1. Introduction

Engineering education in the 21st century requires that students are prepared to face the demands of complex and dynamic work environments; therefore, a student needs to be involved in an experience that comprises complexity, innovation, and the application of knowledge in a chemical engineering curriculum [

1,

2]. Students must develop key professional skills, particularly the ability to design solutions for the industry incorporating safety, health, and environmental restrictions, and using their creativity [

3].

Sustainable engineering comprises practices and processes that solve current problems without damaging, or depleting, resources needed in the future. In contrast, sustainable engineering education is the challenging transformation and adoption of teaching experiences to create awareness in students, to re-think the engineering decisions incorporating the environmental and social impacts of our lifestyles, and to extend these concepts into life-long professional development [

4,

5].

Traditional engineering education focuses on hard skills such as problem solving, mathematical modeling, design, critical thinking, data analysis, and more. However, sustainable engineering education must consider soft and social skills, such as the ability to work in teams, decision-making, and even self-regulation, as key elements of engineering curricula [

6].

According to Hoffman [

7], an engineering capstone course integrates the skills and competencies that students have learned in their engineering program and should provide a simulated “real-world” end-to-end learning experience. The student applies the knowledge of courses such as transport phenomena, thermodynamics, and kinetics, among others, in a capstone project of engineering design and economics whose development takes place during the last year of the degree [

8].

Several experts highlight the importance of creating these learning experiences, in which students face challenging questions, construct their arguments, exchange opinions, accept ideas and conclude based on evidence and reasoning [

9], and point out that a capstone project effectively contributes to learning outcomes related to written communication, presentations and the creation of technical reports [

10,

11]. A capstone project maximizes the potential of sustainable engineering education and prepares students for real work-life challenges using a collaborative working strategy [

6,

12].

The Faculty of Chemical Engineering at Universidad Pontificia Bolivariana (UPB) implemented, in 2016, a curricular transformation that included integration of the Process Design, Process Control, and Process Engineering Laboratory courses through a final degree capstone project in which the students propose basic engineering alternatives, solve material and energy balances, and evaluate the dynamics of the process. Therefore, students select instrumentation, propose a feedback control strategy, and approach the tuning or self-tuning of control loops. A project-based learning methodology was implemented to develop design competencies [

13].

Various authors show the development of a capstone project with application to a laboratory or process control course, i.e., the struvite crystallization process in a laboratory [

11] or the case study of a binary distillation column that involves design, instrumentation, simulation, and control [

14]. However, the capstone project carried out in the Faculty of Chemical Engineering includes the integration of three courses, as previously indicated, and the design and control of processes are applied to a complete plant and not to a single unit operation.

Integration with the Process Control course allowed a better understanding of the concepts seen in this course, as a student carries out simulations, exchanges opinions, plays with variables, etc., which motivates them to work on different topics and concepts related to process control and, in this way, makes use of motivational active learning [

15,

16].

With the development of the capstone project, skills are acquired that favor active learning and encourage metacognition [

17], while allowing the assessment of students’ ability to perform as a team, as recommended by ABET (Accreditation Board for Engineering and Technology) and CDIO (Conceive Design Implement Operate framework) in their learning outcomes for the training of engineers [

18,

19].

2. Materials and Methods

The general methodology that is proposed in this work mainly comprises the implementation of project-based learning for the training of chemical engineers, through the integration of design and process control courses in the development of a final-degree capstone project. The students propose basic engineering alternatives for a process of interest to the country, or strategic areas for sustainable development such as agribusiness, biotechnology, green chemistry, and new materials, among others.

2.1. Development of the Capstone Integrative Project

Students are organized into groups of approximately four members at random and are assigned a problem situation or context to develop the capstone design projects. Generally, the preferred raw material or the production route is mentioned, and an instruction guide is sent with the content of the written progress reports that they must present periodically during the development of the courses.

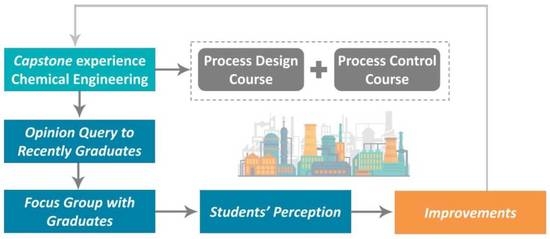

Students develop an integrated design experience, as shown in

Figure 1, which begins with the definition of plant capacity, based on market studies using primary and secondary sources. Therefore, they elaborate a detailed review of technical and scientific literature to give conceptual support to the project; finally, they propose conceptual alternatives. Simultaneously, students prepare an analysis in the form of a baseline to evaluate aspects related to the project that include environmental, social, and technical-legal variables.

The material and energy balances are proposed, and the process is simulated following a hierarchical level design methodology, starting with the reaction zone, the separation zone, and energy integration using the Pinch method. The process equipment is dimensioned based on mathematical models and heuristic rules, and the optimization of the operational conditions supported by the Aspen Hysys software is proposed [

20].

In the Process Control course, students use MS Excel to model steady-state processes and find the operating points of the control. Using Matlab, practices were developed that allow the student to evaluate the stability, controllability, and observability of the processes. Integrating different tools such as Simulink and dynamic Hysys, students evaluate the dynamic response of simple processes in a transient state to propose feedback control strategies. Finally, practices are carried out using the Loop Pro tool [

21]. The students experience a plant-control-room environment as a training alternative, to achieve controller tuning [

22].

After advancing in basic engineering, a proposal for feedback control loops for at least one reactor and one separation equipment is prepared. The block and process diagrams and instruments are proposed based on chemical engineering standards, as well as evidence on the selection of sensor/transmitter elements, indicating their essential characteristics and accessories according to catalogs; the failure mode of the valves used as final control elements; the types of controllers to be used in each control loop; and the actions of the controllers to be used in each control loop.

After the basic engineering preparation, the students carry out the financial evaluation of the process. Monte-Carlo simulations are used to evaluate different scenarios and thereby estimate the net present value (NPV) and the return of investment (ROI) to infer the profitability of the proposed design.

Finally, the students prepare a 15-minute oral presentation before at least one external evaluator who acts as an industrial peer, the course professors, and assistants from the Faculty of Chemical Engineering. Feedback and summative evaluation are given. Aspects that allow assessing the quality of the capstone project on a Likert scale from 0 to 5 include:

Definition of the plant capacity according to basic market studies.

Description of kinetic models and design assumptions.

Evidence of the complete simulation (mass and energy balances).

Evidence of case studies or process optimization.

Sizing of process equipment.

Estimation of costs (NPV, ROI).

Satisfactory process diagrams (blocks, processes flow diagram).

Selection of sensor/transmitter elements for process control.

Evidence of the failure actions of the valves used as final control elements.

Evidence of the types of controllers to be used in each control loop.

Evidence of the actions of the controllers to be used in each control loop.

Management of the time designated for the oral presentation.

2.2. Evaluation of the Design-Control Integration Proposal for the Development of Capstone Projects

The external view of graduates of the program who participate in industrial activities served as a learning evaluation tool and feedback in the orientation of these courses. For this reason, an opinion query was first proposed of the graduates of the program with less than five years of professional practice to assess their perception of the relevance of the capstone design experience in their training process. Second, a focus group was held in 2021 with five experienced professionals with high professional trajectory, advanced training, and experience in the design area, as shown in

Table 1, to evaluate the quality of the capstone project and the value it delivers to newly graduated professionals in chemical engineering.

3. Results and Discussion

3.1. Innovation Implementation Process

With the development of the capstone project, skills are acquired that favor active learning and encourage metacognition [

17] while allowing the evaluation of students’ ability to perform as a team, as recommended by ABET and CDIO in their learning outcomes for the training of engineers [

19]. Additionally, external evaluation by engineers belonging to the industry is incorporated, generating closer feedback on professional practice, which allowed the implementation of improvement actions in the approach, the contents, and the teaching practice in the courses.

The capstone project statement is open and seeks to approach the authentic tasks of an engineer in the context of the profession. Therefore, it is pertinent to confront students with relevant questions, and require them to construct their arguments, exchange ideas, accept ideas and conclude based on evidence and reasoning [

9]. Aspects such as the reaction route, the separation strategy, and the basic control loops must be proposed and evaluated by the students, where they learn to make decisions and integrate prior knowledge. According to several experts [

17], this encourages metacognition, understood as a process of reflecting and directing one’s thinking.

By using computational tools in the courses, it is possible to strengthen research competence, since the students must carry out a bibliographic search, categorize the technical information and, thus, propose alternatives in the synthesis of the processes, following a methodology of hierarchical levels. It was noticed that students learned to select information to complete the degrees of freedom and autonomously solve the mass and energy balances for the processes. In contrast, a macro was programmed in MS Excel that allows solving non-linear systems of equations using homotopic numerical methods.

Active learning, supported by software, is achieved, which converges in courses such as the Process Engineering Laboratory, where the student faces uncertainty, decision-making, and asks “what if?” to whole plant dynamics, to build meaningful learning of industrial process design and control [

23].

The use of computational tools allows students to accelerate the method of analysis of the processes, either by carrying out case studies in a steady state to parametrically optimize the processes or characterize the dynamics of the processes in the transient state to propose a feedback control strategy. By integrating different tools such as Simulink and dynamic HYSYS simulation, the students even approach the estimation of the tuning parameters of the controllers, quickly contrasting different methods for this purpose.

To become self-directed learners, students must learn to assess the demands of the project, as well as their knowledge and skills; in addition, they plan their strategy, monitor their progress, and adjust their strategies in the working group as necessary [

9,

17].

The capstone project is not intended for the student to accumulate knowledge, but to use it in problem solving. With the assistance of computational methods in the design or process control courses, a flipped classroom experience is generated, which has the potential to improve the quality of engineering education by providing opportunities for teachers to implement active learning strategies during class time [

24].

3.2. Evidence Obtained from the Capstone Projects

Between 2016 and 2020, more than 43 processes were evaluated with students in the capstone projects. The deliverables of the project are carried out gradually according to the level of detail so that the teachers of the design and control courses can monitor the conceptual progress. Additionally, evidence suggests that the benefits of these practical exercises accumulate gradually through a learning curve [

1,

25].

Some topics covered in the capstone project from 2016 to date comprise the basic design of process plants to produce ethanol and methanol from residual rice husk, hydrogen from microalgae in photobioreactors, xylitol and acetone from sugarcane bagasse, solvents using the principles of green chemistry using industrial residues and secondary products as raw material, among others.

The deliverables are presented in the format of an article. Additionally, a formative assessment of the argumentation and synthesis capacity is carried out. This presupposes a good learning experience for students; a formative, periodic evaluation process is necessary to allow them to fulfill a higher-order activity. Some examples of the evidence showing the results of the capstone projects are shown in

Figure 2 and

Figure 3.

From this evidence, the group of professors involved in the capstone learned lessons regarding the teaching of the elaboration of process and instrumentation diagrams. In particular, the need to strengthen the plumbing rules in class, especially in the location of the final control elements, and deepen the tuning methods and decision-making processes for the selection of equipment. Since software such as HYSYS handles autotuning methods routines, it is necessary to deepen the knowledge of autotuning methods for commercial controllers.

3.3. Evaluation of the Results

Using computational tools, an improvement in the levels of competence in the integrated courses was determined. Thirteen competencies were considered in total, named C1 to C13, as shown in

Table 2.

The students were requested to complete a survey at the end of the course to determine the perception of the degree of development of the competencies, after participating in the capstone design experience, qualifying said degree of development on a scale of 1 to 5, where 5 was the highest rating. On average, 94% of students felt their competencies in process design increased significantly, as shown in

Figure 4.

They also commented that their communication skills and ability to work effectively within a team had improved, similar to the findings reported by [

1]. Greater mastery of the topics was found in the presentations and a greater participation of students in active learning experiences. The external evaluators recognized the relevance of the results obtained and gave feedback to the students about their professional training process, in general.

In an opinion query carried out on the graduates of the UPB Chemical Engineering program in the period between 2016 and 2019, it was found that 94% consider that it contributes to professional practice, regardless of the professional subject they currently perform, and 78% consider this a highly relevant learning experience, as shown in

Figure 5.

The focus group and opinion query methodologies are recommended in several studies to evaluate the development of competencies and find opportunities for improvement in the teaching and learning processes of chemical engineering in universities [

26]. Even these perceptions of chemical engineering students and graduates have helped to find ways to develop employability skills in the new generations of professionals who will enter the industry.

The experienced professionals participating in the focus group, as shown in

Table 1, issued a concept about the capstone project. They considered it very valuable to develop in the students an integrating vision of different disciplines of the professional cycle of Chemical Engineering. The construction of a proposal to propose a technical, environmental, social, and economically viable solution to an industrial need or a specific technical challenge is successful. As an integrating vision, the capstone covers all the aspects that an ideal Chemical Engineer of the 21st century, as expected in the industry.

The capstone experience was valued as relevant for the students since it brings them closer to reality as chemical engineers. The planning process was highlighted, and they were invited to consider projects related to real challenges for industries, including advanced technological tools such as machine learning to simulate the synthesis of the processes.

3.4. Opportunities for Improvement and Next Steps

The focus group also made it possible to identify improvement opportunities for the capstone project with the integration of the Design and Process Control courses. The experts suggested strengthening aspects such as the safety of processes in the deliverables, incorporating methodologies for the identification of hazards (HAZID) with an approach to a study of risks and operability (HAZOP). They also suggested the importance of defining and communicating to the students the dedication of the work in hours to the design exercise, according to the level of their training.

Chemical engineering students require basic training in process safety to develop capabilities that allow them to design processes safely and also acquire critical thinking about operability with responsibility criteria [

27].

Other opportunities for improvement include the involvement of at least one industry sponsor during the development of capstone projects, to generate mini-open innovation challenges in which students receive feedback on the current state of the chemical sector. They can incorporate business model projects and value proposals related to the circular economy, the search for carbon-neutral processes, products that take advantage of biodiversity, or that incorporate the principles of green chemistry [

3]. This feedback makes it possible to continuously improve the relevance of the capstone project in the training of chemical engineers required by the industry.

4. Conclusions

The Faculty of Chemical Engineering of the Universidad Pontificia Bolivariana developed an integration of the Design and Control of Processes courses to incorporate a project-based learning methodology through a capstone project that has improved meaningful learning for students.

The students showed an improvement in their competencies by implementing computational tools for the development of capstone projects in the courses, strengthening capacities to investigate, making decisions to design, and integrating control concepts in the development of basic process engineering.

Some strategies were implemented to improve students’ learning of the design and control of processes, which involve external evaluation in front of experts in design, operation, and process control in the industry. The learning results allowed improving the development of the integrating courses. In particular, the stability, controllability, and tuning of PID controllers.

A total of 94% of graduates in that period recognize the capstone project and the project-based learning methodology as valuable and relevant aspects of their professional development.

The focus group with five graduate experts in chemical engineering validated the relevance of the integration of Design and Process Control to develop capstone design projects. The experience was valued as relevant and opportunities for improvement from the weakness were identified in topics such as process safety, linking with members or sponsors of the industry, and incorporating themes related to green and sustainable chemistry in the design proposals.

As for weaknesses from the evidence, they were identified as more attention on the plumbing rules being required, especially in the location of the final control elements. Deepening tuning methods and decision-making processes for the selection of equipment was also suggested. Since software such as HYSYS handles autotuning methods routines, it is necessary to deepen the knowledge of autotuning methods for commercial controllers. The professors involved in the capstone project used this diagnosis as a lesson learned to improve integration between process design and control courses.

The capstone integrative project contributes to the quality training of students in chemical engineering and creates conditions for active learning and the development of skills that promote sustainable engineering education.