The Effect of a Phase Change on the Temperature Evolution during the Deposition Stage in Fused Filament Fabrication

Abstract

:1. Introduction

2. Related Work

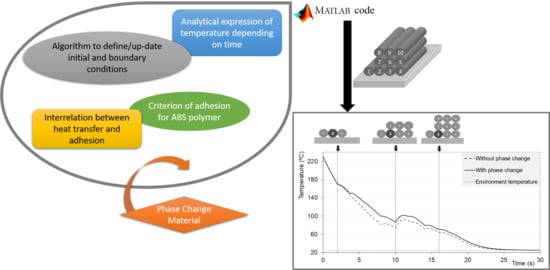

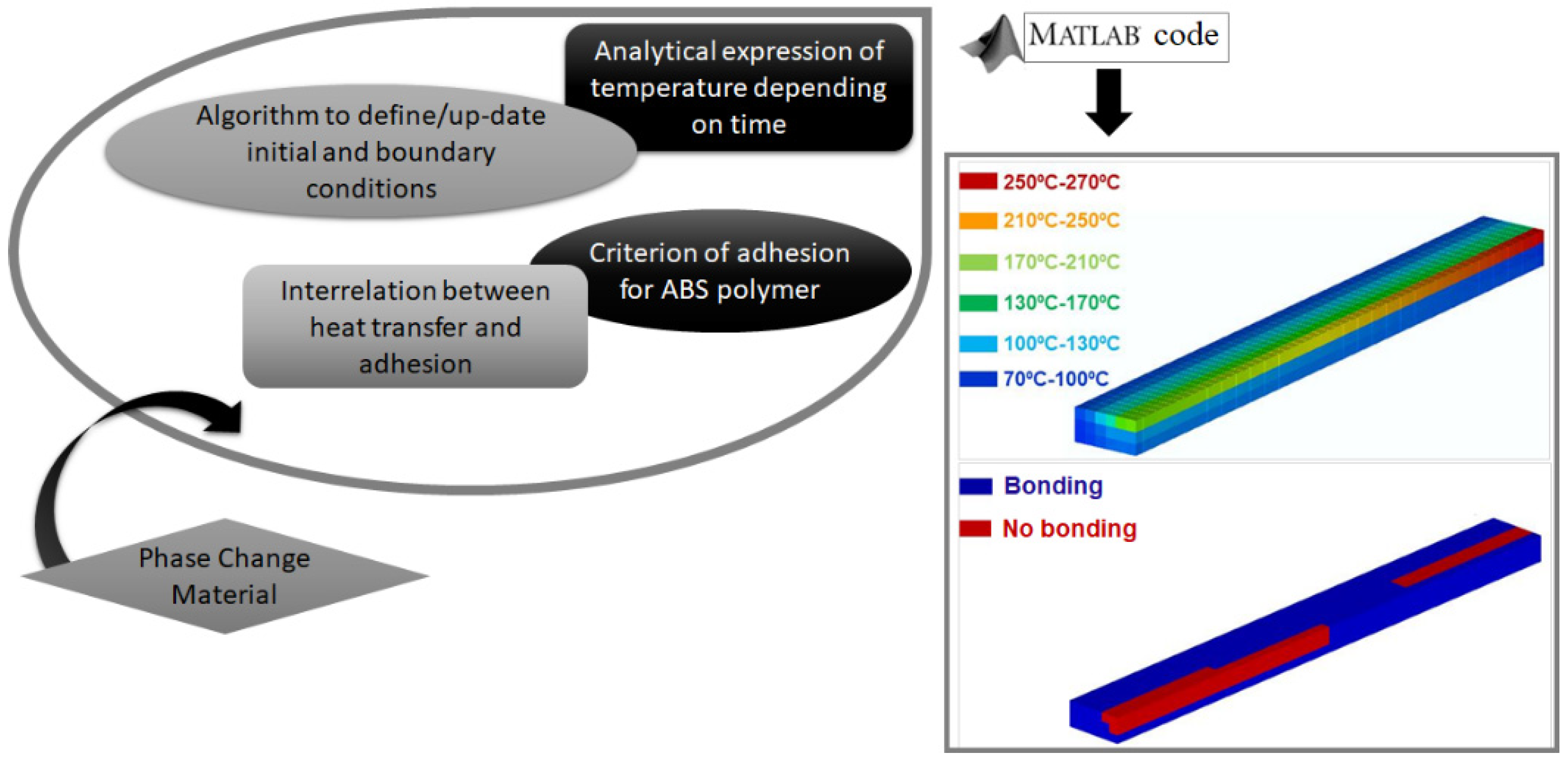

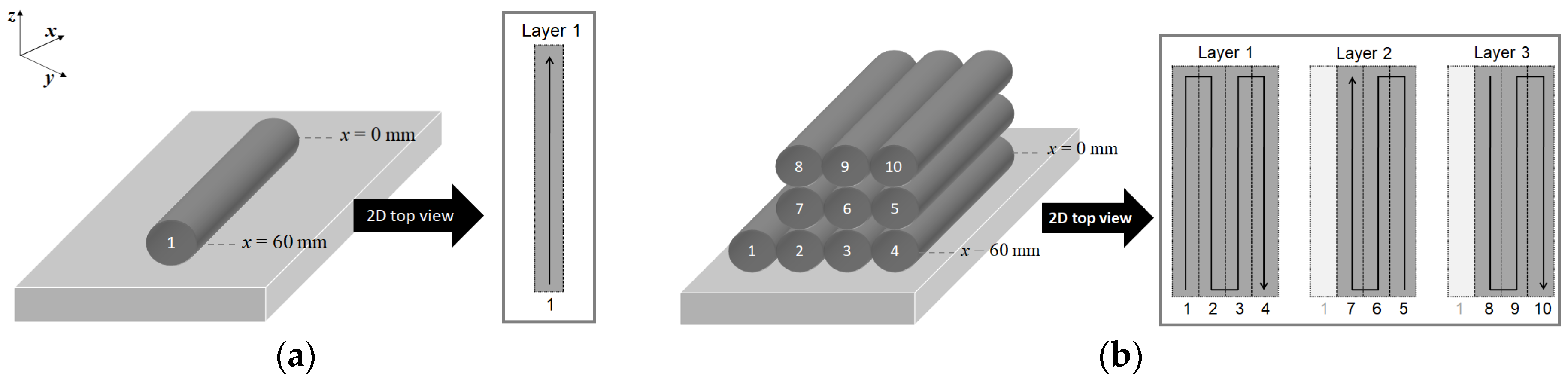

3. A code for the Prediction of Temperature Evolution during Cooling in FFF

3.1. Current Code

- The axial heat conduction is neglected. Given the low thermal conductivity of polymers and the small filaments radii, axial heat conduction is much smaller than convection and conduction between adjacent filaments;

- Computations are carried out when the Biot number is lower than 0.1, i.e., when the temperature gradient in each filament cross-section can be neglected;

- The thermal properties of the polymer are assumed to be temperature independent;

- The thermal contact conductance is assumed to be low (high thermal resistance) while bonding is not achieved, and high when bonding occurs.

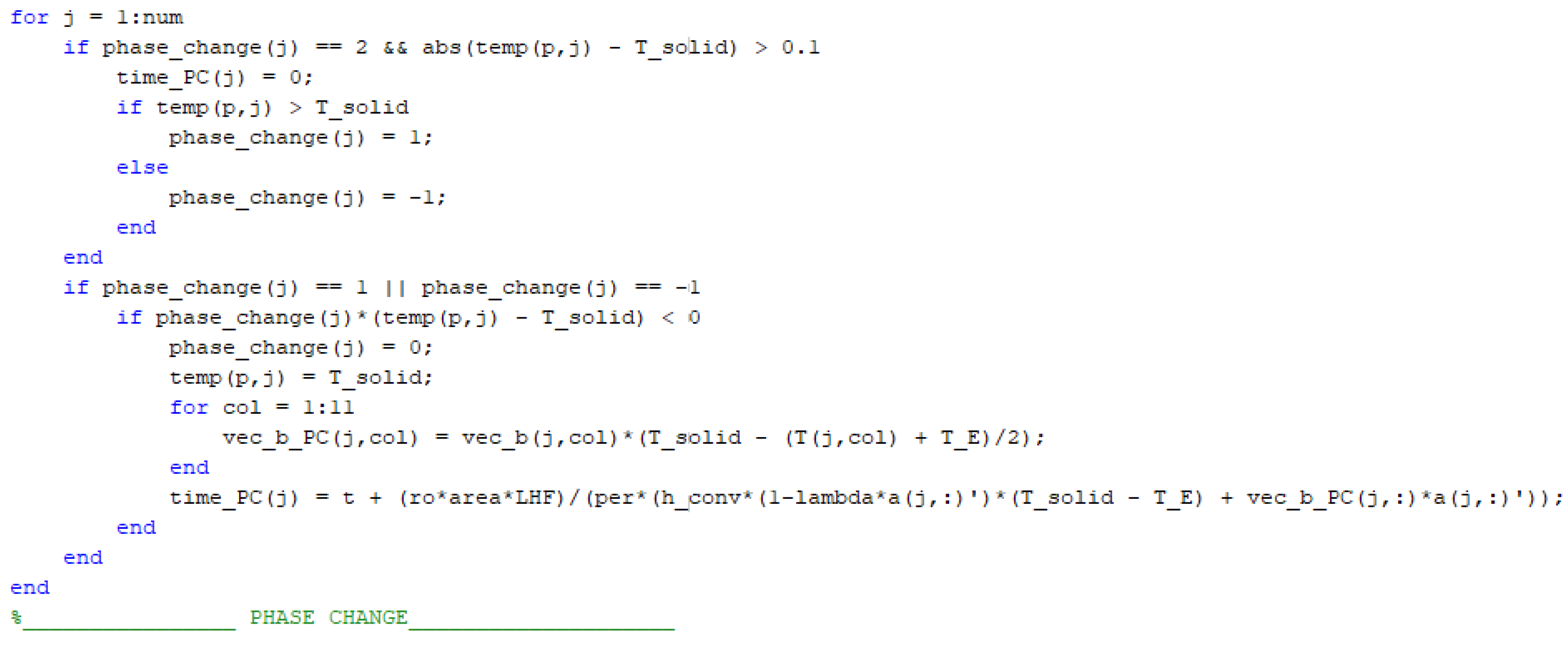

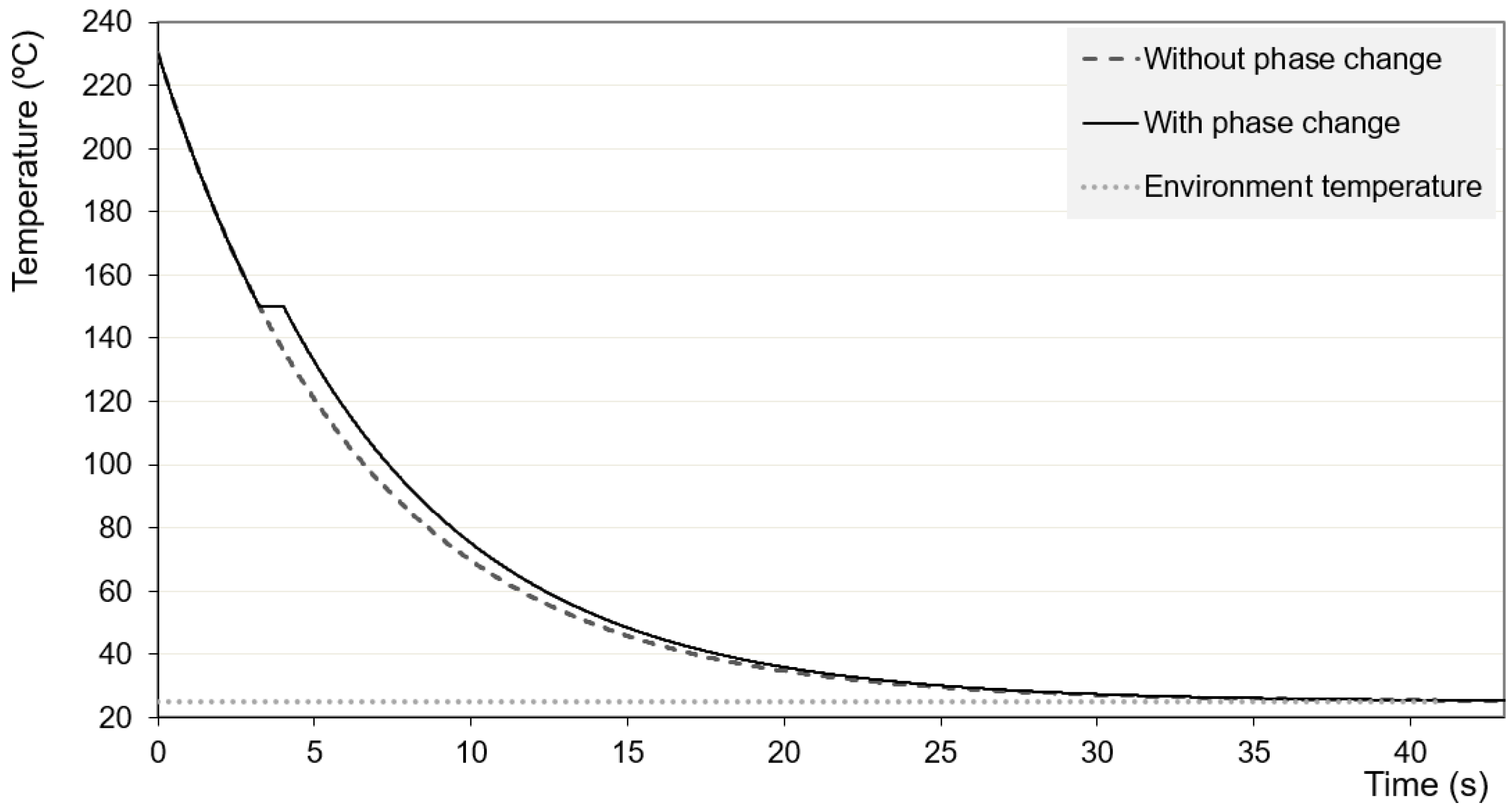

3.2. Insertion of a Phase Change

- Crystallization development during cooling does not affect the thermal properties, which are taken as temperature independent;

- When the temperature of the filament segment reaches , the thermal conditions used to compute are activated at ;

- If is the temperature of the adjacent filament segment for contact at instant , the value of will be assumed as the average between and ;

- If during a phase change a filament contacts a new hotter filament, its phase change is interrupted and the temperatures are re-computed. When its temperature reaches again , is computed for the new thermal conditions;

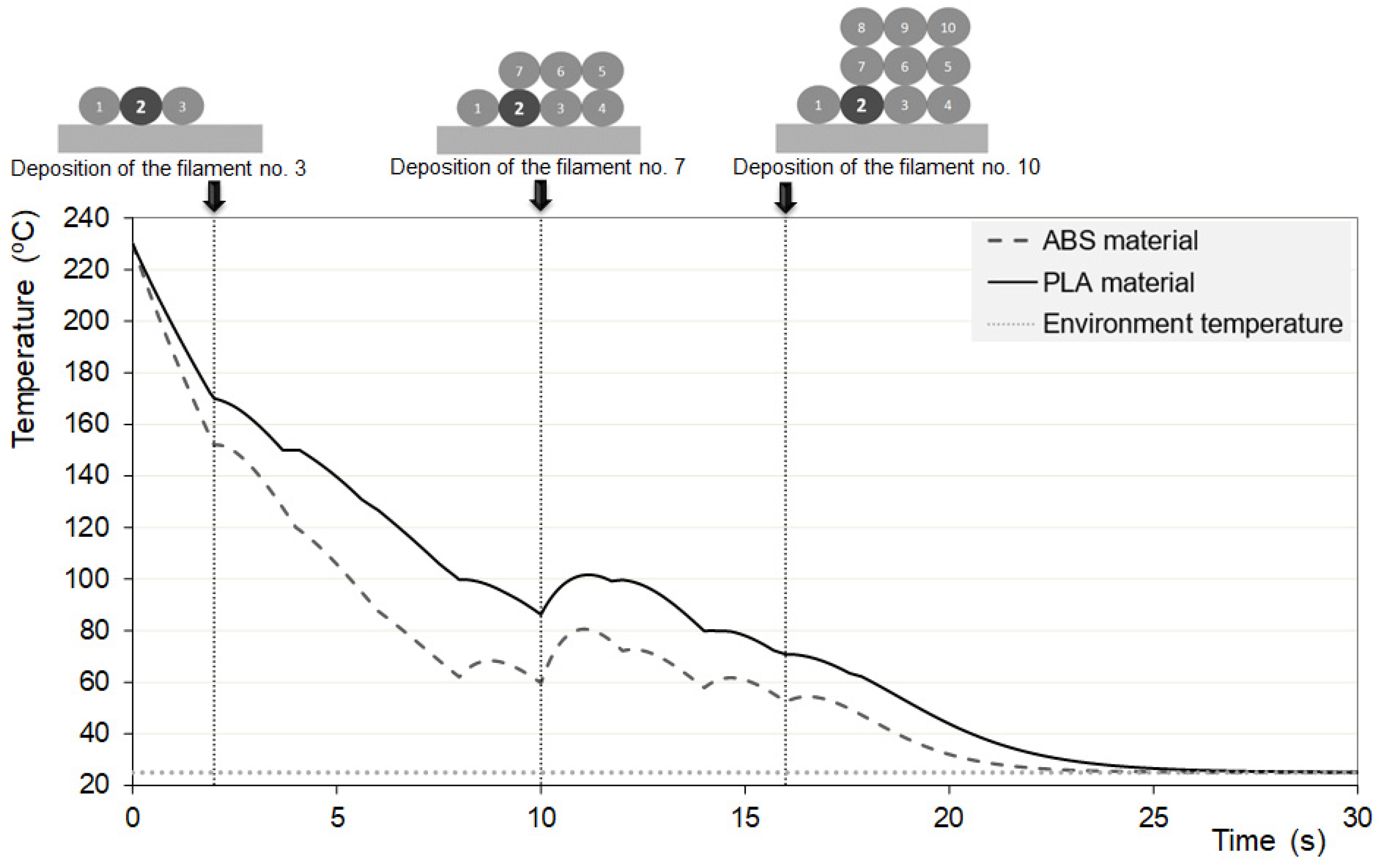

4. Application of the Code to Simple 3D Printed Structures

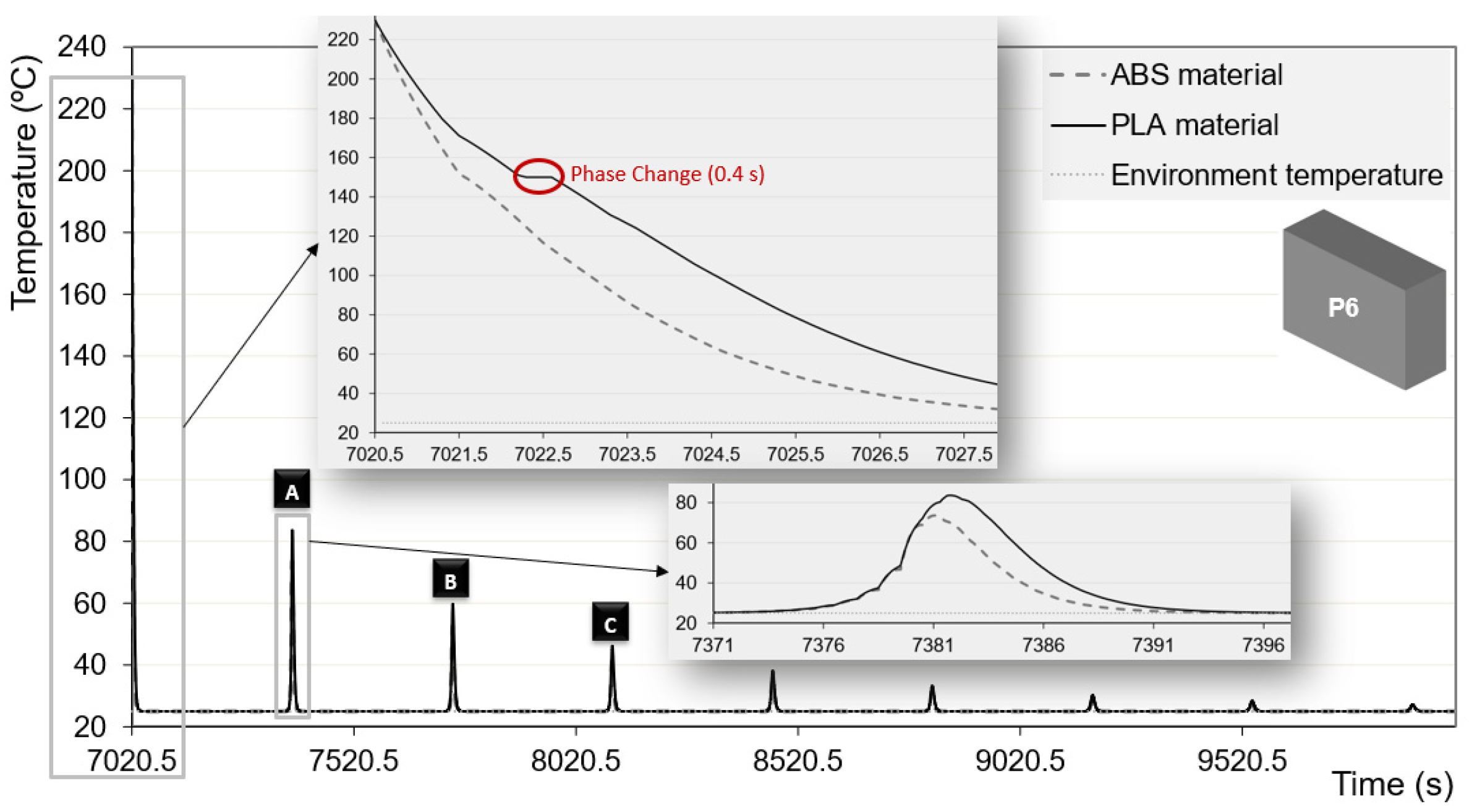

5. Applied Case Study

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gebhardt, A. Understanding Additive Manufacturing: Rapid Prototyping–Rapid Tooling–Rapid Manufacturing, 1st ed.; Hanser: Munich, Germany, 2008. [Google Scholar]

- Chua, C.K.; Leong, K.F.; Lim, C.S. Rapid Prototyping: Principles and Applications, 3rd ed.; World Scientific: Singapore, 2010. [Google Scholar]

- Ingole, D.S.; Kuthe, A.M.; Thakare, S.B.; Talankar, A.S. Rapid prototyping—A technology transfer approach for development of rapid tooling. Rapid Prototyp. J. 2009, 15, 280–290. [Google Scholar] [CrossRef]

- Long, J.; Gholizadeh, H.; Lu, J.; Bunt, C.; Seyfoddin, A. Application of Fused Deposition Modelling (FDM) Method of 3D Printing in Drug Delivery. Curr. Pharm. Des. 2017, 23, 433–439. [Google Scholar] [CrossRef] [PubMed]

- Harris, M.; Potgieter, J.; Archer, R.; Arif, K.M. Effect of material and process specific factors on the strength of printed parts in fused filament fabrication: A review of recent developments. Materials 2019, 12, 1664. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mackay, M.E. The importance of rheological behavior in the additive manufacturing technique material extrusion. J. Rheol. 2018, 62, 1549–1561. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Sun, Q.; Rizvi, G.M.; Bellehumeur, C.T.; Gu, P. Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Carneiro, O.S.; Silva, A.F.; Gomes, R. Fused deposition modeling with polypropylene. Mater. Des. 2015, 83, 768–776. [Google Scholar] [CrossRef]

- Zanjanijam, A.R.; Major, I.; Lyons, J.G.; Lafont, U.; Devine, D.M. Fused Filament Fabrication of PEEK: A Review of Process-Structure-Property Relationships. Polymers 2020, 12, 1665. [Google Scholar] [CrossRef]

- Vanaei, H.; Shirinbayan, M.; Deligant, M.; Raissi, K.; Fitoussi, J.; Khelladi, S.; Tcharkhtchi, A. Influence of process parameters on thermal and mechanical properties of polylactic acid fabricated by fused filament fabrication. Polym. Eng. Sci. 2020, 1–10. [Google Scholar] [CrossRef]

- Vicente, C.M.S.; Martins, T.S.; Leite, M.; Ribeiro, A.; Reis, L. Influence of fused deposition modeling parameters on the mechanical properties of ABS parts. Polym. Adv. Technol. 2020, 31, 501–507. [Google Scholar] [CrossRef]

- Hwang, S.; Reyes, E.I.; Moon, K.; Rumpf, R.C.; Kim, N.S. Thermo-mechanical Characterization of Metal/Polymer Composite Filaments and Printing Parameter Study for Fused Deposition Modeling in the 3D Printing Process. J. Electron. Mater. 2013, 44, 771–777. [Google Scholar] [CrossRef]

- Izdebska, J. Printing on Polymers: Theory and Practice. Printing on Polymers: Fundamentals and Applications; Izdebska, J., Thomas, S., Eds.; William Andrew: Waltham, MA, USA, 2016; pp. 1–20. [Google Scholar]

- Kuznetsov, V.E.; Solonin, A.N.; Urzhumtsev, O.D.; Schilling, R.; Tavitov, A.G. Strength of PLA Components Fabricated with Fused Deposition Technology Using a Desktop 3D Printer as a Function of Geometrical Parameters of the Process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Waseem, M.; Salah, B.; Habib, T.; Saleem, W.; Abas, M.; Khan, R.; Ghani, U.; Siddiqi, M. Multi-Response Optimization of Tensile Creep Behavior of PLA 3D Printed Parts Using Categorical Response Surface Methodology. Polymers 2020, 12, 2962. [Google Scholar] [CrossRef] [PubMed]

- Gosset, A.; Barreiro-Villaverde, D.; Permuy, J.C.; Lema, M.; Ares-Pernas, A.; López, M.J. Experimental and Numerical Investigation of the Extrusion and Deposition Process of a Poly(lactic Acid) Strand with Fused Deposition Modeling. Polymers 2020, 12, 2885. [Google Scholar] [CrossRef]

- Melenka, G.W.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation of dimensional accuracy and material properties of the makerbot 3D desktop printer. Rapid Prototyp. J. 2015, 21, 618–627. [Google Scholar] [CrossRef]

- Milde, J.; Hrusecky, R.; Zaujec, R.; Morovic, L.; Gorog, A. Research of ABS and PLA Materials in the Process of Fused Deposition Modeling Method. Ann. DAAAM Proc. 2017, 28, 812–820. [Google Scholar]

- Hafsa, M.; Ibrahim, M.; Wahab, M.; Zahid, M. Evaluation of FDM pattern with ABS and PLA material. Appl. Mech. Mater. 2013, 465/466, 55–59. [Google Scholar] [CrossRef]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A.M. The influence of Manufacturing Parameters on the Mechanical Behaviour of PLA and ABS Pieces Manufactured by FDM: A comparative Analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef] [Green Version]

- Wojtyla, S.; Klama, P.; Baran, T. Is 3D printing safe? Analysis of the thermal treatment of thermoplastics: ABS, PLA, PET, and nylon. J. Occup. Environ. Hyg. 2017, 14, 80–85. [Google Scholar] [CrossRef]

- Kim, Y.; Yoon, C.; Ham, S.; Park, J.; Kim, S.; Kwon, O.; Tsai, P.J. Emissions of nanoparticles and gaseous material from 3D printer operation. Environ. Sci. Technol. 2015, 49, 12044–12053. [Google Scholar] [CrossRef] [PubMed]

- Rubies, E.; Palacín, J. Design and FDM/FFF Implementation of a Compact Omnidirectional Wheel for a Mobile Robot and Assessment of ABS and PLA Printing Materials. Robotics 2020, 9, 43. [Google Scholar] [CrossRef]

- Shabana, R.V.; Santosh, N.; Sarojini, J.; Vikram, K.A.; Lakshmi, V.V. Evaluating the Mechanical Properties of Commonly Used 3d Printed ABS and PLA Polymers with Multi-Layered Polymers. Int. J. Eng. Adv. Technol. 2019, 8, 2341–2356. [Google Scholar]

- Mudassir, A. Measuring Accuracy of Two 3D Printing Materials, Department of Engineering Technologies; Bowling Green State University: Bowling Green, OH, USA, 2016. [Google Scholar]

- Yang, F.; Pitchumani, R. Healing of Thermoplastic Polymers at an interface under Nonisothermal Conditions. Macromolecules 2020, 35, 3213–3224. [Google Scholar]

- Costa, S.F.; Duarte, F.M.; Covas, J.A. Estimation of filament temperature and adhesion development in Fused Deposition Techniques. J. Mater. Process. Technol. 2017, 245, 167–179. [Google Scholar] [CrossRef]

- Kong, Y.; Hay, J.N. The enthalpy of fusion and degree of crystallinity of polymers as measured by DSC. Eur. Polym. J. 2003, 39, 1721–1727. [Google Scholar] [CrossRef]

- Zgryza, L.; Raczynska, A.; Pasnikowska-Lukaszuk, M. Thermovisual measurements of 3D printing of ABS and PLA filaments. Adv. Sci. Technol. Res. J. 2020, 12, 266–271. [Google Scholar] [CrossRef]

- Costa, S.F.; Duarte, F.M.; Covas, J.A. Thermal conditions affecting heat transfer in FDM/FFE: A contribution towards the numerical modelling of the process. Virtual Phys. Prototyp. 2014, 10, 1–12. [Google Scholar] [CrossRef]

- Costa, S.F.; Duarte, F.M.; Covas, J.A. An Analytical Solution for Heat Transfer during deposition in extrusion-based 3D Printing techniques. In Proceedings of the 15th International Conference Computational and Mathematical Methods in Science and Engineering, Rota Cadiz, Spain, 6–10 July 2015; pp. 1161–1172. [Google Scholar]

- Vanaei, H.R.; Shirinbayan, M.; Costa, S.F.; Duarte, F.M.; Covas, J.A.; Deligant, M.; Khelladi, S.; Tcharkhtchi, A. Experimental study of PLA thermal behavior during fused filament fabrication. J. Appl. Polym. Sci. 2020, 138, 49747. [Google Scholar] [CrossRef]

- Costa, S.; Duarte, F.; Covas, J. Using MATLAB to Compute Heat Transfer in Free Form Extrusion. In MATLAB—A Ubiquitous Tool for the Practical Engineer; InTech: Rijeka, Croatia, 2011; pp. 453–474. [Google Scholar]

- Holman, J.P. Heat Transfer; McGraw-Hill Brasil: New York, NY, USA, 2010. [Google Scholar]

| Property | ABS | PLA |

|---|---|---|

| Density (kg/m3) | 1050 | 1300 |

| Thermal conductivity (W/m·) | 0.2 | 0.1 |

| Specific heat (J/kg·) | 2020 | 2100 |

| Latent heat of fusion (J/kg) | --- | 30 000 |

| Solidification temperature () | --- | 150 |

| Property | Value |

|---|---|

| Process parameters | |

| Extrusion temperature TL () | 230 |

| Environment temperature TE () | 25 |

| Deposition velocity (m/s) | 0.03 |

| Convective heat transfer coefficient hconv (W/m2 )—natural convection | 30 |

| Thermal contact conductance between adjacent filaments hi (W/m2) | 200 |

| Thermal contact conductance between filaments and support hi (W/m2) | 10 |

| Fraction of contact area relative to filament area | 0.2 |

| Filament length (mm) | 60 |

| Filament cross-section geometry | circle |

| Filament cross-section diameter (mm) | 0.25 |

| Deposition sequence | Unidirectional and aligned |

| Computational parameters | |

| Time increment (s) | 0.01 |

| Temperature convergence error () | 0.001 |

| Build Orientation | Number of Filaments | Contact Area with the Support (mm2) |

|---|---|---|

| P1 () | 28,800 | 2700 |

| P2 () | 28,800 | 5400 |

| P3 () | 43,200 | 5400 |

| P4 () | 43,200 | 1800 |

| P5 () | 86,400 | 1800 |

| P6 () | 86,400 | 2700 |

| Build Orientation | Maximum Temperature Difference between ABS and PLA (°C) | Maximum Temperature of Peaks A (°C) | Maximum Temperature of Peaks B (°C) | Maximum Temperature of Peaks C (°C) |

|---|---|---|---|---|

| P1 | 40.4 | ABS: 56.2 PLA: 64.8 | ABS: 40.7 PLA: 45.2 | ABS: 33.8 PLA: 36.4 |

| P2 | 39.4 | ABS: 56.1 PLA: 64.9 | ABS: 40.6 PLA: 45.2 | ABS: 33.7 PLA: 36.4 |

| P3 | 41.6 | ABS: 60.3 PLA: 72.6 | ABS: 43.6 PLA: 51.0 | ABS: 35.9 PLA: 39.1 |

| P4 | 41.2 | ABS: 61.0 PLA: 70.2 | ABS: 43.8 PLA: 49.8 | ABS: 35.9 PLA: 39.4 |

| P5 | 40.4 | ABS: 73.6 PLA: 83.6 | ABS: 52.6 PLA: 59.7 | ABS: 41.4 PLA: 46.1 |

| P6 | 40.4 | ABS: 73.6 PLA: 83.5 | ABS: 52.6 PLA: 59.7 | ABS: 41.4 PLA: 46.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa, S.F.; Duarte, F.M.; Covas, J.A. The Effect of a Phase Change on the Temperature Evolution during the Deposition Stage in Fused Filament Fabrication. Computers 2021, 10, 19. https://0-doi-org.brum.beds.ac.uk/10.3390/computers10020019

Costa SF, Duarte FM, Covas JA. The Effect of a Phase Change on the Temperature Evolution during the Deposition Stage in Fused Filament Fabrication. Computers. 2021; 10(2):19. https://0-doi-org.brum.beds.ac.uk/10.3390/computers10020019

Chicago/Turabian StyleCosta, Sidonie F., Fernando M. Duarte, and José A. Covas. 2021. "The Effect of a Phase Change on the Temperature Evolution during the Deposition Stage in Fused Filament Fabrication" Computers 10, no. 2: 19. https://0-doi-org.brum.beds.ac.uk/10.3390/computers10020019