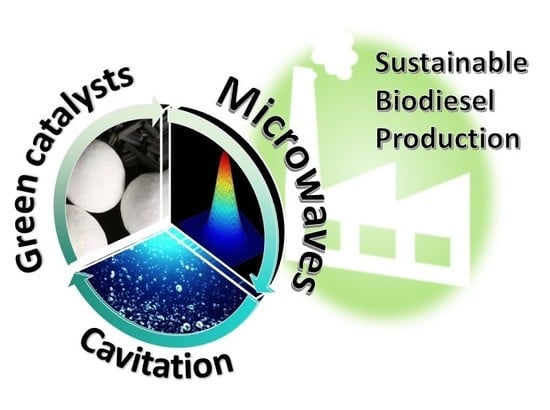

Enabling Technologies and Sustainable Catalysis in Biodiesel Preparation

Abstract

:1. Introduction

2. Enabling Technologies for Biodiesel Production

2.1. Microwave-Assisted Processes

2.2. Cavitation-Assisted Processes

2.2.1. Ultrasound

2.2.2. Hydrodynamic Cavitation

2.3. Combined Technologies

3. Innovative Catalysts for Biodiesel Production

3.1. Enzymes and Ionic Liquids

3.2. Magnetic Catalysts

4. Flow Processes

5. Conclusions

Funding

Conflicts of Interest

Abbreviations

| FA | Fly ashes |

| FAME | Fatty acid methyl ester |

| FFA | Free fatty acid |

| HC | Hydrodynamic cavitation |

| HSM | High-shear mixer |

| IL | Ionic liquid |

| MW | Microwaves |

| PEEK | Polyether ether ketone |

| PTFE | Polytetrafluoroethylene |

| RMS | Root main square |

| RSM | Response surface method |

| US | Ultrasound |

| UVO | Used vegetable oil |

| WCO | Waste cooking oil |

References

- Gavett, E.; Van Dyne, D.; Blase, M.M. Biodiesel: A feasible domestic alternative fuel? In Energy from Biomass and Wastes; Institute of Gas Technology: Chicago, IL, USA, 1993; pp. 709–719. ISBN 0910091889. [Google Scholar]

- Gebremariam, S.N.; Marchetti, J.M. Economics of biodiesel production: Review. Energy Convers. Manag. 2018, 168, 74–84. [Google Scholar] [CrossRef]

- Ramos, M.; Dias, A.P.S.; Puna, J.F.; Gomes, J.; Bordado, J.C. Biodiesel production processes and sustainable raw materials. Energies 2019, 12, 4408. [Google Scholar] [CrossRef] [Green Version]

- Marchetti, J.M.; Miguel, V.U.; Errazu, A.F. Possible methods for biodiesel production. Renew. Sustain. Energy Rev. 2007, 11, 1300–1311. [Google Scholar] [CrossRef]

- Lam, M.K.; Lee, K.T.; Mohamed, A.R. Homogeneous, heterogeneous and enzymatic catalysis for transesterification of high free fatty acid oil (waste cooking oil) to biodiesel: A review. Biotechnol. Adv. 2010, 28, 500–518. [Google Scholar] [CrossRef] [PubMed]

- Gupta, J.; Agarwal, M.; Dalai, A.K. An overview on the recent advancements of sustainable heterogeneous catalysts and prominent continuous reactor for biodiesel production. J. Ind. Eng. Chem. 2020, 88, 58–77. [Google Scholar] [CrossRef]

- Santos, S.; Puna, J.; Gomes, J. A review on bio-based catalysts (immobilized enzymes) used for biodiesel production. Energies 2020, 13, 3013. [Google Scholar] [CrossRef]

- Aransiola, E.F.; Ojumu, T.V.; Oyekola, O.O.; Madzimbamuto, T.F.; Ikhu-Omoregbe, D.I.O. A review of current technology for biodiesel production: State of the art. Biomass Bioenergy 2014, 61, 276–297. [Google Scholar] [CrossRef]

- Khedri, B.; Mostafaei, M.; Safieddin Ardebili, S.M. A review on microwave-assisted biodiesel production. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 41, 2377–2395. [Google Scholar] [CrossRef]

- Gude, V.G.; Martinez-Guerra, E. Green chemistry with process intensification for sustainable biodiesel production. Environ. Chem. Lett. 2018, 16, 327–341. [Google Scholar] [CrossRef]

- Barnard, T.M.; Leadbeater, N.E.; Boucher, M.B.; Stencel, L.M.; Wilhite, B.A. Continuous-flow preparation of biodiesel using microwave heating. Energy Fuels 2007, 21, 1777–1781. [Google Scholar] [CrossRef]

- Hernando, J.; Leton, P.; Matia, M.P.; Novella, J.L.; Alvarez-Builla, J. Biodiesel and FAME synthesis assisted by microwaves: Homogeneous batch and flow processes. Fuel 2007, 86, 1641–1644. [Google Scholar] [CrossRef] [Green Version]

- Choedkiatsakul, I.; Ngaosuwan, K.; Assabumrungrat, S.; Mantegna, S.; Cravotto, G. Biodiesel production in a novel continuous fl ow microwave reactor. Renew. Energy 2015, 83, 25–29. [Google Scholar] [CrossRef]

- Safieddin Ardebili, S.M.; Ge, X.; Cravotto, G. Flow-mode biodiesel production from palm oil using a pressurized microwave reactor. Green Process. Synth. 2019, 8, 8–14. [Google Scholar] [CrossRef]

- Choedkiatsakul, I.; Ngaosuwan, K.; Assabumrungrat, S.; Tabasso, S.; Cravotto, G. Integrated flow reactor that combines high-shear mixing and microwave irradiation for biodiesel production. Biomass Bioenergy 2015, 77, 186–191. [Google Scholar] [CrossRef]

- Chipurici, P.; Vlaicu, A.; Calinescu, I.; Vinatoru, M.; Vasilescu, M.; Ignat, N.D.; Mason, T.J. Ultrasonic, hydrodynamic and microwave biodiesel synthesis—A comparative study for continuous process. Ultrason. Sonochem. 2019, 57, 38–47. [Google Scholar] [CrossRef]

- Hussain, M.N.; Janajreh, I. Acousto-chemical analysis in multi-transducer sonochemical reactors for biodiesel production. Ultrason. Sonochem. 2018, 40, 184–193. [Google Scholar] [CrossRef]

- Martinez-Guerra, E.; Gude, V.G. Continuous and pulse sonication effects on transesterification of used vegetable oil. Energy Convers. Manag. 2015, 96, 268–276. [Google Scholar] [CrossRef]

- Shinde, K.; Nohair, B.; Kaliaguine, S. A parametric study of biodiesel production under ultrasound. Int. J. Chem. React. Eng. 2016, 15. [Google Scholar] [CrossRef]

- Boffito, D.C.; Mansi, S.; Leveque, J.M.; Pirola, C.; Bianchi, C.L.; Patience, G.S. Ultrafast biodiesel production using ultrasound in batch and continuous reactors. ACS Sustain. Chem. Eng. 2013, 1, 1432–1439. [Google Scholar] [CrossRef]

- Delavari, A.; Halek, F.; Amini, M. Continuous biodiesel production in a helicoidal reactor using ultrasound-assisted transesterification reaction of waste cooking oil. Clean Technol. Environ. Policy 2015, 17, 273–279. [Google Scholar] [CrossRef]

- Avellaneda, F.; Salvadó, J. Continuous transesterification of biodiesel in a helicoidal reactor using recycled oil. Fuel Process. Technol. 2011, 92, 83–91. [Google Scholar] [CrossRef]

- Somnuk, K.; Smithmaitrie, P.; Prateepchaikul, G. Two-stage continuous process of methyl ester from high free fatty acid mixed crude palm oil using static mixer coupled with high-intensity of ultrasound. Energy Convers. Manag. 2013, 75, 302–310. [Google Scholar] [CrossRef]

- Somnuk, K.; Prasit, T.; Prateepchaikul, G. Effects of mixing technologies on continuous methyl ester production: Comparison of using plug flow, static mixer, and ultrasound clamp. Energy Convers. Manag. 2017, 140, 91–97. [Google Scholar] [CrossRef]

- Crudo, D.; Bosco, V.; Cavaglià, G.; Grillo, G.; Mantegna, S.; Cravotto, G. Biodiesel production process intensification using a rotor-stator type generator of hydrodynamic cavitation. Ultrason. Sonochem. 2016, 33, 220–225. [Google Scholar] [CrossRef] [PubMed]

- Chuah, L.F.; Klemeš, J.J.; Yusup, S.; Bokhari, A.; Akbar, M.M.; Chong, Z.K. Kinetic studies on waste cooking oil into biodiesel via hydrodynamic cavitation. J. Clean. Prod. 2017, 146, 47–56. [Google Scholar] [CrossRef]

- Samuel, O.D.; Okwu, M.O.; Amosun, S.T.; Verma, T.N.; Afolalu, S.A. Production of fatty acid ethyl esters from rubber seed oil in hydrodynamic cavitation reactor: Study of reaction parameters and some fuel properties. Ind. Crops Prod. 2019, 141, 111658. [Google Scholar] [CrossRef]

- Gude, V.G. Synergism of microwaves and ultrasound for advanced biorefineries. Resour. Technol. 2015, 1, 116–125. [Google Scholar] [CrossRef]

- Leonelli, C.; Mason, T.J. Microwave and ultrasonic processing: Now a realistic option for industry. Chem. Eng. Process. Process Intensif. 2010, 49, 885–900. [Google Scholar] [CrossRef]

- Cravotto, G.; Cintas, P. The combined use of microwaves and ultrasound: Improved tools in process chemistry and organic synthesis. Chem. A Eur. J. 2007, 13, 1902–1909. [Google Scholar] [CrossRef]

- Safieddin Ardebili, S.M.; Hashjin, T.T.; Ghobadian, B.; Najafi, G.; Mantegna, S.; Cravotto, G. Optimization of biodiesel synthesis under simultaneous ultrasound-microwave irradiation using response surface methodology (RSM). Green Process. Synth. 2015, 4, 259–267. [Google Scholar] [CrossRef]

- Martinez-Guerra, E.; Gude, V.G. Synergistic effect of simultaneous microwave and ultrasound irradiations on transesterification of waste vegetable oil. Fuel 2014, 137, 100–108. [Google Scholar] [CrossRef]

- Martinez-Guerra, E.; Gude, V.G. Transesterification of used vegetable oil catalyzed by barium oxide under simultaneous microwave and ultrasound irradiations. Energy Convers. Manag. 2014, 88, 633–640. [Google Scholar] [CrossRef]

- Farvardin, M.; Hosseinzadeh Samani, B.; Rostami, S.; Abbaszadeh-Mayvan, A.; Najafi, G.; Fayyazi, E. Enhancement of biodiesel production from waste cooking oil: Ultrasonic- hydrodynamic combined cavitation system. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 1–15. [Google Scholar] [CrossRef]

- Chua, S.Y.; Periasamy, L.A.; Goh, C.M.H.; Tan, Y.H.; Mubarak, N.M.; Kansedo, J.; Khalid, M.; Walvekar, R.; Abdullah, E.C. Biodiesel synthesis using natural solid catalyst derived from biomass waste—A review. J. Ind. Eng. Chem. 2020, 81, 41–60. [Google Scholar] [CrossRef]

- Sun, C.; Qiu, F.; Yang, D.; Ye, B. Preparation of biodiesel from soybean oil catalyzed by Al-Ca hydrotalcite loaded with K2CO3 as heterogeneous solid base catalyst. Fuel Process. Technol. 2014, 126, 383–391. [Google Scholar] [CrossRef]

- Borah, M.J.; Devi, A.; Borah, R.; Deka, D. Synthesis and application of Co doped ZnO as heterogeneous nanocatalyst for biodiesel production from non-edible oil. Renew. Energy 2019, 133, 512–519. [Google Scholar] [CrossRef]

- Malins, K. The potential of K3PO4, K2CO3, Na3PO4 and Na2CO3 as reusable alkaline catalysts for practical application in biodiesel production. Fuel Process. Technol. 2018, 179, 302–312. [Google Scholar] [CrossRef]

- Vasić, K.; Podrepšek, G.H.; Knez, Ž.; Leitgeb, M. Biodiesel production using solid acid catalysts based on metal oxides. Catalysts 2020, 10, 237. [Google Scholar] [CrossRef] [Green Version]

- Benedictto, G.P.; Legnoverde, M.S.; Tara, J.C.; Sotelo, R.M.; Basaldella, E.I. Synthesis of K + /MgO heterogeneous catalysts derived from MgCO3 for biodiesel production. Mater. Lett. 2019, 246, 199–202. [Google Scholar] [CrossRef]

- Sharma, A.; Kodgire, P.; Kachhwaha, S.S. Biodiesel production from waste cotton-seed cooking oil using microwave-assisted transesterification: Optimization and kinetic modeling. Renew. Sustain. Energy Rev. 2019, 116, 109394. [Google Scholar] [CrossRef]

- Lawan, I.; Garba, Z.N.; Zhou, W.; Zhang, M.; Yuan, Z. Synergies between the microwave reactor and CaO/zeolite catalyst in waste lard biodiesel production. Renew. Energy 2020, 145, 2550–2560. [Google Scholar] [CrossRef]

- Pavlović, S.M.; Marinković, D.M.; Kostić, M.D.; Janković-Častvan, I.M.; Mojović, L.V.; Stanković, M.V.; Veljković, V.B. A CaO/zeolite-based catalyst obtained from waste chicken eggshell and coal fly ash for biodiesel production. Fuel 2020, 267, 117171. [Google Scholar] [CrossRef]

- Silveira Junior, E.G.; Perez, V.H.; Reyero, I.; Serrano-Lotina, A.; Justo, O.R. Biodiesel production from heterogeneous catalysts based K2CO3 supported on extruded γ-Al2O3. Fuel 2019, 241, 311–318. [Google Scholar] [CrossRef]

- Dehghani, S.; Haghighi, M. Sono-sulfated zirconia nanocatalyst supported on MCM-41 for biodiesel production from sunflower oil: Influence of ultrasound irradiation power on catalytic properties and performance. Ultrason. Sonochem. 2017, 35, 142–151. [Google Scholar] [CrossRef] [PubMed]

- Wang, A.; Sudarsanam, P.; Xu, Y.; Zhang, H.; Li, H.; Yang, S. Functionalized magnetic nanosized materials for efficient biodiesel synthesis via acid–base/enzyme catalysis. Green Chem. 2020. [Google Scholar] [CrossRef]

- Zhang, Y.; Xia, X.; Duan, M.; Han, Y.; Liu, J.; Luo, M.; Zhao, C.; Zu, Y.; Fu, Y. Green deep eutectic solvent assisted enzymatic preparation of biodiesel from yellow horn seed oil with microwave irradiation. J. Mol. Catal. B Enzym. 2016, 123, 35–40. [Google Scholar] [CrossRef]

- Panadare, D.C.; Rathod, V.K. Microwave assisted enzymatic synthesis of biodiesel with waste cooking oil and dimethyl carbonate. J. Mol. Catal. B Enzym. 2016, 133, S518–S524. [Google Scholar] [CrossRef]

- Poppe, J.K.; Matte, C.R.; Fernandez-Lafuente, R.; Rodrigues, R.C.; Ayub, M.A.Z. Transesterification of Waste Frying Oil and Soybean Oil by Combi-lipases Under Ultrasound-Assisted Reactions. Appl. Biochem. Biotechnol. 2018, 186, 576–589. [Google Scholar] [CrossRef]

- Gawas, S.D.; Rathod, V.K. Enhancement in synthesis of ethyl laurate catalyzed by fermase by combined effect of ultrasound and stage wise addition of ethanol. Chem. Eng. Process. Process Intensif. 2018, 125, 207–213. [Google Scholar] [CrossRef]

- Wahidin, S.; Idris, A.; Shaleh, S.R.M. Ionic liquid as a promising biobased green solvent in combination with microwave irradiation for direct biodiesel production. Bioresour. Technol. 2016, 206, 150–154. [Google Scholar] [CrossRef]

- Handayani, P.A.; Abdullah, A.; Hadiyanto, H. Biodiesel production from Nyamplung (Calophyllum inophyllum) oil using ionic liquid as a catalyst and microwave heating system. Bull. Chem. React. Eng. Catal. 2017, 12, 293–298. [Google Scholar] [CrossRef]

- Chang, F.; Zhou, Q. Facile Preparation of β-Cyclodextrin-Fe3O4 Magnetic-Brønsted Acidic Ionic Liquid for Biodiesel Production. Waste Biomass Valorization 2020, 11, 1983–1988. [Google Scholar] [CrossRef]

- Gardy, J.; Osatiashtiani, A.; Céspedes, O.; Hassanpour, A.; Lai, X.; Lee, A.F.; Wilson, K.; Rehan, M. A magnetically separable SO4/Fe-Al-TiO2 solid acid catalyst for biodiesel production from waste cooking oil. Appl. Catal. B Environ. 2018, 234, 268–278. [Google Scholar] [CrossRef] [Green Version]

- Dimian, A.C.; Rothenberg, G. An effective modular process for biodiesel manufacturing using heterogeneous catalysis. Catal. Sci. Technol. 2016, 6, 6097–6108. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Liao, J.-D.; Yang, J.-W.; Hsu, W.-D.; Liu, B.H.; Chen, T.-C.; Sivashanmugan, K.; Gedanken, A. Continuous Waste Cooking Oil Transesterification with Microwave Heating and Strontium Oxide Catalyst. Chem. Eng. Technol. 2018, 41, 192–198. [Google Scholar] [CrossRef]

- Tangy, A.; Pulidindi, I.N.; Perkas, N.; Gedanken, A. Continuous flow through a microwave oven for the large-scale production of biodiesel from waste cooking oil. Bioresour. Technol. 2017, 224, 333–341. [Google Scholar] [CrossRef]

- Zenevicz, M.C.P.; Jacques, A.; Silva, M.J.A.; Furigo, A.; Oliveira, V.; de Oliveira, D. Study of a reactor model for enzymatic reactions in continuous mode coupled to an ultrasound bath for esters production. Bioprocess Biosyst. Eng. 2018, 41, 1589–1597. [Google Scholar] [CrossRef]

| System | Substrate | Catalyst a | Methanol:Oil | Conversion | |

|---|---|---|---|---|---|

| Batch and flow | Vegetable oil | KOH 1.0% | 6:1 | 98.9 | [11] |

| Flow | Palm oil | NaOH 1.0% | 12:1 | 99.4 | [13] |

| Flow | Palm oil | NaOH 1.0% | 6:1 | 97.8 | [14] |

| Flow | Palm oil | NaOH | 9.1 | 99.8 | [15] |

| Flow | Sunflower oil | KOH 1.0% | 6:1 | 96.5 | [16] |

| System | Substrate | Catalyst a | Alcohol:Oil | Conversion | |

|---|---|---|---|---|---|

| Bath 40 kHz, titanium horn 20 kHz | WCO * | KOH 1.0% | 9:1 b | 90.6 | [17] |

| Titanium horn 20 kHz | UVO | NaOH 0.5% | 9:1 b | 98.0 | [18] |

| Titanium horn 26 kHz | Canola oil | CH3ONa 0.5% | 4:1 b | 80.0 | [19] |

| Horn 20 kHz | Rapeseed oil | KOH | 1:7 b | 90.0 | [20] |

| Ultrasonic homogeniser | WCO | NaOH 0.5% | 8:6 b | 90.0 | [21,22] |

| Horn 18 kHz | Palm oil | H2SO4, KOH | - | 92.5 | [23] |

| Ultrasonic tubular reactor with 16 clamps 20 kHz | Refined Palm oil | KOH 12 g/L | 4.4:1 | 98.9 | [24] |

| Rotor-stator reactor | Palm oil, WCO | NaOH 3.6 g/L, NaOH 5.6 g/L | 4:1 b | 99.0 | [25] |

| Rotor-stator reactor | WCO | KOH 1.0% | 6:1 b | 98.0 | [26] |

| Rotor-stator reactor | Rubber seed oil | KOH 4.0% | 6:1 c | 92.5 | [27] |

| System | Substrate | Catalyst a | Methanol:Oil | Conversion | |

|---|---|---|---|---|---|

| MW, Pyrex US horn 20 kHz | Palm oil | KOH 1.0% | 6:1 | 97.5 | [31] |

| MW, US horn | WCO | NaOH 0.7% | 6:1 | 97.6 | [32] |

| MW, US horn | WCO | BaO 0.7% | 6:1 | 96.0 | [33] |

| Titanium US horn, rotor-stator reactor | WCO | NaOH 1.0% | 6:1 | 90.4 | [34] |

| System | Substrate | Catalyst | Loading | Alcohol:Oil a | Conversion | |

|---|---|---|---|---|---|---|

| Conventional | Soybean oil | K2CO3/Al-Ca hydrotalcite | 2.0 wt.% | 13:1 | 95.0 | [36] |

| Conventional | Mesua ferrea oil | Co@ZnO | 2.5 wt.% | 9:1 | 98.0 | [37] |

| Conventional | Rapeseed oil | Na2CO3 | 5.0 wt.% | 11:1 | 96.0 | [38,39] |

| Conventional | Sunflower oil | K+@MgO | 3.0 wt.% | 10:3 | 98.0 | [40] |

| MW | WCO | CaO | 1.3 wt.% | 9.6:1 | 90.4 | [41] |

| MW | Waste lard | CaO/zeolite | 3.0 wt./vol.% | 30:1 | 97.1 | [42] |

| Conventional | Sunflower oil | CaO/zeolite | 6.0 wt.% | 6:1 | 97.5 | [43] |

| Conventional | Sunflower oil | K2CO3/γ-Al2O3 | 5.0 wt.% | 12:1 b | 99.3 | [44] |

| Conventional | Sunflower oil | S-ZrO/MCM-41 | 5.0 wt.% | 9:1 | 96.9 | [45,46] |

| MW | Yellow horn seed oil | Novozym 435 | 8.0 wt.% | 6:1 | 95.0 | [47] |

| MW | WCO | Novozym 435 | 10.0 wt.% | 6:1 c | 94.0 | [48] |

| US | Soybean oil, WCO | Combi-lipases | 25.0 wt.% | 5:1 b | 90.0, 70.0 | [49] |

| US | Lauric acid | CALB 10000 | 2.0 wt.% | 2:1 b | 96.8 | [50] |

| MW | Nannochloropsis sp. | [EMIM]MeSO4 | - | - | 36.7 | [51] |

| MW | Calophyllum in. | [BMIM]HSO4 | 0.5 wt.% | 9:1 | 92.8 | [52] |

| Conventional | Jatropha seed oil | [β-CD-6-Im-(CH2)3-HSO3][HSO4]-Fe3O4 | 3.0 wt.% | 10:1 | 94.7 | [53] |

| MW | WCO | SO4/Fe-Al-TiO2 | 3.0 wt.% | 10:1 | 96.0 | [54] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bucciol, F.; Colia, M.; Calcio Gaudino, E.; Cravotto, G. Enabling Technologies and Sustainable Catalysis in Biodiesel Preparation. Catalysts 2020, 10, 988. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10090988

Bucciol F, Colia M, Calcio Gaudino E, Cravotto G. Enabling Technologies and Sustainable Catalysis in Biodiesel Preparation. Catalysts. 2020; 10(9):988. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10090988

Chicago/Turabian StyleBucciol, Fabio, Mariachiara Colia, Emanuela Calcio Gaudino, and Giancarlo Cravotto. 2020. "Enabling Technologies and Sustainable Catalysis in Biodiesel Preparation" Catalysts 10, no. 9: 988. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10090988