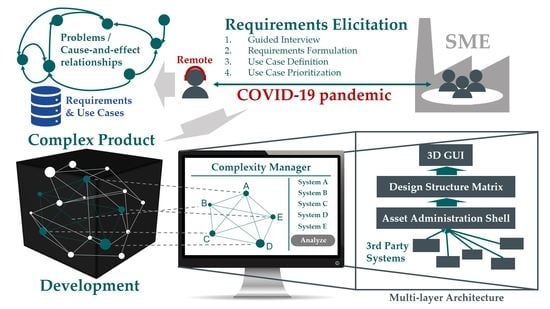

Requirements Elicitation for an Assistance System for Complexity Management in Product Development of SMEs during COVID-19: A Case Study

Abstract

:1. Introduction

- To describe and discuss the methodology and results of a requirements elicitation for an assistance system for complexity management with two SMEs during the COVID-19 global pandemic;

- To model the cause-and-effect relationships of complexity management problems in the product development activities of SMEs;

- To present the assistance system’s software architecture using the Asset Administration Shell as a data basis.

2. Related Work

3. Requirements Elicitation in SMEs for a Complexity Management Assistance System

3.1. Methodology

3.2. Results

3.2.1. System Dynamics Modeling of Complexity Management Problems in SMEs

3.2.2. Requirements Overview

3.2.3. Use Cases Overview

4. Assistance System for Complexity Management in SME Architecture

4.1. Asset Administration Shell for Data Management

4.2. Software Architecture

- REQ 10/UC002.a—Role and department view

- The keyword “Role” implies a role and rights management. Therefore, a database or an interface to an external system must exist which can take over this task.

- Impact: User database or rights database.

- REQ 60/UC004.a—Communication of artifact changes to affected departments

- Automated communication that reacts to changes of specific objects implies another component that monitors all existing artifacts and informs users about changes according to their subscriptions.

- Impact: Communication component, subscription database.

- Section 3.2.3. Use Case Overview

- Based on the use cases and the actors mentioned therein, interfaces to external authoring systems are necessary. These have so far been grouped under PLM, ALM, and ERP.

- Effects: Interface to external systems.

5. Discussion

5.1. Implications

5.2. Limitations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vogel, W.; Lasch, R. Complexity drivers in manufacturing companies: A literature review. Logist. Res. 2016, 9, 1–66. [Google Scholar] [CrossRef]

- Latos, B.A.; Harlacher, M.; Burgert, F.; Nitsch, V.; Przybysz, P.; Niewöhner, S.M. Complexity Drivers in Digitalized Work Systems: Implications for Cooperative Forms of Work. Adv. Sci. Technol. Eng. Syst. J. 2018, 3, 171–185. [Google Scholar] [CrossRef] [Green Version]

- Ulrich, H.; Probst, G.J.B. Anleitung zum Ganzheitlichen Denken und Handeln: Ein Brevier für Führungskräfte, 4th ed.; Haupt: Bern, Switzerland, 1995. [Google Scholar]

- Von Bertalanffy, L. Vorläufer und begründer der systemtheorie. Berl. Colloq. 1971, 17–28. Available online: https://www.bibsonomy.org/bibtex/28cef65f75bf261584a080dcae459936f/isa (accessed on 2 November 2021).

- Browning, T.R.; Eppinger, S.D. Modeling impacts of process architecture on cost and schedule risk in product development. IEEE Trans. Eng. Manag. 2002, 49, 428–442. [Google Scholar] [CrossRef] [Green Version]

- Mattmann, I. Modellintegrierte Produkt-und Prozessentwicklung; Springer Fachmedien Wiesbaden GmbH: Wiesbaden, Germany, 2017. [Google Scholar]

- Renner, I. Methodische Unterstützung Funktionsorientierter Baukastenentwicklung am Beispiel Automobil. Ph.D. Thesis, Technische Universität München, München, Germany, 2007. Available online: https://mediatum.ub.tum.de/doc/627386/file.pdf (accessed on 2 November 2021).

- Törngren, M.; Sellgren, U. Complexity Challenges in Development of Cyber-Physical Systems. In Principles of Modeling; Springer: Cham, Switzerland, 2018; pp. 478–503. [Google Scholar] [CrossRef] [Green Version]

- Törngren, M.; Grogan, P. How to Deal with the Complexity of Future Cyber-Physical Systems? Designs 2018, 2, 40. [Google Scholar] [CrossRef] [Green Version]

- Browning, T.R. Design Structure Matrix Extensions and Innovations: A Survey and New Opportunities. IEEE Trans. Eng. Manag. 2016, 63, 27–52. [Google Scholar] [CrossRef]

- Kossiakoff, A.; Sweet, W.N.; Seymour, S.J.; Biemer, S.M. Systems Engineering Principles and Practice; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Stark, J. Product Lifecycle Management. In Product Lifecycle Management, 2nd ed.; Stark, J., Ed.; Springer: Cham, Switzerland, 2016; pp. 1–35. [Google Scholar] [CrossRef]

- Jarratt, T.A.W.; Eckert, C.M.; Caldwell, N.H.M.; Clarkson, P.J. Engineering change: An overview and perspective on the literature. Res. Eng. Des. 2011, 22, 103–124. [Google Scholar] [CrossRef]

- Jarratt, T.; Clarkson, J.; Eckert, C. Engineering change. In Design Process Improvement; Springer London: London, UK, 2005; pp. 262–285. [Google Scholar] [CrossRef]

- Hofmann, H.F.; Lehner, F. Requirements engineering as a success factor in software projects. IEEE Softw. 2001, 18, 58–66. [Google Scholar] [CrossRef] [Green Version]

- Kamata, M.I.; Tamai, T. How Does Requirements Quality Relate to Project Success or Failure? In Proceedings of the IEEE International Requirements Engineering Conference, Delhi, India, 15–19 October 2007; pp. 69–78. [Google Scholar] [CrossRef]

- Zowghi, D.; Coulin, C. Requirements Elicitation: A Survey of Techniques, Approaches, and Tools. In Engineering and Managing Software Requirements; Springer: Berlin/Heidelberg, Germany, 2005; pp. 19–46. [Google Scholar] [CrossRef] [Green Version]

- Rosen, B.; Furst, S.; Blackburn, R. Overcoming barriers to knowledge sharing in virtual teams. Organ. Dyn. 2007, 36, 259–273. [Google Scholar] [CrossRef]

- Aranda, G.N.; Vizcaíno, A.; Cechich, A.; Piattini, M. Strategies to Minimize Problems in Global Requirements Elicitation. CLEI Electron. J. 2008, 11, 1. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.566.6607&rep=rep1&type=pdf (accessed on 2 November 2021). [CrossRef]

- Lloyd, W.J.; Rosson, M.B.; Arthur, J.D. Effectiveness of elicitation techniques in distributed requirements engineering. In Proceedings of the IEEE Joint International Conference on Requirements Engineering, Essen, Germany, 9–13 September 2002; pp. 311–318. [Google Scholar] [CrossRef]

- Morrison-Smith, S.; Ruiz, J. Challenges and barriers in virtual teams: A literature review. SN Appl. Sci. 2020, 2, 1–33. [Google Scholar] [CrossRef]

- Feitosa, J.; Salas, E. Today’s virtual teams: Adapting lessons learned to the pandemic context. Organ. Dyn. 2021, 50, 1–4. [Google Scholar] [CrossRef] [PubMed]

- ul Amin, T.; Shahzad, B.; Fazal e, A.; Shoaib, M. Economical Requirements Elicitation Techniques During COVID-19: A Systematic Literature Review. Comput. Mater. Contin. 2021, 67, 2665–2680. [Google Scholar] [CrossRef]

- Küstner, C. Assistenzsystem zur Unterstützung der datengetriebenen Produktentwicklung; FAU University Press: Erlangen, Germany, 2020; Available online: https://opus4.kobv.de/opus4-fau/files/14597/Kuestner_Diss_MB_353.pdf (accessed on 2 November 2021).

- Kuestner, C.; Wartzack, S. The realization of an engineering assistance system for the development of noise-reduced rotating machines. In DS 80-4 Proceedings of the 20th International Conference on Engineering Design (ICED 15), Design for X, Design to X, Milan, Italy, 27–30 July 2015; Volume 4, pp. 71–80. Available online: https://www.designsociety.org/publication/37771/ (accessed on 2 November 2021).

- Sauer, C.; Breitsprecher, T.; Küstner, C.; Schleich, B.; Wartzack, S. SLASSY—An Assistance System for Performing Design for Manufacturing in Sheet-Bulk Metal Forming: Architecture and Self-Learning Aspects. AI 2021, 2, 307–329. [Google Scholar] [CrossRef]

- Herbst, S.; Hoffmann, A. Product Lifecycle Management (PLM) mit Siemens Teamcenter: Grundlagen, Anwendung und Best Practices; Carl Hanser Verlag GmbH Co KG: München, Germany, 2018. [Google Scholar]

- Jarratt, T.; Keller, R.; Nair, S.; Eckert, C.; Clarkson, P.J. Visualization Techniques for Product Change and Product Modelling in Complex Design. In Diagrammatic Representation and Inference. Lecture Notes in Computer Science; Goos, G., Hartmanis, J., Leeuwen, J.v., Blackwell, A.F., Marriott, K., Shimojima, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2004; Volume 2980, pp. 388–391. [Google Scholar] [CrossRef]

- Sharman, D.M.; Yassine, A.A. Characterizing complex product architectures. Syst. Eng. 2004, 7, 35–60. [Google Scholar] [CrossRef]

- Peterson, T. Understanding Systems through Graph Theory and Dynamic Visualization. In Proceedings of the 2014 Ground Vehicle Systems Engineering and Technology Symposium (GVSETS), Novi, MI, USA, 4–6 August 2015. [Google Scholar]

- Bastian, M.; Heymann, S.; Jacomy, M. Gephi: An open source software for exploring and manipulating networks. In Proceedings of the Third International AAAI Conference on Weblogs and Social Media, Menlo Park, CA, USA, 17–20 May 2009. [Google Scholar] [CrossRef]

- Batagelj, V.; Mrvar, A. Pajek—Analysis and Visualization of Large Networks. In Graph Drawing Software; Springer: Berlin/Heidelberg, Germany, 2004; pp. 77–103. [Google Scholar] [CrossRef]

- Turner, D. Qualitative Interview Design: A Practical Guide for Novice Investigators. Qual. Rep. 2014, 15, 754–760. [Google Scholar]

- Leech, B.L. Asking Questions: Techniques for Semistructured Interviews. PS Polit. Sci. Polit. 2002, 35, 665–668. [Google Scholar] [CrossRef] [Green Version]

- Adams, W.C. Conducting semi-structured interviews. Handb. Pract. Progr. Eval. 2015, 4, 492–505. [Google Scholar]

- Kallio, H.; Pietilä, A.-M.; Johnson, M.; Kangasniemi, M. Systematic methodological review: Developing a framework for a qualitative semi-structured interview guide. J. Adv. Nurs. 2016, 72, 2954–2965. [Google Scholar] [CrossRef] [PubMed]

- Flanagan, J.C. The critical incident technique. Psychol. Bull. 1954, 51, 327–358. [Google Scholar] [CrossRef] [Green Version]

- Rupp, C. Requirements-Engineering und Management, 4th ed.; Hanser: München, Germany, 2007. [Google Scholar] [CrossRef]

- Mavin, A.; Wilkinson, P.; Harwood, A.; Novak, M. Easy Approach to Requirements Syntax (EARS). In Proceedings of the 2009 17th IEEE International Requirements Engineering Conference, Atlanta, GA, USA, 31 August–4 September 2009; pp. 317–322. [Google Scholar] [CrossRef]

- Firesmith, D. Specifying Good Requirements. J. Object Technol. 2003, 2, 77–87. [Google Scholar] [CrossRef] [Green Version]

- Maalem, S.; Zarour, N. Challenge of validation in requirements engineering. J. Innov. Digit. Ecosyst. 2016, 3, 15–21. [Google Scholar] [CrossRef] [Green Version]

- Forrester, J.W. Industrial Dynamics. J. Oper. Res. Soc. 1997, 48, 1037–1041. [Google Scholar] [CrossRef]

- Plattform Industrie 4.0: Details of Asset Administration Shell. 2020. Available online: https://www.plattform-i40.de/IP/Redaktion/DE/Downloads/Publikation/Details_of_the_Asset_Administration_Shell_Part1_V3.pdf?__blob=publicationFile&v=5 (accessed on 2 November 2021).

- Available online: https://industrialdigitaltwin.org/ (accessed on 7 October 2021).

- Available online: https://unity.com/de (accessed on 7 October 2021).

- Albers, A.; Lohmeyer, Q. Advanced systems engineering–towards a model-based and human-centered methodology. In Proceedings of the 9th International Symposium on Tools and Methods of Competitive Engineering (TMCE 2012), Karlsruhe, Germany, 7–11 May 2012. [Google Scholar]

- Kecher, C.; Salvanos, A.; Hoffmann-Elbern, R. UML 2.5: Das Umfassende Handbuch; Rheinwerk Verlag: Bonn, Germany, 2017. [Google Scholar]

- Barlas, Y. Formal aspects of model validity and validation in system dynamics. Syst. Dyn. Rev. J. Syst. Dyn. Soc. 1996, 12, 183–210. [Google Scholar] [CrossRef]

| Multiply Mentioned Requirements |

|---|

| REQ 02—Documentation and communication of artifact changes |

| REQ 05—Representation of relationships between artifacts |

| REQ 10—Role and department view |

| REQ 19—Documentation of artifact changes |

| REQ 23—Display the product life cycle status of a product |

| REQ 46—No pressure to decide |

| REQ 55—Support for compliance with standardized product development processes REQ 60—Communication of artifact changes to affected departments REQ 81—Communicate change impulse |

| Use Case | Requirements |

|---|---|

| UC001— Making dependencies visible | REQ 005—Representation of relationships between artifacts |

| REQ 006—Representation of relationships between documents and construction files | |

| REQ 007—Traceability of defective materials | |

| REQ 042—Representation of relationships between documents of the development manual | |

| REQ 043—Traceability from requirements elicitation to design | |

| REQ 054—Display of legally indispensable components for new developments | |

| REQ 061—Display of most recent documents during documentation viewing | |

| REQ 064—Display of effects in case of requirement change | |

| REQ 071—Comply and display reporting channels | |

| REQ 079—Differentiation of requirements in development phases | |

| REQ 082—Provide test relevant information | |

| REQ 085—Overview of documents associated with the component | |

| REQ 092—Material usage statement | |

| REQ 096—Relationship between requirements, designs and test cases | |

| REQ 100—Point-and-click-action | |

| REQ 117—Graphical representation of assemblies | |

| REQ 121—Information display in assembly structure REQ 122—Relationships between departments of the product development process REQ 125—Show information when opening artifact | |

| UC008.a— system function give approval | REQ 026—Automatic assignment of document number |

| REQ 039—Digital release of documents | |

| REQ 115—Error prevention through release, check and test processes | |

| UC012.a— Find information | REQ 044—Top-down and bottom-up view of relationships between documents |

| UC012.b— Represent information | REQ 023—Display the product lifecycle status of a product |

| REQ 051—Information display via dashboard | |

| REQ 052—Error management via dashboard | |

| REQ 068—Categorization of document relationships by subject area in tree structure | |

| REQ 073—Display and compare artifact versions | |

| REQ 091—Traffic light system at taskbar | |

| REQ 094—Change impact analysis checklist | |

| REQ 107—Theme classification on dashboard | |

| REQ 108—Traceability matrix | |

| REQ 121—Information display in assembly structure | |

| UC012.f— Represent changes | REQ 089—Display change warning |

| REQ 091—Traffic light system at taskbar | |

| REQ 094—Change impact analysis checklist |

| Use Case ID | Description | Actor |

|---|---|---|

| UC001 | Making dependencies visible | Developer (Product) |

| UC002.a | Manage user roles | Administrator |

| UC002.b | Configure rights management | Administrator |

| UC002.c | Subscribe to artifacts | System user |

| UC002.d | Configure notifications | System user |

| UC003.a | Submit changes | System user |

| UC003.b | (Organizational) evaluation and traceability of a change | System user |

| UC003.c | (Lifecycle) traceability of change effects | System user |

| UC003.d | Changes by external source | External users |

| UC003.e | Limit change options | System user |

| UC003.f | Show status of change | System user |

| UC004.a | Communicate change | System user |

| UC004.b | Communicate change via warning | System user |

| UC004.c | Communicate change—Task management | System user |

| UC005 | Communicate errors | System user |

| UC006 | Create templates | System user |

| UC007 | Perform tests | Quality assurance |

| UC008.a | System function—Give approval | System user |

| UC008.b | System function—Create comments | System user |

| UC008.c.1 | System function—Create plausibility checks | Developer (Software) |

| UC008.c.2 | System function—Carry out plausibility checks | System user |

| UC009 | System function—Make or carry out decision proposals | System user |

| UC010 | System function—Obtain external system data | Third-party system |

| UC011 | System function—Start third-party systems | Third-party system |

| UC012.a | Find information | System user |

| UC012.b | Represent information | System user |

| UC012.c | Filter information | System user |

| UC012.d | Show notifications | System user |

| UC012.e | Display artifact status | System user |

| UC012.f | Represent changes | System user |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herrmann, J.-P.; Imort, S.; Trojanowski, C.; Deuter, A. Requirements Elicitation for an Assistance System for Complexity Management in Product Development of SMEs during COVID-19: A Case Study. Computers 2021, 10, 149. https://0-doi-org.brum.beds.ac.uk/10.3390/computers10110149

Herrmann J-P, Imort S, Trojanowski C, Deuter A. Requirements Elicitation for an Assistance System for Complexity Management in Product Development of SMEs during COVID-19: A Case Study. Computers. 2021; 10(11):149. https://0-doi-org.brum.beds.ac.uk/10.3390/computers10110149

Chicago/Turabian StyleHerrmann, Jan-Phillip, Sebastian Imort, Christoph Trojanowski, and Andreas Deuter. 2021. "Requirements Elicitation for an Assistance System for Complexity Management in Product Development of SMEs during COVID-19: A Case Study" Computers 10, no. 11: 149. https://0-doi-org.brum.beds.ac.uk/10.3390/computers10110149