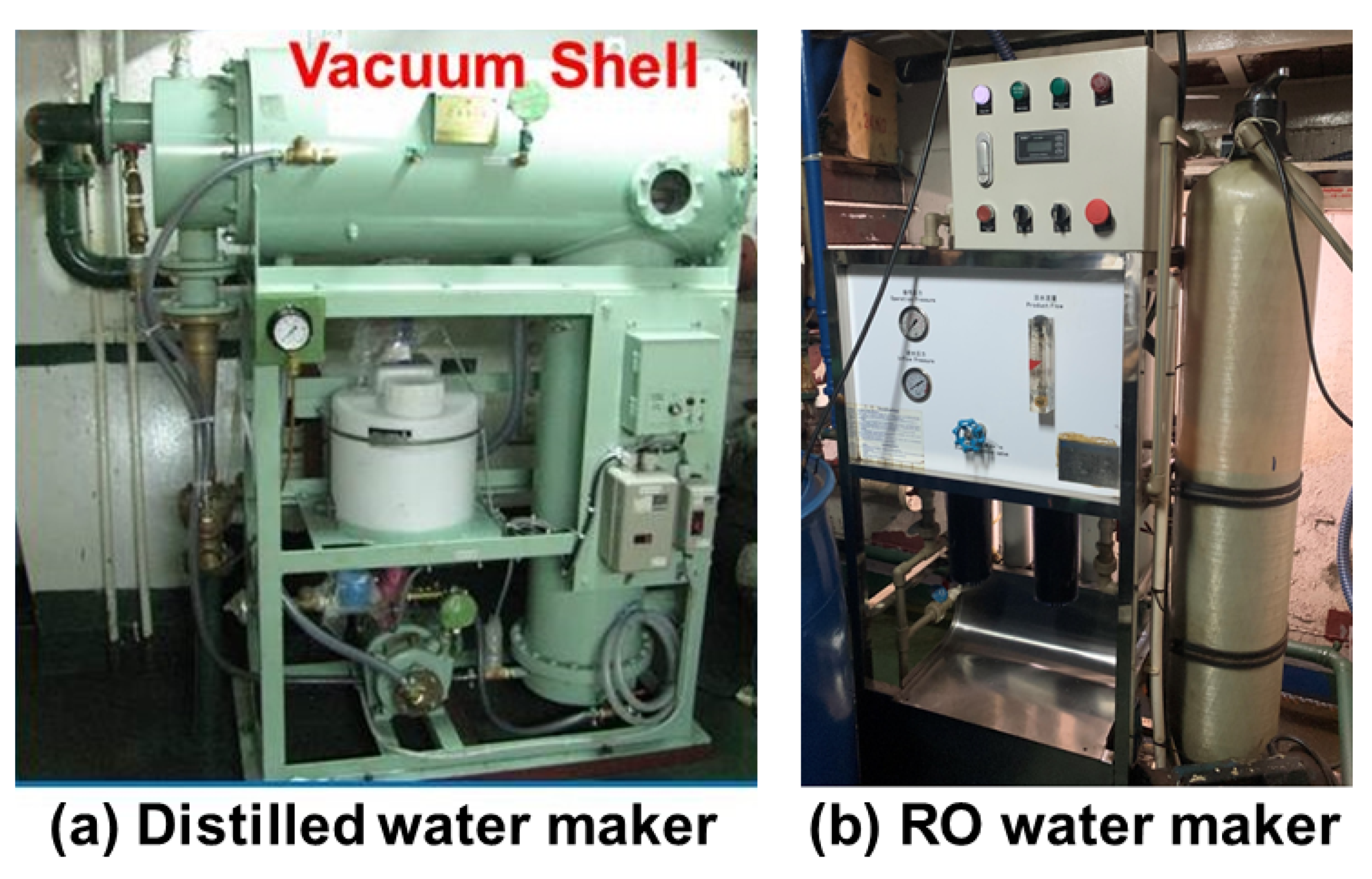

3.1. Drinking Water System and the Production Rate

3.2. Quality of the Distilled or RO Water

3.3. Cost

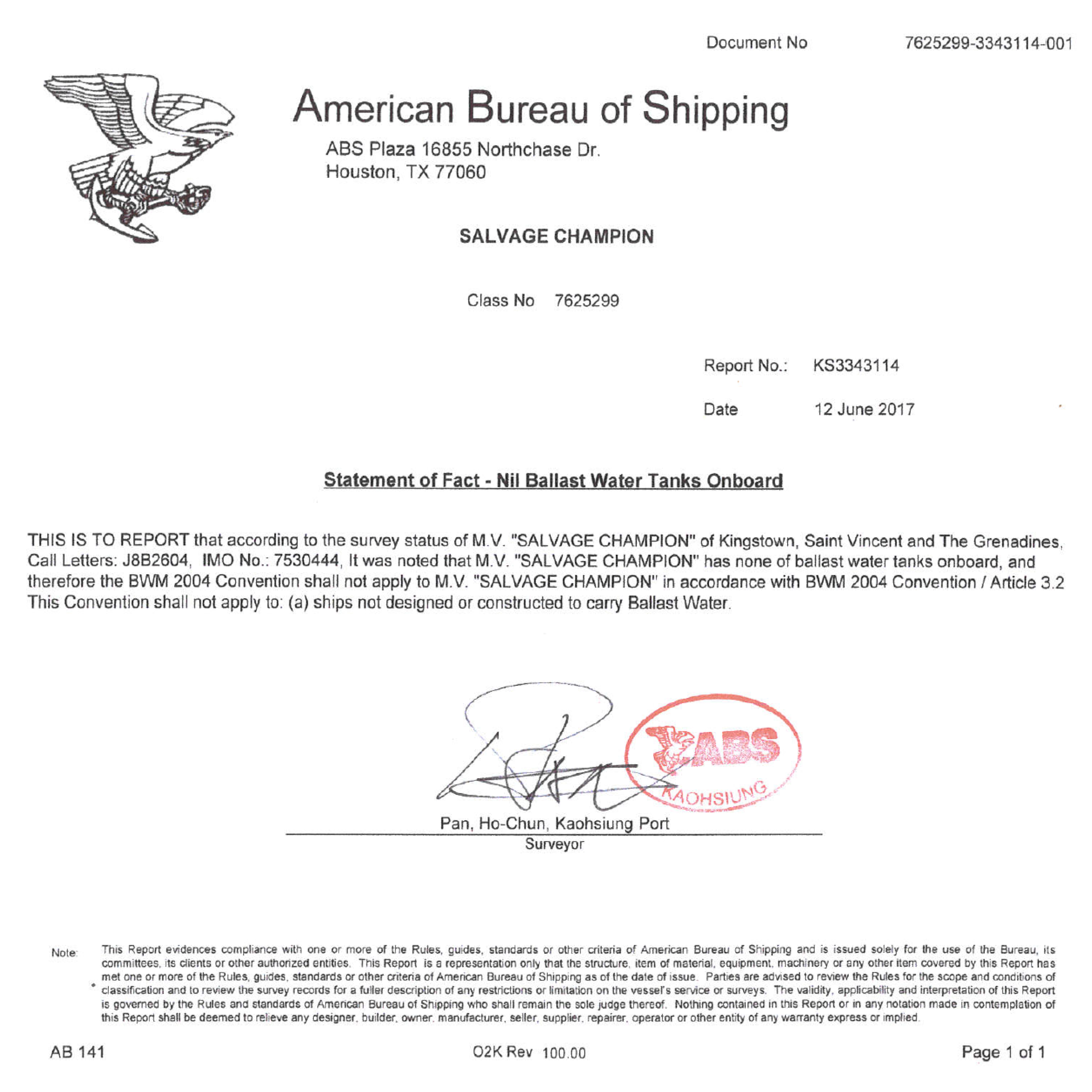

3.4. Nil Ballast Statement from the Ship’s Classification Society

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Werschkun, B.; Banerji, S.; Basurko, O.C.; David, M.; Fuhr, F.; Gollasch, S.; Grummt, T.; Haarich, M.; Jha, A.N.; Kacan, S.; et al. Emerging risks from ballast water treatment: The run-up to the International Ballast Water Management Convention. Chemosphere 2014, 112, 256–266. [Google Scholar] [CrossRef] [Green Version]

- International Maritime Organization. The Globallast Story: Reflections from a Global Family; Globallast Partnerships Project Coordination Unit: London, UK, 2017; p. 92. [Google Scholar]

- Bax, N.; Williamson, A.; Aguero, M.; Gonzalez, E.; Geeves, W. Marine invasive alien species: A threat to global biodiversity. Mar. Pol. 2003, 27, 313–323. [Google Scholar] [CrossRef]

- Drake, J.M.; Lodge, D.M. Global hot spots of biological invasions: Evaluating options for ballast-water management. Proc. R. Soc. B Biol. Sci. 2004, 271, 575–580. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hallegraeff, G.M. Transport of toxic dinoflagellates via ships’ ballast water: Bioeconomic risk assessment and efficacy of possible ballast water management strategies. Mar. Ecol. Prog. Ser. 1998, 168, 297–309. [Google Scholar] [CrossRef] [Green Version]

- Ostenfeld, C.H. Immigration of a plankton diatom into a quite new area within recent years; Biddulphia sinensis in the North Sea Water. Hydrobiology 2007, 3, 362–374. [Google Scholar] [CrossRef] [Green Version]

- Cheng, M.; Liu, T.K.; Olenin, S.; Su, P.X. Risk assessment model based on expert’s perspective for ballast water management. Ocean Coastal Manage. 2019, 171, 80–86. [Google Scholar] [CrossRef]

- Lakshmi, E.; Priya, M.; Achari, V.S. An overview on the treatment of ballast water in ships. Ocean Coastal Manage. 2021, 199, 105296. [Google Scholar] [CrossRef]

- International Maritime Organization. Status of IMO Treaties-Comprehensive Information on the Status of Multilateral Conventions and Instruments in Respect of Which the International Maritime Organization or its Secretary-General Performs Depositary or Other Functions; International Maritime Organization: London, UK, 2021. [Google Scholar]

- International Maritime Organization. International Convention for the contorl and management of ship’s ballast water and sediments. In Proceedings of the International Conference on Ballast Water Management for Ships, London, UK, 9–13 February 2004. [Google Scholar]

- Stehouwer, P.P.; Buma, A.; Peperzak, L. A comparison of six different ballast water treatment systems based on UV radiation, electrochlorination and chlorine dioxide. Environ. Technol. 2015, 36, 2094–2104. [Google Scholar] [CrossRef]

- Tsolaki, E.; Diamadopoulos, E. Technologies for ballast water treatment: A review. J. Chem. Technol. Biotechnol. 2010, 85, 19–32. [Google Scholar] [CrossRef]

- Wang, Z.; Corbett, J. Scenario-based cost-effectiveness analysis of ballast water treatment strategies. Manag. Biol. Invasions 2021, 12, 108–124. [Google Scholar] [CrossRef]

- Riviera Newsletters. Tanker Operators Reveal BWMS Costs; Riviera Newsletters: London, UK, 2018; Available online: https://www.rivieramm.com/opinion/opinion/tanker-operators-reveal-bwms-costs-24705 (accessed on 10 June 2021).

- Albert, R.J.; Viveiros, E.; Falatko, D.S.; Tamburri, M.N. Feasibility of potable water generators to meet vessel numeric ballast water discharge limits. Mar. Pollut. Bull. 2017, 120, 82–89. [Google Scholar] [CrossRef]

- Estevez-Calvar, N.; Gambardella, C.; Miraglia, F.; Pavanello, G.; Greco, G.; Faimali, M.; Garaventa, F. Potential use of an ultrasound antifouling technology as a ballast water treatment system. J. Sea Res. 2018, 133, 115–123. [Google Scholar] [CrossRef]

- Batista, W.; Fernandes, F.; Lopes, C.; Lopes, R.; Miller, W.; Ruiz, G. Which ballast Water management system will you put aboard? Remnant anxieties: A Mini-Review. Environments 2017, 4, 54. [Google Scholar] [CrossRef] [Green Version]

- Balaji, R.; Yaakob, O.; Koh, K.K. A review of developments in ballast water management. Environ. Rev. 2014, 22, 298–310. [Google Scholar] [CrossRef]

- Scriven, D.R.; DiBacco, C.; Locke, A.; Therriault, T.W. Ballast water management in Canada: A historical perspective and implications for the future. Mar. Pol. 2015, 59, 121–133. [Google Scholar] [CrossRef]

- Outinen, O.; Bailey, S.A.; Broeg, K.; Chasse, J.; Clarke, S.; Daigle, R.M.; Gollasch, S.; Kakkonen, J.E.; Lehtiniemi, M.; Normant-Saremba, M.; et al. Exceptions and exemptions under the ballast water management convention - Sustainable alternatives for ballast water management? J. Environ. Manage. 2021, 293, 112823. [Google Scholar] [CrossRef]

- Lui, H.K.; Chen, C.T.A. Reconciliation of pH25 and pHinsitu acidification rates of the surface oceans: A simple conversion using only in situ temperature. Limnol. Oceanogr. Methods 2017, 15, 328–335. [Google Scholar] [CrossRef] [Green Version]

- Lui, H.K.; Chen, C.T.A. Deducing acidification rates based on short-term time series. Sci. Rep. 2015, 5, 11517. [Google Scholar] [CrossRef] [PubMed]

- Bates, N.R.; Astor, Y.M.; Church, M.J.; Currie, K.; Dore, J.E.; Gonzalez-Davila, M.; Lorenzoni, L.; Muller-Karger, F.; Olafsson, J.; Santana-Casiano, J.M. A time-series view of changing surface ocean chemistry due to ocean uptake of anthropogenic CO2 and ocean acidification. Oceanography 2014, 27, 126–141. [Google Scholar] [CrossRef] [Green Version]

- Mekkes, L.; Renema, W.; Bednaršek, N.; Alin, S.R.; Feely, R.A.; Huisman, J.; Roessingh, P.; Peijnenburg, K.T.C.A. Pteropods make thinner shells in the upwelling region of the California Current Ecosystem. Sci. Rep. 2021, 11, 1731. [Google Scholar] [CrossRef] [PubMed]

- Orr, J.C.; Fabry, V.J.; Aumont, O.; Bopp, L.; Doney, S.C.; Feely, R.A.; Gnanadesikan, A.; Gruber, N.; Ishida, A.; Joos, F.; et al. Anthropogenic ocean acidification over the twenty-first century and its impact on calcifying organisms. Nature 2005, 437, 681–686. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.T.A.; Bychkov, A.S.; Wang, S.L.; Pavlova, G.Y. An anoxic Sea of Japan by the year of 2200? Mar. Chem. 1999, 67, 249–265. [Google Scholar] [CrossRef]

- Chen, C.T.A. Buoyancy leads to high productivity of the Changjiang diluted water: A note. Acta Oceanol. Sin. 2008, 27, 133–140. [Google Scholar]

- Chen, C.T.A.; Wang, S.L. Carbon, alkalinity and nutrient budgets on the East China Sea continental shelf. J. Geophys. Res. 1999, 104, 20675–20686. [Google Scholar] [CrossRef]

- The Council of the European Union. Council Directive 98/83/EC of 3 November 1998 on the Quality of Water Intended for Human Consumption (with the Consolidated Text and Latest Amendments in 2015); European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Fernandes, J.A.; Santos, L.; Vance, T.; Fileman, T.; Smith, D.; Bishop, J.D.D.; Viard, F.; Queiros, A.M.; Merino, G.; Buisman, E.; et al. Costs and benefits to European shipping of ballast-water and hull-fouling treatment: Impacts of native and non-indigenous species. Mar. Pol. 2016, 64, 148–155. [Google Scholar] [CrossRef] [Green Version]

| Name | Length (m) | Gross Tonnage (Ton) | Ballast Capacity (m3) | Type of Water Maker | Classification Society | Ballast-Free Certification by Class | Navigation after Installation till 1 January 2021 (Mile) 2 |

|---|---|---|---|---|---|---|---|

| Salvage Ace | 65 | 1714 | 571 1 | Distillation+ RO | ABS | √ | > 30,000 |

| Salvage Champion | 65 | 1830 | 610 1 | RO | ABS | √ | > 30,000 |

| Salvage Titan | 68 | 2057 | 420 | Distillation | CCS | - | > 10,000 |

| Test Item | Drinking Water Standards of EU [29] | Distilled Water Sample | |

|---|---|---|---|

| Salvage Titan | Salvage Ace | ||

| Temperature (°C) | 36 | 31.2 | |

| Salinity (psu) | 0.0 | 0.1 | |

| pH | 6.5–9.5 | 6.7 at 23.5 °C | 7.41 |

| E. coli | 0 CFU/250 mL | <10 CFU/100 mL | |

| Phytoplankton | 48 cells/L | ||

| Zooplankton | ND (individual/L) | ||

| ---------------------------mg/L--------------------------- | |||

| Dissolved O2 | 6.9 | 6.96 | |

| Biological oxygen demand | 1.4 | ||

| Chemical oxygen demand | 1.6 | ||

| Total organic carbon | 0.60 | ||

| Mineral grease | 0.5 | ||

| Total phenols | 0.01 | ||

| Chlorophyll-a | ND (<0.0003) | ||

| Cadmium | 0.005 | ND (<0.002) | ND (<0.0001) |

| Chromium | 0.05 | ND (<0.004) | 0.0003 |

| Copper | 2 | 0.207 | 0.0123 |

| Mercury | 0.001 | ND (<0.0004) | ND (<0.0001) |

| Zinc | 2.05 | 0.156 | |

| Lead | 0.01 | 0.00263 | 0.0029 |

| Nickle | 0.02 | 0.0417 | |

| Manganese | 0.05 | 0.0078 | |

| Arsenic | 0.01 | ND (<0.0005) | |

| Ammonia-N | 0.5 | 0.08 | 0.46 |

| Nitrite-N | 0.5 | ND < 0.002 | 0.011 |

| Nitrate-N | 50 | ND < 0.01 | 0.128 |

| Phosphate | <0.0005 | 0.015 | |

| Power of Vessel’s Generator (kW) | Power of Water Maker (kW) | Practical Diesel Consumption (tonne/day) | Cost (US$/day) 3 | ||||

|---|---|---|---|---|---|---|---|

| Name | Maximum | Practical Use 1 | Generator 2 | Water Maker | Generator | Water Maker | |

| Salvage ACE | 320 | 80 | 2.75 | 0.70 | 0.024 | 385 | 13.2 |

| Salvage Champion | 320 | 80 | 2.75 | 0.70 | 0.024 | 385 | 13.2 |

| Salvage Titan | 416 | 104 | 8.25 | 0.91 | 0.072 | 500.5 | 39.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, K.-T.; Lui, H.-K.; Chen, C.-T.A.; Liu, L.-L.; Yang, L.; Dong, C.-D.; Chen, C.-W. Using Onboard-Produced Drinking Water to Achieve Ballast-Free Management. Sustainability 2021, 13, 7648. https://0-doi-org.brum.beds.ac.uk/10.3390/su13147648

Lu K-T, Lui H-K, Chen C-TA, Liu L-L, Yang L, Dong C-D, Chen C-W. Using Onboard-Produced Drinking Water to Achieve Ballast-Free Management. Sustainability. 2021; 13(14):7648. https://0-doi-org.brum.beds.ac.uk/10.3390/su13147648

Chicago/Turabian StyleLu, Kun-Tu, Hon-Kit Lui, Chen-Tung Arthur Chen, Li-Lian Liu, Lei Yang, Cheng-Di Dong, and Chiu-Wen Chen. 2021. "Using Onboard-Produced Drinking Water to Achieve Ballast-Free Management" Sustainability 13, no. 14: 7648. https://0-doi-org.brum.beds.ac.uk/10.3390/su13147648