Assessing Rebar Corrosion through the Combination of Nondestructive GPR and IRT Methodologies

Abstract

:1. Introduction

2. Materials and Methods

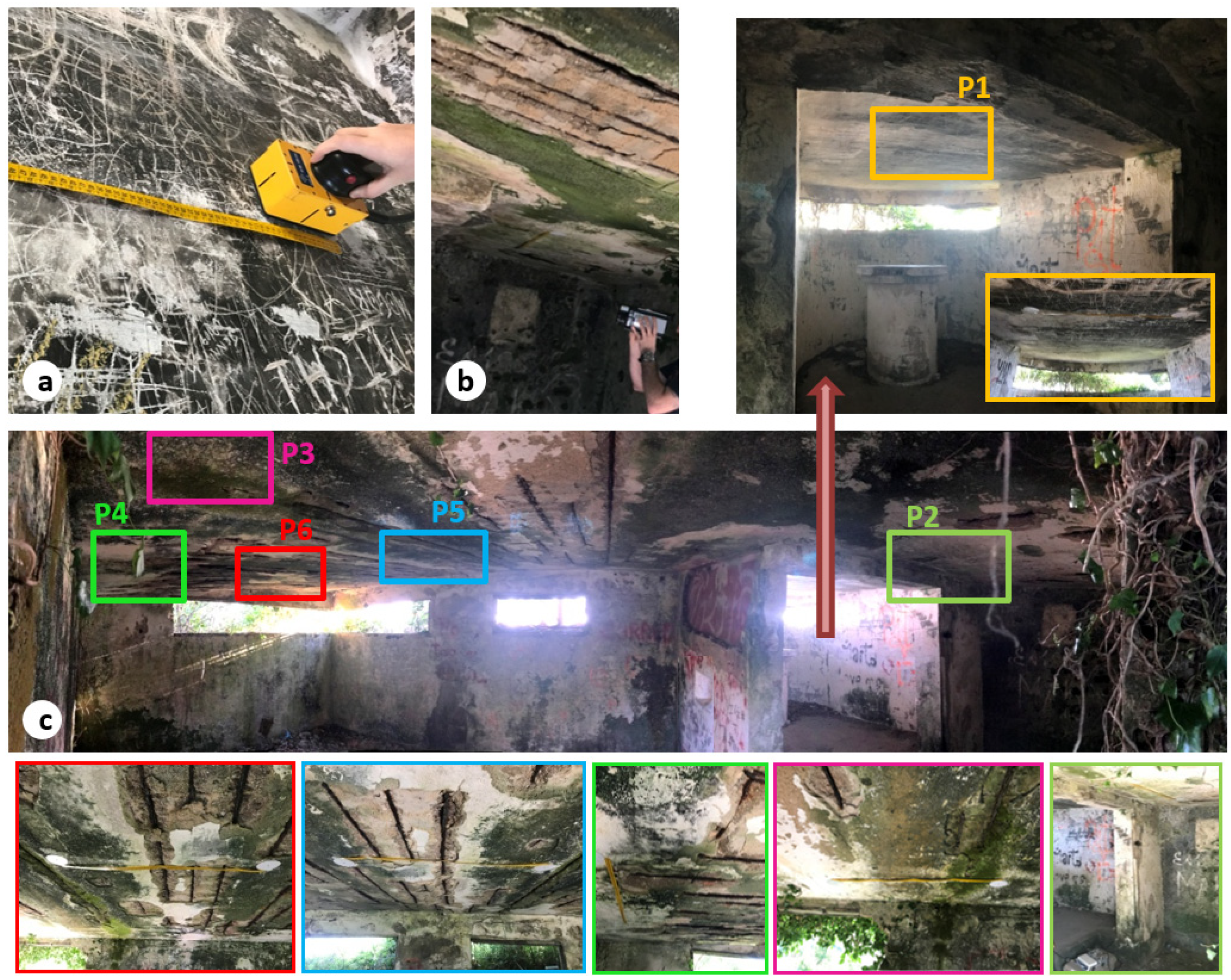

2.1. Case Study

2.2. GPR Data Acquisition and Processing

2.3. IRT Data Acquisition and Processing

3. Results and Discussion

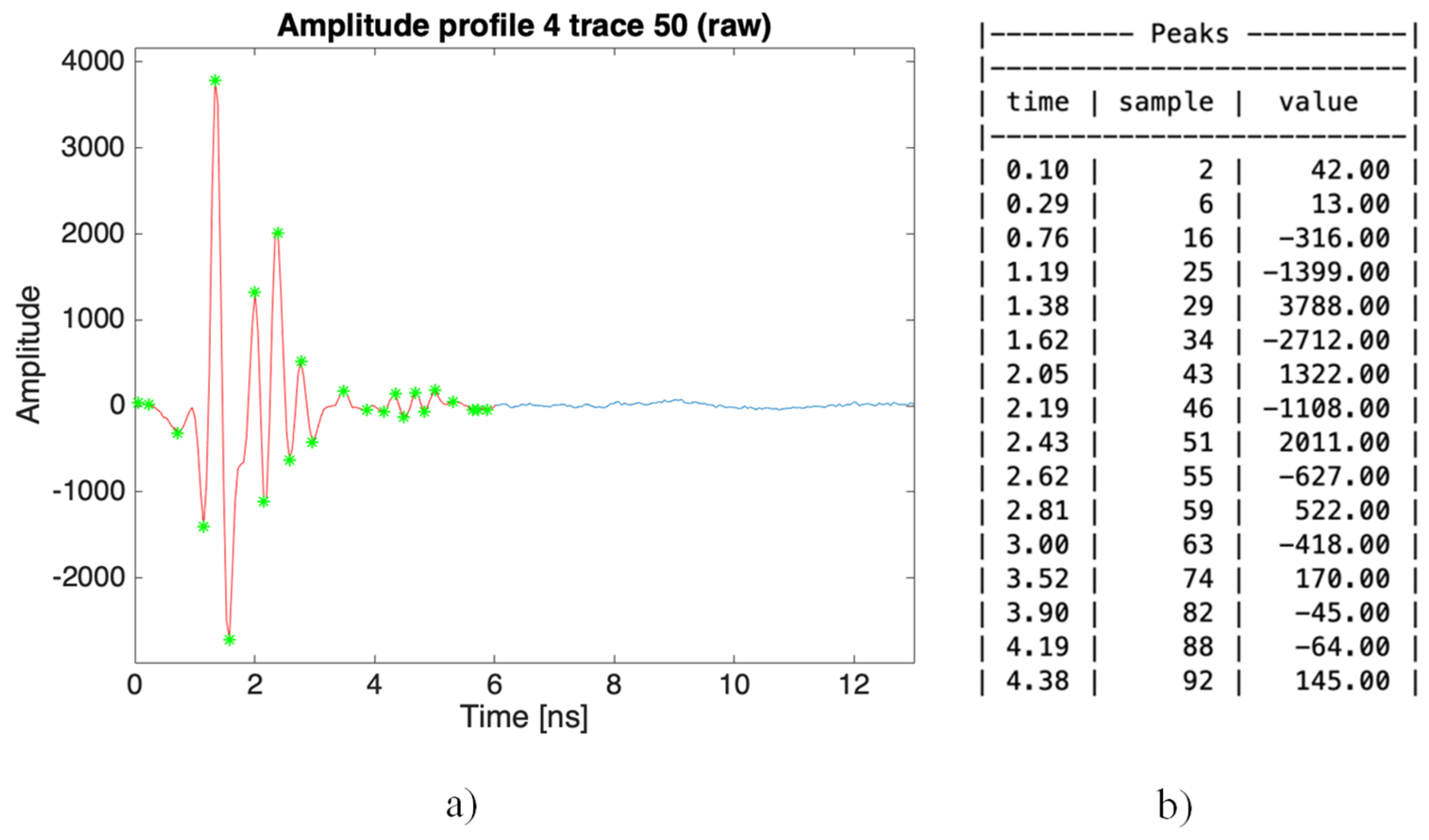

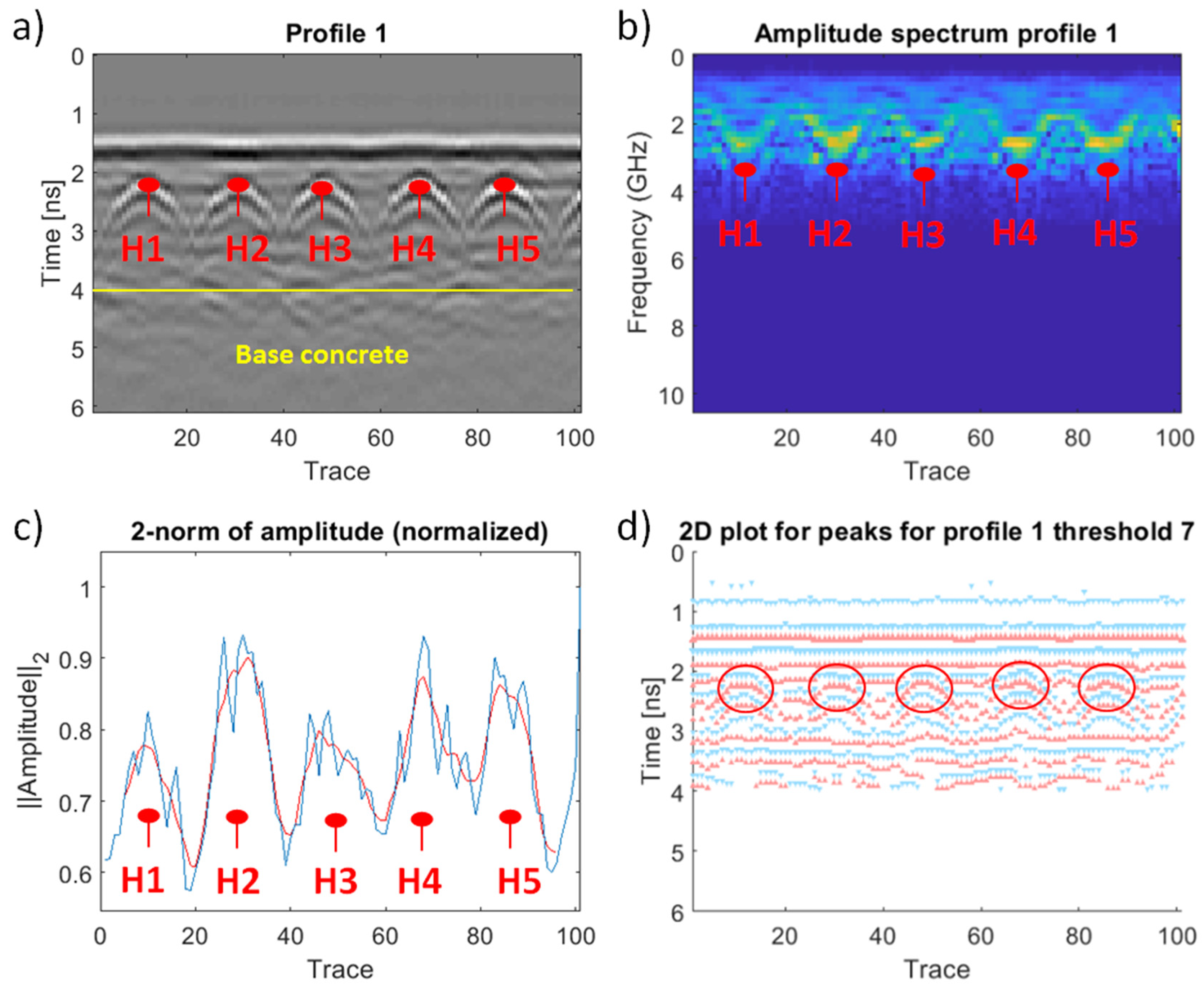

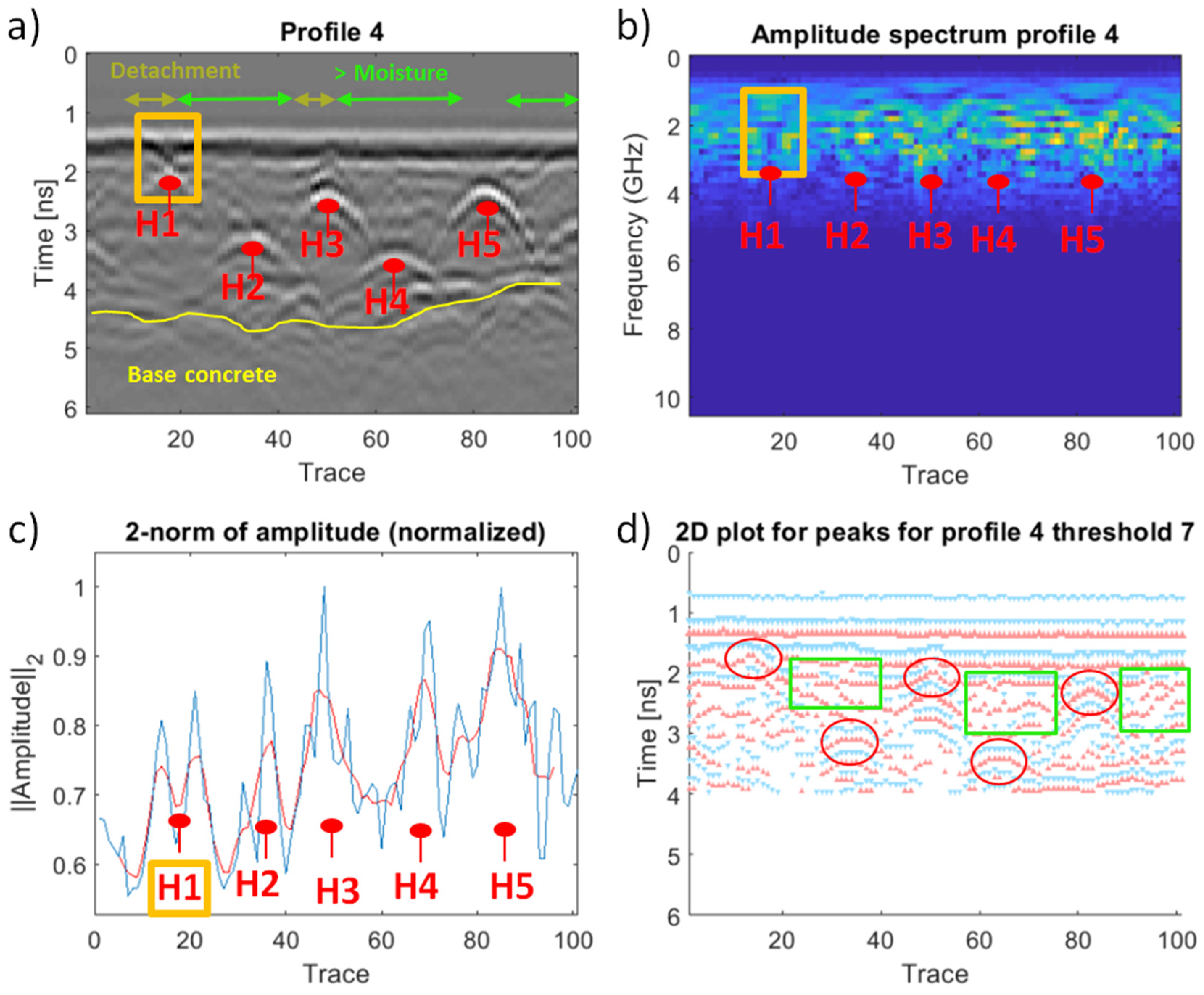

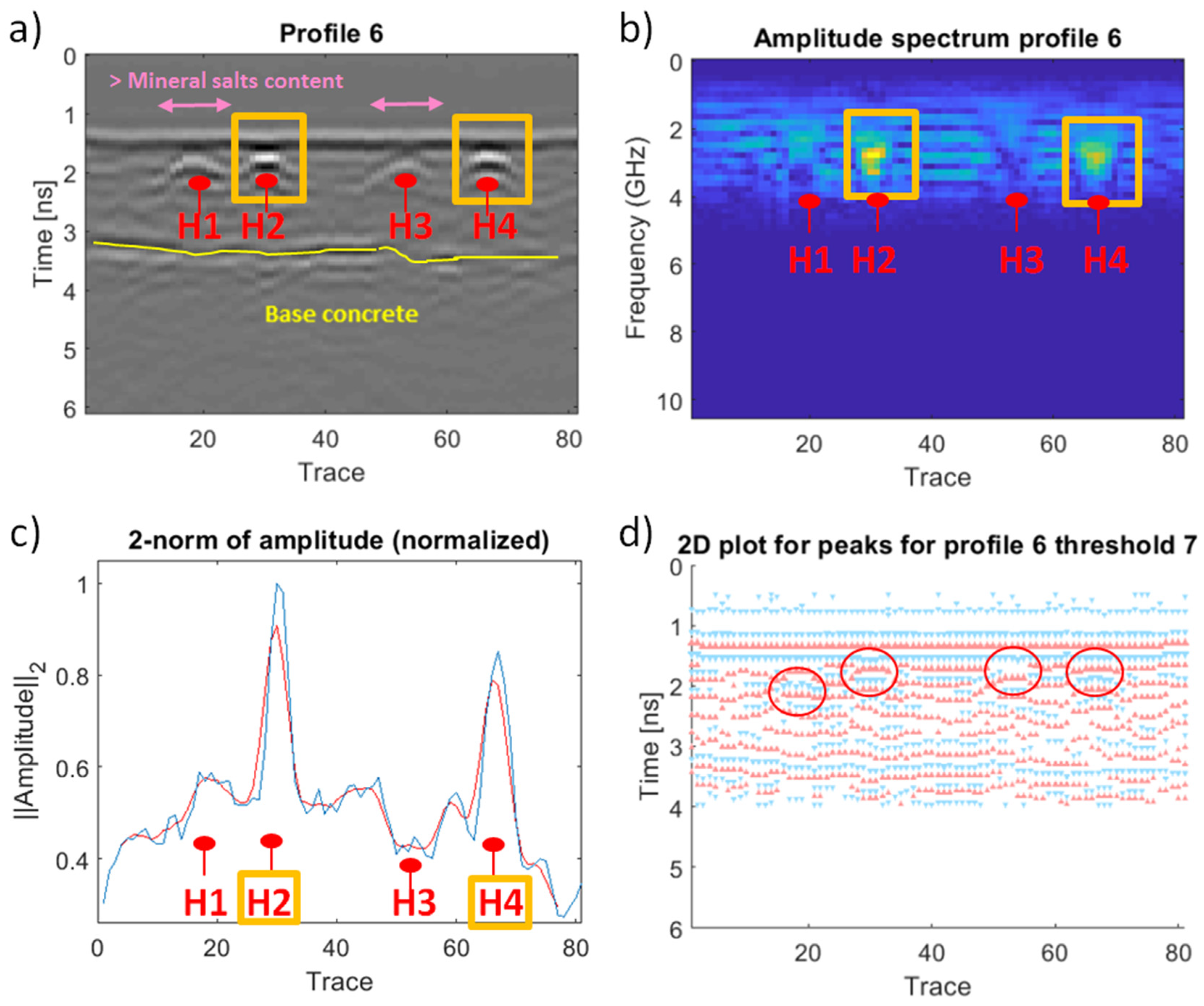

3.1. GPR Imaging and Data Interpretation

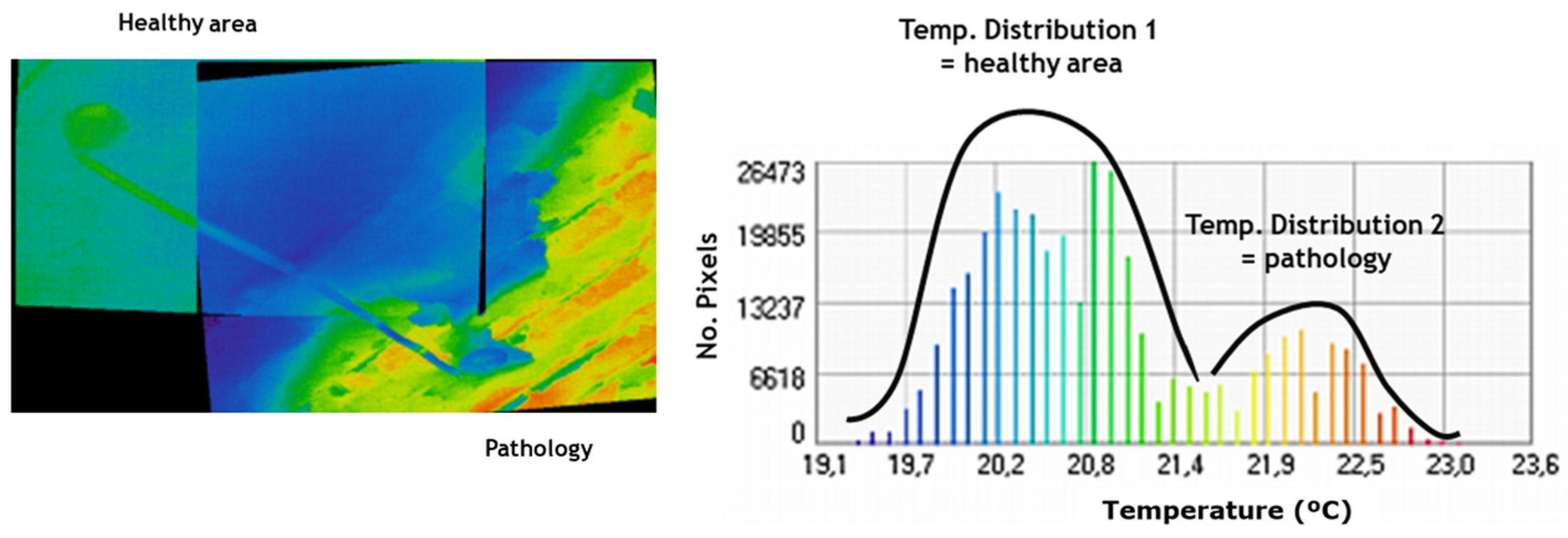

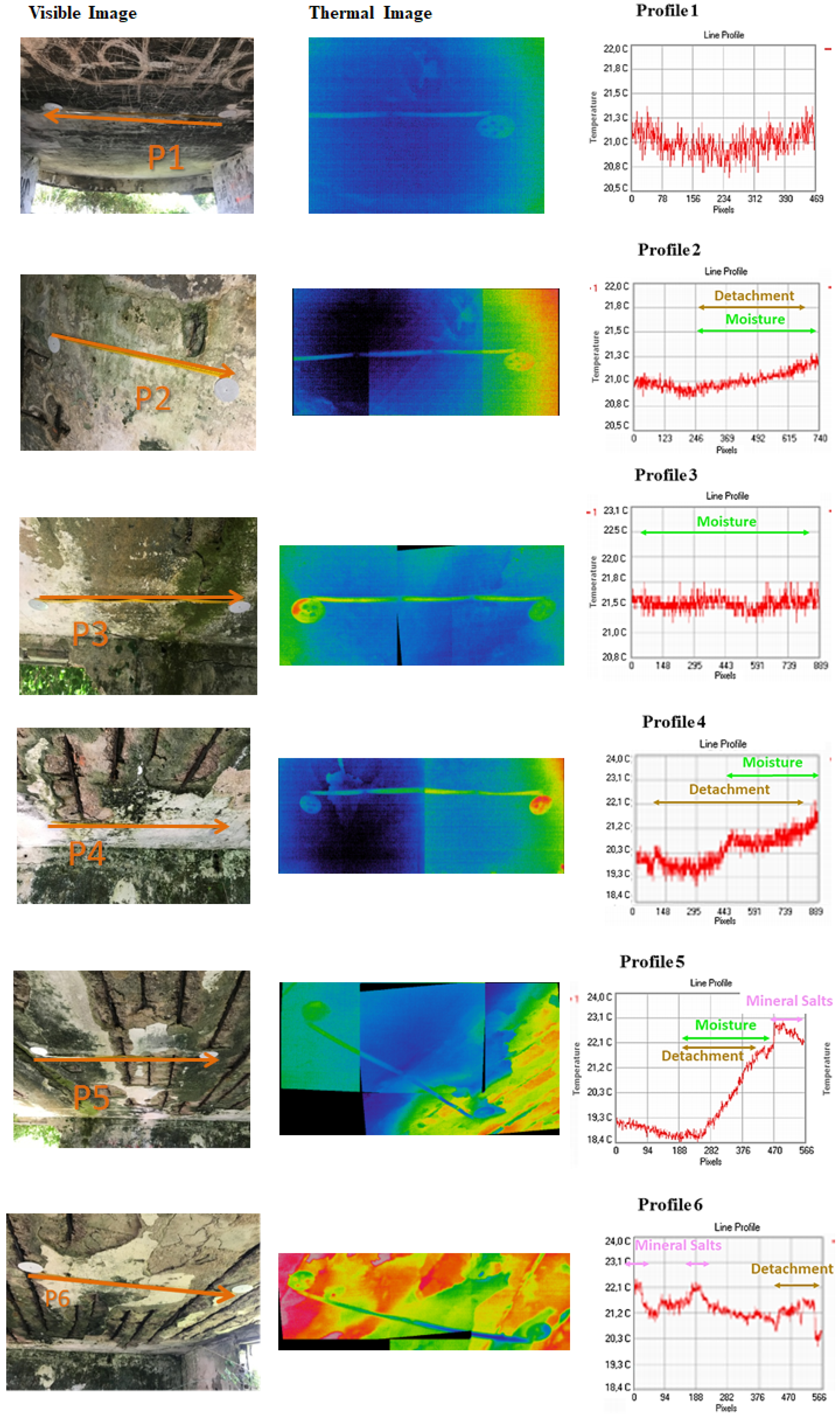

3.2. IRT Data Interpretation

3.3. Joint Interpretation of Both Techniques

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Ahmad, S. Reinforcement corrosion in concrete structures, its monitoring and service life prediction. Cem. Concr. Compos. 2003, 25, 459–471. [Google Scholar] [CrossRef]

- Ma, F.Y. Corrosive effects of chlorides on metals. Pitting Corros. 2012, 294, 139–178. [Google Scholar] [CrossRef]

- Alsharqawi, M.; Abu, S.; Zayed, T. Integrated condition rating and forecasting method for bridge decks using Visual Inspection and Ground Penetrating Radar. Autom. Constr. 2018, 89, 135–145. [Google Scholar] [CrossRef]

- Assouli, B.; Simescu, F.; Debicki, G.; Idrissi, H. Detection and identification of concrete cracking during corrosión of reinforced concrete by acoustic emission coupled to the electrochemical techniques. NDTE Int. 2005, 38, 682–689. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, S.; Sharma, S.; Mukherjee, A. Monitoring invisible corrosion in concrete using a combination of wave propagation techniques. Cem. Concr. Compos. 2018, 90, 89–99. [Google Scholar] [CrossRef]

- Zaki, A.; Chai, H.K.; Aggelis, D.G.; Alver, N. Nondestructive Evaluation for Corrosion Monitoring in Concrete: A review and Capability of Acoustic Emission Technique. Sensors 2015, 15, 19069–19101. [Google Scholar] [CrossRef] [PubMed]

- Klysz, G.; Balayssac, J. Determination of volumetric water content of concrete using ground-penetrating radar. Cem. Concr. Res. 2007, 37, 1145–1290. [Google Scholar] [CrossRef]

- Hong, S. GPR Based Periodic Monitoring of Reinforcement Corrosion in Chloride Contaminated Concrete. Ph.D. Thesis, Technische Universität, Berlin, Germany, 2015. [Google Scholar] [CrossRef]

- Hong, S.; Wai-Lok, H.; Wilsch, G.; Wiggenhauser, H.; Helmerich, R. Periodic mapping of reinforcement corrosion in intrusive chloride contaminated concrete with GPR. Constr. Build. Mater. 2014, 66, 671–684. [Google Scholar] [CrossRef]

- Hasan, M.I.; Yazdani, N. An experimental study for quantitative estimation of rebar corrosion in concrete using ground penetrating radar. J. Eng. 2016, 2016, 8. [Google Scholar] [CrossRef]

- Kabir, S.; Zaki, A. Detection and quantification of corrosion damage using ground penetrating radar (GPR). In Proceedings of the Progress in Electromagnetics Research Symposium (PIERS 2011), Marrakesh, Morocco, 20–23 March 2011. [Google Scholar]

- Barnes, C.L. State of the art bridge deck condition evaluation and management using Ground Penetrating Radar. In Proceedings of the Transportation Association of Canada, Montreal, QC, Canada, 30 September–1 October 2014. [Google Scholar]

- Karunanayake, K.T.S.; Dissanayake, P.B.R.; Galagedara, L.W. Ground penetrating radar wave behavior under different corrosion levels of concrete. In Proceedings of the 15th International Conference on Ground Penetrating Radar, Brussels, Belgium, 30 June–4 July 2014. [Google Scholar]

- Zamora, J.L.; Guerrero, C.N. Evaluación de la Aplicabilidad de la Técnica de la Termografía Infrarroja al Reconocimiento del Estado de Elementos de Hormigón. Master’s Thesis, Universitat Politécnica de Catalunya, Barcelona, Spain, 2013. [Google Scholar]

- Muñoz, N.; Marino, B.M.; Thomas, L.P. Characterization of the thermal behavior of a prototype building in Tandil (Buenos Aires). Scielo 2015, 26, 78–87. [Google Scholar] [CrossRef]

- Hong, S.; Wiggenhauser, H.; Helmerich, R.; Dong, B.; Dong, P.; Xing, F. Long-term monitoring of reinforcement corrosion in concrete using ground penetrating radar. Corros. Sci. 2017, 114, 123–132. [Google Scholar] [CrossRef]

- Cobîrzan, N.; Balog, A.; Belean, B.; Dədârlat, D.; Streza, M. Thermophysical properties of masonry units: Accurate characterization by means of photothermal techniques and relationship to porosity and mineral composition. Constr. Build. Mater. 2016, 105, 297–306. [Google Scholar] [CrossRef]

- Cadelano, G.; Bortolin, A.; Ferrarini, G.; Molinas, B.; Giantin, D.; Zonta, P.; Bison, P. Corrosion detection in pipelines using infrared thermography: Experiments and data processing methods. J. Nondestruct. Eval. 2016, 35, 49. [Google Scholar] [CrossRef]

- Mulaveesala, R.; Siddiqui, J.; Arora, V.; Dua, G.; Subbarao, G.; Muniyappa, A. Testing and evaluation of concrete structures by thermal wave imaging. Proc. SPIE 2015, 9485, 94850G. [Google Scholar] [CrossRef]

- Chulkov, A.; Vasilov, V. Comparing thermal stimulation techniques in infrared thermographic inspection of corrosion in steel. IOP Conf. Ser. Mater. Sci. Eng. 2015, 81, 012100. [Google Scholar] [CrossRef]

- Brooke, C. Thermal imaging for the archaeological investigation of historic buildings. Remote Sens. 2018, 10, 1401. [Google Scholar] [CrossRef]

- Chintakunta, S.; Boone, S. Nondestructive inspection protocol for reinforced concrete barriers and bridge railings. AIP Conf. Proc. 2014, 1581, 852–859. [Google Scholar] [CrossRef]

- Carlomagno, G.; Di Maio, R.; Fedi, M.; Meola, C. Integration of infrared thermography and high-frequency electromagnetic methods in archaeological surveys. J. Geophys. Eng. 2011, 8, 93–105. [Google Scholar] [CrossRef]

- Solla, M.; Lagüela, S.; González, H.; Arias, P. Approach to identify cracking in asphalt pavement using GPR and infrared thermographic methods: Preliminary findings. NDT E Int. 2014, 62, 55–65. [Google Scholar] [CrossRef]

- Lagüela, S.; Solla, M.; Vilariño, L.; Armesto, J. Inspection of radiant heating floor applying nondestructive testing techniques: GPR and IRT. DYNA 2015, 190, 221–226. [Google Scholar] [CrossRef]

- ReflexW Manual. Available online: http://www.sandmeier-geo.de (accessed on 27 July 2018).

- Garrido, I.; Lagüela, S.; Sfarra, S.; Madruga, F.; Arias, P. Automatic detection of moistures in different construction materials from thermographic images. J. Therm. Anal. Calorim. 2019, 1–20. [Google Scholar] [CrossRef]

- Annan, P. GPR Principles, Procedures and Applications; Sensors and Software Inc.: Mississauga, ON, Canada, 2003; p. 278. [Google Scholar]

- McGraw, D. The measurement of the dielectric constant of three different shapes of concrete blocks. Int. J. Recent Res. Appl. Stud. 2015, 25, 82–102. [Google Scholar]

- Park, B.; Kim, J.; Lee, J.; Kang, M.S.; An, Y.K. Underground object classification for urban roads using instantaneous phase analysis of Ground-Penetrating Radar (GPR) Data. Remote Sens. 2018, 10, 1417. [Google Scholar] [CrossRef]

- Paparrizos, J.; Gravano, L. K-Shape: Efficient and Accurate Clustering of Time Series. SIGMOD Record 2016, 45, 69–76. [Google Scholar] [CrossRef]

- Garrido, I.; Lagüela, S.; Suárez, L.; Arias, P. Machine Learning applied to infrared thermography: Detection, classification and delimitation of pathologies in infrastructures. Preliminary Results. In Proceedings of the 15th International Workshop on Advanced Infrared Technology and Applications, Firenze, Italy, 16–19 September 2019. [Google Scholar]

| GPR Profile | Length | Description | Image |

|---|---|---|---|

| 1 | 1 m | Zone without pathologies used as a reference |  |

| 2 | 1 m | Zone with high presence of moisture, fissuration, delamination, and calcium carbonate salts |  |

| 3 | 1 m | Moisture, fissuration, delamination, rust, and calcium carbonate salts |  |

| 4 | 1 m | Fractures, cracks, concrete detachment, spalling, corroded steel rebars, and calcium carbonate salts |  |

| 5 | 1 m | Moisture, concrete detachment, spalling, corroded steel rebars, rust, and calcium carbonate salts |  |

| 6 | 0.8 m | Moisture, concrete detachment, spalling, corroded steel rebars, and calcium carbonate salts |  |

| Filters | Parameters |

|---|---|

| Subtract-DC-Shift | Time window: 9–12 ns |

| Gain Function (Linear Exponential) | Linear: 1 & Exponential: 1 |

| Subtracting average | Traces: 250 |

| Bandpass (Butterworth) | Low cut: 500 MHz & High cut: 5000 MHz |

| H | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Profile 1 | Trace | 11 | 30 | 48 | 68 | 86 | ||||

| A | Peak 1 | −1732 | −1603 | −1869 | −2329 | −2188 | ||||

| Peak 2 | 2883 | 3016 | 3153 | 3285 | 3198 | |||||

| Peak 3 | −1269 | −1216 | −1391 | −1512 | −1577 | |||||

| twt (ns) | Peak 1 | 2.09 | 2.09 | 2.09 | 2.05 | 2.09 | ||||

| Peak 2 | 2.28 | 2.28 | 2.24 | 2.24 | 2.24 | |||||

| Peak 3 | 2.43 | 2.48 | 2.43 | 2.43 | 2.43 | |||||

| Profile 2 | Trace | 6 | 28 | 38 | 46 | 60 | 72 | 81 | 99 | |

| A | Peak 1 | −3271 | −3801 | 1102 | −1107 | 1807 | 1001 | −7482 | −923 | |

| Peak 2 | 5743 | 5735 | −1008 | 2100 | −2201 | −2492 | 6480 | 2387 | ||

| Peak 3 | −2637 | −2924 | 667 | −836 | 1952 | 2559 | −3270 | −1239 | ||

| twt (ns) | Peak 1 | 1.81 | 1.76 | 1.81 | 2.05 | 1.81 | 1.76 | 1.66 | 2.43 | |

| Peak 2 | 2.00 | 1.95 | 1.95 | 2.33 | 1.95 | 1.90 | 1.86 | 2.57 | ||

| Peak 3 | 2.19 | 2.14 | 2.14 | 2.57 | 2.14 | 2.05 | 2.05 | 2.76 | ||

| Profile 3 | Trace | 3 | 17 | 30 | 47 | 67 | 77 | 85 | 98 | |

| A | Peak 1 | −690 | −1699 | −423 | −3748 | −741 | 1986 | −1892 | −788 | |

| Peak 2 | 1645 | 3491 | 1019 | 4155 | 1216 | −2722 | 3636 | 1055 | ||

| Peak 3 | −790 | −1567 | −400 | −1778 | −713 | 2749 | −1467 | −495 | ||

| twt (ns) | Peak 1 | 2.57 | 1.81 | 2.71 | 1.71 | 2.76 | 1.76 | 1.85 | 2.9 | |

| Peak 2 | 2.76 | 1.95 | 2.90 | 1.90 | 3.00 | 1.95 | 2.05 | 3.09 | ||

| Peak 3 | 2.95 | 2.14 | 3.14 | 2.09 | 3.19 | 2.09 | 2.24 | 3.33 | ||

| Profile 4 | Trace | 18 | 36 | 50 | 63 | 82 | ||||

| A | Peak 1 | −2401 | −734 | −1108 | −711 | −1412 | ||||

| Peak 2 | −2015 | 1175 | 2011 | 745 | 2610 | |||||

| Peak 3 | 2110 | −845 | −627 | −284 | −928 | |||||

| twt (ns) | Peak 1 | 1.62 | 2.95 | 2.19 | 3.28 | 2.14 | ||||

| Peak 2 | 1.81 | 3.14 | 2.43 | 3.48 | 2.33 | |||||

| Peak 3 | 2.00 | 3.33 | 2.62 | 3.62 | 2.52 | |||||

| Profile 5 | Trace | 12 | 28 | 52 | 67 | 83 | ||||

| A | Peak 1 | −6486 | −5411 | −6126 | −5534 | −6145 | ||||

| Peak 2 | 5830 | 5037 | 3038 | 3706 | 3759 | |||||

| Peak 3 | −2982 | −2687 | −1079 | −1982 | −2234 | |||||

| twt (ns) | Peak 1 | 1.62 | 1.62 | 1.52 | 1.52 | 1.52 | ||||

| Peak 2 | 1.81 | 1.86 | 1.71 | 1.67 | 7.71 | |||||

| Peak 3 | 2.00 | 2.00 | 1.86 | 1.86 | 1.86 | |||||

| Profile 6 | Trace | 18 | 30 | 53 | 67 | |||||

| A | Peak 1 | −5827 | −8614 | −3748 | −8369 | |||||

| Peak 2 | 3674 | 8389 | 2778 | 7431 | ||||||

| Peak 3 | −1403 | −4962 | −588 | −3937 | ||||||

| twt (ns) | Peak 1 | 1.57 | 1.62 | 1.57 | 1.57 | |||||

| Peak 2 | 1.81 | 1.76 | 1.90 | 1.76 | ||||||

| Peak 3 | 2.05 | 1.95 | 2.09 | 1.90 | ||||||

| PROFILE | IMAGE 1 | IMAGE 2 | INTERPRETATION |

|---|---|---|---|

| Profile 1 |  |  | No pathologies are detected nor delimited |

| Profile 2 |  |  | Delimitation of detachment and moisture. The pathologies are considered as one, no differentiation is possible between them |

| Profile 3 |  |  | Constant moisture |

| Profile 4 |  |  | Moisture + detached areas in the surroundings of the profile |

| Profile 5 |  |  | Image 1—moisture Image 2—border of the concrete detachment, caused by the moisture detected. The contour of the mineral salts cannot be detected with the methodology, due to their low importance regarding the number of pixels in comparison with the moisture |

| Profile 6 |  |  | Image 1, 2—borders of concrete detachment, caused by moisture. Again, the contour of the mineral salts cannot be detected with the methodology due to their low importance regarding the number of pixels in comparison with the detachment |

| Anomalies | GPR | IRT |

|---|---|---|

| Visible rebars (corroded material) |

|

|

| Moisture |

|

|

| Mineral salts |

|

|

| Detachments |

|

|

| Voids |

|

|

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Solla, M.; Lagüela, S.; Fernández, N.; Garrido, I. Assessing Rebar Corrosion through the Combination of Nondestructive GPR and IRT Methodologies. Remote Sens. 2019, 11, 1705. https://0-doi-org.brum.beds.ac.uk/10.3390/rs11141705

Solla M, Lagüela S, Fernández N, Garrido I. Assessing Rebar Corrosion through the Combination of Nondestructive GPR and IRT Methodologies. Remote Sensing. 2019; 11(14):1705. https://0-doi-org.brum.beds.ac.uk/10.3390/rs11141705

Chicago/Turabian StyleSolla, Mercedes, Susana Lagüela, Norberto Fernández, and Iván Garrido. 2019. "Assessing Rebar Corrosion through the Combination of Nondestructive GPR and IRT Methodologies" Remote Sensing 11, no. 14: 1705. https://0-doi-org.brum.beds.ac.uk/10.3390/rs11141705