3.1. Direct and Indirect CO2 Emissions

The direct CO

2 emissions from each industry sector were estimated by the proportion of energy sources, such as coal/peat and oil, utilized per industry sector in the input–output table. The total amount of CO

2 that is directly emitted by the “electricity, gas and water supply (16)” sector is utilized to estimate the indirect emissions of each industry sector according to the distribution of the supplied commodity of the “electricity, gas, and water supply (16)” sector across the remaining industry sectors within the input–output table, as previously described in Step 2. As a result, the top five total CO

2-emitting industry sectors, including both direct and indirect emissions, have been identified in top-down order as “coke, refined petroleum products and nuclear fuel (7)”, “electricity, gas and water supply (16)”, “transport and storage (19)”, “chemicals and chemical products (8)”, and “basic metals, fabricated metal products, with the exception of machinery and equipment (11)”. If direct and indirect emissions are considered separately, the rank of direct CO

2 emissions also follows the same order; however, the rank of indirect CO

2 emissions was determined to be in the order of “basic metals, fabricated metal products, with the exception of machinery and equipment (11)”, “public administration and defense, compulsory social security, health and social work (25)”, “electricity, gas and water supply (16)”, “chemicals and chemical products (8)”, and “wholesale and retail trade, repairs (17)”.

Figure 3 provides the amount of CO

2 that is emitted across the industry sectors in units of million tons, which is the average value of four time series data sets, namely, 1995, 2000, 2005, and 2010.

“Public administration and defense, compulsory social security, health and social work (25)” was ranked sixth in direct CO

2 emissions but was ranked second for indirect CO

2 emissions. This discrepancy is attributed to the inclusion of the defense industry in this industry sector. Due to the significant defense expenditures and allocations of capital for the countries, the role of defense in the “public administration and defense, compulsory social security, health and social work (25)” industry sector is comparatively high. A large correlation value of 0.833 (

p-value < 0.01) was obtained between the defense expenditure and the industry sector (25) of various countries [

32]. The US demonstrated the highest level of national defense spending with USD 609.9 billion in 2014, which is 17 times the level of national defense spending in Korea (USD 36 billion) and 13 times the level of national defense spending in Japan (USD 45.8 billion) [

33], and emits significant amounts of CO

2 from the use of various energy sources, including jet fuel and diesel, which correspond to the “coke, refined petroleum products, and nuclear fuels (7)” industry sector.

The CO

2 emissions for the basic metals industry are shown in

Figure 4. The direct emissions in 2010 constituted 1,183.7 million tons, which was 1.4 times the 1995 level of 856.8 million tons but which is actually lower than expected considering the increase in steel and non-ferrous metal production that the industry has observed during identical periods. The amount of indirect emissions in 2010 was 216.4 million tons, which was two times the 1995 level (107.5 million tons). The steel production in 2010 was 2.5 times the level in 1995. Production via the BF route increased 2.9 times, and production via the EAF route increased 1.6 times. The major non-ferrous metals that constitute the basic metals industry include Al, Cu, and Zn. Global Al production in 2010 totaled more than 46 million tons compared with 19 million tons in 1995, which is a 2.5-fold increase. Cu production in 2010 was more than 20 million tons, compared with 11 million in 1995, which is a 1.8-fold increase. Zn totaled more than 12 million tons in 2010 compared with seven million tons in 1995, which is a 1.8-fold increment.

More specifically, CO2 emissions showed a significant increase in China from 2005; the amount of CO2 that was directly emitted and indirectly emitted in 2010 was 908.34 tons and 155.73 million tons, respectively, which was 1.7 times (547.91 million tons) the 1995 level and three times (51.71 million tons) the 1995 level, respectively. Although the increase in the amount of direct emissions in China may be correlated with the increase in steel production via the BF process, the increase in the reduction of indirect emissions is likely to be a combination of both an increase in the production of steel via the EAF route and the processing of non-ferrous metals, such as Al, Cu, and Zn. Al electrolytic smelting in China by the Hall–Heroult process, which consumes approximately 14,000 kWh/ton-Al compared with 400 kWh/ton-steel by the EAF route, produced approximately 16.2 million tons of CO2 emissions in 2010 compared with 1.78 million tons of CO2 emissions in 1995. Zinc also demonstrated a significant increase in production to 5.16 million tons of Zn in 2010 compared with 1.08 million tons of Zn in 1995. Copper exhibited a relatively steady increase compared with the substantial increases observed for Al and Zn. Korea yielded direct CO2 emissions and indirect CO2 emissions of 57.9 million tons and 7.71 million tons in 2010 compared with 31.53 million tons and 4.19 million tons in 1995, respectively. Similar to China, Korea is also concentrated towards the BF route, which is heavily dependent on coal/peat and coke for energy and the reduction of iron ore, which produces higher levels of direct CO2 emissions. A steady increase in steel production by the EAF route of 13.89 million tons to 24 million tons from 1995 to 2010 seems to correlate with the increase in indirect CO2 emissions for Korea. The US experienced a continuous decrease in direct CO2 emissions from the basic metals industry and a decrease in indirect CO2 emissions from 1995 to 2005 and a sudden increase in these emissions in 2010: 30.5 million tons in 1995, 19.64 million tons in 2000, 16.22 million tons in 2005, and 30.43 million tons in 2010. The overall steady decrease in direct CO2 emissions in the US was attributed to the merging of steel companies and the subsequent shutdown of inefficient plants, which was replaced by the EAF route. The US has an unusually large concentration of electric arc furnaces within the steelmaking plant due to its comparatively low electricity costs and abundance of high-grade low-cost scrap. However, even with the competitive electricity costs within the US, the non-ferrous industry, including Al, Zn, and Cu, experienced significant slowdowns and shutdowns owing to the excessively high consumption of electricity in the electrolysis of these non-ferrous basic metals. Thus, fluctuations in the indirect CO2 emissions occurred in the US because some of these non-ferrous electrolysis processes were shut down. Japan experienced an increase in direct CO2 emissions from 88.27 million tons in 1995 to 117.06 million tons in 2010. The indirect CO2 emissions seemed to remain relatively steady (10.33 million tons in 1995, 9.23 million tons in 2000, 11.78 million tons in 2005, and 10.23 million tons in 2010). Unlike the US, the price of electricity is comparatively high in Japan, which probably prevents significant capital investments in EAF production capacity and is dominated by the integrated steel mills. Although scrap costs and availability may not be prohibitive in Japan, the cost of electrical energy means that it is difficult to make the EAF process economical unless energy support is provided. In addition, large-scale non-ferrous basic metals production is limited in these high-electricity-cost regions. Germany experienced a significant decrease in direct CO2 emissions from 1995 (75.48 million tons) to 2010 (19.4 million tons). Indirect CO2 emissions were 12.34 million tons in 2010, which is similar to 1995 levels. The amount of non-ferrous basic metals production in Germany was not significant within the range of this study.

Thus, it would seem that the direct emissions levels of Korea, China, and Japan are increasing along with the indirect emissions, except for Japan. This trend is correlated with the amount of steel and the non-ferrous basic metals that are produced and the dominant production route for a particular country. China, Korea, and Japan experienced production increases within the integrated steel route that utilizes coal/peat and oil as its major energy source, which yielded direct CO

2 emissions. The utilization of coal and oil energy sources is speculated to be pulverized coal injection (PCI) into the blast furnace or the supplemental heat via coal or oil heating within the various steelmaking processes. Steel production by the EAF route also expanded within the time scale that was identified in this study, which generates higher amounts of indirect CO

2 emissions. In addition, China experiences significant increases not only in steel production, but also in its non-ferrous sector, which is more energy-intensive per ton of metal compared with steel. Countries, such as the US, that are heavily concentrated towards the EAF route and non-ferrous metals production, in which electricity is the main energy source, will experience continued increases in indirect CO

2 emissions. Therefore, the scheme of direct and indirect CO

2 emissions in the basic metals industry is closely related to the dominant process route that is taken by the respective countries and the production amounts of major non-ferrous metals, including Al, Cu, and Zn.

Figure 5 shows the productivity of the basic metals process with direct and indirect CO

2 emissions. The productivity represents the amount of produced basic metals in thousand tons with direct and indirect CO

2 emissions divided by the energy costs in US million dollars. In 2010, Germany had the highest productivity of basic metals, with direct CO

2 emissions of 5.23, whereas Korea had the lowest productivity of 1.50. This estimate is likely to be related to the increase in the cost of energy for Korea with respect to the other countries. For the productivity of basic metals with indirect CO

2 emissions in 2010, the US had the highest productivity of 4.97, whereas Germany had the lowest productivity of 1.12. The lower value for Germany suggests a significant change in the amount of produced basic metals with respect to the other countries.

3.2. CO2 Emissions arc Elasticity

The CO2 emissions arc elasticity was calculated to observe the changes in the total CO2 emissions with changes in the total consumption cost of the input energy sources. The arc elasticity is given as an absolute value, which describes the sensitivity of the changes in CO2 to changes in the energy costs over a defined time period. The cost of a product within a certain range can affect the amount of product demand in the demand curve, and the sensitivity of the product consumption with respect to cost can be estimated by dividing the amount of demand change with the corresponding price change. A small elasticity index indicates a low sensitivity; thus, the amount of manufactured products or CO2 emissions within this period would not be significantly affected. A large elasticity index indicates a high sensitivity; thus, the amount of CO2 emissions would significantly decrease. In this study, the elasticity of the total CO2 emissions with respect to the total consumed cost of the energy source has been considered for the five major industrial countries.

The energy sources within the basic metals industry have been identified to be the “mining and quarrying (2)”, “coke, refined petroleum products and nuclear fuel (7)”, and “electricity, gas and water supply (16)”. Using available data from 1995 to 2010, the average elasticity is provided in

Table 4. An elasticity value of zero indicates perfect inelasticity, which suggests no changes in CO

2 emissions with variations in the input energy cost. Daily necessities would fall within this area. An elasticity value between unity and zero indicates an inelastic behavior, in which the change in the CO

2 is smaller than the changes in the input energy cost. An elasticity value of unity indicates unit elasticity, in which the amount of change in the CO

2 is equivalent to the changes in the input energy cost. An elasticity value greater than the unit value indicates elastic behavior, in which the change in CO

2 emissions is greater than the changes in the input energy costs. Overall, the elasticity index was not stable over the entire period. Within the 1990s, most of the countries studied showed high elasticity with coke/peat, but with time the elasticity of Electricity became pronounced. In particular, Korea, Japan, and Germany showed a high elasticity to Electricity. This could be due to the overall higher consumption or the price increase of electricity within the steel industry.

The CO

2 emissions of the basic metals industry can be estimated from Equation (6). The estimated CO

2 emissions indicate that Korea has a CO

2 emissions increment of 3.43 million tons per one million USD in consumed input energy source costs.

where

qi is the CO

2 emissions of country “

I”,

is the elasticity factor value of industry sector (2) for country “

I”,

is the elasticity factor value of industry sector (7) for country “

I”,

is the elasticity factor value of industry sector (16) for country “

I”,

xm is the input cost of industry sector (2),

xc is the input cost of industry sector (7), and

xe is the input cost of industry sector (16).

Specifically, Japan and Germany demonstrated a more pronounced sensitivity in CO2 emissions with higher prices in electricity as the energy source compared with China and the US, but were comparatively less sensitive to the total cost of coal/peat as the energy source. An elasticity index of 4.74 for Japan suggests a significant sensitivity to the electricity energy source; thus, slight changes in electricity costs can significantly affect the amount of basic metals produced and hence CO2 emissions. Japan is comparatively insensitive to the coke/peat and oil energy sources. Conversely, China and the US experienced more pronounced changes in CO2 emissions as the input total cost of the coal/peat increased. Thus, depending on the country, the changes in CO2 emissions can be affected by the dominant energy source and the concentration of the industry within a country with respect to this energy source. This situation enables the effect of a particular energy source on CO2 emissions to be closely verified and demonstrates its importance to the sustainability of the industry in terms of energy.

3.3. Potential Neutralization Capacity of CO2

The available forest resources and land masses within a country that emits CO

2 can be effectively neutralized from the photosynthesis of plants, vegetation and forest resources. Recent studies describe the effect of global climate change due to a significant decrease in the Amazon forest vegetation and stress the importance of forest resources for carbon storage through photosynthesis [

34]. This study incorporates some of the findings of previous studies of CO

2 absorption rates per forest resource area and the total forest area in a country in which CO

2 is emitted [

35]. To simplify the calculations, agricultural areas and vegetation have been excluded from the forest area.

The CO

2 neutralization ability for each country from 1995 to 2010 is shown in

Table 5 in five-year intervals. The forest area, with its prominent amount of broad-leaf trees, in Korea in 2010 was 6222 thousand ha and the CO

2 emission was 563 million tons. Assuming a CO

2 neutralization potential of 13.54 tons per 1 ha, the neutralization ability would be 15% of the total emitted CO

2. In the US, the CO

2 absorption ability was estimated to be approximately 11.6 ton/ha with a neutralization ability above 66% due to its large area of needle-leaf forest resources. The concentration of manufacturing within a small land mass is attributed to this lower CO

2 neutralization ability for Korea, which caused Korea to implement drastic emissions trading schemes in January 2015. These schemes will likely impede the sustainability of the steel and manufacturing industry if potential solutions to either lower CO

2 or increase the neutralization abilities for the country are not improved.

A time series analysis was performed to estimate the average CO

2 neutralization ability, in which the neutralization potential was used as the dependent variable and the forest area and CO

2 emissions were used as the independent variables. Thus, future estimates from the time-series analysis consider the variation factors and analyze the dynamic relationship of the serial correlation among the time-series data. The variation for a specified time is affected by previous changes or previous errors (white noise). The Auto-Regressive Integrated Moving Average (ARIMA) model utilizes this relationship in the following equation

where ε

t represent mutually independent average values, which sum to 0, and the fixed variance exhibits a normal distribution. Thus, ε

t is white noise, and φ

0 … φ

p and θ

1 … θ

q are undetermined parameters. The ARIMA analysis identifies the dynamic characteristics of the time-series data and enables relatively accurate estimates, which are broadly applied to stock markets, economics, and resource management. This study also attempted to estimate future trends of the CO

2 neutralization potential of various countries using the ARIMA model. The ARIMA model consists of three parts and is expressed as ARIMA (p, d, q), where p is the order of the regression analysis, d is the order of the differentiation, and q is the order of the moving average. The effective model equations for estimating the dependent variable are provided in

Table 6.

The coefficient of determination that describes the suitability of the model was determined to be greater than 0.90 [

36]. The coefficients of determination near zero suggest a low usefulness of the model, whereas a higher value near 1 suggests a high usefulness of the model. Using available data to 2010 limits the accuracy of estimates and trends. Within this estimate, the emitted CO

2 negatively affects the neutralization and the forest area positively affects the neutralization. For China, the neutralization ability seems to decrease even when the forest area increases. These results are attributed to the rate of industrial expansion and the rate of increase in CO

2 emissions, which substantially exceeds the increments of forest areas that are set within the estimates. This finding corresponds to the rate at which the CO

2 emissions are increasing within China and its effective ability to neutralize its CO

2 emissions. For Korea, the CO

2 neutralization ability has seen a significant decrease since 1995, and the constant of the model yields a negative value. However, if the forest area were to increase in Korea then this country could achieve greater improvements in neutralization ability compared with other countries. Thus, the capacity for Korea’s neutralization ability to improve with forest farming and expansion of its forest area may be sufficient. The estimated neutralization ability from 2015 to 2030 in five-year intervals from the analysis of the ARIMA model is provided in

Figure 6. This estimate accounts for the dynamic changes of the forest area and CO

2 emissions in terms of time for a particular country. Korea, China, and Japan show a decrease in the estimated CO

2 neutralization ability, whereas Germany and the US appear to have a neutralization ability that will remain stagnant or slightly increase. Korea and China both show a steep decline in the neutralization ability for the actual and estimated values. If the forest area remains constant or decreases, the neutralization ability of the country will become negative with a total loss of neutralization capacity. Conversely, the slight increases in the neutralization potentials for Germany and the US are attributed to its trend in lower CO

2 emissions and increases in forest area.

3.4. Possible Scenario to Increase CO2 Neutralization

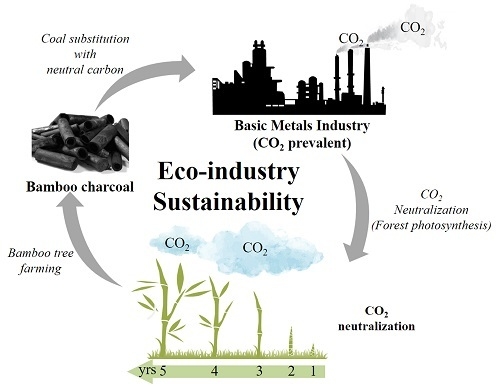

A potential scenario has been provided, in which controlled industry expansion is possible without significant industry contraction if forest resources can be effectively utilized. Using Korea as an example country and bamboo forest farming as a tree species to be used, the annual CO

2 neutralization of rapidly growing trees has been measured to be between 29 and 47 ton-CO

2/ha [

30,

37,

38,

39,

40]. Studies have shown that bamboo species can grow in excess of 30 cm per day [

41]. After a five-year period, these bamboo trees can also be utilized as carbon sources as bamboo charcoal, which may replace some of the fixed carbon that is used for fuel, and would be considered to be carbon neutral.

Approximately 20% of the bamboo charcoal with respect to its initial weight can be produced. Because approximately 30 tons of bamboo wood can be produced from 1 ha, six tons of charcoal can be produced from a unit ha of bamboo forest. The chemical analyses provided in various studies suggest that less than 4% of ash is present in bamboo after pyrolysis. The major ash composition includes K2O, SiO2, and P2O5, which are also present in coal that is employed in the steel industry in considerably higher quantities. Coal that is employed for PCI significantly varies; thus, an average value from previously published references has been applied, in which SiO2 and Al2O3 constitute approximately 60% of the total ash content and 20% of the average as-received coal weight. Thus, coal contains five times the amount of ash than bamboo charcoal.

If the PCI in the BF is substituted with the carbon neutral bamboo charcoal, which has similar calorific value of approximately 3000 kcal/kg, 150 kg-coal/ton-hot metal could be replaced. These changes would cause a potential decrease in CO

2 of approximately 440 kg-CO

2/ton-hot metal. In addition to the substitution by the carbon neutral charcoal, acidic oxides of SiO

2 and Al

2O

3 of approximately 18 kg/ton-hot metal will also decrease. Because the fluidity of the slag in the BF must be maintained by the addition of CaO at a fixed CaO/SiO

2 ratio of approximately 1.3, the substitution by charcoal will decrease the slag amount by 41.4 kg/ton-hot metal. This decrease in slag amount will subsequently decrease the carbon that is consumed in the BF by approximately 7 kg/ton-hot metal, which would correspond to 26 kg-CO

2/ton-hot metal. Thus, the substitution of the PCI with bamboo charcoal would correspond to a decrease in the CO

2 emissions in the blast furnace by 466 kg-CO

2/ton-hot metal. According to WSA statistics [

9], 41 million tons of total hot metal were produced in Korea in 2013, which represents an annual CO

2 reduction of approximately 19 million tons.

Figure 7a estimates the possible CO

2 reduction from the substitution of PCI in the BF with various amounts of bamboo charcoal. Using the ARIMA model and assuming a 50% substitution of the PCI with bamboo wood charcoal and a neutralization capacity of 38 ton-CO

2/ha, the effect of bamboo wood charcoal for the basic metals CO

2 neutralization was forecasted to 2030 using the ARIMA model. The average increase in CO

2 emissions of the basic metals industry during the forecasted time range to 2030 was 10% on average based on the emissions between 2010 and 2014; this estimate was employed for the forecasted values applied in the ARIMA model. The results in

Figure 7b indicate that the large slope of the decrease in the eco-CO

2 index has been significantly deflected and the neutralization ability can be maintained at approximately 13% in 2030, even with the expected industry expansion forecasted by the ARIMA model by substituting PCI with bamboo wood charcoal and the bamboo farming of 50,000 ha.