A Challenge-Based Learning Experience in Industrial Engineering in the Framework of Education 4.0

Abstract

:1. Introduction

1.1. Challenge-Based Learning

1.2. Industry and Education 4.0

1.2.1. Industry 4.0 Effects

- They provide elements so that an organization can reach and maintain higher levels of quality in the product or service.

- It provides an internationally recognized standard of prestige.

- It allows companies to reduce costs, achieve more profitability and increase productivity levels.

- It motivates and engages workers through consultation and participation.

- It facilitates relations with suppliers, customers and collaborators both national and international.

- It encourages implementation of continuous improvement processes

1.2.2. Education 4.0

1.3. Cyber-Physical Spaces

1.4. Ux and Emotional Domotics

2. Materials and Methods

2.1. Scenario Description

- Performs successful planning, design, installation, operation, evaluating and optimizing work systems that assure organizations’ competitiveness through the use of industrial and systems engineering tools.

- Being up-to-date in their knowledge and grasp of concepts, methodologies and tools of industrial and systems engineering and other areas. They should also have the capacity to adapt rapidly to changes in their work environment, in a globally competitive setting.

- Interact with and influence the organization by leading work groups.

- Showing initiative and entrepreneurial abilities.

- Consider social and environmental sustainability issues when making decisions.

- Respect people and the environment, and make decisions based on ethical criteria.

- (a)

- An ability to apply knowledge of mathematics, science and engineering;

- (b)

- An ability to design and conduct experiments, as well as to analyze and interpret data;

- (c)

- An ability to design a system, component, or process to meet desired needs within realistic constraints such as economic, environmental, social, political, ethical, health and safety, manufacturability, and sustainability;

- (d)

- An ability to function in multidisciplinary teams;

- (e)

- An ability to identify, formulate, and solve engineering problems;

- (f)

- An understanding of professional and ethical responsibility;

- (g)

- An ability to communicate effectively (3g1 orally, 3g2 written);

- (h)

- The broad education necessary to understand the impact of engineering solutions in a global, economic, environmental, and societal context;

- (i)

- A recognition of the need for, and an ability to engage in, life-long learning;

- (j)

- A knowledge of contemporary issues;

- (k)

- An ability to use the techniques, skills, and modern engineering tools necessary for engineering practice.

2.2. Course Context

- b. An ability to design and conduct experiments, as well as to analyze and interpret data;

- e. An ability to identify, formulate, and solve engineering problems;

- k. An ability to use the techniques, skills, and modern engineering tools necessary for engineering practice.

- Obtain information through mapping of the system to be studied, diagnosis of the current situation and definition of the problem using diagnostic tools and specialized software.

- Generate the idea of the system that provides the expected service and establish alternative solutions using specialized software.

- Evaluate the solution alternatives through economic, technical and human resources criteria using evaluation tools through specialized software.

- Plan and schedule the solution implementation project as well as control the execution of the project through specialized software.

- Present the results orally and in writing.

2.3. Case Context

- Understand the basis of the implemented technologies.

- Evaluate the experimental protocol and implementation.

- Identify potential risks for the process, users or tools.

- Identify areas of opportunity for either the process or the designed instruments.

- Determine the required improvements for future iterations.

- Prepare a complete systematic report and manual to be used by future teams of researchers and designers.

- Present and defend their conclusions in front of the clients (in this case the researchers).

- Evaluation and optimization for continuous improvement;

- Process analysis;

- Ergonomy analysis.

2.4. Development of the Implementation

2.4.1. Theoretical Background

2.4.2. Workstation Design

- Definition of the challenge: The main objective for the client was to evaluate a new seasonal packaging proposal through the sensory experience of the user to identify according to certain variables, which were the designs that should be launched to the market according to the season of the year.

- Objectives:

- Analyze the process that takes place in the domotic laboratory for the evaluation of a product through the sensory experience and facial expression of the user.

- Propose improvements in the generation of the process that are repeatable for future evaluations of products and/or services.

- Propose improvements in the external environment of the emotional domotic cabin to improve the user experience.

2.4.3. Testing Booth

2.4.4. Analysis Experiment

- Facial expressions;

- Heart rate;

- Galvanic skin response;

- Mouse cursor recording;

- Scene recording;

- Temperature;

- Humidity;

- Light hue.

2.4.5. Continuous Improvement

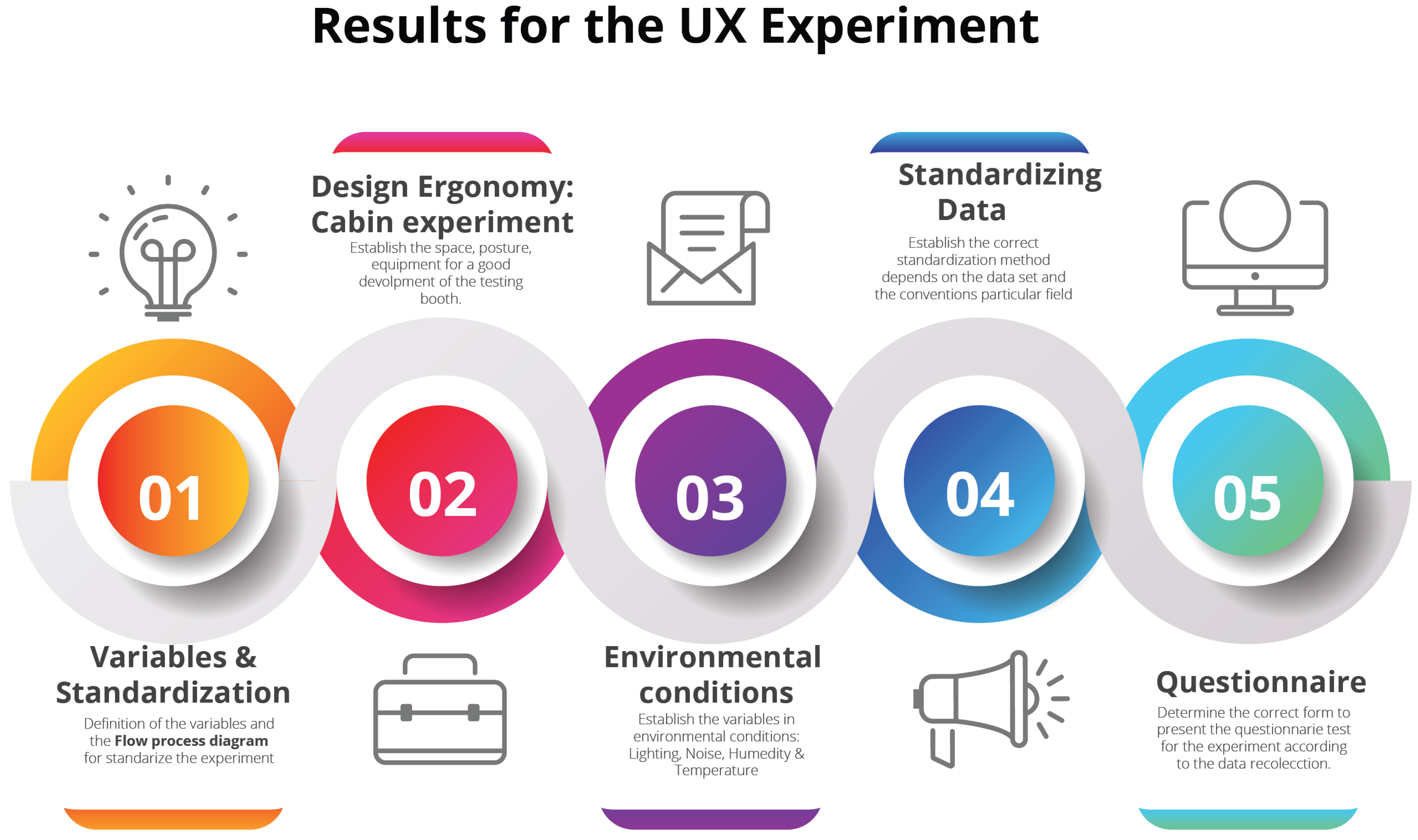

3. Results

3.1. Students’ Experience Results

- Variables and Standardization: prototypes, variables, materials For the development of this experiment, the data collected in Table 1 provided by the client were considered:The relevant variables to be analyzed with each bottle were determined by the client and were the following:

- First impression;

- Bottle’s grip;

- Dosage measurement;

- Spill prevention;

- Comparative quality against other bottles;

- Year season evocated by each bottle’s design;

- Residue prevention.

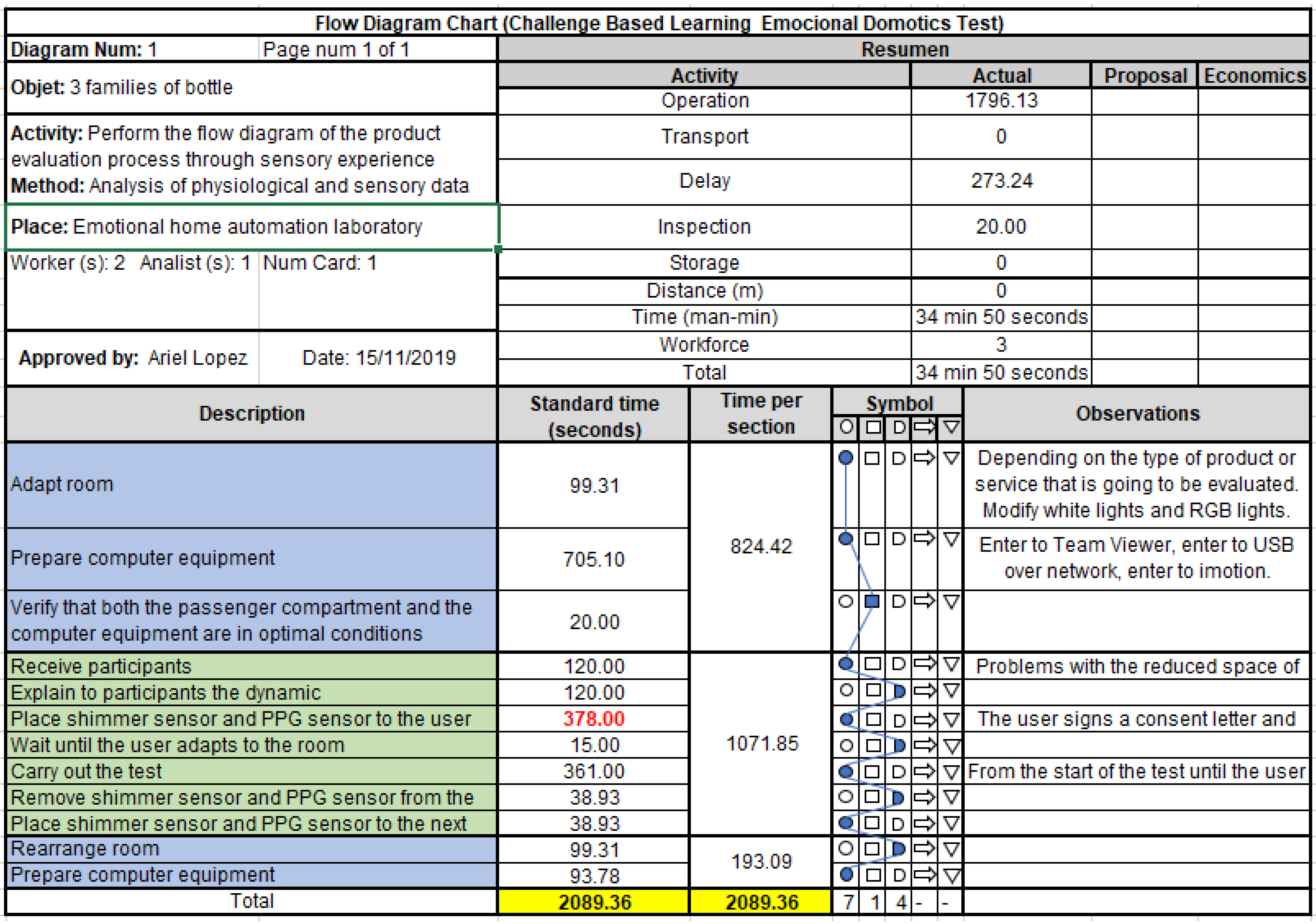

For the UX analysis during the experiment, the users facial expressions, galvanic skin response and heart rate were measured. To better understand the product evaluation process by the experimental subject, one may use the diagram in Figure 6. The knowledge and the veracity of the times established in the previous diagram were provided directly by the home automation laboratory. In the table, it is marked in red the activity with the longest duration, and critical impact on the process optimization.The final result was a total time of 34 min and 50 s (35 min), since the cabin is prepared until it is ready to receive the second person who will perform the experiment and, in order to understand the information contained in the diagram, it is important to mention the following particularities about it:- Blue Activities: are those performed by laboratory technicians and must be performed in that time by internet connections and the time that the machinery and computer equipment needs to start.

- Green Activities: are those that take place when the sample of users that will carry out the experiment arrives.

It is important to reiterate that this process flow diagram begins at Stage 3 of the project: execution and control. The previous stages (initiation and planning) are not considered in this diagram.Flow diagram. Students’ findings: The total time in the flow diagram, which both operators (the controller and the one in charge of interacting with the user) take is 35 min. This time ranges from the preparation of the cabin until the second person is ready to enter to perform the experiment. Additionally, it was found that the longest time invested by the users (in conjunction with the operators) occurred during the placing of the shimmer sensor and in the reading and confirmation of their data, that is, a total of 6.2 min is allocated, per user, which makes the total process time increase too much for all the participants. - Design Ergonomy: Cabin Experiment As can be seen in Figure 3, regarding the user’s position in the testing booth’s seat, it can be seen that it is not in the recommended ergonomic position Figure 3 (image on the right). In the first instance, it can be noticed that the chair does not have wheels on the lower part, which makes its movement difficult. The second point that can be noticed is that the user does not rest his back on the seat, which may be a cause of future lumbar pain and discomfort in the lower back, upper back and neck. Another aspect that can be seen is that the table does not allow the user to be completely attached to the desktop by the base it has. The cross (support) of the table does not allow the user’s knees to be under the table nor the extension of the arms to reach the mouse comfortably. Finally, it can be noted that the top edge of the monitor is above the user’s vision. This, in the long term, causes tired vision and may have an influence on the results due to the fact that the camera is indispensable in this type of analysis.After the analysis, the students’ remarks and proposals to improve the testing space capabilities are the following:

- Modify the furniture to allow the user to sit comfortably, this may include returning the mobility to the chair to allow the approximation of the seat to move into the recommended position.

- Change to a chair that does not have fabric so that odors are not retained.

- Allow adjustment of the chair’s height.

- Switch to a table where it is possible for the knees to enter underneath (avoid the cross support to avoid damage).

- Have a cushion for the back in case the user requires it and a bench for the feet if the case that this is also necessary.

- Regarding the height of the computer, it is recommended to have it on a movable base, so that it sits perfectly at the height of the operator’s eyes, so that there are be no faults in terms of capturing their movements.

- Even though the population did not voluntarily express any dissatisfaction with the environment inside the cabin or with the furniture occupied, a questionnaire was not applied on the environment in which they interacted during the test to understand their opinion.

- Regarding the environment outside of the testing booth, the population expressed a discomfort regarding the place where the emotional domotic cabin was located. Given that the space was very small and cramped with boxes, people working and other laboratory materials, the first impression of the users was affected by the external environment in which they had to wait, beyond the test they performed.

- Ergonomy: Environmental conditions The environmental conditions’ ergonomy takes into account various aspects of the testing space. The aspects considered for this evaluation are the following:

- Ilumination In terms of lighting, the final tonality of the interior turned orange. Therefore, it is classified within Group One, defined for residential premises and for colder environments. This point is clarified later in lighting recommendations.According to the NOM-025-STPS-2008 [53], the lighting intensity of the testing booth (82–93 luxes) is low if the visual activity is classified according to the standard. The visual tasks performed are simple visual inspection requirements, no assembly task or any other type requiring more detail of distinction is needed. However, if the Testing booth is considered as an interior, the minimum number of luxes would be equal to 100. Therefore, the lighting range of the place would be slightly below the norm.

- Temperature The interior temperature (24–26 C) is within the permissible limits of the standard according to NOM-015-STPS-2001 [54]. The Ministry of Labor and Social Security indicates a maximum exposure of 4 h in a temperature range of 18 to 34 C. Therefore, there is no problem related to the norm, considering that the exposure time is only 9 min.

- Humidity Similarly, the effective temperature of the work area shows a relative humidity of between 20% and 60%, placing the humidity of the Testing booth (>50%) within the limits. Despite this, in this section a series of recommendations are made to better shape the environment.

- Sound The National Institute for Occupational Safety and Health (NIOSH) and the NOM-011-STPS-2001 [55] recommends differing exposure times for different noise levels. The noise generated in the cabin is low noise (70% volume), so it is not necessary to consider the exposure time. In addition, this time is relatively short and does not generate discomfort for the user. In any case it is important to consider the regulation at all times so as not to exceed the recommended duration. In Figure 7 we can see the noise exposure limits according to the NIOSH.

Based on this analysis and the conditions inside the testing booth during the experiment, the following recommendations were made by the students for the continous improvement:- Illumination As previously mentioned, three different colors of lighting (green, red and white) are mixed inside the interior, which in the end create an orange shade perceived by the user. A recommendation is that the shades vary depending on the season in which the test is presented, warm colors in case the tests are in spring, intermediate colors in summer–autumn and cold colors for the winter season.It is also important to express the desired message with the tonality of lighting. It is important to remember that the emotions and behavior of human beings depend on the environment in which they find themselves. The psychology of color associates different feelings based on color.The orange hue is considered good for the interior of the passenger compartment. The orange color is a friendly and accessible color, associated with happiness and innovation. It also points out that it is a good option for residential spaces where you want guests to feel welcome. Therefore, it is an excellent option for the user to feel confident in the facilities.As an alternative to this color, the use of the color blue is recommended since in the psychology of color, the meaning of the color blue is closely related to the sea and the sky. Stability, harmony, peace, calm and trust are just some of the feelings that can be generated in people.In terms of lighting levels, the use of LED technology is recommended to reach the minimum levels of the standard. Some advantages of LED lighting are significant energy saving, long life, low heat emission, low light pollution, among others.

- Sound and Temperature The recommended sound, temperature and lighting vary depending on the day the test is performed. The recommendation is that it be carried out from Monday to Thursday for the different periods of the year. The ideal is to condition the cabin according to the place where you are going to buy the product. In this case, being a commercial product, the design of the cabin should simulate the appearance of a store with shelves and products of the same category. The objective of this is for the user to experience a real situation in a simulated environment and with real representative samples of each of the product families.The test also allows a greater dynamism with respect to the assembly since, in a single day, the testing of only one season would be carried out, maintaining the same levels of sound, temperature, lighting and even the same aroma. This would avoid the changing of ambience according to the different seasons of the year, increasing the number of records made in each test.The following scheme (Table 2) was designed taking into account the product that was being evaluated and the season that was intended to be emulated throughout the experiment (note: this is considering a Mexican household with an average temperature in the usage room):The setting specifications are defined according to the first proposed questionnaire. This questionnaire is filled in by the company and based on whether the purchasing environment is planned, the season in which it is desired to apply it and the specific characteristics that are to be analyzed. It is important to adapt the booth to the relevant aromas and songs. An example of this would be to decorate the booth with lights and Christmas songs in the case of winter weather. Another recommendation within the same category of aromas is that the products to be tested have the scents of the original, if what you want is to know what product you want to buy in terms of the liquid and not in terms of the shape of the product.

- Standardize Data: Analysis of Population for the Challenge The sample that the client provided for the sampling of the products cannot be considered a representative sample of the population due to the number of people who performed the experiment. This has as a consequence that the results presented by the cabin of emotional domotics have a low level of reliability and can be questioned. Given that 3 different product sizes were analyzed, the sample size of each of the families had to be calculated with the following formula [56]:where:

- N: Size of the population or universe (total number of possible respondents). In this case, the client had to consider the number of people that are more likely to buy each of the sizes that were available due to their characteristics and needs. An example would be the number of women between 15 and 29 years old for family 1 of products (600 mL) that live in the CDMX.Note: According to a study conducted by the National Institute of Statistics and Geography (INEGI) in 2015, 22.8% of the female population in the CDMX complied with this characteristic, which represented 1,068,637 women in that year. This number would have to be further refined according to socio-economic level, brand preferences, etc.

- k: Constant that depends on the level of confidence that is assigned. The level of confidence indicates the probability that the results of the research are true: a 95.5% confidence is the same as a possibility of error of 4.5%.The most used K values and their confidence levels are listed in the Table 3:

- e: Desired sampling error. The sampling error is the difference that can exist between the result obtained by asking a sample of the population and the one that would be obtained if the total population was asked.

- p: Proportion of individuals who possess the characteristic of study in the population. These data are generally unknown and it is usually assumed that , which is the safest option.

- q: Proportion of individuals who do not possess that characteristic, that is .

- n: Size of the sample (number of surveys that must be performed) for the tests; flow diagram of the process, and the adaptation conditions of the workplace, or area where it was carried out performing the sensory perception experiment; ergonomics.

- Questionnaire Based on the users’ perception analysis, it was determined by the students that the population did not show displeasure nor rejection at the time of carrying out the questionnaire, since it served as a complement to experience on the test that was applied to them; that is, the students considered that the questionnaire was answered with truth and conviction of what they had just received during the experiment.

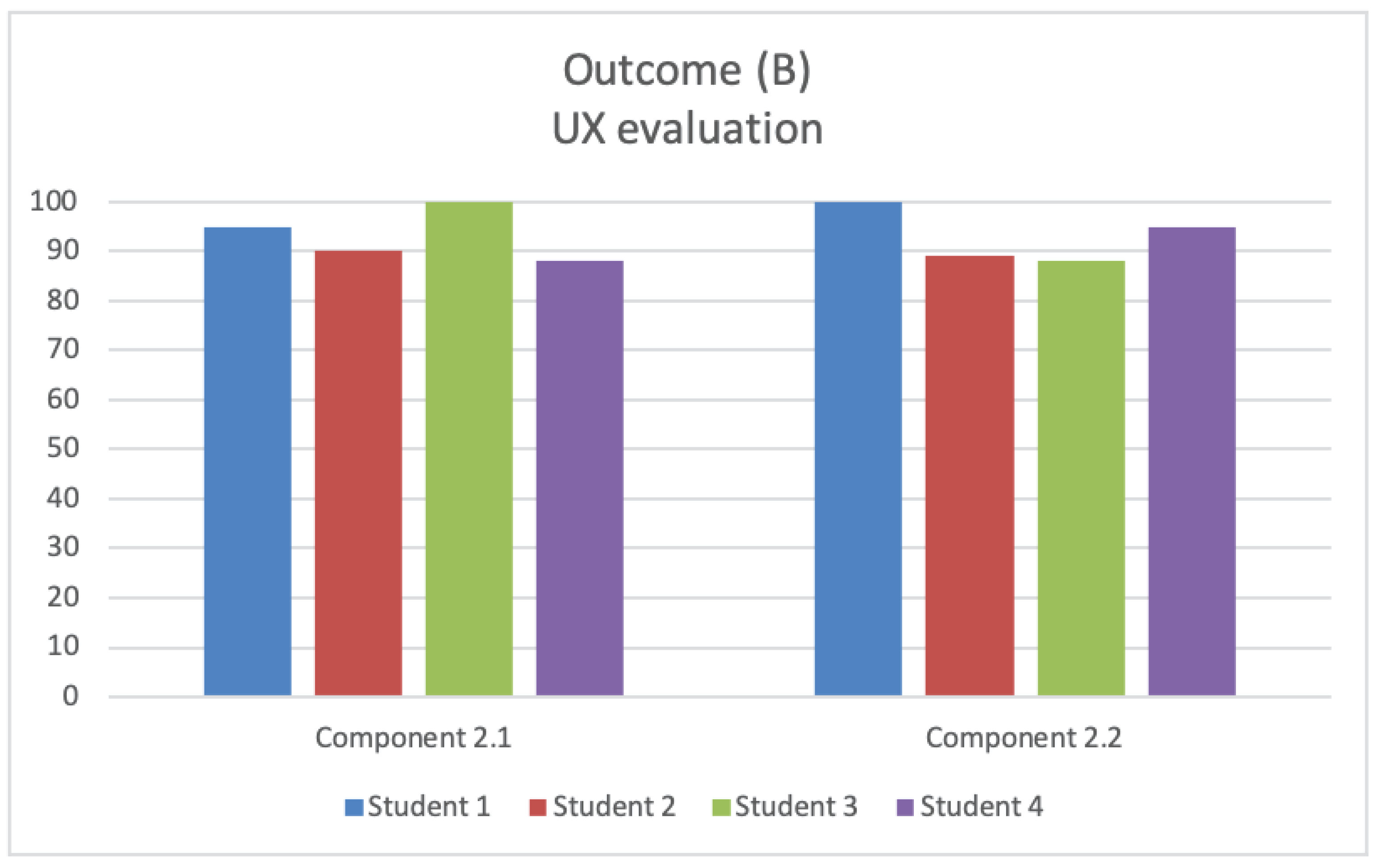

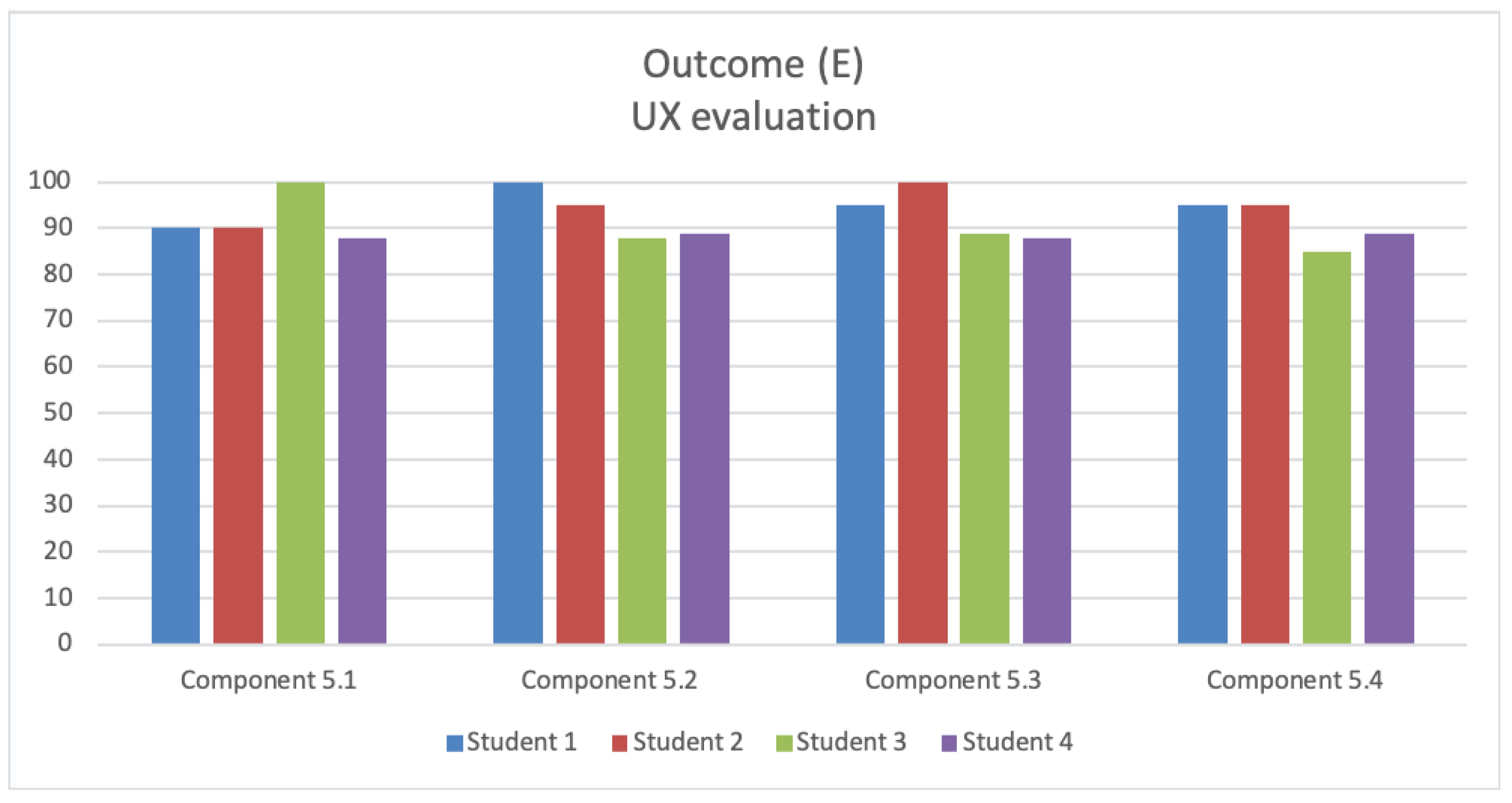

3.2. Methodology Implementation Results

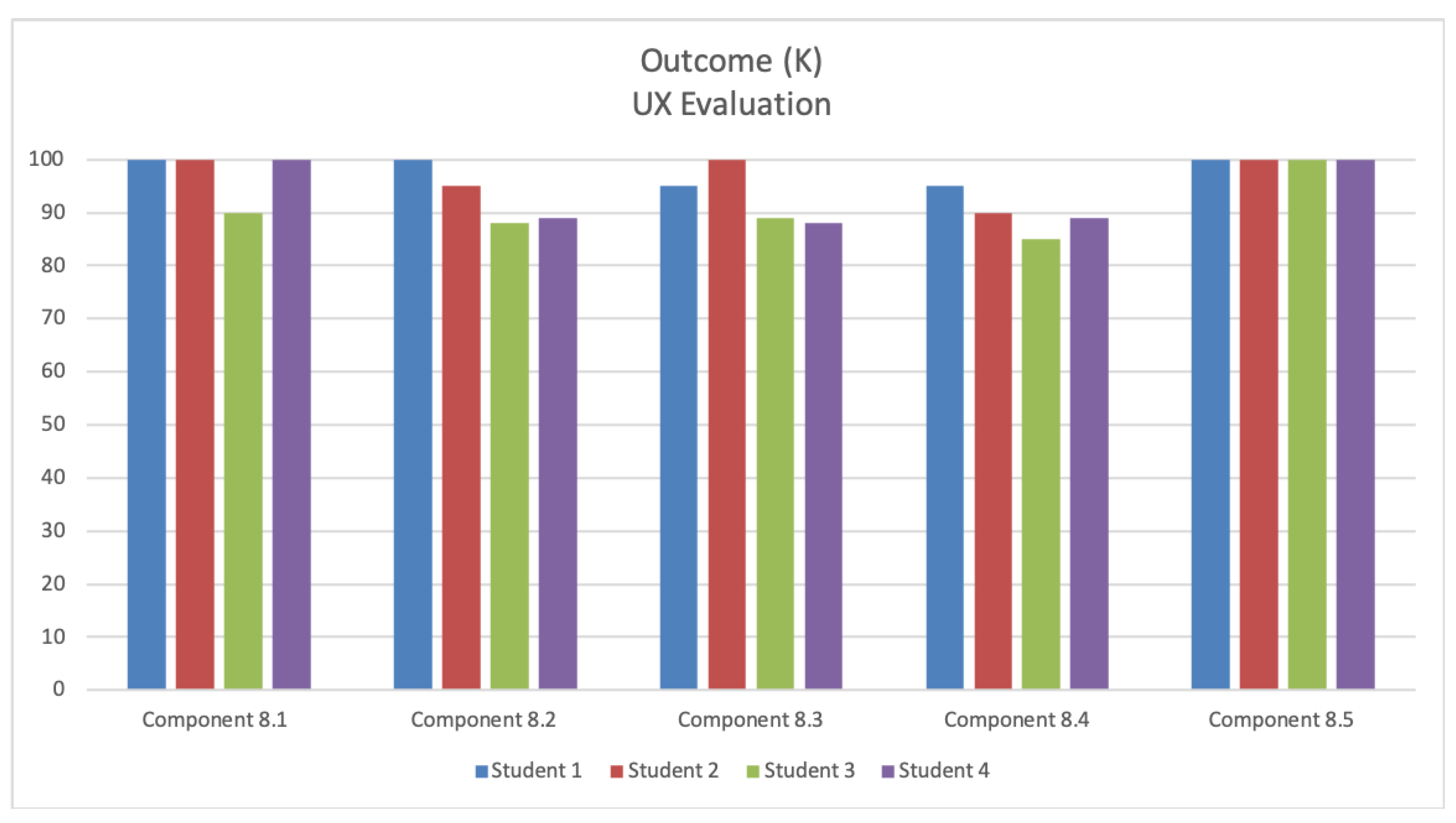

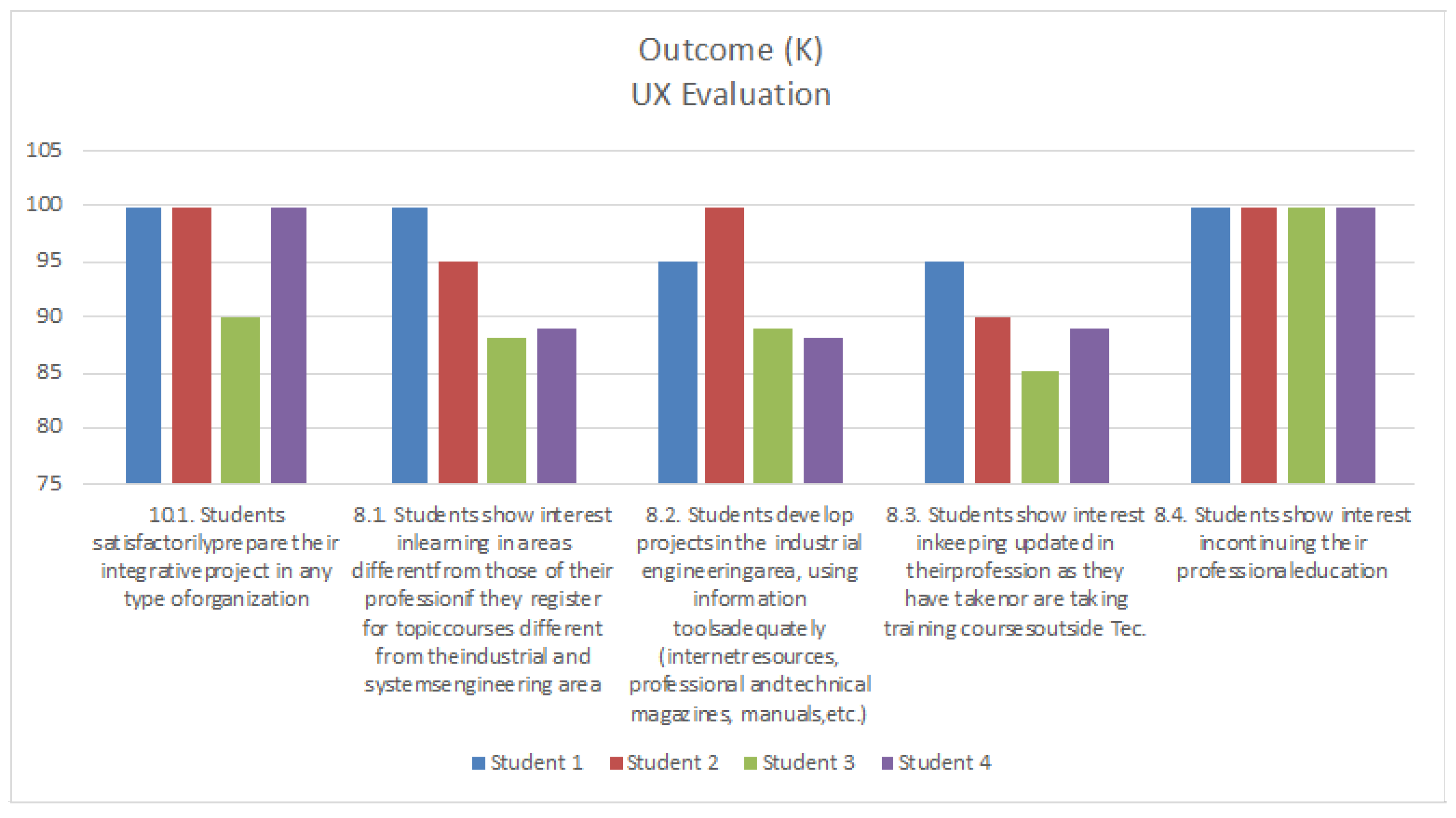

3.3. Students’ Academic Results and Perception

- Component 2.1 Students demonstrate they are able to collect and process data;

- Component 2.2 Students demonstrate they are able to perform statistical analysis, interpret the results and write reports.

- Component 5.1 Students separate the critical variables of a problem and reformulate the problems in order to understand their behavior;

- Component 5.2 Students make diagnoses to identify and describe a problem;

- Component 5.3 Students design and develop a solutions’ action plan;

- Component 5.4 Students resolve a problem by implementing the solutions proposed.

- Component 10.1 Students satisfactorily prepare their integrative project in any type of organization;

- Component 8.1 Students show interest in learning in areas different from those of their profession if they register for topic courses different from the industrial and system engineering area;

- Component 8.2 Students develop projects in the industrial engineering area, using information tools adequately (internet resources, professional and technical magazines, manuals, etc.);

- Component 8.3 Students show interest in keeping updated in their profession as they have taken or are taking training courses outside the institution;

- Component 8.4 Students show interest in continuing their professional education.

- “The class is very interesting because it gives an avant-garde approach with current tools that will be handled in the professional field.”

- “The project was very interesting, I had never done a project where we could unite disciplinary knowledge in two areas of development such as industrial design and industrial engineering.”

- “The use of technological tools has been impressive; prior to this project I did not know that there is an evaluation of emotions and that they can be quantified and that these types of studies are the new trends that we will face in the world for various areas, it is very interesting how to be able to see the user experience and that from business decisions can be made.”

4. Discussion

4.1. Impact on Future Education

- Adaptive. This consists of designing learning ecosystems, face-to-face or virtual, according to the characteristics and needs of educators and students.

- Self-regulating. This assumes that the student is able to control their behavior and, consequently, be proactive in complex situations.

- Experimental. This creates educational situations where the student explores his or her skills to manipulate reality.

- Active. This makes the student an agent of change, rather than a container of information.

- Interactive. This fosters the relationship between the student and other agents, as well as with their environment.

- Collaborative. This implies that students achieve common goals by pooling efforts and resources.

- Problem-based. Involve students in solving real problems.

- Project-based. Involves students in carrying out an action plan focused on addressing a particular need or solving a specific problem.

- Promotion of entrepreneurial talent.

- Promotion of STEM vocations and training in digital skills aligned with Industry 4.0.

- Promotion of dual training in cooperation with firms, particularly with the Engineering Development and Innovation Centers and the technology sector.

4.2. Cbl Vs Traditional Course

4.3. Future Work

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CBL | Challenge-Based Learning |

| CPS | Cyber-Physical Systems |

| ED | Emotional Domotics |

| ICT | Information and Communication Technologies |

| LED | Light Emitter Diode |

| MOOCS | Massive Online Open Courses |

| NIOSH | National Institute for Occupational Safety and Health |

| NOM | Official Mexican Norm |

| PPG | Photoplethysmogram |

| TRIZ | Theory for the resolution of inventive related tasks |

| UX | User Experience |

References

- Marx, R.W.; Blumenfeld, P.C.; Krajcik, J.S.; Soloway, E. Enacting Project-Based Science. Elem. Sch. J. 1997, 97, 341–358. [Google Scholar] [CrossRef]

- Frank, M.; Lavy, I.; Elata, D. Implementing the Project-Based Learning Approach in an Academic Engineering Course. Int. J. Technol. Des. Educ. 2003, 13, 273–288. [Google Scholar] [CrossRef]

- Moti, F.; Barzilai, A. Project-Based Technology: Instructional Strategy for Developing Technological Literacy Moti. J. Technol. Educ. 2006, 18, 38–52. [Google Scholar]

- Blumenfeld, P.C.; Soloway, E.; Marx, R.W.; Krajcik, J.S.; Guzdial, M.; Palincsar, A. Motivating Project-Based Learning: Sustaining the Doing, Supporting the Learning. Educ. Psychol. 1991, 26, 369–398. [Google Scholar] [CrossRef]

- Benešová, A.; Tupa, J. Requirements for Education and Qualification of People in Industry 4.0. Procedia Manuf. 2017, 11, 2195–2202. [Google Scholar] [CrossRef]

- Miranda, J.; Lopez, C.S.; Navarro-Tuch, S.A.; Bustamante, M.R.; Molina, J.M.; Molina, A. Open Innovation Laboratories as Enabling Resources to Reach the Vision of Education 4.0. In Proceedings of the 2019 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Valbonne Sophia-Antipolis, France, 17–19 June 2019; pp. 1–7. [Google Scholar] [CrossRef]

- Mourtzis, D.; Vlachou, E.; Dimitrakopoulos, G.; Zogopoulos, V. Cyber- Physical Systems and Education 4.0—The Teaching Factory 4.0 Concept. Procedia Manuf. 2018, 23, 129–134. [Google Scholar] [CrossRef]

- Tvenge, N.; Martinsen, K. Integration of digital learning in industry 4.0. Procedia Manuf. 2018, 23, 261–266. [Google Scholar] [CrossRef]

- Stark, R.; Kind, S.; Neumeyer, S. Innovations in digital modelling for next generation manufacturing system design. CIRP Ann. 2017, 66, 169–172. [Google Scholar] [CrossRef]

- Yu, Z.; Zhou, L.; Ma, Z.; El-Meligy, M.A. Trustworthiness Modeling and Analysis of Cyber-physical Manufacturing Systems. IEEE Access 2017, 5, 26076–26085. [Google Scholar] [CrossRef]

- Rauch, E.; Vickery, A.; Garcia, M.; Rojas, R.; Matt, D.T. Axiomatic Design based Design of a Software Prototype for Smart Shopfloor Management. MATEC Web Conf. 2018, 223, 01012. [Google Scholar] [CrossRef]

- Bertoncelli, T.; Mayer, O.; Lynass, M. Creativity, Learning Techniques and TRIZ. Procedia CIRP 2016, 39, 191–196. [Google Scholar] [CrossRef]

- Schallock, B.; Rybski, C.; Jochem, R.; Kohl, H. Learning Factory for Industry 4.0 to provide future skills beyond technical training. Procedia Manuf. 2018, 23, 27–32. [Google Scholar] [CrossRef]

- Hong, J.C.; Chen, M.Y.; Wong, A.; Hsu, T.F.; Peng, C.C. Developing physics concepts through hands-on problem solving: A perspective on a technological project design. Int. J. Technol. Des. Educ. 2012, 22, 473–487. [Google Scholar] [CrossRef]

- Lin, K.Y.; Williams, P.J. Two-stage hands-on technology activity to develop preservice teachers’ competency in applying science and mathematics concepts. Int. J. Technol. Des. Educ. 2017, 27, 89–105. [Google Scholar] [CrossRef] [Green Version]

- Pirttimaa, M.; Husu, J.; Metsärinne, M. Uncovering procedural knowledge in craft, design, and technology education: A case of hands-on activities in electronics. Int. J. Technol. Des. Educ. 2017, 27, 215–231. [Google Scholar] [CrossRef]

- Niiranen, S. Supporting the development of students’ technological understanding in craft and technology education via the learning-by-doing approach. Int. J. Technol. Des. Educ. 2019, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Apple Inc. Challenge Based Learning: Take Action and Make a Difference; Technical Report; Apple Inc.: Cupertino, CA, USA, 2008. [Google Scholar]

- Johnson, L.F.; Smith, R.S.; Smythe, J.T.; Varon, R.K. Challenge-Based Learning an Approach for Our Time a Research Report from the New Media Consortium; Technical Report; The New Media Consortium: Austin, TX, USA, 2009. [Google Scholar]

- Mora-Salinas, R.; Torres, C.R.; Castillo, D.H.; Gijón, C.R.; Rodriguez-Paz, M.X. The i-semester experience: Undergraduate challenge based learning within the automotive industry. In Proceedings of the IEEE Global Engineering Education Conference, EDUCON, Dubai, United Arab Emirates, 8–11 April 2019; pp. 505–509. [Google Scholar] [CrossRef]

- Gaskins, W.B.; Johnson, J.; Maltbie, C.; Kukreti, A. Changing the Learning Environment in the College of Engineering and Applied Science Using Challenge Based Learning. Int. J. Eng. Pedagog. (IJEP) 2015, 5, 33. [Google Scholar] [CrossRef]

- Chanin, R.; Santos, A.R.; Nascimento, N.; Sales, A.; Pompermaier, L.; Prikladnicki, R. Integrating challenge based learning into a smart learning environment: Findings from a mobile application development course. In Proceedings of the International Conference on Software Engineering and Knowledge Engineering, SEKE, San Francisco, CA, USA, 1–3 July 2018; pp. 704–706. [Google Scholar] [CrossRef]

- Roblek, V.; Meško, M.; Krapež, A. A Complex View of Industry 4.0. SAGE Open 2016, 6, 215824401665398. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, R.; Möhring, M.; Härting, R.C.; Reichstein, C.; Neumaier, P.; Jozinović, P. Industry 4.0—Potentials for Creating Smart Products: Empirical Research Results. In Lecture Notes in Business Information Processing; Springer: Cham, Switzerland, 2015; Volume 208, pp. 16–27. [Google Scholar] [CrossRef]

- International Organisation for Standardisation (ISO). ISO Occupational Health and Safety Management Systems Standard (ISO 450001); International Organization for Standardization: London, UK, 2018. [Google Scholar]

- Office of the Deputy Director-General for Policy (DDG/P) in Consultation with LABADMIN/OSH. Review of the Implementation of ILO—ISO Agreements; Technical Report October; International Labour Office: Geneva, Switzerland, 2017. [Google Scholar]

- Miranda, J.; Navarrete, C.; Noguez, J.; Molina-Espinosa, J.M.; Ramírez-Montoya, M.S.; Navarro-Tuch, S.A.; Bustamante-Bello, M.R.; Rosas-Fernández, J.B.; Molina, A. The Core Components of Education 4.0 in Higher Education: Three Case Studies in Engineering Education. Comput. Electr. Eng. 2021, 93, 1–27. [Google Scholar] [CrossRef]

- Ramírez-Montoya, M.S.; Loaiza-Aguirre, M.I.; Zúñiga-Ojeda, A.; Portuguez-Castro, M. Characterization of the Teaching Profile within the Framework of Education 4.0. Future Internet 2021, 13, 91. [Google Scholar] [CrossRef]

- Loose, C.C.; Ryan, M.G. Cultivating Teachers When the School Doors Are Shut: Two Teacher-Educators Reflect on Supervision, Instruction, Change and Opportunity during the Covid-19 Pandemic. Front. Educ. 2020, 5, 1–11. [Google Scholar] [CrossRef]

- Jahanmir, S.; Saka, N.; Tucker, C.; Kim, S.G. Advances in Multidisciplinary Engineering; ASME Press: New York, NY, USA, 2016. [Google Scholar] [CrossRef]

- Sarkar, S. The role of information and communication technology (ICT) in higher education for the 21st century. Science 2012, 1, 30–40. [Google Scholar]

- Serth, S. Integrating Professional Tools in Programming Education with MOOCs. In IEEE Frontiers in Education Conference (FIE); IEEE: Cincinatti, OH, USA, 2019; p. 2. [Google Scholar]

- Narasareddygari, M.R.; Brown, T.M.; Walia, G.; Radermacher, A.; Kotala, P. Using Digital Learning Objects in SEP-CyLE to Support CS1 Pedagogy An Empirical Investigation. In IEEE Frontiers in Education Conference (FIE); IEEE: Cincinatti, OH, USA, 2019; p. 8. [Google Scholar]

- dos Santos, J.M.; Bremgartner, V.; Queiroz Neto, J.P.; Lima, H.; Pereira, M. ROBÔ-TI: Educational Robotics and Project-Based Learning Stimulating High School Students in the Information Technology Area. In IEEE Frontiers in Education Conference (FIE); IEEE: Cincinatti, OH, USA, 2019; p. 8. [Google Scholar]

- Salas, R.P. Teaching Robotics to Undergraduate Computer Science Students: A different approach. In IEEE Frontiers in Education Conference (FIE); IEEE: Cincinatti, OH, USA, 2019; p. 7. [Google Scholar]

- Vahid, F.; Edgcomb, A.; Lysecky, R.; Rajasekhar, Y. New web-based learning content for core programming concepts using Coral. In IEEE Frontiers in Education Conference (FIE); IEEE: Cincinatti, OH, USA, 2019; p. 5. [Google Scholar]

- Menold, J.; Berdanier, C.; Ritter, S.; Handley, M.; Starkey, E.; Byron, M.; Grady, C.; Miiller, S.; Parkinson, M. BUILDing a community of female makers through hands-on experiences in a university MakerSpace. In IEEE Frontiers in Education Conference (FIE); IEEE: Cincinatti, OH, USA, 2019; p. 8. [Google Scholar]

- Knox, M.E. Integration of Mixed Reality into an Engineering Laboratory Experience for Online Students. In IEEE Frontiers in Education Conference (FIE); IEEE: Cincinatti, OH, USA, 2019; p. 5. [Google Scholar]

- Marcolino, A.S.; Praça, E.; da Silva, E.G. Towards a Practical Approach to Improve the Interdisciplinary Teaching and Learning Process through M-learning Innovative Projects. In IEEE Frontiers in Education Conference (FIE); IEEE: Cincinatti, OH, USA, 2019; p. 5. [Google Scholar]

- Boguski, R.; Cury, D.; Gava, T. TOM: An intelligent tutor for the construction of knowledge represented in concept maps. In IEEE Frontiers in Education Conference (FIE); IEEE: Cincinatti, OH, USA, 2019; p. 7. [Google Scholar]

- Cheng, Q.; Lopez, F.; Hadjixenofontos, A. Integrating Introductory Data Science into Computer and Information Literacy through Collaborative Project-based Learning. In IEEE Frontiers in Education Conference (FIE); IEEE: Cincinatti, OH, USA, 2019; p. 5. [Google Scholar]

- Homann Topin, L.O.; Torres, M.; Barwaldt, R.; Espíndola, D.; Castro de Freitas, A.L.; Maciel Ribeiro, L.; Pias, M.; Sartori Junior, J. Towards Machine Learning for Enhanced Maths Teaching to the Blind. In IEEE Frontiers in Education Conference (FIE); IEEE: Cincinatti, OH, USA, 2019; p. 8. [Google Scholar]

- Davis, K.C. Teaching Database Querying in the Cloud. In IEEE Frontiers in Education Conference (FIE); IEEE: Cincinatti, OH, USA, 2019; p. 7. [Google Scholar]

- Stöckli, S.; Schulte-Mecklenbeck, M.; Borer, S.; Samson, A.C. Facial expression analysis with AFFDEX and FACET: A validation study. Behav. Res. Methods 2018, 50, 1446–1460. [Google Scholar] [CrossRef]

- Gutiérrez-Martínez, Y.; Navarro-Tuch, S.A.; López-Aguilar, A.A.; Bustamante-Bello, R.; Gutierrez-Martinez, Y.; Navarro-Tuch, S.A.; Lopez-Aguilar, A.A.; Bustamante-Bello, M.R. Environmental Impact for Labor Stations Learning through Emotional Domotics Analysis and Workstation Simulation. In Proceedings of the 2018 International Conference on Mechatronics, Electronics and Automotive Engineering (ICMEAE), Cuernavaca, Mexico, 27–30 November 2018; pp. 124–128. [Google Scholar] [CrossRef]

- Navarro-Tuch, S.A.S.; Bustamante-Bello, M.R.; Izquierdo-Reyes, J.; Avila-Vazquez, R.; Ramirez-Mendoza, R.; Jose Luis, P.H.P.H.P.H.; Gutierrez-Martinez, Y. Emotional domotics: Inhabitable home automation system for emotion modulation through facial analysis. In Intelligent Systems and Applications; Bi, Y., Kapoor, S., Bhatia, R., Eds.; Springer International Publishing: Cham, Switzerland, 2018; Volume 751, pp. 218–241. [Google Scholar] [CrossRef]

- Navarro-Tuch, S.A.; Lopez-Aguilar, A.A.; Bustamante-Bello, M.R.; Molina, A.; Izquierdo-Reyes, J.; Curiel Ramirez, L.A. Emotional domotics: A system and experimental model development for UX implementations. Int. J. Interact. Des. Manuf. (IJIDeM) 2019, 13, 1587–1601. [Google Scholar] [CrossRef]

- Herrera Quintero, L.F. Viviendas inteligentes ( Domótica ). Rev. Ing. E Investig. 2005, 25, 47–53. [Google Scholar]

- International Organisation for Standardisation (ISO). Ergonomics of Human-System Interaction—Part 11: Usability: Definitions and Concepts; British Standards Institution: London, UK, 2018. [Google Scholar]

- Kaasinen, E.; Kymäläinen, T.; Niemelä, M.; Olsson, T.; Kanerva, M.; Ikonen, V. A User-Centric View of Intelligent Environments: User Expectations, User Experience and User Role in Building Intelligent Environments. Computers 2012, 2, 1–33. [Google Scholar] [CrossRef] [Green Version]

- Kraft, C. User Experience Innovation; Apress: Berkeley, CA, USA, 2012. [Google Scholar] [CrossRef]

- Redfern, A. The Essential Guide to Classroom Practice; Routledge: London, UK, 2018. [Google Scholar] [CrossRef]

- Lozano Alarcon, J. NORMA Oficial Mexicana, Condiciones de Iluminación en los Centros de Trabajo, NOM-025-STPS-2008; Secretaria del Trabajo y Previsión Social: Mexico City, Mexico, 2008. [Google Scholar]

- Abascal Carranza, C.M. Norma Oficial Mexicana, Condiciones Termicas Elevadas o Abatidas-Condiciones de Seguridad e Higiene NOM-015-STPS-2001; Secretaria del Trabajo y Previsión Social: Mexico City, Mexico, 2002. [Google Scholar]

- Abascal Carranza, C.M. NORMA Oficial Mexicana, Condiciones de Seguridad e Higiene en los Centros de Trabajo Donde se Genere Ruido. NOM-011-STPS-2001; Secretaria del Trabajo y Previsión Social: Mexico City, Mexico, 2002. [Google Scholar]

- Levine, D.M.; Krehbiel, T.C.; Berenson, M.L. Estadística para Administración, 6th ed.; Pearson Education: Estado de México, Mexico, 2014; p. 624. [Google Scholar]

- Self, J.A.; Baek, J.S. Interdisciplinarity in design education: Understanding the undergraduate student experience. Int. J. Technol. Des. Educ. 2017, 27, 459–480. [Google Scholar] [CrossRef]

- Brown, M.; McCormack, M.; Reeves, J.; Brooks, C.; Grajek, S. The Horizon Report Trends; Technical Report 1; EDUCAUSE Publications: Boulder, CO, USA, 2020. [Google Scholar]

- Wallner, T.; Wagner, G. Academic Education 4.0. In International Conference on Education and New Developments; World Institute for Advanced Research and Science: Lisbon, Portugal, 2016; pp. 155–159. [Google Scholar]

| Family | 1 | 2 | 3 |

|---|---|---|---|

| BOTTLE’S SIZE | 600 mL | 1 gallon (3.8 L) | 5 L |

| Bottle’s amount | 3 | 2 | 2 |

| # Persons in test | 10 | 10 | 10 |

| # of women | 10 | 10 | 7 |

| # of men | 0 | 0 | 3 |

| Age range | 18–26 years | 36–43 years | 36–43 years |

| Season | Sound/Music | Temperature | Ilumination | Background | |

|---|---|---|---|---|---|

| [dB] | [°C] | [Tone Temperature] | [Lux] | ||

| Spring | 65–68 | 26 | Warm | 95 | Laundry room |

| Summer | 65–68 | 21 | Intermediate | 95 | Laundry room |

| Autumn | 65–68 | 21 | Intermediate | 95 | Laundry room |

| Winter | 65–68 | 18 | Cold | 95 | Laundry room |

| k | 1.15 | 1.28 | 1.44 | 1.65 | 1.96 | 2 | 2.58 |

| Confidence Level | 75% | 80% | 85% | 90% | 95% | 95.5% | 99% |

| Characteristic | Traditional Knowledge Course Applying (Project-Based Learning) | Challenge-Based Learning Course |

|---|---|---|

| Learning | Students build their knowledge through specifics tasks in the industrial laboratory, according to the theorical needs, the knowledge acquired is applied to carry out the assigned project. | Students work with teachers, experts, a client (enterprise), on real-world problems, in order to develop and applying deeper knowledge of the subjects that they are studying. It is the challenge itself that triggers the generation of new knowledge and the necessary tools or resources. |

| Focus of the course | It faces the students with relevant situations and predefined problems for which a solution is required, according to the theoretical purpose of the course. | It faces students with an open, relevant, problematic situation which requires a real solution. The develop also a multidisciplinary work theme so the student had to develop new abilities. |

| Result of knowledge | It requires the students to generate a product, a presentation or an implementation of solution of the different practices | It requires students to create a solution resulting in a concrete action. |

| Process knowledge | Students work with the assigned practices so their engagement generates products for their learning, in the theoretical aspect as an integrated project. | Students analyze, design, develop and execute the best solution in order to tackle the challenge in a way they and other people see and measure. For this project the students developed a different scenario of solutions and have tangible results. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gutiérrez-Martínez, Y.; Bustamante-Bello, R.; Navarro-Tuch, S.A.; López-Aguilar, A.A.; Molina, A.; Álvarez-Icaza Longoria, I. A Challenge-Based Learning Experience in Industrial Engineering in the Framework of Education 4.0. Sustainability 2021, 13, 9867. https://0-doi-org.brum.beds.ac.uk/10.3390/su13179867

Gutiérrez-Martínez Y, Bustamante-Bello R, Navarro-Tuch SA, López-Aguilar AA, Molina A, Álvarez-Icaza Longoria I. A Challenge-Based Learning Experience in Industrial Engineering in the Framework of Education 4.0. Sustainability. 2021; 13(17):9867. https://0-doi-org.brum.beds.ac.uk/10.3390/su13179867

Chicago/Turabian StyleGutiérrez-Martínez, Yadira, Rogelio Bustamante-Bello, Sergio A. Navarro-Tuch, Ariel A. López-Aguilar, Arturo Molina, and Inés Álvarez-Icaza Longoria. 2021. "A Challenge-Based Learning Experience in Industrial Engineering in the Framework of Education 4.0" Sustainability 13, no. 17: 9867. https://0-doi-org.brum.beds.ac.uk/10.3390/su13179867