1. Introduction

Terrestrial laser scanning (TLS) is a remote sensing technique for high density acquisition of the physical surface of scanned objects, leading to the creation of accurate digital models. For this reason, the TLS technique is currently used in geologic surveys, engineering practice, cultural heritage, and mobile mapping [

1].

A time-of-flight TLS instrument is a laser rangefinder equipped with a radar-like beam orientation system where oscillating and rotating mirrors allow a fast scan of the observed surface. Long-range instruments (

i.e., instruments with range larger than 100 m) with pulse repetition frequency of 2.5–10 kHz or more are available, and instruments with 30–50 m range and pulse repetition frequency of 200 kHz also exist [

2]. The typical beam width of the available instruments is 0.15–0.25 mrad,

i.e., 0.009°–0.015°, whereas angular sampling steps up to 0.001° can be applied. In other words, a spot spacing (or sampling step) of ~1.8 mm at 100 m acquisition distance can be applied, but the corresponding footprint diameter can reach 20 mm, ten times higher. The actual spatial resolution of a TLS instrument,

i.e., its ability to detect two objects on adjacent lines-of-sight (LOSs), depends on both sampling step and laser beam width and is in-between them, as shown by several authors [

3,

4,

5]. The fact that the minimum sampling step can be much smaller than the beam width implies that a reliable evaluation of the spatial resolution is necessary in order to optimize the amount of acquired data and the corresponding acquisition time. If the sampling step is excessively low, a useless, excessively large amount of data could be acquired in an excessive amount of time, whereas if the sampling step is larger than the resolution, information loss can occur and an accurate modeling of some features of the observed object could be hard or impossible. In other words, the key factor is the choice of a sampling step able to ensure the required resolution.

Licthi and Jamtsho [

4] discussed this fact by evaluating the Effective Instantaneous Field of View (EIFOV) for some instruments by assuming that the probability governing the angular position of a range measurement is uniform over the projected laser footprint. Their results show that the higher constraint on EIFOV, which is assumed to be the spatial resolution, is due to the beam width. The distribution of the irradiance along a cross-section of a laser rangefinder beam is typically Gaussian. This fact does not necessarily imply that the corresponding probability governing the angular position is Gaussian itself, but a decrease of the effect of the beam width with respect to the case of uniform probability distribution could occur. On the other hand, [

5] observed a significant effect of the sampling step. Nevertheless, some assertions that can be read in some instrument brochures or in some papers [

6,

7], which simply identify the resolution with the sampling step, seem to be too optimistic. The Nyquist-Shannon sampling theorem [

8] implies that the spatial sampling frequency must be at least two times the maximum spatial frequency occurring in the observed surface. For this reason, ideally, the minimum size of the observable features should be two times the sampling step.

This paper presents the results of both numerical simulations and observations aimed to the optimization of a TLS survey at typical acquisition distances in architectural and cultural heritage application of TLS technique, i.e., up to about 100 m. In particular, an artificial target with differently spaced wood bricks has been scanned from 25 m, 50 m, 75 m and 100 m distance, the corresponding numerical simulations have been carried out and, finally, a brick wall and a historical building, with architectural details and a bust, have been observed. Besides the analysis of the obtained data, insights about the spot spacing necessary to obtain the required resolution (if achievable) in a general case are provided. This paper mainly focuses on evaluation of the sampling step necessary to obtain the required resolution. In this way, operational suggestions to the TLS practitioner are provided. An analysis of effects on the results of the material reflectance completes this study.

2. Laser Scanner Spatial Resolution

Two kinds of resolution can be defined for a TLS instrument: The range resolution, which accounts for its ability to differentiate two objects on the same LOS; and the angular resolution, which is the ability to distinguish two objects on adjacent LOSs. The first specification is governed by pulse length and typically is 3–4 mm for a long range instrument, whereas the second one depends on spatial sampling interval and laser beam width and should lead to a corresponding spatial resolution of ~10–15 mm at 50 m distance [

4]. Besides these specifications, also the intensity resolution,

i.e., the ability to differentiate adjacent areas, having similar but not equal reflectance, can be defined. In this paper the angular resolution, in particular the spatial resolution as a function of the acquisition distance, is the main topic.

In order to maximize the localization performance of a laser rangefinder, in particular of a TLS instrument, the geometry of the laser resonator is such that a Gaussian beam is generated [

9].

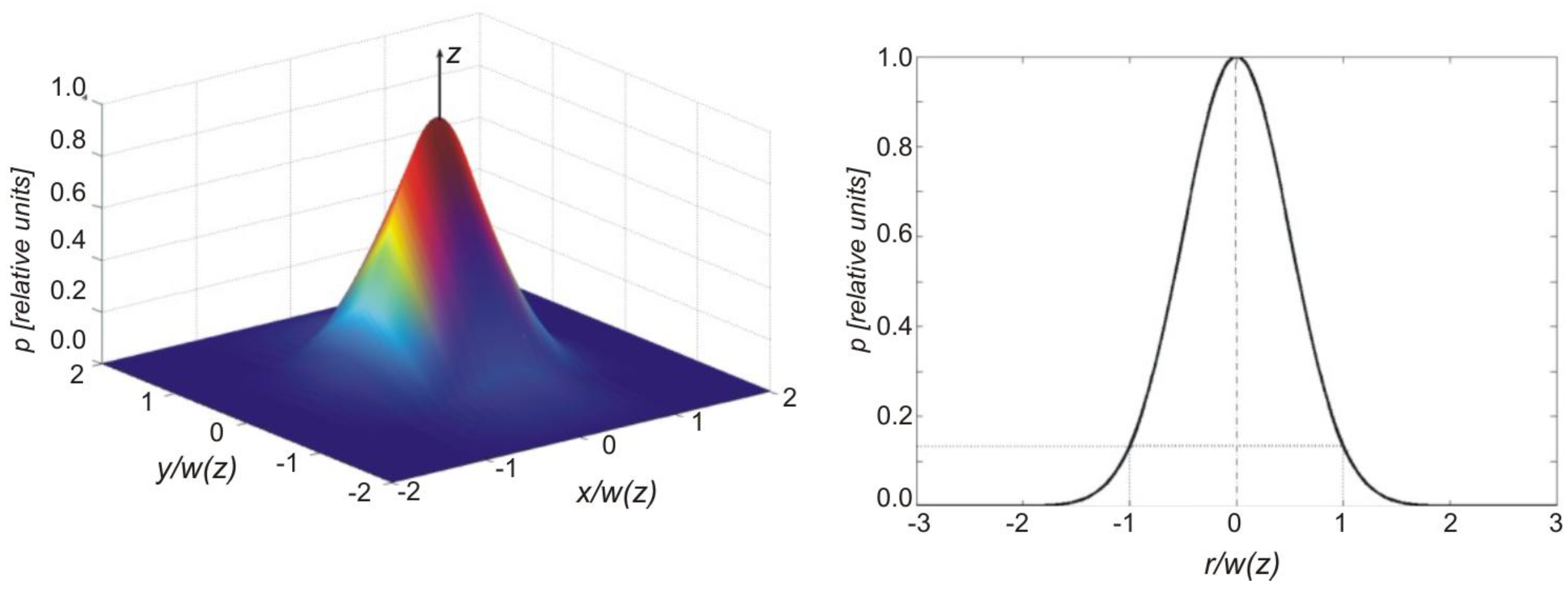

Figure 1 shows the power distribution of a Gaussian beam on a cross-section normal to the propagation direction. The beam diameter is commonly defined as the diameter that encircles 86% of the total beam power, that corresponds to

e−2 of the power axial value (with regard to the field amplitude, at the beam diameter it is

e−1 times the field axial value). Let

w0 be the waist of a Gaussian beam,

i.e., the minimum spot diameter. For a range

r and wavelength

λ, the beam width is

Clearly, it is

w0 =

w(0). The waist is related to the full divergence angle for the fundamental mode by

Besides

Θ, for a plane wave front incident upon a circular aperture of diameter

DF, which is the case in focusing optics, the full-cone angle of the central disc is defined:

This full-cone angle encircles about 84% of the total energy transmitted by the aperture. The angles

Θ and

Θp are very similar, but not equal, and are sometimes confused.

Figure 1.

Power distribution around the laser beam axis (left panel), where z indicates the propagation direction, and radial power profile (right panel). The x, y and radial coordinates are normalized to the beam width w(z), that corresponds to exp(−2) of the power axial value.

Figure 1.

Power distribution around the laser beam axis (left panel), where z indicates the propagation direction, and radial power profile (right panel). The x, y and radial coordinates are normalized to the beam width w(z), that corresponds to exp(−2) of the power axial value.

If

is sufficiently large, which is the case for a long range TLS, a linear approximation of (1) can be used. For example, in the case of Optech ILRIS-3D instrument, it is

where both the spot diameter

D(

r) = 2

w(

r) and the range

r are expressed in meters [

7]. The constant is negligible for

r larger than 300 m.

According to [

4], a good measure of the angular resolution of the instrument can be the EIFOV, which can be computed taking into account the Average Modulation Transfer Functions (AMTFs), see [

10], related to: (i) laser beam width; (ii) spatial sampling; (iii) quantization effects, (iv) focusing optics, where the latter in general can have negligible effects if the diameter of the optics is larger than the beam width. In general, the Modulation Transfer Function (MTF) is the magnitude of the Fourier transform of the point spread function and therefore is able to account for the response of an imaging system to an infinitesimal source of light. An AMTF is the spatially averaged MTF by assuming adequate probability density distributions of the independent variables, in this case the angular coordinates of a spherical reference frame. The AMTF of the whole system is the product of the component AMTFs (note that the variables in the Fourier space are spatial frequencies). Finally, the EIFOV is the length that corresponds to the cut-off spatial frequency threshold,

i.e., the frequency for which the whole system AMTF is 2/

π. To obtain a reliable EIFOV, reasonable hypotheses on the component AMTFs are necessary. With this very interesting approach, the authors obtained a resolution of 17.7 mm at 50 m for the ILRIS-3D instrument. Nevertheless, the practice of this instrument shows that 17.7 mm seems to be a too pessimistic value and that a ~10 mm value seems to be a better estimate for the instrumental resolution at 50 m distance if an adequate spatial sampling is used. Such a discrepancy could be related to the modeling of the beam width’s AMTF, where a uniform probability density function was assumed instead of a Gaussian one.

The EIFOV estimation is not in the scope of this paper, where the resolution is evaluated by means of numerical simulations and observation of an artificial target. The main aim of the paper is instead to search for a way to optimize the sampling step. Note that in all the studied cases, the observations are simulated or performed in normal incidence. If the incidence is not normal, the corresponding effects must be taken into account (e.g., elliptical spot instead of circular spot).

3. Numerical Simulations

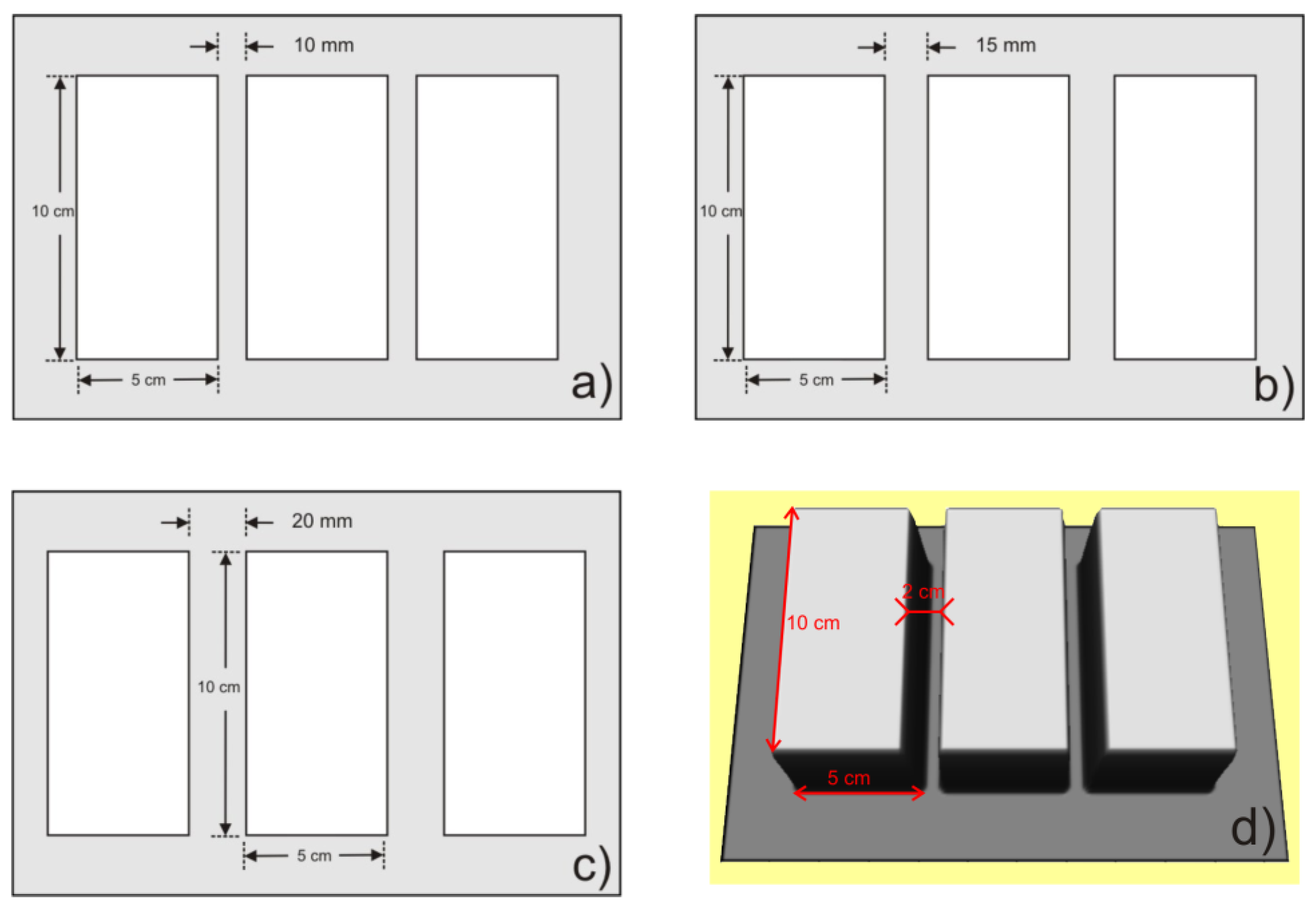

In order to evaluate the effects of sub-sampling and beam width, several series of numerical simulations have been carried out by defining virtual bricks having different spacing. As in the case of the artificial target described in

Section 4, each simulated brick has 100 mm length, 50 mm high and 18 mm visible width with respect to the cement joint, and three systems of parallel bricks are modeled, with 10 mm, 15 mm and 20 mm spacing respectively (

Figure 2). As in the experiments described in

Section 4, the simulations are related to 25 m, 50 m, 75 m and 100 m acquisition distances. To carry out the numerical simulations, it is necessary to model: (a) the geometry of the objects, and (b) the TLS-based observation of these objects. The calculations are performed in MATLAB environment.

The geometry of each system of bricks is represented by a 2.5D elevation model

zhk =

z(

xh,

yk), where

xh and

yk are defined on a regular grid with 0.1 mm spacing and whose plane is parallel to the simulated wall (

Figure 2). The indices

h and

k vary from 1 to

Nx and

Ny respectively, depending on the system size. For example, if the three bricks are 10 mm spaced and simulated together with a 30 mm edge around them, it is

Nx = 2300 and

Ny = 1600. This grid size is 1–2 orders of magnitude lower than the simulated sampling step (the minimum

ss taken into account in the simulations is 1 mm), spot size (the minimum spot size is 16.3 mm, that corresponds to 25 m acquisition distance) and brick spacing (the minimum value is 10 mm). For this reason, according to the Nyquist-Shannon sampling theorem [

8], such a grid does not affect the results and therefore is reasonable.

Figure 2.

Three synthetic targets related to: (a) 10 mm, (b) 15 mm, and (c) 20 mm brick spacing respectively. (d) 3D view of the 20 mm spaced bricks case.

Figure 2.

Three synthetic targets related to: (a) 10 mm, (b) 15 mm, and (c) 20 mm brick spacing respectively. (d) 3D view of the 20 mm spaced bricks case.

The TLS acquisitions are modeled according to the technical specifications of ILRIS-3D instrument (

Table 1) by means of: (i) Generation of Gaussian noise to model the error of the TLS’ rangefinder unit; (ii) Introduction of a Gaussian filter to model the effect of the power distribution of the laser beam; (iii) Decimation of the obtained points to model the spatial sampling.

Table 1.

Optech ILRIS-3D main technical specifications.

Table 1.

Optech ILRIS-3D main technical specifications.

| Parameter | Value | Unit | Condition |

| Wavelength | 1,535 (infrared) | nm | - |

| Laser class | 1M | | - |

| Pulse repetition frequency | 2.5 a | kHz | - |

| Field of view | 40 × 40 b | ° | - |

| Minimum range | 3 c | m | - |

| Maximum range | 1,500 | m | 80% target reflectivity |

| 800 | m | 20% target reflectivity |

| 350 | m | 4% target reflectivity |

| Rangefinder unit accuracy | 7 | mm | 100 m distance |

| Rangefinder unit resolution | 4 | mm | 100 m distance |

| Laser beam divergence | 0.17 d | mrad | - |

| Spot diameter | 20.5 | mm | 100 m distance |

| Single point accuracy | 8 | mm | 100 m distance |

| Modeling accuracy | 3 | mm | 100 m distance |

| Minimum angular spot spacing | 0.02 | mrad | - |

| Minimum spot spacing | 2 | mm | 100 m distance |

The effect of the uncertainties, due to the rangefinder unit, is modeled by means of Gaussian noise with 5 mm standard deviation (SD). The elevation of the

hkth point therefore is

znhk =

zhk +

nhk), where

nhk is a random entry coming from the probability density function

i.e., the Gaussian centered at

zhk with SD

σ = 5 mm. The chosen SD comes from both the ILRIS-3D technical specifications and the comparison between the results of numerical simulations and observations of the artificial target.

As stated above, the power distribution of a TLS laser beam generally has Gaussian profile. In the case of ILRIS-3D instrument, this fact is also confirmed by [

11]. For each point (

xh,

yk,

znhk), a Gaussian filter with standard deviation equal to the beam radius,

i.e.,

with reference to Equation (4), is therefore introduced to blur the model. The filter equation for the

hkth point is

and is used to obtain the blurred elevation

zbhk by means of the equation

where

Nb = 3

D/(2

gs), with

gs = 0.1 mm (reference grid spacing). In other words, the weighted averages in Equation (7) are computed within three SDs and, in this way, the fact that all the points within the spot concur to the pulse reflection is taken into account. Equation (7) is implemented in MATLAB in a very efficient way by means of the ‘fspecial’ function that performs the 2D special filtering.

Finally, the points of the noised and filtered model are decimated in order to simulate the spatial sampling of a TLS instrument. In these calculations the sampling steps 1 mm, 2 mm, etc., up to 20 mm are used. For each acquisition distance, 20 simulations are therefore carried out. The model is very simple, but the technical data provided by the instrument manufacturer do not allow a more sophisticated modeling.

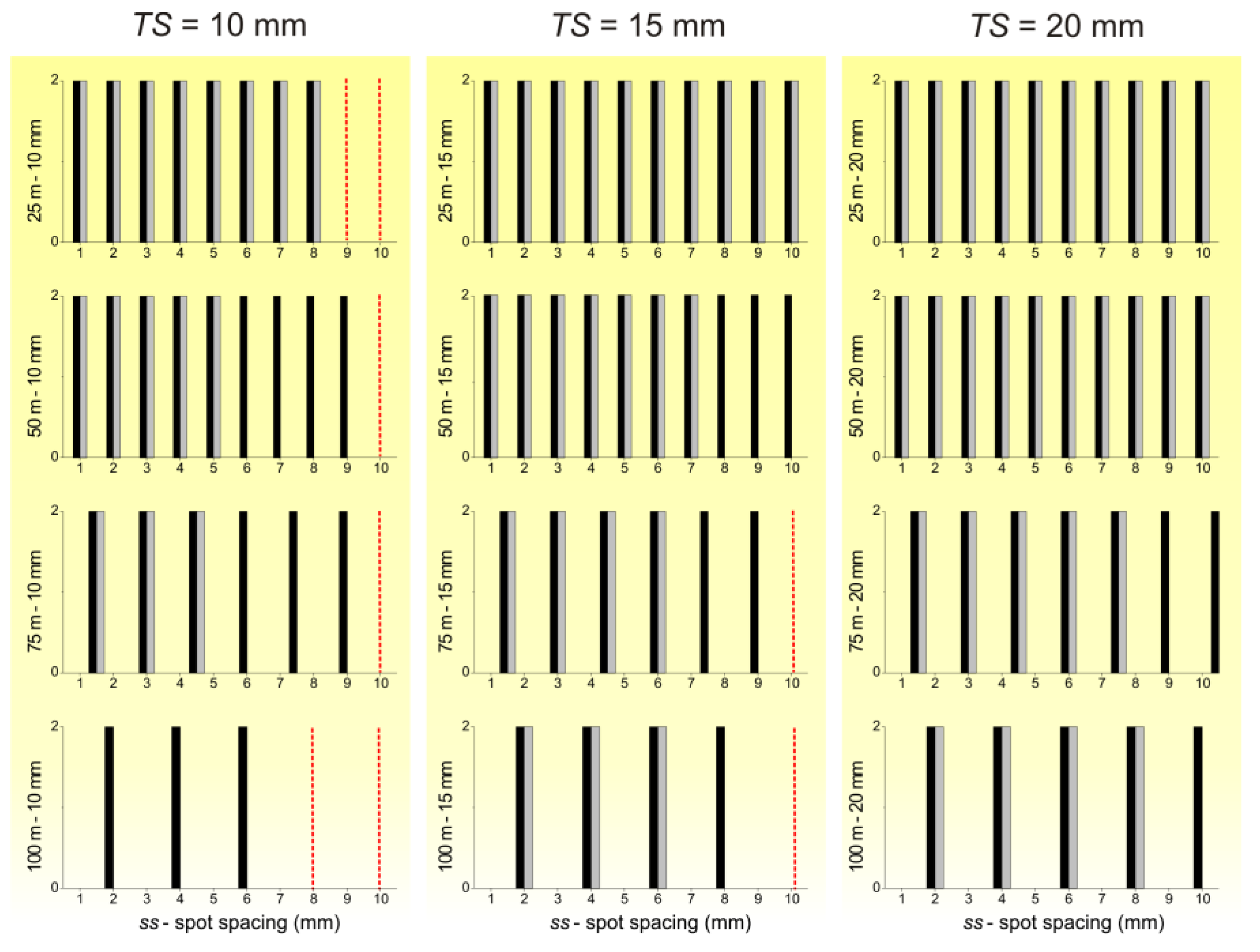

The results for some selected cases are shown in

Figure 3, and the main results are summarized in

Table 2. In this table, in particular, the cases where two different bricks can be easily recognized as distinct objects are shown together with the cases where the recognition is very difficult (borderline cases, corresponding to object spacing like the spatial resolution) and the ones where no recognition as a distinct object can be performed because the object spacing is below the spatial resolution. If a typical notebook with a 32 bit operating system is used, the simulation for an assigned acquisition distance is carried out in a few seconds, and all the results presented here can be obtained in a few minutes. This fact confirms that the 0.1 mm spacing for the reference matrix is a good choice.

Figure 3.

Targets modeled from simulated point clouds at 50 m range. Besides the depicted case, the simulations at the 25 m, 75 m and 100 m modeled distances have been performed.

Figure 3.

Targets modeled from simulated point clouds at 50 m range. Besides the depicted case, the simulations at the 25 m, 75 m and 100 m modeled distances have been performed.

Table 2.

Qualitative results of the target detection at 25, 50, 75 and 100 m. Legend: ss: spatial sampling; 2: recognition of two simulated bricks as distinct objects is easy; 1: borderline recognition cases, i.e., recognition difficult; 0: recognition not possible.

Table 2.

Qualitative results of the target detection at 25, 50, 75 and 100 m. Legend: ss: spatial sampling; 2: recognition of two simulated bricks as distinct objects is easy; 1: borderline recognition cases, i.e., recognition difficult; 0: recognition not possible.

| 25 m distance—synthetic | 50 m distance—synthetic |

| ss (mm) | Brick spacing (mm) | ss (mm) | Brick spacing (mm) |

| 10 mm | 15 mm | 20 mm | 10 mm | 15 mm | 20 mm |

| 1 | 2 | 2 | 2 | 1 | 2 | 2 | 2 |

| 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 3 | 2 | 2 | 2 | 3 | 2 | 2 | 2 |

| 4 | 2 | 2 | 2 | 4 | 2 | 2 | 2 |

| 5 | 2 | 2 | 2 | 5 | 2 | 2 | 2 |

| 6 | 2 | 2 | 2 | 6 | 2 | 2 | 2 |

| 7 | 2 | 2 | 2 | 7 | 1 | 2 | 2 |

| 8 | 1 | 2 | 2 | 8 | 1 | 1 | 2 |

| 9 | 0 | 1 | 2 | 9 | 1 | 1 | 1 |

| 10 | 0 | 1 | 1 | 10 | 0 | 1 | 1 |

| 75 m distance—synthetic | 100 m distance—synthetic |

| ss (mm) | Brick spacing (mm) | ss (mm) | Brick spacing (mm) |

| 10 mm | 15 mm | 20 mm | 10 mm | 15 mm | 20 mm |

| 1.5 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 3 | 2 | 2 | 2 | 4 | 2 | 2 | 2 |

| 4.5 | 2 | 2 | 2 | 6 | 1 | 1 | 2 |

| 6 | 1 | 2 | 2 | 8 | 0 | 1 | 1 |

| 7.5 | 1 | 1 | 2 | 10 | 0 | 0 | 1 |

| 9 | 1 | 1 | 1 | |

| 10.5 | 0 | 0 | 1 |

Since these simulations allow an evaluation of the effects on spatial resolution of changes in beam width and in spatial sampling, they can be used to simulate the behavior of an instrument on the basis of its technical specifications. In particular, the results could be used for choosing instrument type for a specific application. Finally, the MATLAB scripts developed to perform the numerical simulations can be requested from the authors, see contact information.

5. Discussion and Conclusions

The long range TLS instruments generally work at ranges from a couple of ten meters to some hundreds of meters, and are characterized by a laser beam whose diameter linearly increases along with the distance. The chosen spot spacing is generally smaller than the spot diameter providing a partial spot overlap. In the case of Optech ILRIS-3D, for example, a ratio between spot diameter (D) and spot spacing (ss) equal to 10 can be set. However, the actual resolution of a point cloud depends on both D and ss. Numerical modeling and experiments were carried out in order to study the ability of the ILRIS-3D instrument in surface shape details capturing for ranges lower than or equal to 100 m. The analyses described here were driven by the necessity of planning a series of TLS surveys in the city of Bologna, therefore for architectural survey and cultural heritage purposes. To carry out these surveys in an efficient way, a knowledge of the actual limitations imposed by ss and D on the target detection was very important. An approach to sampling step optimization in a TLS survey, aimed to reliably estimate the maximum sampling step that can be used to warrant the acquisition of a surface with the desired level of detail, was therefore developed. In other words, the aim was the computation of the optimal ratio between the sampling step and the desired resolution, since a larger sampling step with the same amount of information leads to less acquisition time.

The results show that the resolution estimates provided by [

4] seem to be quite pessimistic. For example, at 50 m distance their estimate for ILRIS-3D instrument is 17.7 mm, but the experimental and numerical results obtained here show that a 10 mm interstice between two bricks can be easily acquired and modeled for such an acquisition distance. On the other hand, too optimistic affirmations can also be found, as in the case of [

6], which identifies the resolution with the sampling step thanks to the correlated sampling,

i.e., the sampling with overlapped laser spots. If a 0.9 mm sampling step is used at 50 m acquisition distance,

i.e., the minimum possible ILRIS-3D spot spacing at such a distance, according to [

6], this should lead to a point cloud with a similar resolution, but this is incorrect. The resolution is 10 mm instead and can be achieved by applying a 5.0 mm sampling step (

ss/

TS = 0.5). If the approach suggested by [

6] is used, a larger amount of data is acquired in a time correspondingly 30 times higher, without any gain in the actual amount of acquired information.

A very interesting result is that an empirical relation between the range and the

ss/

TS ratio exists, Equation (8). With this equation, or the corresponding

Table 5, the user can settle the optimal sampling step,

ss, for which a required object separation,

TS, is obtained. The equation holds for ILRIS-3D instrument, but the proposed method can easily be applied to other instruments to obtain the corresponding empirical equations. The method has a general validity, since the physical processes involved in the TLS-based acquisition are the same for each time-of-flight instrument, but a data fit based on the specific characteristics of the used instrument is necessary. The comparison between the experimental data and the simulation results shows that from the beam width and the sampling step, and assuming reliable noise levels, a relatively accurate estimation of the spatial resolution as well as of the optimal

ss/

TS ratio can be carried out. In this way, a user can evaluate the required sampling step for the available instrument, or can choose between two or more instruments for a specific observation if they are available. The fact that the obtained empirical law is related to a simple geometry of the target should be noted. This is an ideal limit for surveying and therefore the corresponding

ss/

TS values are insuperable thresholds. If a

ss/

TS value larger than this threshold is set, surely the required resolution is not achieved. Nevertheless, in the case of a complex surface, the sampling step should be ~10% shorter than the threshold, as shown in the case of the historical building observation.

The experiments and the numerical simulations deal with acquisition distances up to 100 m, and the results could not be directly extrapolated to significantly longer distances. Other experiments, with artificial targets having different shapes and sizes, will be carried out in order to extend the results at distances up to one kilometer. Moreover, other experiments are planned to study the real relation between r and D for some commercially available long range TLS instruments.

The fact that the model resolution is beyond the scope of this paper should be noted. Although the final result of a TLS survey is sometimes a digital model, this study deals with instrumental performance, in particular spatial resolution, not with model resolution. If the modeling of sharp features like edges, thin tubes, wires and others is necessary, the obtained ss/TS values could be overestimated because a more adequate number of points would be required.