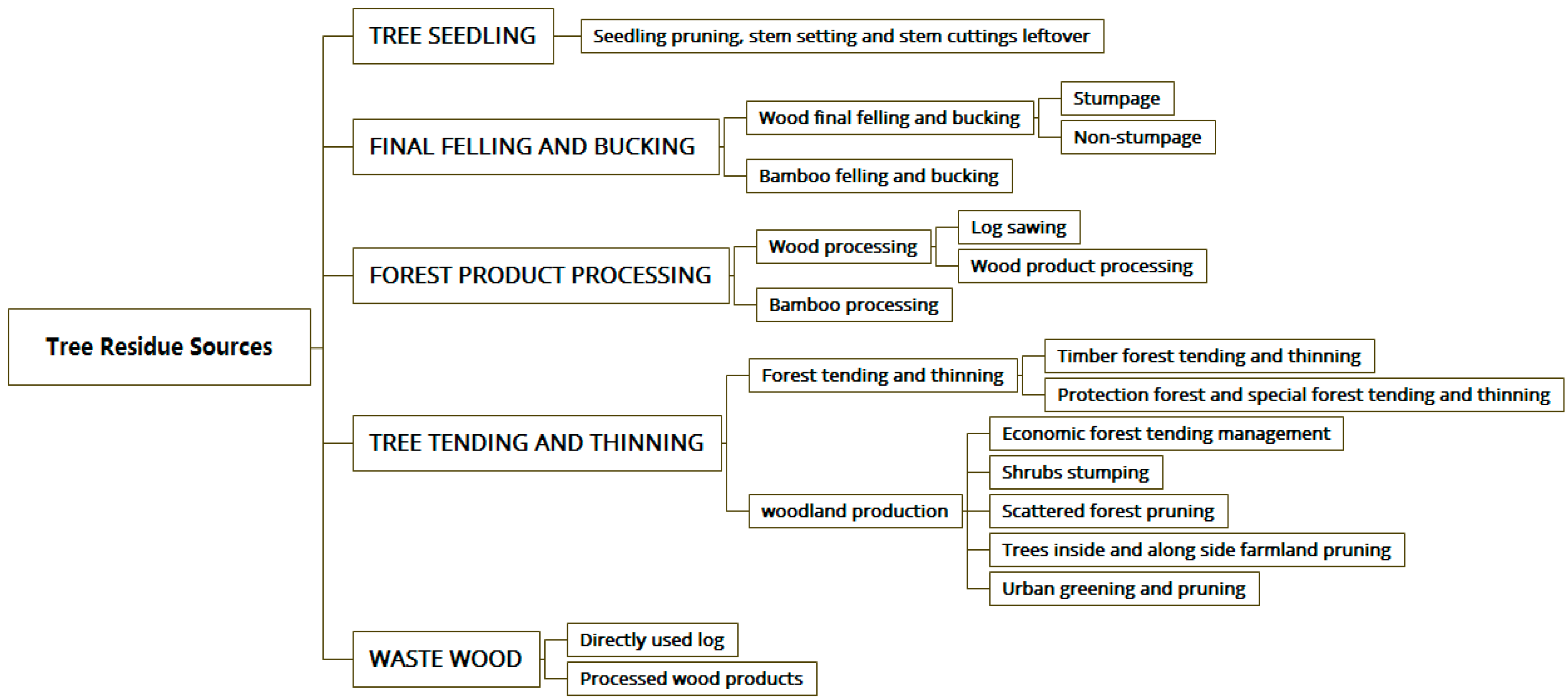

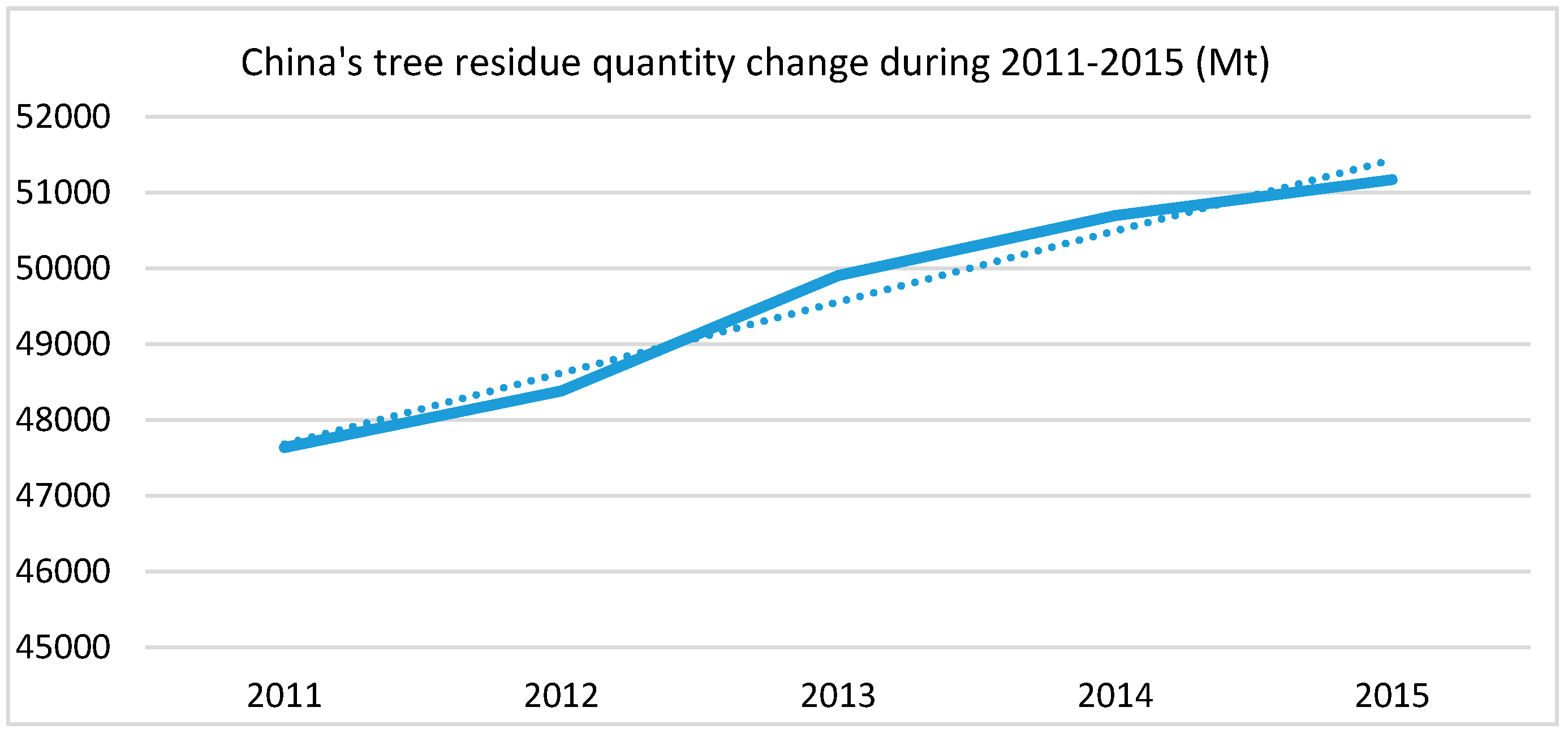

This study uses the top-down model to estimate the residue quantity of the five categories. It comprehensively considers the data availability and rationality when selecting specific variables. The following paragraphs will explain the calculation method in detail.

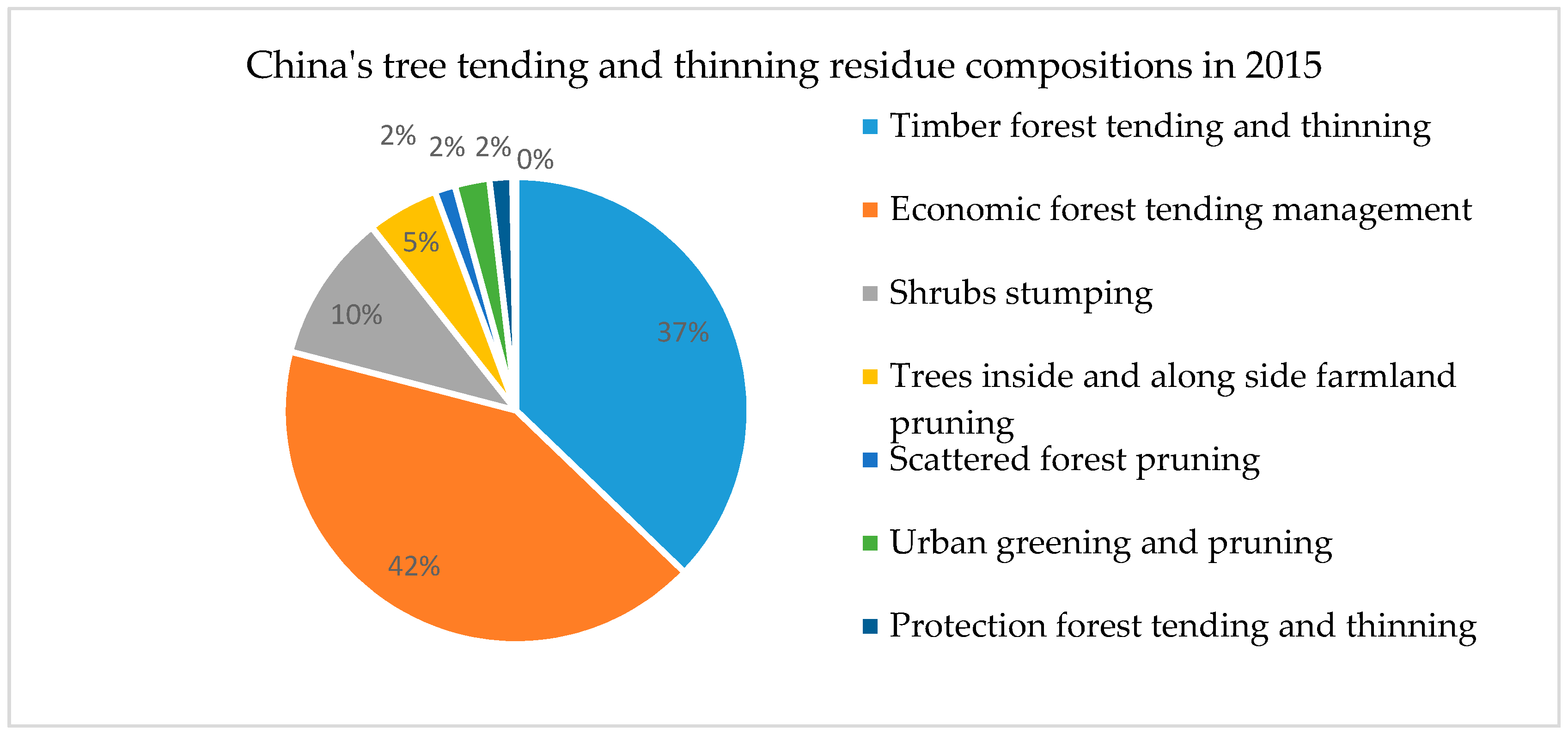

2.2.1. Estimation of Tree Tending and Thinning Residue

The thinning and pruning of different types and different intensities produce undersized timber, branch and root residues of different qualities and quantities. This study therefore makes a detailed division of the forest type and thinning intensity, and calculates the residue from urban tree pruning.

• Estimation Formula

The yields of tree residue are variable depending on the different forest types in different areas, and their productivity and collectability [

1]. By referring to Yuan’s calculation method for tree residue quantity and Perttu, A.’s thinning intensity data , this study constructs the Formulas (1) and (2).

where

is the quantity (Mt) of tending and thinning residue;

is the reserve (m

3) or area (hectare) of the

j-th type forest of

i-th age group;

is the thinning intensity or residue production intensity of the

j-th type forest of

i-th age group;

is the residue output ratio of the

j-th type forest of

i-th age group;

i = 1 or 2 refers to the young growth forest and middle-aged forest respectively; and

= 1, 2 or 3 stands for timber forest, protection forest and special forest respectively.

where

is the quantity (Mt) of woodland production residue; and

is the area (hectare) of economic forest, shrubbery and scattered forest or the number of trees inside and alongside farmland.

stands for the residue output ratio of the corresponding forest type. See

Table 1 and

Table 2 for the values of the variables.

According to the study of Guo Huibin on the interlucation of natural forest and man-made young growth forest, it is appropriate to choose 10% and 15% for the thinning intensity of young growth forest and middle-aged forest [

37]. However, considering that middle-aged forest thinning will deliver 40% of industrial logs [

38], i.e., that the tree residue is 60% of articles obtained from thinning, the middle-aged forest thinning intensity was eventually determined to be 9%. The residue output intensity of protection forest and special forest was determined to be 0.2 [

1,

36]. In addition, the tree residue output of the economic forest varies from area to area, and thus it was divided into three areas, southern, plain and hilly and northern areas. The southern area includes Zhejiang, Fujian, Jiangxi, Hunan, Hubei, Guangdong, Hainan, Yunnan, Guizhou, Sichuan, Chongqing, Guangxi and Tibet, totally 13 provinces, municipalities and autonomous regions; the plain and hilly area includes Beijing, Tianjin, Hebei, Shandong, Henan, Jiangsu, Anhui and Shanghai provinces (municipalities); and the northern area includes Liaoning, Jilin, Heilongjiang, Ningxia, Xinjiang, Shanxi, Shaanxi, Gansu and Qinghai, totally 10 provinces (autonomous regions). Taiwan, Hong Kong and Macao are not included in the study [

18].

• Estimation of urban greening tree residue

Based on the provision of the Evaluation Standards for Urban Landscaping and Greening that “the shrub coverage in greenbelt should not be lower than 70%” [

39], this study converted the greening area of various regions [

40,

41] into a minimum vertical projection area of the trees and shrubs of various regions. Then it referred to the number of garden trees in Tianjin in 2015 [

42,

43,

44] to calculate trees in a unit vertical projection area, then estimated the quantity of greening trees in various regions by multiplying trees in a unit vertical projection area and the minimum vertical projection area of trees and shrubs of various regions, and then worked out the urban greening trees of various regions. Finally, this study adopted the residue output ratio of trees inside and alongside farmland to estimate the quantity of urban green tree residue of various regions.

According to the data in China Statistical Yearbook 2016, the urban green coverage of 31 provinces varies in the range of 29.8–48.4%, and the average urban green coverage is 39.43%. The urban green coverage of Beijing is 48.4% (highest), while Tianjin’s level is 36.4%, which represents the lower level of urban greening in China. Because only the greening tree numbers of Beijing and Tianjin city are available, based on the conservative estimation principle, this study adopts Tianjin’s green coverage to estimate trees in a unit greening area.

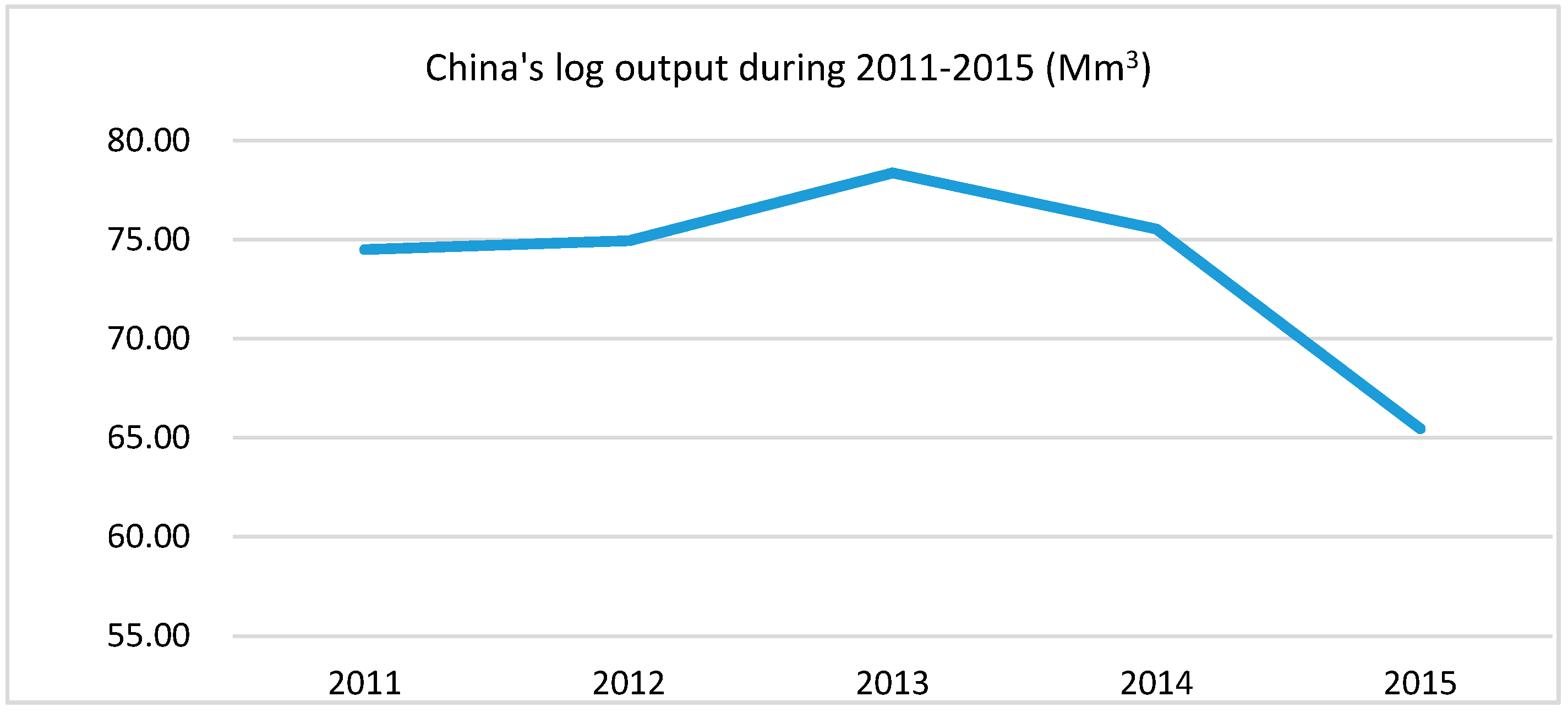

2.2.2. Estimation of Final Felling and Bucking Residue

Considering that firewood is not a tree residue source according to the definition and classification of tree residue in this study, this study revised Wang’s calculation equation [

18], constructing Formulas (3) and (4), to calculate the tree residue produced in the final felling and bucking by stumpage residue and non-stumpage residue, specifically calculating the timber output, percent of merchantable volume, wood density, and other variables. The non-stumpage residue was calculated based on the stumpage reserve and corresponding proportion. Because the volume and quality of wood will vary with the moisture content of wood, the wood density refers to the density of a moisture content, for example full dry density, air-dry density (moisture content about 15%) and basic density. Among them, air-dry density is the most commonly used index in estimating the amount of forest residue, due to the fact that its humidity tends to balance with the relative humidity of the atmosphere. This study adopts the air-dry density to indicate wood density,

where

is the quantity (Mt) of stumpage residue produced in the process of tree final felling and bucking;

is the annual log output (m

3) from tree final felling and bucking process of China;

is the percent of merchantable volume (proportion between log volume and stumpage volume);

stands for annual output (m

3) of firewood from the tree final felling and bucking process; and

is the wood air-dry density (i.e., the weight of air-dry timber is divided by the volume of air-dry wood).

where

is the quantity (Mt) of non-stumpage residue produced in the process of tree final felling and bucking; and c stands for the proportion of non-stumpage biomass of the stumpage volume.

This study selected 0.618 t/m

3 (the mean air-dry density of the 228 main tree species of China) [

45] as the value of wood air-dry density, and based on Wang’s study, chose 77.17% (weighted average of 1393 samples of the percent of merchantable volume in 43 studies) [

18] as the value for the percent of merchantable volume.

The non-stumpage residue mainly includes branches and roots. This study determines the factor c according to the percentage of the respective non-stumpage residue of broad-leaved trees and conifer, and the weight of the two kinds of timber output (the area of broad-leaved trees and conifer is 1:1). See

Table 3 for the related data.

This study chose the worst residue output occasion, and calculated the quantity of non-stumpage final felling residue regardless of whether they were conifer or broad-leaved trees. Since the biomass of branches and roots is 25% and 20% of the stumpage volume (

Table 3), c is determined to be 45% accordingly.

2.2.3. Estimation of Forest Product Processing Residue

The forest product processing residue consists of residue produced in the stages of log sawing and sawn timber being produced into wood products. The process of log sawing is based on the sawn timber output; the process of sawn timber being produced into wood product is based on the factory lumber statistics data. Thus, the wood processing residue is calculated by comprehensively considering the proportion of log sawing residue and the wood product processing residue. Based on Wang’s study [

18] and taking account the loss factor of residue in the sawing process and wood product processing, this study constructed Formula (5).

where

is quantity (Mt) of forest product processing residue;

is the annual output (m

3) of sawn timber;

is the sawn timber yield rate, which refers to the ratio of the volume of the square lumber (the finished product of the sawing process) to the volume of the log before sawing.

is the attrition rate of residue from the sawing process. Some factors such as mechanical loss and powder collection difficulties result in residue losses in the sawing process. The attrition rate of residue in the sawing process refers to the ratio of the loss volume of residue in the sawing process to the volume of the log sawn.

is the annual output (m

3) of factory lumber, specifically the timber used for processing in the forestry statistics yearbook;

stands for the wood product yield rate; and

is the attrition rate of residue produced in the wood product processing. See

Table 4 for the forest product processing yield rate, residue proportion and residue attrition rate.

The study chose the worst occasion of residue output, 74%, for the sawn timber yield rate

, and 60% for the wood product yield rate

. The attrition rate of the sawing process and wood product processing is 4% and 1.5% respectively [

6] while the proportion of obtainable residue for the sawn timber and wood product processing is 22% and 38.5%, respectively.

2.2.4. Estimation of Bamboo Felling and Bucking and Processing Residue

Considering that bamboo timber uses quite different technology and standards from wood processing, felling and bucking, and that the residue proportion is different, this study calculated the bamboo processing, felling and bucking residue separately. Based on the significant correlation between the ground part biomass of bamboo and the bamboo culm [

46,

47,

48,

49,

50], this study estimated the weight of bamboo branches and leaves through the weight of bamboo culm and arrived at the residue proportion by working out the bamboo timber utilization rate. This study borrowed Wang’s estimation formula [

18]. However, instead of only choosing a comprehensive proportion between bamboo culm and branches and leaves, this study investigated and set the proportions for the large-diameter

Phyllostachys heterocycla cv.

pubescens, and other bamboo and small-diameter bamboo separately to estimate the weight of bamboo branches and leaves. Formula (6) is as follows:

where

is quantity (Mt) of the bamboo felling and processing residue;

i = 1, 2 or 3 stands for large-diameter

Phyllostachys heterocycla cv.

pubescens, and other species of bamboo with a large diameter and a small diameter respectively;

is the output for species

i of bamboo;

is the proportion between bamboo branches and leaves and bamboo culms for species

i of bamboo;

is the proportion of the bamboo timber processing residue (ratio between the bamboo processing residue and the bamboo timber volume); and

is the weight of the unit of bamboo timber.

• Proportion between bamboo culm and branches and leaves

The proportion between bamboo branches and leaves and bamboo culm refers to the ratio between the dry weight of fixed and dried branches and leaves and the bamboo culm. The proportion is different among different species of bamboo. China’s bamboo mainly includes Phyllostachys heterocycla cv. pubescens and others. To simplify the calculation, we set the proportion for the large-diameter Phyllostachys heterocycla cv. pubescens, other bamboo and small-diameter bamboo.

Researchers mostly choose

Phyllostachys heterocycla cv.

pubescens for a specific area to estimate the proportion of various organs of the ground part of the bamboo [

46,

48,

49,

50,

51]. Xu Zhenguo studied the relationship of the biomass of the ground part among

Dendrocalamus latiflorus of different ages and the results show that the proportion of bamboo culm mass increases with age [

52]. See

Table 5 for the proportion between bamboo branches and leaves and bamboo culm of

Phyllostachys heterocycla cv.

pubescens, other species of bamboo and small-diameter bamboo in previous studies.

This study chose the lowest occasion of residue output and determined the proportion between bamboo branches and leaves and bamboo culm of

Phyllostachys heterocycla cv.

pubescens to be 26.1%, and 23.6% for the proportion of other species of bamboo, represented by

Dendrocalamus latiflorus; for the small-diameter bamboo, we adopted the data of one-year

Dendrocalamus latiflorus, i.e., 40.8% [

52]; the unit bamboo culm weight is 15 kg/bamboo tree [

18].

• Proportion of bamboo timber processing residue

A lot of research has been carried out on the bamboo timber processing and utilization rate. For example, Liu Zhikun (2003) and Zheng Xingfu (2004) and other scholars have drawn the conclusion that “above 60% bamboo timber become processing residue” [

53,

54]. Except for bamboo particleboard, the utilization rates of other kinds of bamboo use are all below 50%, and some even as low as 20–25%. For example, the utilization rate of bamboo flooring is 20–25% [

55]. The bamboo timber utilization rate of various kinds of bamboo board profiles is only 30–50% [

56]. This study supposed a high processing utilization rate (i.e., the low discard rate) and adopted 50% for the proportion of bamboo timber processing residue.

2.2.5. Estimation of Waste Wood

To facilitate the estimation, the study divided the waste wood into two categories, first, the directly used log (Purlin for house building, wire pole and pit prop, etc.) that is eliminated with expiry of the service life, and second, replaced processed wood products. When estimating the waste wood recycling quantity (Mt) from the perspective of the directly used log and wood product service life, this study traced the directly used log and wood product output throughout history, and set an average service life and a recycling rate for them to estimate the current potential waste wood quantity [

18].

China’s wood-based panel output has kept growing over the past decade, from 30 million cubic meters in 2000 to 320 million cubic meters in 2015, wood products made from wood-based panels (such as furniture, etc.) continue to increase, and have become a major source of waste wood. However, considering that the main material of wood-based panels is tree residue, in order to avoid double counting, the estimation in this study does not include the quantity of recycled wood products made from wood-based panels. The estimation formula is as follows:

where

stands for the waste wood quantity (Mt) in

n-th year;

is the output (m

3) of directly used log in

m-th year;

is the recycling rate of directly used log;

is the output (m

3) of processing timber in

m’ year;

is the sawn timber yield rate;

is the wood product yield rate;

is the wood product recycling rate; and

p is the wood air-dry density. The differences between

n and

m and

n and

indicate the service life of directly used log and wood product, in this study both are set as 12 years, and the recycling rate of these two kinds of waste wood are both set at 65% [

18].