A Life Cycle Environmental Impact Comparison between Traditional, Hybrid, and Electric Vehicles in the European Context

Abstract

:1. Introduction

2. Method and System Details

- Goal and scope definition

- Life cycle inventory (LCI)

- Life cycle impact assessment (LCIA)

- Interpretation of results

3. Goal and Scope Definition

- (1)

- Climate change: mainly due to the increase in greenhouse gases (GHG) in the atmosphere, it is accounted for by the global warming potential (GWP) which expresses the equivalent mass of CO2 emitted to obtain a product or a service.

- (2)

- Fine particulate matter formation: focusing on human population intake of PM2.5, the change in ambient concentration of PM2.5 after the emission of primary PM2.5 or precursors (e.g., NH3, NOX, SO2) is evaluated by means of the Particulate Matter Formation Potentials (PMFP), expressed in terms of the equivalent mass of PM2.5 [14,15].

- (3)

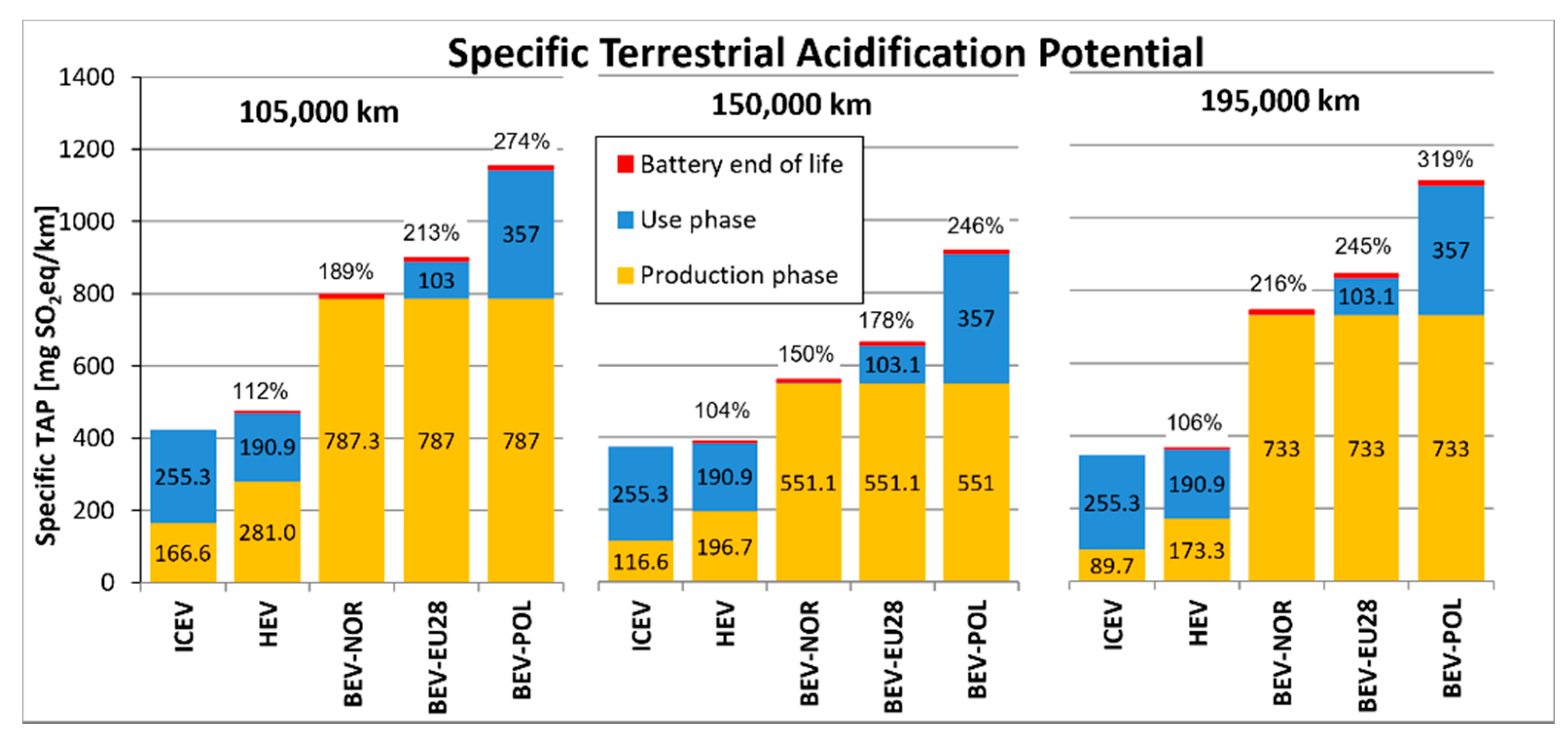

- Terrestrial acidification: soil acidity variation due to acid deposition is taken into account by means of the Terrestrial Acidification Potentials (TAP) which expresses the amount of acidifying emissions (e.g., NOX, NH3, and SO2) introduced in the atmosphere in terms of the equivalent mass of SO2 [14,15].

- (4)

- Mineral resource scarcity: although minerals are available in almost infinite amounts in the world, the real availability of a mineral resource primarily depends on the grade, i.e., the concentration of the mineral within an ore. The primary extraction of a mineral resource leads to an overall decrease in the concentration of that resource in ores worldwide. The lower is the grade of a mineral, the larger will be the amount of ore mined to extract the same amount of resource in the future, which obviously will imply larger land use, higher energy consumption, and waste production: this is the environmental impact related to the mineral resource depletion. The Surplus Ore Potential (SOP), expressed as the equivalent mass of copper, indicates the average extra amount of ore produced in the future caused by the extraction of a mineral resource considering all future production of that mineral resource [14,15,16].

- (5)

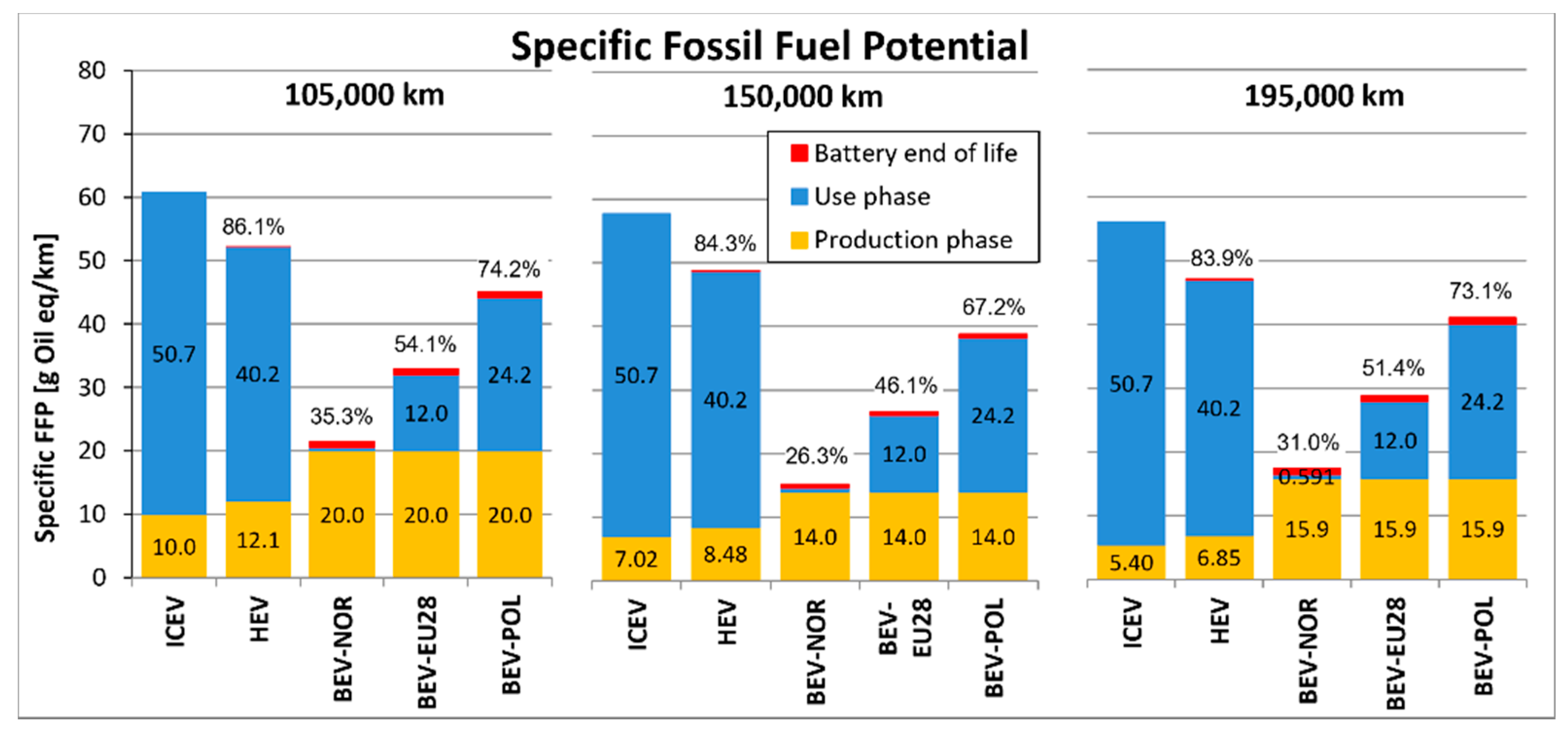

- Fossil resource scarcity: with the same significance and approach followed for mineral resources, depletion of fossil energy resources is expressed in terms of the equivalent mass of oil using the Fossil Fuel Potential (FFP), which is calculated as the ratio between the higher heating value of the fossil resource and the higher heating value of crude oil [14,15].

- (6)

- The three vehicles compared were assumed to be produced in Germany in 2019: the reason for this assumption is that, as reported by ACEA [17], Germany is the European state with the largest production of passenger cars (4.66 million units in 2019, i.e., 30% of EU production) followed by Spain (2.18 million units in 2019, 14% of EU production).

- (7)

- The lithium-ion batteries of both the hybrid and the electric vehicles were assumed to be manufactured in China, which is the largest producer in the world: considering, for example, lithium-ion bases batteries for electric vehicles, in 2017 about 70% of the world production (145 out of 206 GWh) came from China [18].

- (8)

- A reference lifetime distance of 150,000 km traveled in Europe was assumed for each of the three vehicles considered: this was established considering that in the European Union, a passenger car travels an average distance of 12,529 km each year, and has an average useful life of 11.5 years [19]—it results in an average distance traveled by a passenger car during the lifetime of 144,085 km, rounded by the authors to 150,000 km.

4. Life Cycle Inventory

5. Life Cycle Impact Assessment

5.1. Production Stage

- Components

- Fluids

- Battery

5.1.1. Battery Production

- LCO—Lithium Cobalt Oxide (LiCoO2)

- LMO—Lithium Manganese Oxide (LiMn2O4)

- NMC—Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2)

- LFP—Lithium Iron Phosphate (LiFePO4)

- NCA—Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO2)

5.1.2. Vehicle Production Results

5.2. Use Stage

5.2.1. Energy Consumption

5.2.2. On-Road Emissions

5.3. End-of-Life

Electric Vehicle Battery Disposal

6. Results of the LCA Analysis and Discussion

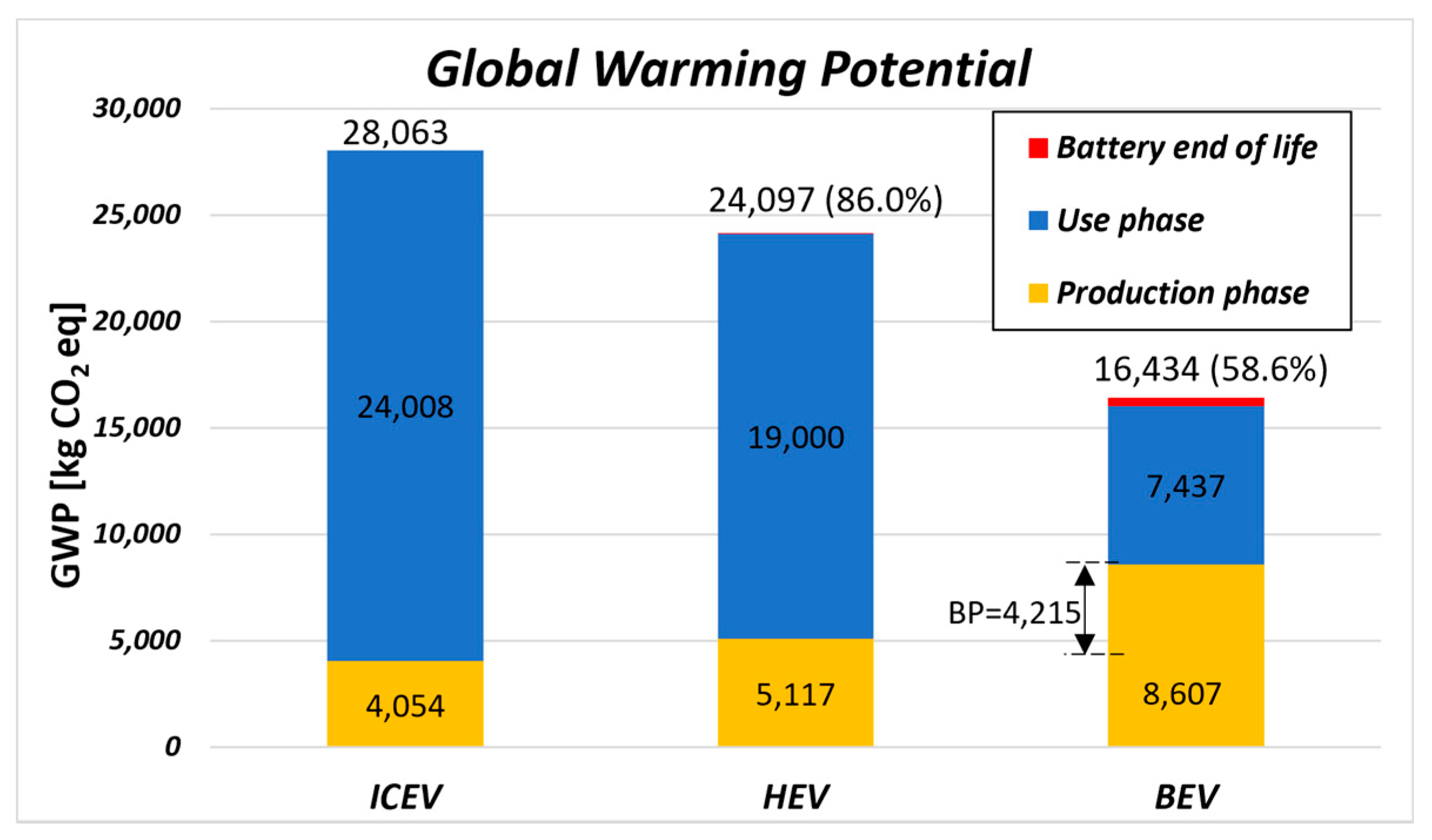

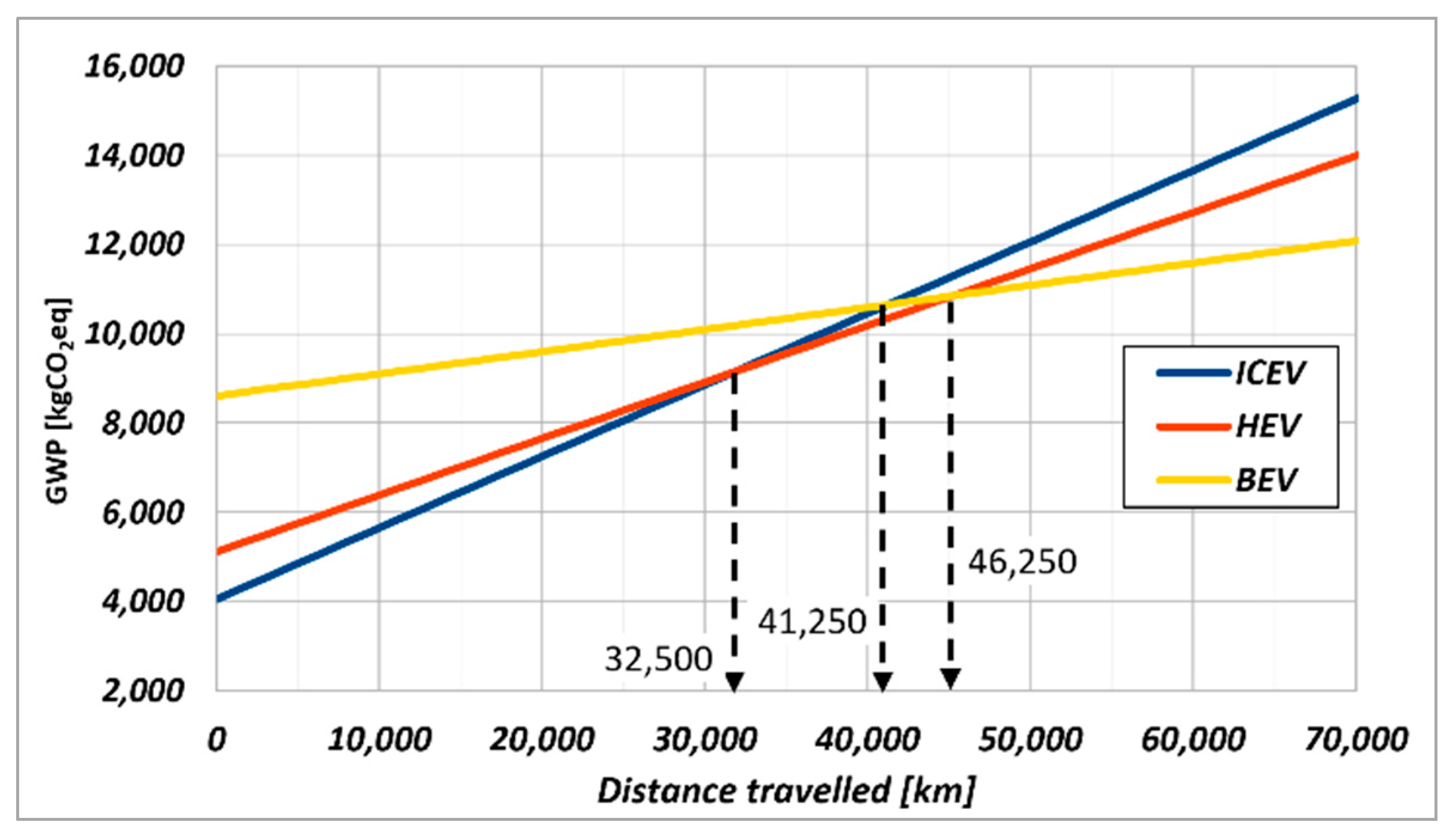

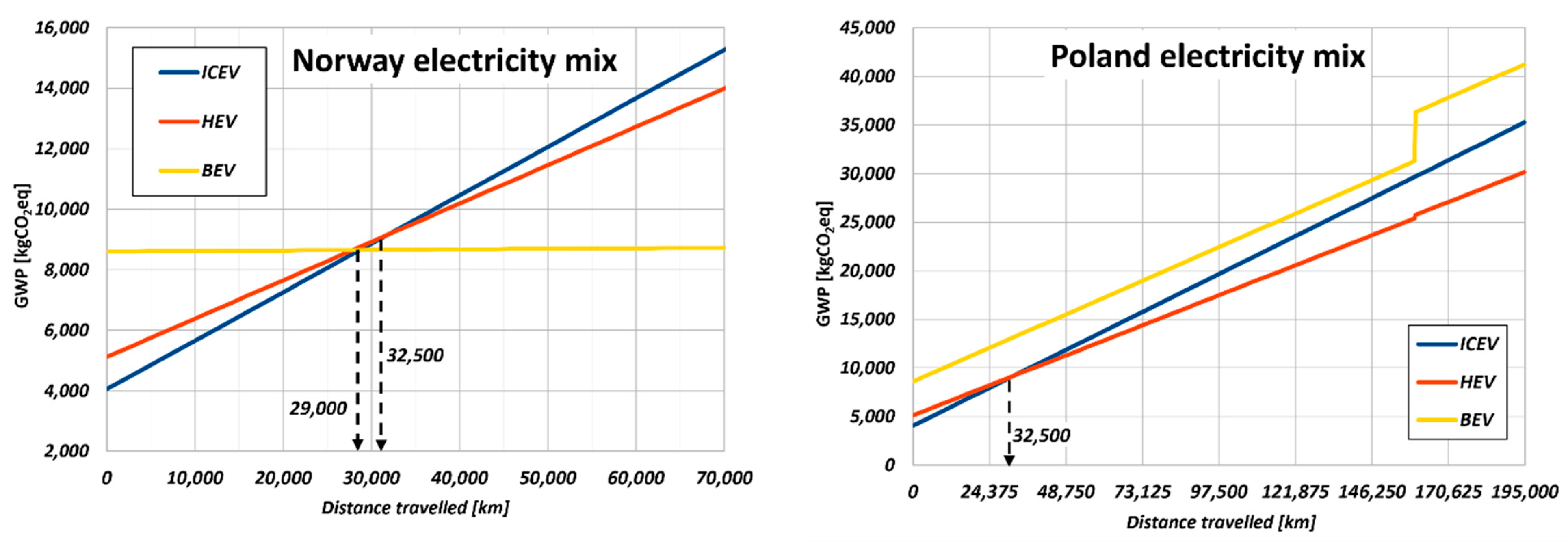

6.1. Global Warming Effect

6.2. Terrestrial Acidification

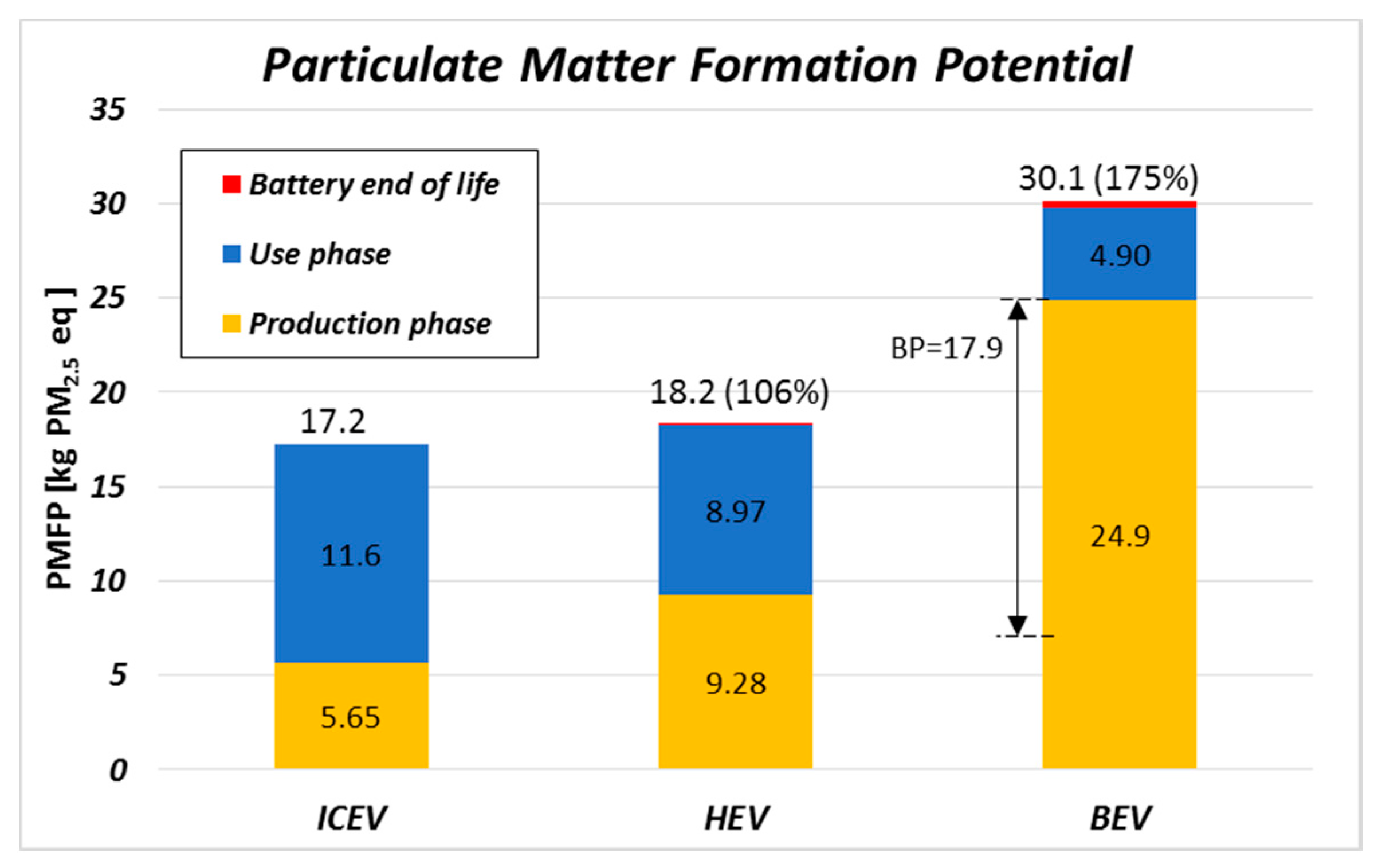

6.3. Particulate Matter Formation

6.4. Mineral Resource Deployment

6.5. Fossil Resource Deployment

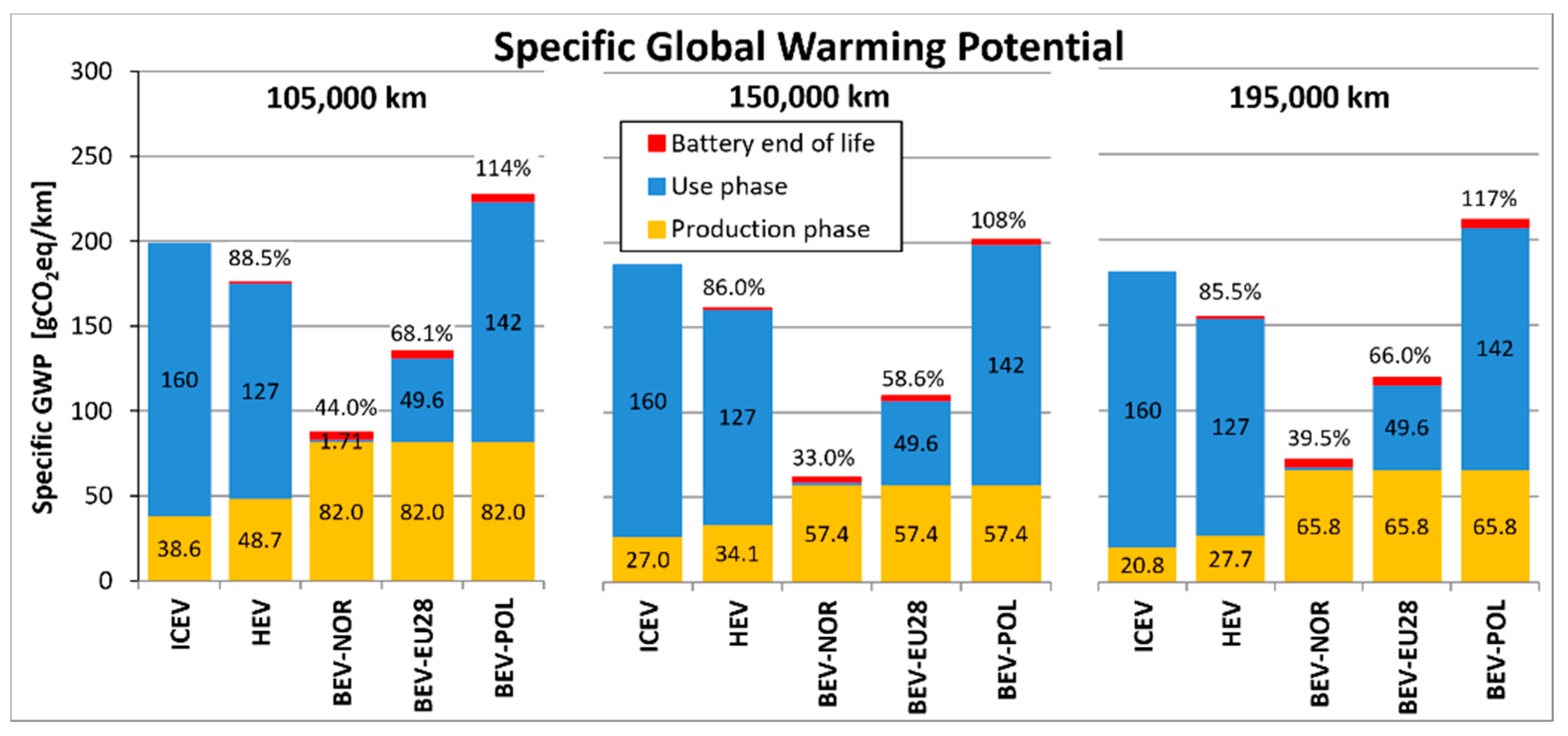

7. Scenario Analysis

8. Results of the Scenario Analysis and Discussion

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations and Symbols

| BBEV | Electric vehicle battery capacity |

| BE5 | Gasoline with 5% ethanol from biomass |

| BEV | Battery electric vehicle |

| BHEV | Hybrid electric vehicle battery capacity |

| BOM | Bill of material |

| CHEV | Hybrid electric vehicle fuel tank capacity |

| CICEV | Internal combustion engine vehicle fuel tank capacity |

| CNG | Compressed natural gas |

| Dtot | Electric vehicle total driving distance on the WLTP cycle |

| eCO2 | CO2 emitted per kilometer on the WLTP cycle [g/km] |

| EoL | End-of-life |

| Etrac | Total traction energy required by ICEV or HEV during its entire life |

| Etrac,BEV | Total traction energy required by the BEV during its entire life |

| F[kWh/km] | Electric vehicle energy consumption per kilometer on the WLTP cycle |

| F[l/km] | Fuel consumption per kilometer on the WLTP cycle |

| fCO2 | CO2 emitted by the combustion of a liter of BE5 [g/km] |

| FFP | Fossil fuel potential [kg Oil-eq] |

| GHG | Greenhouse gases |

| GWP | Global warming potential [kg CO2-eq] |

| HEV | Hybrid electric vehicle |

| ICEV | Internal combustion engine vehicle |

| Ix,source | Characterization factor connected to the production of the total mass of fuel employed by the ICEV or by the HEV |

| LCA | Life cycle assessment |

| LCI | Life cycle inventory |

| LCIA | Life cycle impact assessment |

| LCO | Lithium Cobalt Oxide (LiCoO2) |

| LFP | Lithium Iron Phosphate (LiFePO4) |

| LHV | Fuel Lower Heating Value |

| LMO | Lithium Manganese Oxide (LiMn2O4) |

| LPG | Liquefied petroleum gas |

| mbattery | Mass of vehicle battery |

| mBEV | Kerb mass of the battery electric vehicle |

| mempty | Empty mass of each vehicle (i.e., related to vehicle components only) |

| mfluids | Mass of vehicle fluids |

| mfuel | Total mass of fuel consumed by the vehicle during its entire life |

| mHEV | Kerb mass of the hybrid electric vehicle |

| mICEV | Kerb mass of the internal combustion engine vehicle |

| mkerb | Kerb mass of the generic vehicle |

| NCA | Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO2) |

| NMC | Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2) |

| P | Maximum power of the generic vehicle |

| PBEV | Battery electric vehicle maximum power |

| PHEV | Hybrid electric vehicle maximum power |

| PICEV | Internal combustion engine vehicle maximum power |

| PMFP | Particulate Matter Formation Potentials [kg PM2.5-eq] |

| RBEV | WLTP driving range of the battery electric vehicle |

| SOP | Surplus ore potential [kg Cu-eq] |

| TAP | Terrestrial acidification potential [kg SO2-eq] |

| UNECE | New European Driving Cycle |

| VHEV | Hybrid electric vehicle engine displacement |

| VICEV | Internal combustion engine vehicle engine displacement |

| W | Mass of the Li-ion polymer battery |

| WLTP | Worldwide harmonized light vehicles test procedure |

| ϕx | Specific impact factor referred to each impact category x and associated to the production of 1 kg of gasoline |

| φx | Specific impact factor referred to each impact category x and associated to the production of 1 kWh of electric energy |

| βB, k | Ratio between battery capacity and WLTP driving range |

| βF, k | Ratio between WLTP consumption and vehicle mass |

| βP, k | Ratio between vehicle maximum power and vehicle mass |

| βW | Capacity-to-mass ratio of the BEV battery |

| θC,i | Ratio between fuel tank capacity and vehicle mass |

| θF,i | Ratio between vehicle consumption and vehicle mass |

| θP,i | Ratio between engine maximum power and vehicle mass |

| θV,i | Ratio between engine maximum power and engine displacement |

| ρfuel | Fuel density |

| ψB, j | Ratio between battery capacity and fuel tank capacity |

| ψC, j | Ratio between fuel tank capacity and vehicle mass |

| ψF, j | Ratio between vehicle consumption and vehicle mass |

| ψP, j | Ratio between maximum vehicle power and vehicle mass |

| ψV, j | Ratio between engine displacement and vehicle mass |

| ψW, j | Ratio between battery capacity and mass battery |

Appendix A

Reference Vehicles Specifications and Characteristics

- (1)

- = ratio between fuel tank capacity and vehicle mass

- (2)

- . = the ratio between engine maximum power and vehicle mass

- (3)

- = the ratio between engine maximum power and engine displacement

- (4)

- = the ratio between vehicle consumption and vehicle mass

- Vehicle mass =

- Fuel tank capacity =

- Maximum output power =

- Consumption =

- Engine displacement =

- (1)

- = ratio between fuel tank capacity and vehicle mass

- (2)

- = ratio between maximum vehicle power and vehicle mass

- (3)

- = ratio between engine displacement and vehicle mass

- (4)

- = ratio between battery capacity and fuel tank capacity

- (5)

- = ratio between vehicle consumption and vehicle mass

- (6)

- = ratio between battery capacity and battery mass

- Vehicle mass =

- Fuel tank capacity =

- Maximum output power =

- Consumption =

- Engine displacement =

- Battery capacity =

- (1)

- = ratio between vehicle maximum power and vehicle mass =

- (2)

- = the ratio between WLTP consumption and vehicle mass

- (3)

- = the ratio between battery capacity and WLTP driving range

- (4)

- = ratio between battery capacity and battery mass

- Maximum output power =

- Battery capacity =

- Consumption =

References

- European Commission. Statistical Pocketbook 2019: EU Energy. 2019. Available online: https://op.europa.eu/it/publication-detail/-/publication/e0544b72-db53-11e9-9c4e-01aa75ed71a1 (accessed on 23 September 2021).

- European Commission. Statistical Pocketbook 2019: EU Transport. 2019. Available online: https://ec.europa.eu/transport/sites/default/files/pocketbook-2019.pdf (accessed on 23 September 2021).

- Wu, Z.; Wang, M.; Zheng, J.; Sun, X.; Zhao, M.; Wang, X. Life cycle greenhouse gas emission reduction potential of battery electric vehicle. J. Clean. Prod. 2018, 190, 462–470. [Google Scholar] [CrossRef]

- Bauer, C.; Hofer, J.; Althaus, H.-J.; Del Duce, A.; Simons, A. The environmental performance of current and future passenger vehicles: Life cycle assessment based on a novel scenario analysis framework. Appl. Energy 2015, 157, 871–883. [Google Scholar] [CrossRef]

- Helmers, E.; Dietz, J.; Weiss, M. Sensitivity Analysis in the Life-Cycle Assessment of Electric vs. Combustion Engine Cars under Approximate Real-World Conditions. Sustainability 2020, 12, 1241. [Google Scholar] [CrossRef] [Green Version]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2012, 17, 53–64. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Bobba, S.; Ardente, F.; Cellura, M.; Di Persio, F. Energy and environmental assessment of a traction lithium-ion battery pack for plug-in hybrid electric vehicles. J. Clean. Prod. 2019, 215, 634–649. [Google Scholar] [CrossRef] [PubMed]

- Hauschild, M.; Goedkoop, M.; Guinee, J.; Heijungs, R.; Huijbregts, M.; Joillet, O.; Margni, M.; De Schryver, A.; Pennington, D.; Pant, R.; et al. Recommendations for Life Cycle Impact Assessment in the European Context, International Reference Life Cycle Data System—ILCD Handbook, EUR 24571 EN.; Publications Office of the European Union: Luxembourg, 2011; JRC61049. [Google Scholar]

- ISO 14040. International Standard, Environmental Management—Life Cycle Assessment—Principles and Framework, 2nd ed.; 389 Chiswick High Road: London, UK, 2006; EN ISO 14040. [Google Scholar]

- Guinee, J.B. Handbook on life cycle assessment operational guide to the ISO standards. Int. J. Life Cycle Assess. 2002, 7, 311–313. [Google Scholar] [CrossRef]

- ACEA. The Automobile Industry Pocket Guide 2019/2020. 2020. Available online: https://www.acea.auto/publication/automobile-industry-pocket-guide-2019-2020 (accessed on 23 September 2021).

- GREET Model—The Greenhouse Gases, Regulated Emissions, and Energy Use in Technologies Model. Available online: https://greet.es.anl.gov/index.php (accessed on 23 September 2021).

- Elgowainy, M.; Wang, A. Overview of Life Cycle Analysis (LCA) with the GREET Model, Argonne National Laboratory. 2019. Available online: https://greet.es.anl.gov/files/workshop_2019_overview (accessed on 23 September 2021).

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level; RIVM Report 2016–2014; Ministry of Health: Bilthoven, The Netherlands, 2016; Available online: www.rivm.nl/en (accessed on 23 September 2021).

- Huijbregts, M.A.J.; Steinmann, Z.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2016, 22, 138–147. [Google Scholar] [CrossRef]

- Vieira, M.D.M.; Ponsioen, T.C.; Goedkoop, M.J.; Huijbregts, M. Surplus Ore Potential as a Scarcity Indicator for Resource Extraction. J. Ind. Ecol. 2016, 21, 381–390. [Google Scholar] [CrossRef]

- ACEA. Economic and Market Report—Full Year 2019. 2020. Available online: www.acea.be (accessed on 23 September 2021).

- IEA. Commissioned EV and Energy Storage Lithium-Ion Battery Cell Production Capacity by Region, and Associated Annual Investment, 2010–2022. Available online: https://www.iea.org/data-and-statistics/charts/commissioned-ev-and-energy-storage-lithium-ion-battery-cell-production-capacity-by-region-and-associated-annual-investment-2010-2022 (accessed on 23 September 2021).

- ACEA. Vehicles in Use Report. 2021. Available online: www.acea.be/statistics/tag/category/vehicles-in-use (accessed on 23 September 2021).

- IEA. Data and Statistics. Available online: www.iea.org/data-and-statistics (accessed on 23 September 2021).

- Burnham, A. Updated Vehicle Specifications in the GREET Vehicle-Cycle Model; Center for Transportation Research; Argonne National Laboratory: Lemont, IL, USA, 2012. [Google Scholar]

- Ellingsen, L.A.-W.; Majeau-Bettez, G.; Singh, B.; Srivastava, A.K.; Valøen, L.O.; Strømman, A.H. Life Cycle Assessment of a Lithium-Ion Battery Vehicle Pack. J. Ind. Ecol. 2013, 18, 113–124. [Google Scholar] [CrossRef] [Green Version]

- Blomgren, G.E. The Development and Future of Lithium Ion Batteries. J. Electrochem. Soc. 2016, 164, A5019–A5025. [Google Scholar] [CrossRef] [Green Version]

- Mathieux, F.; Ardente, F.; Bobba, S.; Nuss, P.; Blengini, G.; Alves Dias, P.; Blagoeva, D.; Torres De Matos, C.; Wittmer, D.; Pavel, C.; et al. Critical Raw Materials and the Circular Economy—Background Report, JRC Science-for-Policy Report, EUR 28832 EN.; Publications Office of the European Union: Luxembourg, 2017; ISBN 978-92-79-74282-8. [Google Scholar] [CrossRef]

- Dunn, J.B.; Gaines, L.; Barnes, M.; Wang, M.; Sullivan, J.S. Material and Energy Flows in the Materials Production, Assembly, and End-of-Life Stages of the Automotive Lithium-Ion Battery Life Cycle. ANL/ESD/12-3; Argonne National Lab: Argonne, IL, USA, 2012. [Google Scholar]

- Dai, Q.; Kelly, J.C.; Gaines, L.; Wang, M. Life Cycle Analysis of Lithium-Ion Batteries for Automotive Applications. Batteries 2019, 5, 48. [Google Scholar] [CrossRef] [Green Version]

- Dai, J.Q.; Dunn, J.; Kelly, J.; Elgowainy, A. Update of Life Cycle Analysis of Lithium-Ion Batteries in the GREET Model. 2017. Available online: https://greet.es.anl.gov/publication-Li_battery_update_2017 (accessed on 23 September 2021).

- Dai, Q.; Kelly, J.C.; Dunn, J.; Benavides, P.T. Update of Bill-of-Materials and Cathode Mate-Rials Production for Lithium-Ion Batteries in the GREET Model. 2018. Available online: https://greet.es.anl.gov/publication-update_bom_cm (accessed on 23 September 2021).

- ISO 1176:1990(en), Road Vehicles-Masses-Vocabulary and Codes. Available online: https://www.iso.org/obp/ui/#iso:std:iso:24444:ed-1:v1:en (accessed on 23 September 2021).

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Althaus, H.-J.; Bauer, C.; Doka, G.; Dones, R.; Hischier, R.; Hellweg, S.; Humbert, S.; Kollner, T.; Loerinick, Y.; Margni, M.; et al. Implementation of Life Cycle Impact Assessment Methods. Ecoinvent Report No. 3, v2.2; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2010. [Google Scholar]

- European Environment Agency. Fuel Quality in the EU in 2016; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar] [CrossRef]

- Gnansounou, E.; Dauriat, A.; Panichelli, L.; Villegas, J. Energy and greenhouse gas balances of biofuels: Biases induced by LCA modelling choices. J. Sci. Ind. Res. 2008, 67, 885–897. Available online: http://nopr.niscair.res.in/handle/123456789/2418 (accessed on 23 September 2021).

- Leonidas, N.; Zissis, S. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019—Update Oct. 2020. European Environmental Agency. 2020. Available online: http://eea.europa.eu/emep-eea-guidebook (accessed on 23 September 2021).

- Recharge. The Advanced Rechargeable Lithium Batteries Association PEFCR—Product Environmental Footprint Category Rules for High Specific Energy Rechargeable Batteries for Mobile Applications Version: H Time of Validity: 31 December 2020. 2018. Available online: https://ec.europa.eu/environment/eussd/smgp/pdf/PEFCR_Batteries.pdf (accessed on 23 September 2021).

- Golder Associates. Environmental Impact Assessment—Tenke Fungurume Project-Volume A: ESIA Introduction and Project Description. 2007. Available online: https://www3.opic.gov/environment/eia/tenke/Volume%20A%20ESIA%20Introduction%20and%20Project%20Description.pdf (accessed on 23 September 2021).

| Impact Category | Characterization Factor | Unit |

|---|---|---|

| Climate change | Global Warming Potential (GWP) | kg CO2-eq |

| Terrestrial acidification | Terrestrial Acidification Potential (TAP) | kg SO2-eq |

| Fine particulate matter formation | Particulate matter formation potential (PMFP) | kg PM2.5-eq |

| Mineral resource scarcity | Surplus ore potential (SOP) | kg Cu-eq |

| Fossil resource scarcity | Fossil fuel potential (FFP) | kg Oil-eq |

| Gasoline Internal Combustion Engine Vehicle (ICEV) | ||||||

|---|---|---|---|---|---|---|

| Vehicle ref. code | ICEV1 | ICEV2 | ICEV3 | ICEV4 | ICEV5 | Reference ICEV |

| Make and model | Volkswagen Polo 1.0 TSI 115 CV | Peugeot 208 PureTech 130 Stop and Start | Opel Corsa 1.2 130 CV | Renault Clio TCe 130 CV | Citroen C3 PureTech 83 Stop and Start Van Live | |

| Tank capacity [L] | 45 | 44 | 44 | 42 | 45 | 44 |

| Vehicle mass [kg] | 1190 | 1233 | 1233 | 1323 | 1165 | 1228.8 |

| Displacement [cm3] | 999 | 1199 | 1199 | 1333 | 1199 | 1176.6 |

| Max power [kW] | 85 | 96 | 96 | 96 | 81 | 90.6 |

| Standard emission | Euro 6d temp | Euro 6d temp | Euro 6d temp | Euro 6d temp | Euro 6d temp | Euro 6d temp |

| WLTP consumption [km/L] | 17.2 | 17.4 | 16.7 | 15.9 | 17.2 | 16.93 |

| Gasoline Hybrid Electric Vehicle (HEV) | ||||||

|---|---|---|---|---|---|---|

| Vehicle ref. code | HEV1 | HEV2 | HEV3 | HEV4 | HEV5 | Reference HEV |

| Make and model | Renault Clio Hybrid E-Tech 140 CV | Toyota Corolla 1.8 Hybrid Touring Sport | Hyundai Ioniq FL Hybrid 1.6 | Toyota Prius 1.8 AWD | Kia Niro 1.6 GDI | |

| Tank capacity [L] | 39 | 43 | 45 | 43 | 45 | 43.0 |

| Vehicle mass [kg] | 1398 | 1430 | 1436 | 1440 | 1490 | 1439 |

| Displacement [cm3] | 1618 | 1798 | 1580 | 1798 | 1580 | 1676 |

| Max power [kW] | 103 | 90 | 104 | 90 | 104 | 98.2 |

| Standard emission | Euro 6d | Euro 6d | Euro 6d | Euro 6d | Euro 6d | Euro 6d |

| WLTP consumption [km/L] | 19.6 | 23.0 | 20.8 | 22.7 | 20.8 | 21.4 |

| Battery capacity [kWh] | 1.2 | 0.75 | 1.56 | 1.3 | 1.56 | 1.27 |

| Battery technology | Li-ion | Li-ion | Li-ion polymer | NiMH | Li-ion polymer | NMC |

| Battery mass [kg] | 38 | // | // | // | 33 | 26.9 |

| Battery Electric Vehicle (BEV) | ||||||

|---|---|---|---|---|---|---|

| Vehicle ref. code | BEV1 | BEV2 | BEV3 | BEV4 | BEV5 | Reference BEV |

| Make and model | Peugeot e-208 | Renault Zoe R110 2019 | Volkswagen e-Golf 2019 | Nissan Leaf S 2019 | Hyundai Ioniq EV 2019 | |

| Vehicle mass [kg] | 1500 | 1500 | 1615 | 1558 | 1575 | 1550 |

| Max power [kW] | 100 | 80 | 100 | 110 | 100 | 97.9 |

| Battery capacity [kWh] | 50 | 45.61 | 35.8 | 40 | 38.3 | 42.1 |

| Battery warranty [km] | 160,000 (70%) | 160,000 (66%) | 160,000 | 160,000 | 200,000 | 160,000 |

| Battery technology | // | NMC 712 | NMC | NMC | NMC 622 | NMC 622 |

| Battery mass [kg] | // | 305 | 318 | 303 | 340 | 374 |

| WLTP Driving range [km] | 340 | 300 | 232 | 270 | 311 | 291 |

| WLTP Consumption [kWh/km] | 0.164 | 0.178 | 0.176 | 0.171 | 0.138 | 0.166 |

| China (2018) | EU-28 (2019) | Germany (2019) | Norway (2019) | Poland (2019) | |

|---|---|---|---|---|---|

| Coal | 66.4% | 15.4% | 30.0% | 0.121% | 73.72% |

| Oil | 0.153% | 1.64% | 0.822% | 0.013% | 1.09% |

| Natural gas | 3.28% | 21.9% | 15.3% | 1.732% | 9.18% |

| Nuclear | 4.09% | 25.3% | 12.1% | 0% | 0% |

| Hydro | 17.1% | 10.9% | 4.24% | 93.4% | 1.63% |

| Wind | 5.07% | 13.3% | 20.4% | 4.1% | 9.20% |

| Solar PV | 2.45% | 4.07% | 7.69% | 0.010% | 0.44% |

| Biofuels | 1.26% | 5.27% | 7.22% | 0.03% | 4.30% |

| Waste | 0.187% | 1.60% | 2.03% | 0.31% | 0.38% |

| Geothermal | 0.002% | 0.206% | 0.0317% | 0% | 0% |

| Solar thermal | 0.004% | 0.178% | 0% | 0% | |

| Tide | 0.0002% | 0.0152% | 0% | 0% | |

| Other sources | 0.141% | 0.168% | 0.244% | 0.05% |

| Component | ICEV | HEV | BEV |

|---|---|---|---|

| Body | 44.1% | 45.3% | 53.5% |

| Powertrain | 25.7% | 17.0% | 1.70% |

| Transmission | 6.30% | 7.20% | 3.30% |

| Chassis | 23.9% | 24.5% | 28.9% |

| Traction motor | 0 | 2.10% | 6.70% |

| Generator | 0 | 2.10% | 0 |

| Controller/Inverter | 0 | 1.80% | 5.90% |

| ICEV | HEV | BEV | |

|---|---|---|---|

| Engine lubricant [kg] | 4.1 | 4.1 | 0.0 |

| Power steering fluid [kg] | 0.0 | 0.0 | 0.0 |

| Brake fluid [kg] | 0.91 | 0.91 | 0.91 |

| Transmission fluid [kg] | 10.9 | 0.91 | 0.91 |

| Powertrain coolant [kg] | 10.4 | 10.4 | 7.2 |

| Windshield wiper fluid [kg] | 2.7 | 2.7 | 2.7 |

| Adhesives [kg] | 13.6 | 13.6 | 13.6 |

| GWP [kg CO2 eq] | TAP [kg SO2 eq] | PMFP [kg PM2.5 eq] | SOP [kg Cu eq] | FFP [kg Oil eq] | Energy Consumption [MJ] | |

|---|---|---|---|---|---|---|

| Body | 1303.0 | 7.1 | 2.2 | 17.7 | 334.2 | 20,890.3 |

| Powertrain | 659.1 | 3.9 | 1.3 | 24.7 | 191.2 | 12,435.9 |

| Transmission | 163.3 | 0.6 | 0.2 | 5.4 | 46.1 | 3081.5 |

| Chassis | 666.1 | 3.3 | 1.1 | 10.1 | 133.5 | 9339.3 |

| Assembly | 1127.5 | 1.8 | 0.6 | 0.0 | 300.4 | 20,413.5 |

| Oil | 13.4 | 0.1 | 0.0 | 0.0 | 4.0 | 219.8 |

| Brake fluid | 3.0 | 0.0 | 0.0 | 0.0 | 0.9 | 48.8 |

| Transmission fluid | 35.8 | 0.2 | 0.1 | 0.0 | 10.7 | 586.1 |

| Coolant | 18.0 | 0.1 | 0.0 | 0.0 | 4.1 | 205.9 |

| Adhesives | 48.8 | 0.3 | 0.1 | 0.0 | 23.3 | 1190.8 |

| Windshield wiper fluid | 4.9 | 0.0 | 0.0 | 0.0 | 0.9 | 41.7 |

| Battery | 11.7 | 0.2 | 0.1 | 5.1 | 4.1 | 251.6 |

| GWP [kg CO2 eq] | TAP [kg SO2 eq] | PMFP [kg PM2.5 eq] | SOP [kg Cu eq] | FFP [kg Oil eq] | Energy Consumption [MJ] | |

|---|---|---|---|---|---|---|

| Body | 1574.7 | 8.5 | 2.70 | 18.8 | 403.9 | 25,246.1 |

| Powertrain | 523.0 | 3.0 | 0.97 | 16.6 | 142.5 | 9373.7 |

| Transmission | 317.3 | 3.9 | 1.20 | 20.1 | 61.7 | 5155.5 |

| Chassis | 803.3 | 3.9 | 1.32 | 10.5 | 161.0 | 11,263.5 |

| Traction Motor | 74.1 | 1.4 | 0.41 | 9.8 | 16.3 | 1188.9 |

| Generator | 74.1 | 1.4 | 0.41 | 9.8 | 16.3 | 1188.9 |

| Controller/Inverter | 63.4 | 0.5 | 0.16 | 3.9 | 20.5 | 1263.2 |

| Assembly | 1320.2 | 2.1 | 0.70 | 0.0 | 351.8 | 23,902.1 |

| Oil | 13.4 | 0.1 | 0.03 | 0.0 | 4.0 | 219.8 |

| Brake fluid | 3.0 | 0.0 | 0.01 | 0.0 | 0.9 | 48.8 |

| Transmission. Fluid | 3.0 | 0.0 | 0.01 | 0.0 | 0.9 | 48.8 |

| Coolant | 18.0 | 0.1 | 0.02 | 0.0 | 4.1 | 205.9 |

| Adhesives | 48.8 | 0.3 | 0.07 | 0.0 | 23.3 | 1190.8 |

| Windshield wiper fluid | 4.9 | 0.0 | 0.00 | 0.0 | 0.9 | 41.7 |

| Battery BOM | 214.0 | 1.6 | 0.50 | 6.4 | 45.0 | 2949.6 |

| Battery assembly | 20.0 | 0.0 | 0.01 | 0.0 | 5.7 | 289.2 |

| GWP [kg CO2 eq] | TAP [kg SO2 eq] | PMFP [kg PM2.5 eq] | SOP [kg Cu eq] | FFP [kg Oil eq] | Energy Consumption [MJ] | |

|---|---|---|---|---|---|---|

| Body | 1627.6 | 8.8 | 2.80 | 22.1 | 417.4 | 26,094.7 |

| Powertrain | 57.9 | 0.8 | 0.25 | 4.4 | 17.3 | 1035.7 |

| Transmission | 127.8 | 1.6 | 0.48 | 8.2 | 24.8 | 2075.8 |

| Chassis | 832.4 | 4.1 | 1.36 | 12.7 | 166.8 | 11,671.7 |

| Traction Motor | 213.9 | 4.0 | 1.18 | 28.6 | 47.1 | 3431.6 |

| Controller/Inverter | 182.5 | 1.5 | 0.46 | 11.1 | 59.1 | 3637.3 |

| Assembly | 1421.8 | 2.2 | 0.75 | 0.0 | 378.9 | 25,742.7 |

| Brake fluid | 3.0 | 0.0 | 0.01 | 0.0 | 0.9 | 48.8 |

| Transmission fluid | 3.0 | 0.0 | 0.01 | 0.0 | 0.9 | 48.8 |

| Coolant | 12.5 | 0.1 | 0.01 | 0.0 | 2.8 | 143.3 |

| Adhesives | 48.8 | 0.3 | 0.07 | 0.0 | 23.3 | 1190.8 |

| Windshield wiper fluid | 4.9 | 0.0 | 0.00 | 0.0 | 0.9 | 41.7 |

| Battery BOM | 3008.0 | 50.3 | 14.92 | 180.7 | 683.3 | 43,210.8 |

| Battery assembly | 658.5 | 0.9 | 0.23 | 0.0 | 187.6 | 9519.7 |

| GWP [kg CO2 eq/kg] | 0.596896 |

| TAP [kg SO2 eq/kg] | 0.00529478 |

| PMFP [kg PM2.5 eq/kg] | 0.00169847 |

| SOP [kg Cu eq/kg] | 0.00157793 |

| FFP [kg Oil eq/kg] | 1.14230 |

| Energy consumption [MJ/kg] | 7.0463 |

| GWP [kg CO2 eq/kWh] | 0.2994 |

| TAP [kg SO2 eq/kWh] | 0.0006227 |

| PMFP [kg PM2.5 eq/kWh] | 0.0001971 |

| SOP [kg Cu eq/kWh] | 0.0000 |

| FFP [kg Oil eq/kWh] | 0.07252 |

| Energy consumption [MJ/kWh] | 6.8368 |

| ICEV | HEV | BEV | |

|---|---|---|---|

| Total fuel consumed [kg] | 6662.4 | 5274.9 | 0 |

| Traction energy [kWh] | 77,173 | 61,101 | 24,841 |

| Source production energy [kWh] | 13,040 | 10,325 | 47,176 |

| GWP [kg CO2eq/kWh] | 3976.7 | 3148.6 | 7436.5 |

| TAP [kg SO2eq/kWh] | 35.276 | 27.930 | 15.469 |

| PMFP [kg PM2.5eq/kWh] | 11.316 | 8.9594 | 4.8965 |

| SOP [kg Cu eq/kWh] | 10.513 | 8.3235 | 0 |

| FFP [kg Oil eq/kWh] | 7610.4 | 6025.6 | 1801.4 |

| ICEV | HEV | |

|---|---|---|

| Type of car | Petrol Small | Hybrid Petrol Small |

| Technology | Euro 6 d-temp | Euro 6 |

| CO2 [g/km] | 133.5 | 105.7 |

| CO [g/km] | 0.69 | 0.042 |

| NMHC [g/km] | 0.048 | 0.001 |

| NOX [g/km] | 0.056 | 0.013 |

| N2O [g/km] | 0.0013 | 0.0002 |

| NH3 [g/km] | 0.0123 | 0.0328 |

| Pb [g/km] | 1.82 × 10−5 | 1.82 × 10−5 |

| CO2 lube [g/km] | 0.398 | 0.398 |

| ICEV | HEV | |

|---|---|---|

| GWP [kg CO2 eq] | 20,032 | 15,860 |

| TAP [kg SO2 eq] | 3.024 | 0.7020 |

| PMFP [kg PM2.5 eq] | 0 | 0 |

| SOP [kg Cu eq] | 0.2400 | 0.03000 |

| FFP [kg Oil eq] | 0 | 0 |

| ICEV | HEV | BEV | |

|---|---|---|---|

| GWP [kg CO2 eq] | 24,008 | 19,009 | 7437 |

| TAP [kg SO2 eq] | 38.300 | 28.632 | 15.47 |

| PMFP [kg PM2.5 eq] | 11.556 | 8.9894 | 4.896 |

| SOP [kg Cu eq] | 10.513 | 8.3235 | 0 |

| FFP [kg Oil eq] | 7610.4 | 6025.6 | 1801 |

| HEV | BEV | |

|---|---|---|

| GWP [kg CO2 eq] | 28.46 | 396.0 |

| TAP [kg SO2 eq] | 0.07371 | 1.026 |

| PMFP [kg PM2.5 eq] | 0.02063 | 0.2870 |

| SOP [kg Cu eq] | 0 | 0 |

| FFP [kg Oil eq] | 6.610 | 91.97 |

| Energy consumption [MJ] | 488.2 | 6794 |

| spec. GWP [gCO2eq/km] | spec. TAP [mgSO2eq/km] | spec. PMFP [mgPM2.5eq/km] | spec. SOP [mgCu-eq/km] | FFP [gOil-eq/km] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Prod. | Use | Batt. EoL | Prod. | Use | Batt. EoL | Prod. | Use | Batt. EoL | Prod. | Use | Batt. EoL | Prod. | Use | Batt. EoL | ||

| EUROPE 105,000 km | ICEV | 38.6 | 160 | 0.00 | 167 | 255 | 0.00 | 53.8 | 77.0 | 0.00 | 600 | 70.1 | 0.00 | 1053 | 50.7 | 0.00 |

| HEV | 48.7 | 127 | 0.271 | 281 | 191 | 0.702 | 88.4 | 59.9 | 0.196 | 999 | 55.5 | 0.00 | 1272 | 40.2 | 0.0629 | |

| BEV | 82.0 | 49.6 | 3.77 | 787 | 103 | 9.77 | 237 | 32.6 | 2.73 | 2817 | 94.9 | 0.00 | 2101 | 12.0 | 0.876 | |

| EUROPE 150,000 km | ICEV | 27.0 | 160 | 0.00 | 117 | 255 | 0.00 | 37.7 | 77.0 | 0.00 | 420 | 70.1 | 0.00 | 1053 | 50.7 | 0.00 |

| HEV | 34.1 | 127 | 0.190 | 197 | 191 | 0.491 | 61.9 | 59.9 | 0.138 | 699 | 55.5 | 0.00 | 1272 | 40.2 | 0.0441 | |

| BEV | 57.4 | 49.6 | 2.64 | 551 | 103 | 6.84 | 166 | 32.6 | 1.91 | 1972 | 94.9 | 0.00 | 2101 | 12.0 | 0.613 | |

| EUROPE 195,000 km | ICEV | 20.8 | 160 | 0.00 | 89.7 | 255 | 0.00 | 29.0 | 77.0 | 0.00 | 323 | 70.1 | 0.00 | 1053 | 50.7 | 0.00 |

| HEV | 27.7 | 127 | 0.292 | 173 | 191 | 0.756 | 54.1 | 59.9 | 0.212 | 617 | 55.5 | 0.00 | 1335 | 40.2 | 0.0678 | |

| BEV | 65.8 | 49.6 | 4.06 | 733 | 103 | 10.5 | 219 | 32.6 | 2.94 | 2611 | 94.9 | 0.00 | 3097 | 12.0 | 0.943 | |

| NORWAY 105,000 km | ICEV | 38.6 | 160 | 0.00 | 167 | 255 | 0.00 | 53.8 | 77.0 | 0.00 | 600 | 70.1 | 0.00 | 1053 | 50.7 | 0.00 |

| HEV | 48.7 | 127 | 0.271 | 281 | 191 | 0.702 | 88.4 | 59.9 | 0.196 | 999 | 55.5 | 0.00 | 1272 | 40.2 | 0.0629 | |

| BEV | 82.0 | 1.71 | 3.77 | 787 | 1.48 | 9.77 | 237 | 0.354 | 2.73 | 2817 | 27.2 | 0.00 | 2101 | 0.591 | 0.876 | |

| NORWAY 150,000 km | ICEV | 27.0 | 160 | 0.00 | 117 | 255 | 0.00 | 37.7 | 77.0 | 0.00 | 420 | 70.1 | 0.00 | 1053 | 50.7 | 0.00 |

| HEV | 34.1 | 127 | 0.190 | 197 | 191 | 0.491 | 61.9 | 59.9 | 0.138 | 699 | 55.5 | 0.00 | 1272 | 40.2 | 0.0441 | |

| BEV | 57.4 | 1.71 | 2.64 | 551 | 1.48 | 6.84 | 166 | 0.354 | 1.91 | 1972 | 27.2 | 0.00 | 2101 | 0.591 | 0.613 | |

| NORWAY 195,000 km | ICEV | 20.8 | 160 | 0.00 | 89.7 | 255 | 0.00 | 29.0 | 77.0 | 0.00 | 323 | 70.1 | 0.00 | 1053 | 50.7 | 0.00 |

| HEV | 27.7 | 127 | 0.292 | 173 | 191 | 0.756 | 54.1 | 59.9 | 0.212 | 617 | 55.5 | 0.00 | 1335 | 40.2 | 0.0678 | |

| BEV | 65.8 | 1.71 | 4.06 | 733 | 1.48 | 10.5 | 219 | 0.354 | 2.94 | 2611 | 27.2 | 0.00 | 3097 | 0.591 | 0.943 | |

| POLAND 105,000 km | ICEV | 38.6 | 160 | 0.00 | 167 | 255 | 0.00 | 53.8 | 77.0 | 0.00 | 600 | 70.1 | 0.00 | 1053 | 50.7 | 0.00 |

| HEV | 48.7 | 127 | 0.271 | 281 | 191 | 0.702 | 88.4 | 59.9 | 0.196 | 999 | 55.5 | 0.00 | 1272 | 40.2 | 0.0629 | |

| BEV | 82.0 | 142 | 3.77 | 787 | 357 | 9.77 | 237 | 107 | 2.73 | 2817 | 89.8 | 0.00 | 2101 | 24.2 | 0.876 | |

| POLAND 150,000 km | ICEV | 27.0 | 160 | 0.00 | 117 | 255 | 0.00 | 37.7 | 77.0 | 0.00 | 420 | 70.1 | 0.00 | 1053 | 50.7 | 0.00 |

| HEV | 34.1 | 127 | 0.190 | 197 | 191 | 0.491 | 61.9 | 59.9 | 0.138 | 699 | 55.5 | 0.00 | 1272 | 40.2 | 0.0441 | |

| BEV | 57.4 | 142 | 2.64 | 551 | 357 | 6.84 | 166 | 107 | 1.91 | 1972 | 89.8 | 0.00 | 2101 | 24.2 | 0.613 | |

| POLAND 195,000 km | ICEV | 20.8 | 160 | 0.00 | 89.7 | 255 | 0.00 | 29.0 | 77.0 | 0.00 | 323 | 70.1 | 0.00 | 1053 | 50.7 | 0.00 |

| HEV | 27.7 | 127 | 0.292 | 173 | 191 | 0.756 | 54.1 | 59.9 | 0.212 | 617 | 55.5 | 0.00 | 1335 | 40.2 | 0.0678 | |

| BEV | 65.8 | 142 | 4.06 | 733 | 357 | 10.5 | 219 | 107 | 2.94 | 2611 | 89.8 | 0.00 | 3097 | 24.2 | 0.943 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pipitone, E.; Caltabellotta, S.; Occhipinti, L. A Life Cycle Environmental Impact Comparison between Traditional, Hybrid, and Electric Vehicles in the European Context. Sustainability 2021, 13, 10992. https://0-doi-org.brum.beds.ac.uk/10.3390/su131910992

Pipitone E, Caltabellotta S, Occhipinti L. A Life Cycle Environmental Impact Comparison between Traditional, Hybrid, and Electric Vehicles in the European Context. Sustainability. 2021; 13(19):10992. https://0-doi-org.brum.beds.ac.uk/10.3390/su131910992

Chicago/Turabian StylePipitone, Emiliano, Salvatore Caltabellotta, and Leonardo Occhipinti. 2021. "A Life Cycle Environmental Impact Comparison between Traditional, Hybrid, and Electric Vehicles in the European Context" Sustainability 13, no. 19: 10992. https://0-doi-org.brum.beds.ac.uk/10.3390/su131910992