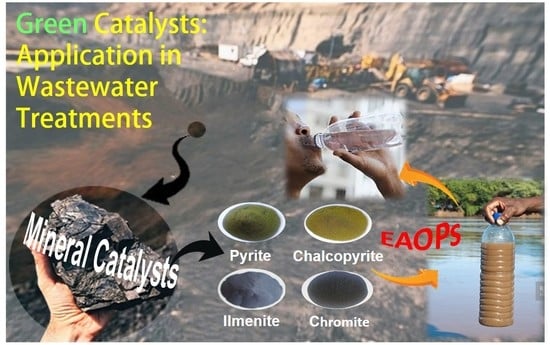

Application of Mineral Iron-Based Natural Catalysts in Electro-Fenton Process: A Comparative Study

Abstract

:1. Introduction

2. Results and Discussion

2.1. Characterization of Mineral Iron based Catalysts

2.2. Effect of Operating Parameter on CFZ Decay Kinetics during HEF

2.2.1. Effect of Applied Current

2.2.2. Effect of Catalyst Dosage

2.3. Mineralization of CFZ during HEFPs

2.4. Kinetics of CFZ Degradation by HEF

2.5. Mineralization Current Efficiency (MCE) and Specific Energy Consumption (SEC)

2.6. Stability and Reusability of the Catalysts

2.7. Comparison of the Performance of the HEF Process Using Mineral Catalysts with other Processes for CFZ Degradation/Mineralization

3. Material and Methods

3.1. Materials

3.2. Analysis Methods

3.3. Procedures of Heterogeneous Electro-Fenton Process

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brillas, E.; Martínez-Huitle, C.A. Decontamination of wastewaters containing synthetic organic dyes by electrochemical methods. An updated review. Appl. Catal. B Environ. 2015, 166, 603–643. [Google Scholar] [CrossRef]

- García-Montoya, M.F.; Gutierrez-Granados, S.; Alatorre-Ordaz, A.; Galindo, R.; Ornelas, R.; Peralta-Hernandez, J.M. Application of electrochemical/BDD process for the treatment wastewater effluents containing pharmaceutical compounds. J. Ind. Eng. Chem. 2015, 31, 238–243. [Google Scholar] [CrossRef]

- Jain, B.; Singh, A.K.; Kim, H.; Lichtfouse, E.; Sharma, V.K. Treatment of organic pollutants by homogeneous and heterogeneous Fenton reaction processes. Environ. Chem. Lett. 2018, 16, 947–967. [Google Scholar] [CrossRef] [Green Version]

- Rodrigo, M.; Oturan, N.; Oturan, M.A. Electrochemically assisted remediation of pesticides in soils and water: A review. Chem. Rev. 2014, 114, 8720–8745. [Google Scholar] [CrossRef]

- Mompelat, S.; Le Bot, B.; Thomas, O. Occurrence and fate of pharmaceutical products and by-products, from resource to drinking water. Environ. Int. 2009, 35, 803–814. [Google Scholar] [CrossRef]

- Besse, J.-P.; Kausch-Barreto, C.; Garric, J. Exposure assessment of pharmaceuticals and their metabolites in the aquatic environment: Application to the French situation and preliminary prioritization. Hum. Ecol. Risk Assess. 2008, 14, 665–695. [Google Scholar] [CrossRef]

- Gros, M.; Petrović, M.; Barceló, D. Wastewater treatment plants as a pathway for aquatic contamination by pharmaceuticals in the Ebro river basin (northeast Spain). Environ. Toxicol. Chem. Int. J. 2007, 26, 1553–1562. [Google Scholar] [CrossRef]

- Wei, R.; Ge, F.; Huang, S.; Chen, M.; Wang, R. Occurrence of veterinary antibiotics in animal wastewater and surface water around farms in Jiangsu Province, China. Chemosphere 2011, 82, 1408–1414. [Google Scholar] [CrossRef]

- Gurkan, Y.Y.; Turkten, N.; Hatipoglu, A.; Cinar, Z. Photocatalytic degradation of cefazolin over N-doped TiO2 under UV and sunlight irradiation: Prediction of the reaction paths via conceptual DFT. Chem. Eng. J. 2012, 184, 113–124. [Google Scholar] [CrossRef]

- Rechelo, B.S.; Kogawa, A.C.; Salgado, H.R.N. Quantitative analysis of cefazolin sodium in lyophilized powder by infrared spectrophotometry: Green, low cost, fast and effective. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2019, 208, 157–161. [Google Scholar] [CrossRef]

- Ikehata, K.; Naghashkar, N.J.; El-Din, M.G. Degradation of aqueous pharmaceuticals by ozonation and advanced oxidation processes: A review. Ozone Sci. Eng. 2006, 28, 353–414. [Google Scholar] [CrossRef]

- Xiao, Y.; Song, X.; Liu, Z.; Li, R.; Zhao, X.; Huang, Y. Photocatalytic removal of cefazolin using Ag3PO4/BiOBr under visible light and optimization of parameters by response surface methodology. J. Ind. Eng. Chem. 2017, 45, 248–256. [Google Scholar] [CrossRef]

- Li, L.; Wei, D.; Wei, G.; Du, Y. Transformation of cefazolin during chlorination process: Products, mechanism and genotoxicity assessment. J. Hazard. Mater. 2013, 262, 48–54. [Google Scholar] [CrossRef] [PubMed]

- Stackelberg, P.E.; Gibs, J.; Furlong, E.T.; Meyer, M.T.; Zaugg, S.D.; Lippincott, R.L. Efficiency of conventional drinking-water-treatment processes in removal of pharmaceuticals and other organic compounds. Sci. Total Environ. 2007, 377, 255–272. [Google Scholar] [CrossRef] [PubMed]

- Simazaki, D.; Kubota, R.; Suzuki, T.; Akiba, M.; Nishimura, T.; Kunikane, S. Occurrence of selected pharmaceuticals at drinking water purification plants in Japan and implications for human health. Water Res. 2015, 76, 187–200. [Google Scholar] [CrossRef] [PubMed]

- Carmona, E.; Andreu, V.; Picó, Y. Occurrence of acidic pharmaceuticals and personal care products in Turia River Basin: From waste to drinking water. Sci. Total Environ. 2014, 484, 53–63. [Google Scholar] [CrossRef]

- Wieszczycka, K.; Filipowiak, K.; Wojciechowska, I.; Aksamitowski, P. Novel ionic liquid-modified polymers for highly effective adsorption of heavy metals ions. Separation Purif. Technol. 2020, 236, 116313. [Google Scholar] [CrossRef]

- Gibson, L. Mesosilica materials and organic pollutant adsorption: Part B removal from aqueous solution. Chem. Soc. Rev. 2014, 43, 5173–5182. [Google Scholar] [CrossRef]

- Pelalak, R.; Soltani, R.; Heidari, Z.; Malekshah, R.E.; Aallaei, M.; Marjani, A.; Rezakazemi, M.; Kurniawan, T.A.; Shirazian, S. Molecular dynamics simulation of novel diamino-functionalized hollow mesosilica spheres for adsorption of dyes from synthetic wastewater. J. Mol. Liq. 2020, 322, 114812. [Google Scholar] [CrossRef]

- Soltani, R.; Pelalak, R.; Pishnamazi, M.; Marjani, A.; Shirazian, S. Synthesis of Multi-organo-functionalized Fibrous silica KCC-1 for Highly Efficient Adsorption of Acid Fuchsine and acid Orange II from Aqueous Solution. Sci. Rep. 2020. [Google Scholar] [CrossRef]

- Soltani, R.; Pishnamazi, M.; Pelalak, R.; Rezakazemi, M.; Marjani, A.; Dinari, M.; Sarkar, S.M.; Shirazian, S. Preparation of COOH-KCC-1/polyamide 6 composite by in situ ring-opening polymerization: Synthesis, characterization, and Cd(II) adsorption study. J. Environ. Chem. Eng. 2020, 104683. [Google Scholar] [CrossRef]

- Pelalak, R.; Heidari, Z.; Soltani, H.; Shirazian, S. Mathematical model for numerical simulation of organic compound recovery using membrane separation. Chem. Eng. Technol. 2018, 41, 345–352. [Google Scholar] [CrossRef]

- Soltani, H.; Pelalak, R.; Heidari, Z.; Ghadiri, M.; Shirazian, S. CFD simulation of transport phenomena in wastewater treatment via vacuum membrane distillation. J. Porous Media 2016, 19, 515–526. [Google Scholar] [CrossRef]

- Nguyen, P.; Carvalho, G.; Reis, M.A.; Oehmen, A. A review of the biotransformations of priority pharmaceuticals in biological wastewater treatment processes. Water Res. 2020, 188, 116446. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, B.; Sellamuthu, B.; Ouarda, Y.; Drogui, P.; Tyagi, R.D.; Buelna, G. Review on fate and mechanism of removal of pharmaceutical pollutants from wastewater using biological approach. Bioresour. Technol. 2017, 224, 1–12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Heidari, Z.; Alizadeh, R.; Ebadi, A.; Pelalak, R.; Oturan, N.; Oturan, M.A. Degradation of furosemide using photocatalytic ozonation in the presence of ZnO/ICLT nanocomposite particles: Experimental, modeling, optimization and mechanism evaluation. J. Mol. Liq. 2020, 319, 114193. [Google Scholar] [CrossRef]

- Rosal, R.; Rodríguez, A.; Perdigón-Melón, J.; Mezcua, M.; Hernando, M.; Letón, P.; García-Calvo, E.; Agüera, A.; Fernández-Alba, A. Removal of pharmaceuticals and kinetics of mineralization by O3/H2O2 in a biotreated municipal wastewater. Water Res. 2008, 42, 3719–3728. [Google Scholar] [CrossRef]

- Pelalak, R.; Alizadeh, R.; Ghareshabani, E. Enhanced heterogeneous catalytic ozonation of pharmaceutical pollutants using a novel nanostructure of iron-based mineral prepared via plasma technology: A comparative study. J. Hazard. Mater. 2020, 392, 122269. [Google Scholar] [CrossRef]

- Oturan, M.A.; Aaron, J.-J. Advanced Oxidation Processes in Water/Wastewater Treatment: Principles and Applications. A Review. Crit. Rev. Environ. Sci. Technol. 2014, 44, 2577–2641. [Google Scholar] [CrossRef]

- Giwa, A.; Yusuf, A.; Balogun, H.A.; Sambudi, N.S.; Bilad, M.R.; Adeyemi, I.; Chakraborty, S.; Curcio, S. Recent advances in advanced oxidation processes for removal of contaminants from water: A comprehensive review. Process Saf. Environ. Prot. 2020, 146, 220–256. [Google Scholar] [CrossRef]

- Tufail, A.; Price, W.E.; Mohseni, M.; Pramanik, B.K.; Hai, F.I. A critical review of advanced oxidation processes for emerging trace organic contaminant degradation: Mechanisms, factors, degradation products, and effluent toxicity. J. Water Process Eng. 2020, 101778. [Google Scholar] [CrossRef]

- Heidari, Z.; Alizadeh, R.; Ebadi, A.; Oturan, N.; Oturan, M.A. Efficient photocatalytic degradation of furosemide by a novel sonoprecipited ZnO over ion exchanged clinoptilolite nanorods. Sep. Purif. Technol. 2020, 242, 116800. [Google Scholar] [CrossRef]

- Pelalak, R.; Alizadeh, R.; Ghareshabani, E.; Heidari, Z. Degradation of sulfonamide antibiotics using ozone-based advanced oxidation process: Experimental, modeling, transformation mechanism and DFT study. Sci. Total Environ. 2020, 734, 139446. [Google Scholar] [CrossRef] [PubMed]

- Casado, J. Towards industrial implementation of Electro-Fenton and derived technologies for wastewater treatment: A review. J. Environ. Chem. Eng. 2019, 7, 102823. [Google Scholar] [CrossRef]

- Chaplin, B.P. Critical review of electrochemical advanced oxidation processes for water treatment applications. Environ. Sci. Process. Impacts 2014, 16, 1182–1203. [Google Scholar] [CrossRef] [PubMed]

- Brillas, E.; Sirés, I.; Oturan, M.A. Electro-Fenton Process and Related Electrochemical Technologies Based on Fenton’s Reaction Chemistry. Chem. Rev. 2009, 109, 6570–6631. [Google Scholar] [CrossRef]

- Zhou, M.; Oturan, M.A.; Sires, I. Electro-Fenton Process; Springer: Berlin, Germany, 2018. [Google Scholar]

- Barhoumi, N.; Oturan, N.; Olvera-Vargas, H.; Brillas, E.; Gadri, A.; Ammar, S.; Oturan, M.A. Pyrite as a sustainable catalyst in electro-Fenton process for improving oxidation of sulfamethazine. Kinetics, mechanism and toxicity assessment. Water Res. 2016, 94, 52–61. [Google Scholar] [CrossRef]

- Ammar, S.; Oturan, M.A.; Labiadh, L.; Guersalli, A.; Abdelhedi, R.; Oturan, N.; Brillas, E. Degradation of tyrosol by a novel electro-Fenton process using pyrite as heterogeneous source of iron catalyst. Water Res. 2015, 74, 77–87. [Google Scholar] [CrossRef]

- Ganiyu, S.O.; Martínez-Huitle, C.A. Nature, Mechanisms and Reactivity of Electrogenerated Reactive Species at Thin-Film Boron-Doped Diamond (BDD) Electrodes During Electrochemical Wastewater Treatment. ChemElectroChem 2019, 6, 2379–2392. [Google Scholar] [CrossRef]

- Nidheesh, P.; Divyapriya, G.; Oturan, N.; Trellu, C.; Oturan, M.A. Environmental applications of boron-doped diamond electrodes: 1. Applications in water and wastewater treatment. ChemElectroChem 2019, 6, 2124–2142. [Google Scholar] [CrossRef]

- Weiss, E.; Groenen-Serrano, K.; Savall, A. Electrochemical mineralization of sodium dodecylbenzenesulfonate at boron doped diamond anodes. J. Appl. Electrochem. 2007, 37, 1337–1344. [Google Scholar] [CrossRef]

- Panizza, M.; Cerisola, G. Application of diamond electrodes to electrochemical processes. Electrochim. Acta 2005, 51, 191–199. [Google Scholar] [CrossRef]

- Ganiyu, S.O.; Zhou, M.; Martínez-Huitle, C.A. Heterogeneous electro-Fenton and photoelectro-Fenton processes: A critical review of fundamental principles and application for water/wastewater treatment. Appl. Catal. B Environ. 2018, 235, 103–129. [Google Scholar] [CrossRef]

- Poza-Nogueiras, V.; Rosales, E.; Pazos, M.; Sanromán, M. Current advances and trends in electro-Fenton process using heterogeneous catalysts—A review. Chemosphere 2018, 201, 399–416. [Google Scholar] [CrossRef]

- Nidheesh, P.V. Heterogeneous Fenton catalysts for the abatement of organic pollutants from aqueous solution: A review. RSC Adv. 2015, 5, 40552–40577. [Google Scholar] [CrossRef]

- Thomas, N.; Dionysiou, D.D.; Pillai, S.C. Heterogeneous Fenton catalysts: A review of recent advances. J. Hazard. Mater. 2021, 404, 124082. [Google Scholar] [CrossRef]

- Barhoumi, N.; Labiadh, L.; Oturan, M.A.; Oturan, N.; Gadri, A.; Ammar, S.; Brillas, E. Electrochemical mineralization of the antibiotic levofloxacin by electro-Fenton-pyrite process. Chemosphere 2015, 141, 250–257. [Google Scholar] [CrossRef]

- Expósito, E.; Sánchez-Sánchez, C.M.; Montiel, V. Mineral Iron Oxides as Iron Source in Electro-Fenton and Photoelectro-Fenton Mineralization Processes. J. Electrochem. Soc. 2007, 154, 116–122. [Google Scholar] [CrossRef]

- Fang, G.-D.; Dionysiou, D.D.; Al-Abed, S.R.; Dong-Mei, Z. Superoxide radical driving the activation of persulfate by magnetite nanoparticles: Implications for the degradation of PCBs. Appl. Catal. B Environ. 2013, 129, 325–332. [Google Scholar] [CrossRef]

- Silveira, J.E.; Zazo, J.A.; Pliego, G.; Casas, J.A. Landfill leachate treatment by sequential combination of activated persulfate and Fenton oxidation. Waste Manag. 2018, 81, 220–225. [Google Scholar] [CrossRef]

- Barhoumi, N.; Olvera-Vargas, H.; Oturan, N.; Huguenot, D.; Gadri, A.; Ammar, S.; Brillas, E.; Oturan, M.A. Kinetics of oxidative degradation/mineralization pathways of the antibiotic tetracycline by the novel heterogeneous electro-Fenton process with solid catalyst chalcopyrite. Appl. Catal. B Environ. 2017, 209, 637–647. [Google Scholar] [CrossRef]

- Pataquiva-Mateus, A.Y.; Zea, H.R.; Ramirez, J.H. Degradation of Orange II by Fenton reaction using ilmenite as catalyst. Environ. Sci. Pollut. Res. 2017, 24, 6187–6194. [Google Scholar] [CrossRef] [PubMed]

- Pelalak, R.; Baniadam, M.; Maghrebi, M. Controllable purification, cutting and unzipping of multi-walled carbon nanotubes with a microwave method. Appl. Phys. A 2013, 111, 951–957. [Google Scholar] [CrossRef]

- Wu, X.; Qin, S.; Dubrovinsky, L. Structural characterization of the FeTiO3–MnTiO3 solid solution. J. Solid State Chem. 2010, 183, 2483–2489. [Google Scholar] [CrossRef]

- Saavedra, A.; García-Meza, J.V.; Cortón, E.; González, I. Attachment of Leptospirillum sp. to chemically modified pyrite surfaces. Fast and simple electrochemical monitoring of bacterial-mineral interactions. Hydrometallurgy 2020, 199, 105534. [Google Scholar]

- Sarkar, S.; Kumar, T.N.; Ray, D.; Bhattacharya, S.; Shukla, A.D.; Moitra, H.; Dagar, A.; Chauhan, P.; Sen, K.; Das, S. Mineralogy and spectroscopy (VIS near infrared and micro-Raman) of chromite from Nidar ophiolite complex, SE Ladakh, India: Implications for future planetary exploration. Planet. Space Sci. 2019, 165, 1–9. [Google Scholar]

- Yang, B.; Yan, H.; Zeng, M.; Huang, P.; Jia, F.; Teng, A. A novel copper depressant for selective flotation of chalcopyrite and molybdenite. Miner. Eng. 2020, 151, 106309. [Google Scholar] [CrossRef]

- Garcia-Segura, S.; Brillas, E.; Cornejo-Ponce, L.; Salazar, R. Effect of the Fe3+/Cu2+ ratio on the removal of the recalcitrant oxalic and oxamic acids by electro-Fenton and solar photoelectro-Fenton. Sol. Energy 2016, 124, 242–253. [Google Scholar] [CrossRef]

- Zazou, H.; Oturan, N.; Sönmez Çelebi, M.; Hamdani, M.; Oturan, M.A. Cold incineration of 1,2-dichlorobenzene in aqueous solution by electrochemical advanced oxidation using DSA/Carbon felt, Pt/Carbon felt and BDD/Carbon felt cells. Sep. Purif. Technol. 2019, 208, 184–193. [Google Scholar] [CrossRef]

- Oturan, N.; Ganiyu, S.O.; Raffy, S.; Oturan, M.A. Sub-stoichiometric titanium oxide as a new anode material for electro-Fenton process: Application to electrocatalytic destruction of antibiotic amoxicillin. Appl. Catal. B Environ. 2017, 217, 214–223. [Google Scholar] [CrossRef]

- Shokri, M.; Isapour, G.; Behnajady, M.A.; Dorosti, S. A comparative study of photocatalytic degradation of the antibiotic cefazolin by suspended and immobilized TiO2 nanoparticles. Desalination Water Treat. 2016, 57, 12874–12881. [Google Scholar] [CrossRef]

- Samarghandi, M.; Rahmani, A.; Asgari, G.; Ahmadidoost, G.; Dargahi, A. Photocatalytic removal of cefazolin from aqueous solution by AC prepared from mango seed+ ZnO under uv irradiation. Glob. Nest J. 2018, 20, 399–407. [Google Scholar]

- Fan, Y.; Zhou, Z.; Feng, Y.; Zhou, Y.; Wen, L.; Shih, K. Degradation mechanisms of ofloxacin and cefazolin using peroxymonosulfate activated by reduced graphene oxide-CoFe2O4 composites. Chem. Eng. J. 2020, 383, 123056. [Google Scholar] [CrossRef]

- Hsu, M.H.; Kuo, T.H.; Chen, Y.E.; Huang, C.H.; Hsu, C.C.; Lin, A.Y.C. Substructure Reactivity Affecting the Manganese Dioxide Oxidation of Cephalosporins. Environ. Sci. Technol. 2018, 52, 9188–9195. [Google Scholar] [CrossRef]

| Parameters. | I (mA) | kapp (min−1) | R2 |

|---|---|---|---|

| Chalcopyrite | 50 | 0.111 | 0.994 |

| 100 | 0.196 | 0.957 | |

| 200 | 0.241 | 0.991 | |

| 400 | 0.329 | 0.995 | |

| 500 | 0.368 | 0.999 | |

| Pyrite | 50 | 0.074 | 0.986 |

| 100 | 0.117 | 0.995 | |

| 200 | 0.219 | 0.986 | |

| 400 | 0.285 | 0.992 | |

| 500 | 0.331 | 0.997 | |

| Chromite | 50 | 0.109 | 0.995 |

| 100 | 0.123 | 0.99 | |

| 200 | 0.209 | 0.996 | |

| 400 | 0.323 | 0.997 | |

| 500 | 0.355 | 0.999 | |

| Ilmenite | 50 | 0.069 | 0.987 |

| 100 | 0.125 | 0.956 | |

| 200 | 0.179 | 0.979 | |

| 400 | 0.219 | 0.977 | |

| 500 | 0.221 | 0.989 |

| Method | Catalyst | Experimental Condition | Results | Ref. |

|---|---|---|---|---|

| Photocatalysis | TiO2 | [CFZ] = 10 mM, [Cat] = 1.2 g L−1, pH = 6.4 | 53% degradation in 60 min | [9] |

| Photocatalysis | N-doped TiO2 | [CFZ] = 10 mM, [Cat] = 1.2 g L−1, pH = 6.4 | 80% degradation in 30 min | [9] |

| Sono-catalysis | Ag3PO4/BiOBr composites | [CFZ] = 0.03 mM, [Cat] = 0.75 g L−1, pH = 6.25 | complete degradation in 30 min | [12] |

| Photocatalysis | TiO2 | [CFZ] = 0.04 mM, [Cat] = 0.4 g L−1, pH = 5, Light intensity = 17 W m−2 | 86% COD removal in 120 min | [62] |

| Photocatalysis | ZnO/Activated carbon | [CFZ] = 0.2 mM, [Cat] = 100 mg L−1, pH = 3 | 96% degradation in 60 min | [63] |

| Peroxy-mono-sulfate oxidation | CoFe2O4-rGO and PMS | [CFZ] = 0.04 mM, [Cat] = 0.1 g L−1, [PMS] = 0.1 mM, pH = 6.5 | almost complete degradation in 30 min | [64] |

| MnO2 oxidation | δ-MnO2 | [CFZ] = 0.3 µM, [Cat] = 4 mg L−1, pH = 4 | 20% degradation in 30 h | [65] |

| Heterogeneous electro-Fenton | Chalcopyrite | [CFZ] = 0.2 mM, [Cat] = 1 g L−1, I = 200 mA, pH = 3 | complete degradation in 15 min and almost complete mineralization in 8 h | This study |

| Heterogeneous electro-Fenton | Ilmenite Pyrite Chromite | [CFZ] = 0.2 mM, [Cat] = 1 g L−1, I = 200 mA, pH = 3 | complete degradation in 20 min and almost complete mineralization in 8 h | This study |

| Common Name | Chemical Formula | PubChem | Chemical Structure | CAS No. | MW | |

|---|---|---|---|---|---|---|

| Substance ID | (nm) | (g/mol) | ||||

| Cefazolin | C14H14N8O4S3 | 23675322 |  | 271 | 25953-19-9 | 476.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heidari, Z.; Pelalak, R.; Alizadeh, R.; Oturan, N.; Shirazian, S.; Oturan, M.A. Application of Mineral Iron-Based Natural Catalysts in Electro-Fenton Process: A Comparative Study. Catalysts 2021, 11, 57. https://0-doi-org.brum.beds.ac.uk/10.3390/catal11010057

Heidari Z, Pelalak R, Alizadeh R, Oturan N, Shirazian S, Oturan MA. Application of Mineral Iron-Based Natural Catalysts in Electro-Fenton Process: A Comparative Study. Catalysts. 2021; 11(1):57. https://0-doi-org.brum.beds.ac.uk/10.3390/catal11010057

Chicago/Turabian StyleHeidari, Zahra, Rasool Pelalak, Reza Alizadeh, Nihal Oturan, Saeed Shirazian, and Mehmet A. Oturan. 2021. "Application of Mineral Iron-Based Natural Catalysts in Electro-Fenton Process: A Comparative Study" Catalysts 11, no. 1: 57. https://0-doi-org.brum.beds.ac.uk/10.3390/catal11010057