Comparison of Flow Injection-MS/MS and LC-MS/MS for the Determination of Ochratoxin A

Abstract

:1. Introduction

2. Results and Discussion

2.1. Recovery Study

2.2. Instrument Limit of Quantitation

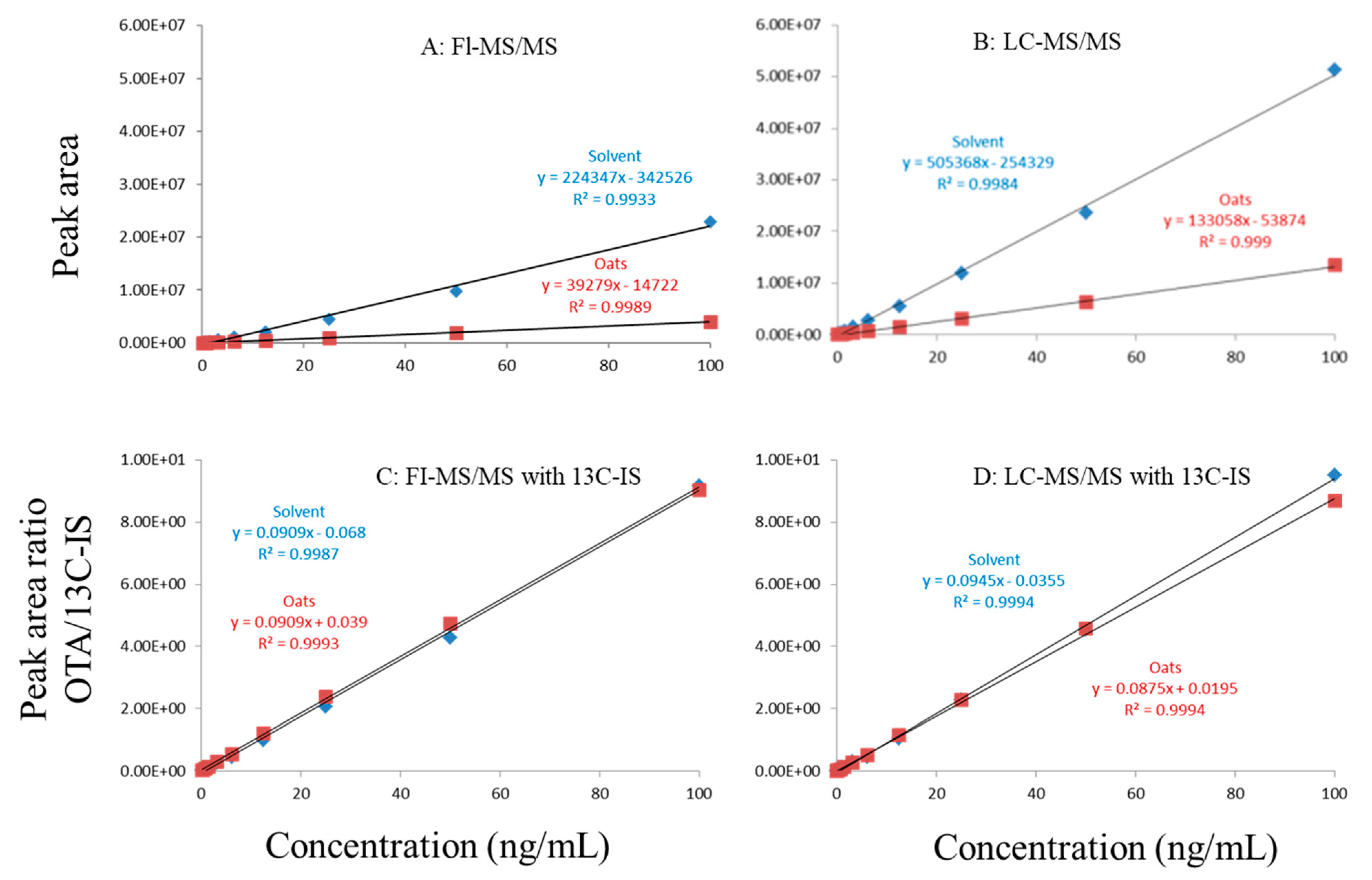

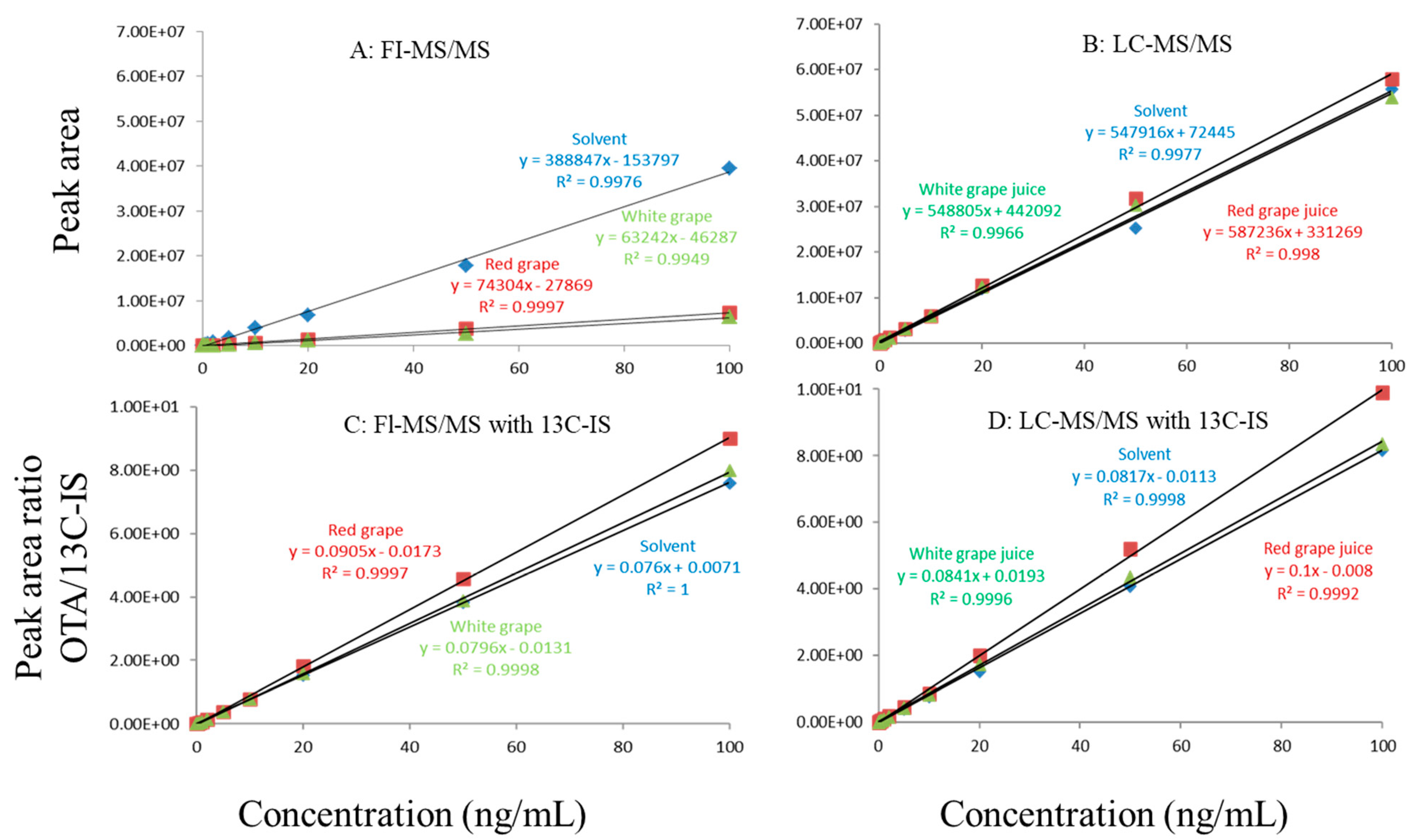

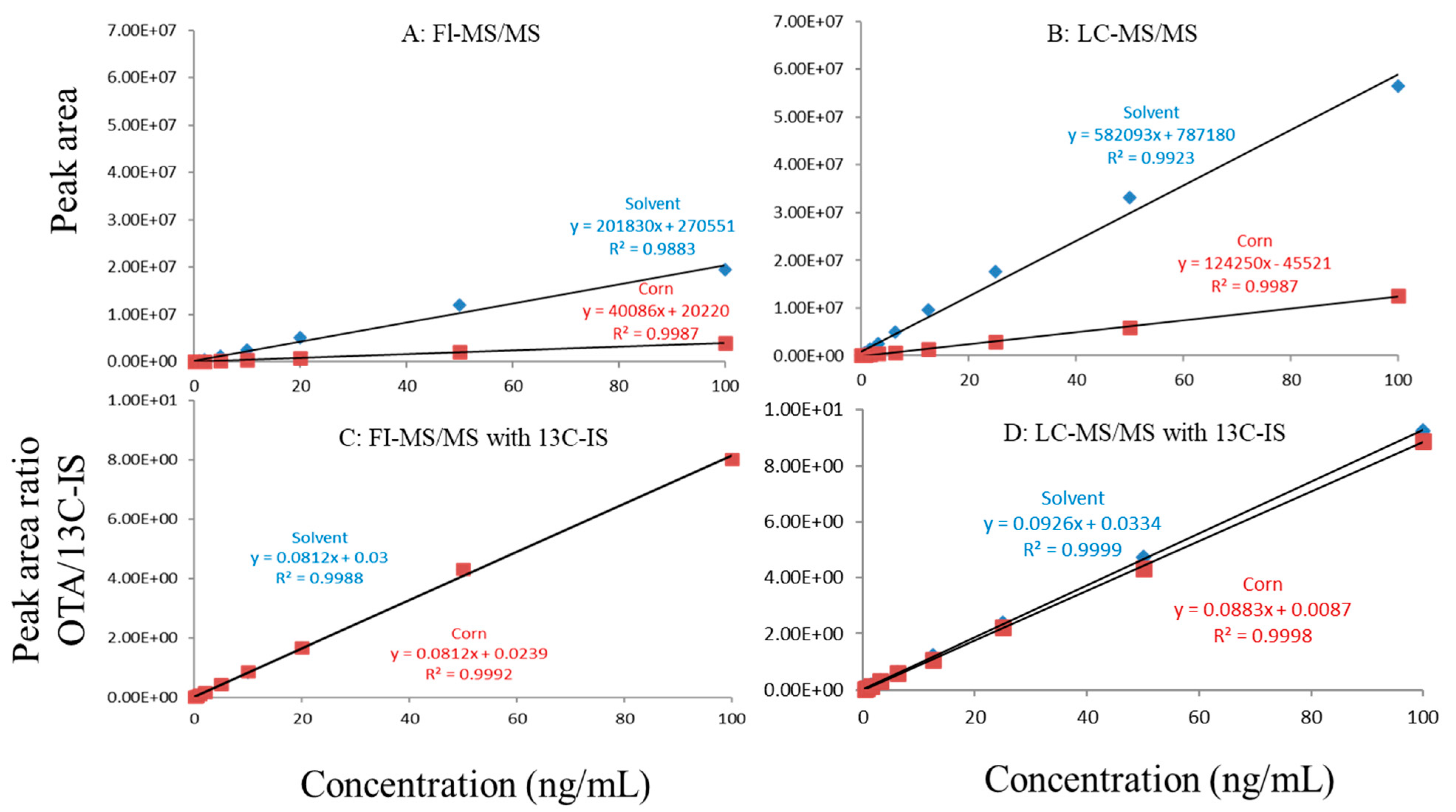

2.3. Evaluation of Matrix Effects

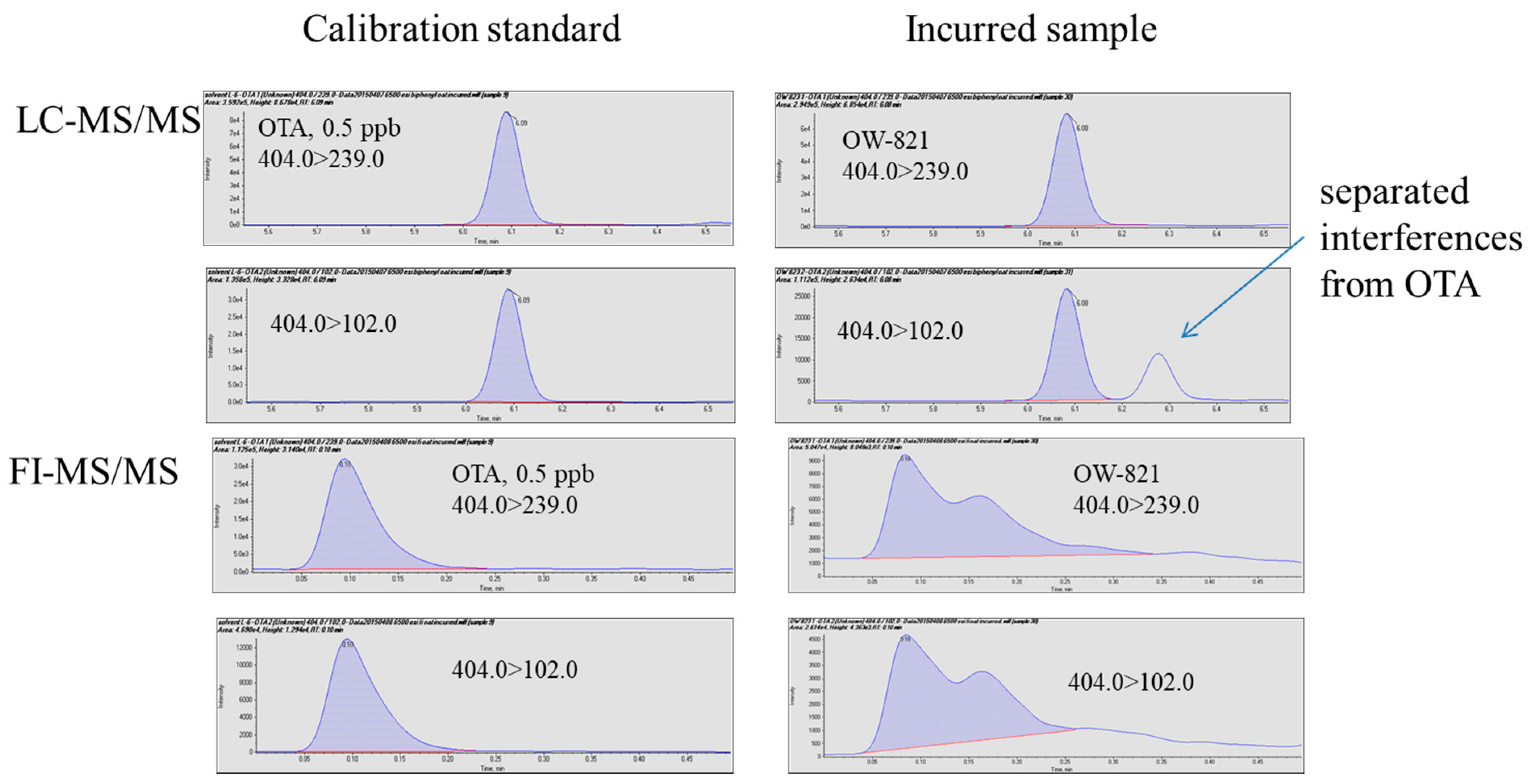

2.4. Analysis of Incurred Samples

3. Conclusions

4. Materials and Methods

4.1. Sample Preparation

4.2. Recovery Studies

4.3. LC-MS/MS Analysis

4.4. Flow Injection MS-MS Analysis

4.5. Matrix Effects

4.6. Matrix-Dependent Instrument Limit of Detection

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Palumbo, J.D.; O’Keeffe, T.L.; Ho, Y.S.; Santillan, S.J. Occurrence of ochratoxin a contamination and detection of ochratoxigenic Aspergillus species in retail samples of dried fruits and nuts. J. Food Prot. 2015, 78, 836–842. [Google Scholar] [CrossRef] [PubMed]

- Duarte, S.C.; Pena, A.; Lino, C.M. A review on ochratoxin A occurrence and effects of processing of cereal and cereal derived food products. Food Microbiol. 2010, 27, 187–198. [Google Scholar] [CrossRef]

- Lai, X.W.; Liu, R.C.; Ruan, C.Q.; Zhang, H.; Liu, C.L. Occurrence of aflatoxins and ochratoxin A in rice samples from six provinces in China. Food Control 2015, 50, 401–404. [Google Scholar] [CrossRef]

- Cappozzo, J.; Jackson, L.; Lee, L.H.; Zhou, W.; Al-Taher, F.; Zweigenbaum, J.; Ryu, D.J. Occurrence of Ochratoxin A in Infant Foods in the United States. J. Food Prot. 2017, 80, 251–256. [Google Scholar] [CrossRef]

- Imperato, R.; Campone, L.; Piccinelli, A.L.; Veneziano, A.; Rastrelli, L. Survey of aflatoxins and ochratoxin a contamination in food products imported in Italy. Food Control 2011, 22, 1905–1910. [Google Scholar] [CrossRef]

- Kumar, R.; Ansari, K.M.; Saxena, N.; Dwivedi, P.D.; Jain, S.K.; Das, M. Detection of Ochratoxin A in wheat samples in different regions of India. Food Control 2012, 6, 63–67. [Google Scholar] [CrossRef]

- Malir, F.; Ostry, V.; Novotna, E. Toxicity of the mycotoxin ochratoxin A in the light of recent data. Toxin Rev. 2013, 32, 19–33. [Google Scholar] [CrossRef]

- Pohland, A.E.; Nesheim, S.; Friedman, L. Ochratoxin A: A review (Technical Report). Pure Appl. Chem. 1992, 64, 1029–1046. [Google Scholar] [CrossRef]

- EFSA Opinion of the scientific panel on contaminants in the food chain on request from the commission related to ochratoxin A in food. EFSA J. 2006, 365, 1–56.

- Leblanc, J.C.; Nebbia, C.S.; Nielsen, E.; Ntzani, E.; Petersen, A.; Sand, S.; Schwerdtle, T.; Vleminckx, C.; Wallace, H.; Alexander, J.; et al. Risk assessment of ochratoxin A in food. EFSA J. 2020, 18, 6113–6263. [Google Scholar]

- Qi, X.Z.; Yang, X.; Chen, S.Y.; He, X.Y.; Dweep, H.; Guo, M.Z.; Cheng, W.H.; Xu, W.T.; Luo, Y.B.; Gretz, N.; et al. Ochratoxin A induced early hepatotoxicity: New mechanistic insights from microRNA, mRNA and proteomic profiling studies. Sci. Rep. 2014, 4, 5163. [Google Scholar] [CrossRef] [Green Version]

- IARC. Some naturally occurring substances: Food items and constituents, heterocyclic aromatic amines and mycotoxins; Ochratoxin A. In IARC Monographs on the Evaluation of Carcinogenic Risks to Humans; International Agency for Research on Cancer: Lyon, France, 1993; Volume 56, pp. 489–521. [Google Scholar]

- Aydin, G.; Ozcelik, N.; Cicek, E.; Soyoz, M. Histopathologic changes in liver and renal tissues induced by Ochratoxin A and melatonin in rats. Hum. Exp. Toxicol. 2003, 22, 383–391. [Google Scholar] [PubMed]

- Creppy, E.E.; Chiarappa, P.; Baudrimont, I.; Borracci, P.; Moukha, S.; Carratù, M.R. Synergistic effects of fumonisin B1 and ochratoxin A: Are in vitro cytotoxicity data predictive of in vivo acute toxicity? Toxicology 2004, 201, 115–123. [Google Scholar] [CrossRef] [PubMed]

- Pfohl-Leszkowicz, A.; Manderville, R.A. Ochratoxin A: An overview on toxicity and carcinogenicity in animals and humans. Mol. Nutr. Food Res. 2007, 51, 61–99. [Google Scholar] [CrossRef]

- Stoev, S.D.; Stefanov, M.; Denev, S. Experimental mycotoxicosis in chickens induced by ochratoxin A and penicillic acid and intervention with natural plant extracts. Vet. Res. Commun. 2004, 28, 727–746. [Google Scholar] [CrossRef]

- Scudamore, K.A.; Banks, J.; MacDonald, S.J. Fate of ochratoxin A in the processing of whole wheat grains during milling and bread production. Food Addit. Contam. 2003, 20, 1153–1163. [Google Scholar] [CrossRef]

- Worldwide regulations for mycotoxins in food and feed in 2003. In FAO Food and Nutrition Paper 81; Food and Agricultural Organization of the United Nations: Rome, Italy, 2004.

- COMMISSION REGULATION (EC) No 1881/2006 19. COMMISSION REGULATION (EC) No 1881/2006 of 19 December 2006 Setting Maximum Levels for Certain Contaminants in Foodstuffs. Available online: http://extwprlegs1.fao.org/docs/pdf/eur68134.pdf (accessed on 28 June 2021).

- National Health Commission of the People’s Republic of China. GB 2761-2017 Maximum Levels of Mycotoxins in Foods. Available online: http://www.nhc.gov.cn/cms-search/xxgk/getManuscriptXxgk.htm?id=b83ad058ff544ee39dea811264878981 (accessed on 28 June 2021).

- Food Safety and Standards Authority of India. Food Safety and Standards (Contaminants, Toxins and Residues) Regulation. 2011. Available online: https://www.fssai.gov.in/upload/uploadfiles/files/Contaminants_Regulations.pdf (accessed on 28 June 2021).

- U.S. FDA Compliance Program Guidance manual. Chapter 07. Molecular Biology and Natural Toxins, 7307.001. Available online: https://www.fda.gov/media/140749/download (accessed on 28 June 2021).

- Barna-Vetró, I.; Solti, L.; Téren, J.; Gyöngyösi, A.; Szabó, E.; Wölfling, A. Sensitive ELISA Test for Determination of Ochratoxin A. J. Agric. Food Chem. 1996, 44, 4071–4074. [Google Scholar] [CrossRef]

- Danks, C.; Ostoja-Starzewska, S.; Flint, J.; Banks, J.N. The development of a lateral flow device for the discrimination of OTA producing and non-producing fungi. Asp. Appl. Biol. 2003, 68, 21–28. [Google Scholar]

- Cruz-Aguado, J.A.; Penner, G. Determination of Ochratoxin A with a DNA Aptamer. J. Agric. Food Chem. 2008, 56, 10456–10461. [Google Scholar] [CrossRef] [PubMed]

- Nesheim, S.; Hardin, N.F.; Trucksess, M.W.; Eppley, J. Analysis of ochratoxins A and B and their esters in barley, using partition Fitness for purpose–Ochratoxin A analytical developments and thin-layer chromatography. II collaborative study. J. Assoc. Off. Anal. Chem. 1973, 56, 817–821. [Google Scholar]

- Aresta, A.; Cioffi, N.; Palmisano, F.; Zambonin, C.G. Simultaneous determination of ochratoxin A and cyclopiazonic, mycophenolic, and tenuazonic acids in cornflakes by solid phase microextraction coupled to high-performance liquid chromatography. J. Agric. Food Chem. 2003, 27, 5232–5237. [Google Scholar] [CrossRef]

- Nesheim, S.; Stack, M.E.; Trucksess, R.M.; Eppley, J. Rapid solvent-efficient method for liquid chromatographic determination of ochratoxin A in corn, barley, and kidney: Collaborative study. J. Assoc. Off. Anal. Chem. 1992, 75, 481–488. [Google Scholar]

- Lauwers, M.; De Baere, S.; Letor, B.; Rychlik, M.; Croubels, S.; Devreese, M. Multi LC-MS/MS and LC-HRMS Methods for Determination of 24 Mycotoxins including Major Phase I and II Biomarker Metabolites in Biological Matrices from Pigs and Broiler Chickens. Toxins 2019, 11, 171. [Google Scholar] [CrossRef] [Green Version]

- Liao, C.D.; Wong, J.W.; Zhang, K.; Yang, P.; Wittenberg, J.B.; Trucksess, M.W.; Hayward, D.G.; Lee, N.S.; Chang, J.S. Multi-mycotoxin Analysis of Finished Grain and Nut Products Using Ultrahigh-Performance Liquid Chromatography and Positive Electrospray Ionization–Quadrupole Orbital Ion Trap High-Resolution Mass Spectrometry. J. Agric. Food Chem. 2015, 63, 8314–8332. [Google Scholar] [CrossRef]

- Nanita, S.C.; Kaldon, L.G. Emerging flow injection mass spectrometry methods for high-throughput quantitative analysis. Anal. Bioanal. Chem. 2016, 408, 23–33. [Google Scholar] [CrossRef]

- Beckmann, M.; Parker, D.; Enot, D.P.; Duval, E.; Draper, J. High-throughput, nontargeted metabolite fingerprinting using nominal mass flow injection electrospray mass spectrometry. Nat. Protoc. 2008, 3, 486–504. [Google Scholar] [CrossRef] [PubMed]

- Nanita, S.C.; Pentz, A.M.; Bramble, F.Q. High-throughput pesticide residue quantitative analysis achieved by tandem mass spectrometry with automated flow injection. Anal. Chem. 2009, 81, 3134–3142. [Google Scholar] [CrossRef]

- Southam, A.D.; Weber, R.J.; Engel, J.; Jones, M.R.; Viant, M.R. A complete workflow for high-resolution spectral-stitching nanoelectrospray direct-infusion mass-spectrometry-based metabolomics and lipidomics. Nat. Protoc. 2016, 12, 310–328. [Google Scholar] [CrossRef] [PubMed]

- Sander, M.; Becker, S.; Thiery, J.; Ceglarek, U. Simultaneous identification and quantitation of triacyglycerol species in human plasma by flow-injection electrospray ionization tandem mass spectrometry. Chromatographia 2015, 78, 435–443. [Google Scholar] [CrossRef]

- Kristiansen, G.K.; Brock, R.; Bojesen, G. Comparison of flow injection/thermospray MS/MS and LC/thermospray MS/MS methods for determination of sulfonamides in meat and blood. Anal. Chem. 1994, 66, 3253–3258. [Google Scholar] [CrossRef]

- Hutchinson, S.E.; Leveridge, M.V.; Heathcote, M.L.; Francis, P.; Williams, L.; Gee, M.; Munoz-Muriedas, J.; Leavens, B.; Shillings, A.; Jones, E.; et al. Enabling lead discovery for histone lysine demethylases by high-throughput RapidFire mass spectrometry. J. Biomol. Screen. 2012, 17, 39–48. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sinclair, I.; Stearns, R.; Pringle, S.; Wingfield, J.; Datwani, S.; Hall, E.; Ghislain, L.; Majlof, L.; Bachman, M. Novel Acoustic Loading of a Mass Spectrometer: Toward Next-Generation High-Throughput MS Screening. J. Lab. Autom. 2016, 21, 19–26. [Google Scholar] [CrossRef] [Green Version]

- Sinclair, I.; Bachman, M.; Addison, D.; Rohman, M.; Murray, D.C.; Davies, G.; Mouchet, E.; Tonge, M.E.; Stearns, R.G.; Ghislain, L.; et al. Acoustic Mist Ionization Platform for Direct and Contactless Ultrahigh-Throughput Mass Spectrometry Analysis of Liquid Samples. Anal. Chem. 2019, 91, 3790–3794. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, K.; Schaab, M.R.; Southwood, G.; Tor, E.R.; Aston, L.S.; Song, W.L.; Eitzer, B.; Majumdar, S.; Lapainis, T.; Mai, H.; et al. A Collaborative Study: Determination of Mycotoxins in Corn, Peanut Butter, and Wheat Flour Using Stable Isotope Dilution Assay (SIDA) and Liquid Chromatography–Tandem Mass Spectrometry (LC-MS/MS). J. Agric. Food Chem. 2017, 65, 7138–7152. [Google Scholar] [CrossRef]

- US FDA CVM GFI #118 Mass Spectrometry for Confirmation of Identity of Animal Drug Residues. Available online: https://www.fda.gov/regulatory-information/search-fda-guidance-documents/cvm-gfi-118-mass-spectrometry-confirmation-identity-animal-drug-residues (accessed on 28 June 2021).

- Eeckhaut, A.V.; Lanckmans, K.; Sarre, S.; Smolders, I.; Michotte, Y. Validation of bioanalytical LC–MS/MS assays: Evaluation of matrix effects. J. Chromatogr. B. 2009, 877, 2198–2207. [Google Scholar] [CrossRef]

- EPA Definition and Procedure for the Determination of the Method Detection Limit, Revision 2. 2016. Available online: https://www.epa.gov/sites/production/files/2016-12/documents/mdl-procedure_rev2_12-13-2016.pdf (accessed on 25 May 2021).

| Conc. (ppb) | White Grape Juice | Red Grape Juice | Corn | Oat | ||||

|---|---|---|---|---|---|---|---|---|

| FI-MS/MS | LC-MS/MS | FI-MS/MS | LC-MS/MS | FI-MS/MS | LC-MS/MS | FI-MS/MS | LC-MS/MS | |

| 1 | ND | 108 (4) | ND | 109 (2) | ND | 115 (8) | ND | 106 (7) |

| 5 | 84 (6) | 106 (2) | 80 (4) | 105 (3) | 89 (7) | 109 (5) | 117 (15) | 103 (3) |

| 20 | 90 (4) | 103 (5) | 79 (3) | 100 (6) | 94 (3) | 109 (4) | 97 (5) | 111 (4) |

| 100 | 96 (2) | 105 (3) | 85 (5) | 106 (2) | 97 (5) | 110 (3) | 94 (4) | 117 (4) |

| Instrument Performance | White Grape Juice | Red Grape Juice | Corn | Oat | Solvent | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| FI-MS/MS | LC-MS/MS | FI-MS/MS | LC-MS/MS | FI-MS/MS | LC-MS/MS | FI-MS/MS | LC-MS/MS | FI-MS/MS | LC-MS-MS | |

| LOQ (ppb) | 0.24 | 0.06 | 0.28 | 0.05 | 0.29 | 0.06 | 0.35 | 0.02 | 0.12 | 0.02 |

| Linear range (ppb) | 0.25–100 | 0.05–100 | 0.25–100 | 0.05–100 | 0.25–100 | 0.05–100 | 0.5–100 | 0.02–100 | 0.1–100 | 0.02–100 |

| Linearity (r2) | 0.9998 | 0.9996 | 0.9997 | 0.9992 | 0.9992 | 0.9998 | 0.9993 | 0.9991 | 0.9992 | 0.9989 |

| Samples | FI-MS/MS | LC-MS/MS | Ref. Value |

|---|---|---|---|

| C-9999G (corn) | 63.0 ± 3.5 | 62.3 ± 3.2 | 62.1 ± 17.9 |

| OW-821 (wheat flour) | ND | 90.8 ± 3.7 | 93.7 ± 9.6 |

| OW-825 (wheat flour) | ND | 7.6 ± 1.1 | 7.0 ± 1.8 |

| NIST 1565 blank (corn) | ND | ND | ND |

| NIST 1565 incurred (corn) | 10.8 ± 0.4 | 8.3 ± 0.3 | 9.4 ± 1.2 |

| C-3023 (oat) | 6.8 ± 1.2 | 7.6 ± 1.1 | 8.2 ± 3.6 |

| Mycotoxin | CAS# | Formula | Molecular Weight (Da) | LC-MS/MS Parameters | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Rt (min) | Q1 (m/z) | Q3 (m/z) | DP (V) | EP (V) | CE (V) | CXP (V) | ||||

| Ochratoxin A | 303-47-9 | C20H18ClNO6 | 403.1 | 6.0 | 404 | 239 | 66 | 10 | 41 | 16 |

| 102 | 66 | 10 | 101 | 16 | ||||||

| 13C20-ochratoxin A | NA | 13C20H18ClNO6 | 423.1 | 6.0 | 424 | 250 | 66 | 10 | 41 | 14 |

| 110 | 66 | 10 | 109 | 18 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K. Comparison of Flow Injection-MS/MS and LC-MS/MS for the Determination of Ochratoxin A. Toxins 2021, 13, 547. https://0-doi-org.brum.beds.ac.uk/10.3390/toxins13080547

Zhang K. Comparison of Flow Injection-MS/MS and LC-MS/MS for the Determination of Ochratoxin A. Toxins. 2021; 13(8):547. https://0-doi-org.brum.beds.ac.uk/10.3390/toxins13080547

Chicago/Turabian StyleZhang, Kai. 2021. "Comparison of Flow Injection-MS/MS and LC-MS/MS for the Determination of Ochratoxin A" Toxins 13, no. 8: 547. https://0-doi-org.brum.beds.ac.uk/10.3390/toxins13080547