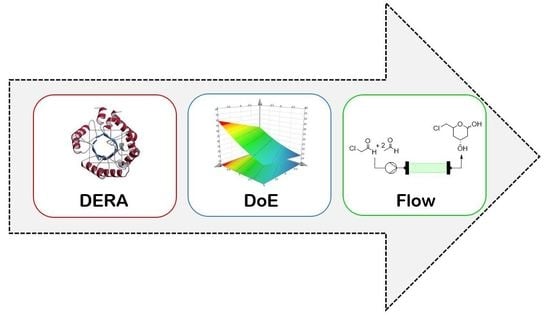

DERA in Flow: Synthesis of a Statin Side Chain Precursor in Continuous Flow Employing Deoxyribose-5-Phosphate Aldolase Immobilized in Alginate-Luffa Matrix

Abstract

:1. Introduction

2. Results and Discussion

2.1. Design of Experiments for Optimal Batch Conditions

2.2. Substrate Screening

2.3. Kinetics

2.4. Immobilization of DERA in Alginate-Luffa Matrix

2.5. Flow Application

2.5.1. Residence Time Distribution

2.5.2. Design of Experiments for Continuous Flow Application

2.5.3. Continuous Synthesis

3. Materials and Methods

3.1. General

3.2. Enzyme Expression and Purification

3.3. Optimization of Reaction Conditions in Batch Using Design of Experiments (DoE)

3.4. GC Analysis

3.5. Substrate Screening

3.6. Immobilization in Beads

3.7. Immobilization in ALM for Batch Reactions

3.8. Immobilization in ALM for Flow Application

3.9. Design of Experiments for Optimizing Flow Process

3.10. Continuous Synthesis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- World Health Organization. The top 10 Causes of Death. Available online: https://www.who.int/news-room/fact-sheets/detail/the-top-10-causes-of-death (accessed on 24 January 2019).

- Wilkins, E.; Wilson, L.; Wickramasinghe, K.; Bhatnagar, P.; Leal, J.; Luengo-Fernandez, R.; Burns, R.; Rayner, M.; Townsend, N. European Cardiovascular Disease Statistics 2017; European Heart Network: Brussels, Belgium, 2017. [Google Scholar]

- National Heart, Lung, and Blood Institute (NHLBI). Ischemic Heart Disease. Available online: https://www.nhlbi.nih.gov/health-topics/ischemic-heart-disease (accessed on 13 September 2019).

- Wald, E.J.; Law, M.R. A strategy to reduce cardiovascular disease by more than 80%. BMJ 2003, 326, 1419. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Feingold, K.R.; Grunfeld, C. Endotext. Cholesterol Lowering Drugs; MDText. com, Inc.: South Dartmouth, MA, USA, 2000. [Google Scholar]

- Istvan, E.S.; Deisenhofer, J. Structural mechanism for statin inhibition of HMG-CoA reductase. Science 2001, 292, 1160–1164. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gazzerro, P.; Proto, M.C.; Gangemi, G.; Malfitano, A.M.; Ciaglia, E.; Pisanti, S.; Santoro, A.; Laezza, C.; Bifulco, M. Pharmacological actions of statins: A critical appraisal in the management of cancer. Pharmacol. Rev. 2012, 64, 102–146. [Google Scholar] [CrossRef] [PubMed]

- Stancu, C.; Sima, A. Statins: Mechanism of action and effects. J. Cell. Mol. Med. 2001, 5, 378–387. [Google Scholar] [CrossRef] [PubMed]

- Müller, M. Chemoenzymatic synthesis of building blocks for statin side chains. Angew. Chem. Int. Ed. 2005, 44, 362–365. [Google Scholar] [CrossRef] [PubMed]

- Liljeblad, A.; Kallinen, A.; Kanerva, L. Biocatalysis in the Preparation of the Statin Side Chain. Curr. Org. Synth. 2009, 6, 362–379. [Google Scholar] [CrossRef] [Green Version]

- Ručigaj, A.; Krajnc, M. Optimization of a Crude Deoxyribose-5-phosphate Aldolase Lyzate-Catalyzed Process in Synthesis of Statin Intermediates. Org. Process Res. Dev. 2013, 17, 854–862. [Google Scholar] [CrossRef]

- Ručigaj, A.; Krajnc, M. Kinetic modeling of a crude DERA lysate-catalyzed process in synthesis of statin intermediates. Chem. Eng. J. 2015, 259, 11–24. [Google Scholar] [CrossRef]

- Wolberg, M.; Dassen, B.H.N.; Schürmann, M.; Jennewein, S.; Wubbolts, M.G.; Schoemaker, H.E.; Mink, D. Large-Scale Synthesis of New Pyranoid Building Blocks Based on Aldolase-Catalysed Carbon-Carbon Bond Formation. Adv. Synth. Catal. 2008, 350, 1751–1759. [Google Scholar] [CrossRef]

- Jennewein, S.; Schürmann, M.; Wolberg, M.; Hilker, I.; Luiten, R.; Wubbolts, M.; Mink, D. Directed evolution of an industrial biocatalyst: 2-deoxy-D-ribose 5-phosphate aldolase. Biotechnol. J. 2006, 1, 537–548. [Google Scholar] [CrossRef]

- Fei, H.; Zheng, C.-C.; Liu, X.-Y.; Li, Q. An industrially applied biocatalyst: 2-Deoxy-d-ribose-5-phosphate aldolase. Process Biochem. 2017, 63, 55–59. [Google Scholar] [CrossRef]

- Tao, J.; Xu, J.-H. Biocatalysis in development of green pharmaceutical processes. Curr. Opin. Chem. Biol. 2009, 13, 43–50. [Google Scholar] [CrossRef] [PubMed]

- Britton, J.; Majumdar, S.; Weiss, G.A. Continuous flow biocatalysis. Chem. Soc. Rev. 2018, 47, 5891–5918. [Google Scholar] [CrossRef] [PubMed]

- Barbas, C.F.; Wang, Y.-F.; Wong, C.-H. Deoxyribose-5-phosphate Aldolase as a Synthetic Catalyst. J. Am. Chem. Soc. 1990, 112, 2013–2014. [Google Scholar] [CrossRef]

- Gijsen, H.J.M.; Wong, C.-H. Unprecedented Asymmetric Aldol Reactions with Three Aldehyde Substrates Catalyzed by 2-Deoxyribose-5-phosphate Aldolase. J. Am. Chem. Soc. 1994, 116, 8422–8423. [Google Scholar] [CrossRef]

- Gijsen, H.J.M.; Wong, C.-H. Sequential One-Pot Aldol Reactions Catalyzed by 2-Deoxyribose-5-phosphate Aldolase and Fructose-1,6-diphosphate Aldolase. J. Am. Chem. Soc. 1995, 117, 2947–2948. [Google Scholar] [CrossRef]

- Gijsen, H.J.M.; Wong, C.-H. Sequential Three- and Four-Substrate Aldol Reactions Catalyzed by Aldolases. J. Am. Chem. Soc. 1995, 117, 7585–7591. [Google Scholar] [CrossRef]

- Sakuraba, H.; Yoneda, K.; Yoshihara, K.; Satoh, K.; Kawakami, R.; Uto, Y.; Tsuge, H.; Takahashi, K.; Hori, H.; Ohshima, T. Sequential aldol condensation catalyzed by hyperthermophilic 2-deoxy-d-ribose-5-phosphate aldolase. Appl. Environ. Microbiol. 2007, 73, 7427–7434. [Google Scholar] [CrossRef] [Green Version]

- Wong, C.-H.; Garcia-Junceda, E.; Chen, L.; Blanco, O.; Gijsen, H.J.M.; Steensma, D.H. Recombinant 2-Deoxyribose-5-phosphate Aldolase in Organic Synthesis: Use of Sequential Two-Substrate and Three-Substrate Aldol Reactions. J. Am. Chem. Soc. 1995, 117, 3333–3339. [Google Scholar] [CrossRef]

- Dick, M.; Hartmann, R.; Weiergräber, O.H.; Bisterfeld, C.; Classen, T.; Schwarten, M.; Neudecker, P.; Willbold, D.; Pietruszka, J. Mechanism-based inhibition of an aldolase at high concentrations of its natural substrate acetaldehyde: Structural insights and protective strategies. Chem. Sci. 2016, 4493–4502. [Google Scholar] [CrossRef] [Green Version]

- Gutmann, B.; Cantillo, D.; Kappe, C.O. Continuous-Flow Technology—A Tool for the Safe Manufacturing of Active Pharmaceutical Ingredients. Angew. Chem. Int. Ed. 2015, 54, 6688–6728. [Google Scholar] [CrossRef] [PubMed]

- Plutschack, M.B.; Pieber, B.; Gilmore, K.; Seeberger, P.H. The Hitchhiker’s Guide to Flow Chemistry. Chem. Rev. 2017, 117, 11796–11893. [Google Scholar] [CrossRef] [PubMed]

- Steinreiber, J.; Schurmann, M.; Wolberg, M.; van Assema, F.; Reisinger, C.; Fesko, K.; Mink, D.; Griengl, H. Overcoming thermodynamic and kinetic limitations of aldolase-catalyzed reactions by applying multienzymatic dynamic kinetic asymmetric transformations. Angew. Chem. Int. Ed. 2007, 46, 1624–1626. [Google Scholar] [CrossRef] [PubMed]

- Colella, M.; Carlucci, C.; Luisi, R. Supported Catalysts for Continuous Flow Synthesis. Top. Curr. Chem. 2018, 376, 46. [Google Scholar] [CrossRef] [PubMed]

- Britton, J.; Raston, C.L. Multi-step continuous-flow synthesis. Chem. Soc. Rev. 2017, 46, 1250–1271. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Phisalaphong, M.; Budiraharjo, R.; Bangrak, P.; Mongkolkajit, J.; Limtong, S. Alginate-loofa as carrier matrix for ethanol production. J. Biosci. Bioeng. 2007, 104, 214–217. [Google Scholar] [CrossRef]

- Dzionek, A.; Wojcieszyńska, D.; Guzik, U. Natural carriers in bioremediation: A review. Electron. J. Biotechnol. 2016, 23, 28–36. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.; Min Xie, Y.; Huang, X.; Zhou, S.; Ruan, D. Mechanical properties of luffa sponge. J. Mech. Behav. Biomed. 2012, 15, 141–152. [Google Scholar] [CrossRef]

- Ogbonna, J.C.; Liu, Y.-C.; Liu, Y.-K.; Tanaka, H. Loofa (Luffa cylindrica) sponge as a carrier for microbial cell immobilization. J. Biosci. Bioeng. 1994, 78, 437–442. [Google Scholar] [CrossRef]

- Murray, P.M.; Bellany, F.; Benhamou, L.; Bucar, D.-K.; Tabor, A.B.; Sheppard, T.D. The application of design of experiments (DoE) reaction optimisation and solvent selection in the development of new synthetic chemistry. Org. Biomol. Chem. 2016, 14, 2373–2384. [Google Scholar] [CrossRef] [Green Version]

- Weissman, S.A.; Anderson, N.G. Design of Experiments (DoE) and Process Optimization. A Review of Recent Publications. Org. Process Res. Dev. 2015, 19, 1605–1633. [Google Scholar] [CrossRef]

- Lendrem, D.; Owen, M.; Godbert, S. DOE (Design of Experiments) in Development Chemistry: Potential Obstacles. Org. Process Res. Dev. 2001, 5, 324–327. [Google Scholar] [CrossRef]

- Robinson, P.K. Enzymes: Principles and biotechnological applications. Essays Biochem. 2015, 59, 1–41. [Google Scholar] [CrossRef] [PubMed]

- Dick, M.; Weiergräber, O.H.; Classen, T.; Bisterfeld, C.; Bramski, J.; Gohlke, H.; Pietruszka, J. Trading off stability against activity in extremophilic aldolases. Sci. Rep. 2016, 6. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wilton, D.C. Acrolein, an Irreversible Active-Site-Directed Inhibitor of Deoxyribose 5-phosphate Aldolase? Biochem. J. 1976, 153, 495–497. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lichtenegger, G.J.; Tursic, V.; Kitzler, H.; Obermaier, K.; Khinast, J.G.; Gruber-Wölfler, H. The Plug & Play Reactor: A Highly Flexible Device for Heterogeneous Reactions in Continuous Flow. Chem. Ing. Tech. 2016, 88, 1518–1523. [Google Scholar] [CrossRef]

- Ošlaj, M.; Cluzeau, J.; Orkić, D.; Kopitar, G.; Mrak, P.; Casar, Z. A highly productive, whole-cell DERA chemoenzymatic process for production of key lactonized side-chain intermediates in statin synthesis. PLoS ONE 2013, 8, e62250. [Google Scholar] [CrossRef] [Green Version]

| [min] | Bo [--] | ||

|---|---|---|---|

| 0.10 | 60.5 | 62.7 | 15.0 |

| 0.25 | 24.2 | 26.8 | 9.5 |

| 0.50 | 12.1 | 11.4 | 33.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grabner, B.; Pokhilchuk, Y.; Gruber-Woelfler, H. DERA in Flow: Synthesis of a Statin Side Chain Precursor in Continuous Flow Employing Deoxyribose-5-Phosphate Aldolase Immobilized in Alginate-Luffa Matrix. Catalysts 2020, 10, 137. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10010137

Grabner B, Pokhilchuk Y, Gruber-Woelfler H. DERA in Flow: Synthesis of a Statin Side Chain Precursor in Continuous Flow Employing Deoxyribose-5-Phosphate Aldolase Immobilized in Alginate-Luffa Matrix. Catalysts. 2020; 10(1):137. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10010137

Chicago/Turabian StyleGrabner, Bianca, Yekaterina Pokhilchuk, and Heidrun Gruber-Woelfler. 2020. "DERA in Flow: Synthesis of a Statin Side Chain Precursor in Continuous Flow Employing Deoxyribose-5-Phosphate Aldolase Immobilized in Alginate-Luffa Matrix" Catalysts 10, no. 1: 137. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10010137