A New Modification of Rb[Al(NH2)4] and Condensation in Solid State

Abstract

:1. Introduction

2. Materials and Methods

2.1. General Information

2.2. Synthesis

2.3. Characterization

3. Results and Discussion

3.1. Thermal Analysis

3.2. Spectroscopy

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lan, Y.; Chen, X.; Cao, Y.; Xu, Y.; Xun, L.; Xu, T.; Liang, J. Low-temperature synthesis and photoluminescence of AlN. J. Cryst. Growth 1999, 207, 247–250. [Google Scholar] [CrossRef]

- Dwilinski, R.; Baranowski, J.; Kaminska, M.; Doradziński, R.; Garczyński, J.; Sierzputowski, L. On GaN Crystallization by Ammonothermal Method. Acta Phys. Pol. A 1996, 90, 763–766. [Google Scholar] [CrossRef]

- Hertrampf, J.; Becker, P.; Widenmeyer, M.; Weidenkaff, A.; Schlücker, E.; Niewa, R.; Schluecker, E. Ammonothermal Crystal Growth of Indium Nitride. Cryst. Growth Des. 2018, 18, 2365–2369. [Google Scholar] [CrossRef]

- Li, Y.-D.; Duan, X.-F.; Qian, Y.-T.; Yang, L.; Ji, M.-R.; Li, C.-W. Solvothermal Co-reduction Route to the Nanocrystalline III−V Semiconductor InAs. J. Am. Chem. Soc. 1997, 119, 7869–7870. [Google Scholar] [CrossRef]

- Nicholas, N.J.; Franks, G.V.; Ducker, W.A. The mechanism for hydrothermal growth of zinc oxide. CrystEngComm 2012, 14, 1232–1240. [Google Scholar] [CrossRef]

- Maruska, H.P.; Tietjen, J.J. The preparation and properties of vapor-deposited single-crystalline GaN. Appl. Phys. Lett. 1969, 15, 327–329. [Google Scholar] [CrossRef]

- Tietjen, J.J.; Amick, J.A. The Preparation and Properties of Vapor-Deposited Epitaxial GaAs1−xPx Using Arsine and Phosphine. J. Electrochem. Soc. 1966, 113, 724–728. [Google Scholar] [CrossRef]

- Juza, R.; Jacobs, H.; Gerke, H. Ammonothermalsynthese von Metallamiden und Metallnitriden. Ber. Bunsen-Ges. Phys. Chem. 1966, 70, 1103–1105. [Google Scholar] [CrossRef]

- Richter, T.M.M.; Niewa, R. Chemistry of Ammonothermal Synthesis. Inorganics 2014, 2, 29–78. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Alt, N.S.A.; Schlücker, E.; Niewa, R. Novel alkali metal amidogallates as intermediates in ammonothermal GaN crystal growth. J. Cryst. Growth 2014, 403, 22–28. [Google Scholar] [CrossRef]

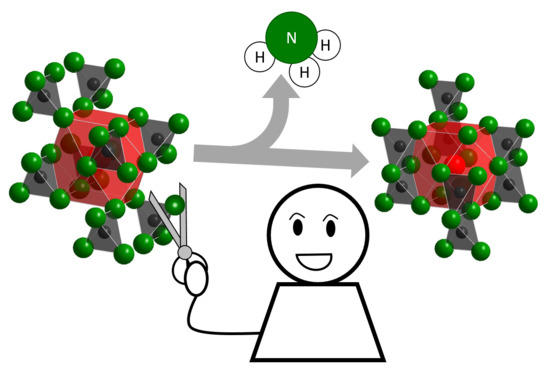

- Hertrampf, J.; Schlücker, E.; Gudat, D.; Niewa, R. Dissolved Intermediates in Ammonothermal Crystal Growth: Stepwise Condensation of [Ga(NH2)4]− toward GaN. Cryst. Growth Des. 2017, 17, 4855–4863. [Google Scholar] [CrossRef]

- Zhang, S.; Hintze, F.; Schnick, W.; Niewa, R. Intermediates in Ammonothermal GaN Crystal Growth under Ammonoacidic Conditions. Eur. J. Inorg. Chem. 2013, 2013, 5387–5399. [Google Scholar] [CrossRef]

- Wang, B.; Callahan, M.; Rakes, K.; Bouthillette, L.; Wang, S.-Q.; Bliss, D.; Kolis, J. Ammonothermal growth of GaN crystals in alkaline solutions. J. Cryst. Growth 2006, 287, 376–380. [Google Scholar] [CrossRef]

- Wang, B.; Callahan, M.J. Transport growth of GaN crystals by the ammonothermal technique using various nutrients. J. Cryst. Growth 2006, 291, 455–460. [Google Scholar] [CrossRef]

- Ehrentraut, D.; Hoshino, N.; Kagamitani, Y.; Yoshikawa, A.; Fukuda, T.; Itoh, H.; Kawabata, S. Temperature effect of ammonium halogenides as mineralizers on the phase stability of gallium nitride synthesized under acidic ammonothermal conditions. J. Mater. Chem. 2007, 17, 886–893. [Google Scholar] [CrossRef]

- Yoshida, K.; Aoki, K.; Fukuda, T. High-temperature acidic ammonothermal method for GaN crystal growth. J. Cryst. Growth 2014, 393, 93–97. [Google Scholar] [CrossRef]

- Hertrampf, J.; Alt, N.S.A.; Schlücker, E.; Niewa, R. Three Solid Modifications of Ba[Ga(NH2)4]2: A Soluble Intermediate in Ammonothermal GaN Crystal Growth. Eur. J. Inorg. Chem. 2017, 2017, 902–909. [Google Scholar] [CrossRef]

- Jacobs, H.; Jänichen, K. Darstellung und Kristallstruktur von Tetraamido-Aluminaten des Rubidiums und Caesiums, Rb[Al(NH2)4] und Cs[Al(NH2)4]. J. Less Common Met. 1990, 159, 315–325. [Google Scholar] [CrossRef]

- Cao, H.; Guo, J.; Chang, F.; Pistidda, C.; Zhou, W.; Zhang, X.; Santoru, A.; Wu, H.; Schell, N.; Niewa, R.; et al. Transition and Alkali Metal Complex Ternary Amides for Ammonia Synthesis and Decomposition. Chem. A Eur. J. 2017, 23, 9766–9771. [Google Scholar] [CrossRef]

- Alt, N.S.; Meissner, E.; Schluecker, E. Development of a novel in situ monitoring technology for ammonothermal reactors. J. Cryst. Growth 2012, 350, 2–4. [Google Scholar] [CrossRef]

- Zhang, S. Intermediates during the Formation of GaN under Ammonothermal Conditions. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2014. [Google Scholar]

- Hüttig, G.F. Apparat zur gleichzeitigen Druck- und Raummessung von Gasen. (Tensi-Eudiometer.). Z. Anorg. Allg. Chem. 1920, 114, 161–173. [Google Scholar] [CrossRef]

- Rodríguez-Carvajal, J. Introduction to the Program Fullprof: Refinement of Crystal and Magnetic Structures from Powder and Single Crystal Data; CEA: Saclay, France, 2001. [Google Scholar]

- Sheldrick, G.M. Crystal structure refinement with SHELXL. Acta Crystallogr. Sect. C Struct. Chem. 2015, C71, 3–8. [Google Scholar] [CrossRef]

- Blase, W.; Cordier, G.; Ludwig, M.; Kniep, R. Sr3[Al2N4]: A Nitridoaluminate with Corrugated Tetrahedral Chains AlN4/23−]. Z. Naturforsch. B 1994, 49, 501–505. [Google Scholar] [CrossRef]

- Ludwig, M.; Niewa, R.; Kniep, R. Dimers [Al2N6]12- and Chains AlN4/23−] in the Crystal Structures of Ca6[Al2N6] and Ba3[Al2N4]. Z. Naturforsch. B 1999, 54, 461–465. [Google Scholar] [CrossRef]

- Jacobs, H. Neubestimmung von Struktur und Eigenschaften isotyper Natriumtetraamidometallate des Aluminiums und Galliums. Z. Anorg. Allg. Chem. 1993, 619, 381–386. [Google Scholar] [CrossRef]

- Wright, A.F.; Nelson, J.S. Consistent structural properties for AlN, GaN, and InN. Phys. Rev. B 1995, 51, 7866–7869. [Google Scholar] [CrossRef]

- Wang, J.; Wang, W.; Ding, P.; Yang, Y.; Fang, L.; Esteve, J.; Polo, M.; Sánchez, G. Synthesis of cubic aluminum nitride by carbothermal nitridation reaction. Diam. Relat. Mater. 1999, 8, 1342–1344. [Google Scholar] [CrossRef]

| PXRD | scXRD | Jacobs et al. [18] | ||

|---|---|---|---|---|

| Crystal system | monoclinic | monoclinic | monoclinic | tetragonal |

| Space group | C2/c | C2/c | P2/c | P4/n |

| a (pm) | 1047.68(9) | 1040.21(6) | 1051.9(3) | 740.6(4) |

| b (pm) | 538.99(4) | 528.15(3) | 541.9(4) | 740.6(4) |

| c (pm) | 1045.69(9) | 1038.88(6) | 1051.0(3) | 538.6(4) |

| β ° | 90.338(3) | 90.098(4) | 90.30(2) | 90 |

| Z | 4 | 4 | 4 | 2 |

| Density (calc.) (g/cm3) | 1.986 | 2.055 | ||

| V (106 pm3) | 591.86(7) | 570.75(6) | 599.09 | 295.38 |

| χ2 | 1.56 | |||

| Radiation | Cu-Kα1 | Mo-Kα | ||

| µ (mm−1) | 12.00 | 8.7 | ||

| Monochromator | Germanium | Graphite | ||

| Reflections collected/independent | 85 | 10,833/664 | ||

| Parameters | 16 | 49 | ||

| Temperature (K) | 293 | 293 | ||

| Index ranges h/k/l | ±13/±6/±13 | |||

| Pattern refined within | 15.0–70.0° | |||

| 2-Theta max. (deg.) | 70.00 | 54.90 | ||

| F(000) | 344 | |||

| R1|Fo| ≥ 4σ(Fo) | 0.0515 | |||

| R1/wR2/GooF | 0.0579/0.1510/1.163 | |||

| Largest e- difference peak/hole (106 pm−3) | 1.90/−0.64 | |||

| Twin matrix | ||||

| Atom | Wyckoff | x | y | z | B/Ueq | Occ. |

|---|---|---|---|---|---|---|

| Rb | 4c | ¼ | ¼ | 0 | 2.519 | 1 |

| Al(1) | 4e | 0 | 0.4543 (23) | ¼ | 1.540 | 1 |

| N(1) | 8f | 0.0299 (12) | 0.2582 (32) | 0.3786 (19) | 3.079 | 1 |

| N(2) | 8f | 0.3634 (17) | 0.1792 (31) | 0.2818 (14) | 3.079 | 1 |

| Rb | 4c | ¼ | ¼ | 0 | 0.0317 (3) | 1 |

| Al(1) | 4e | 0 | 0.4901 (6) | ¼ | 0.0201 (6) | 0.834 (4) |

| Al(2) | 4e | ¼ | 0.4670 (25) | ¼ | 0.0201 (6) | 0.166 (4) |

| N(1) | 8f | 0.0274 (7) | 0.2529 (10) | 0.3847 (6) | 0.0406 (26) | 0.95 (4) |

| N(2) | 8f | 0.3651 (5) | 0.2179 (10) | 0.2758 (7) | 0.0277 (22) | 0.89 (3) |

| Distances | This Work, PXRD | This Work, scXRD | Jacobs et al. [18] |

| Rb–N | 2 × 319.3 (14) | 2 × 310.8 (7) | 4 × 316.7 (17) |

| 2 × 320.4 (14) | 2 × 312.6 (7) | 4 × 376.3 (22) | |

| 2 × 346.3 (15) | 2 × 360.2 (6) | 4 × 377.4 (22) | |

| 2 × 373.1 (15) | 2 × 369.8 (1) | ||

| 2 × 379.3 (15) | 2 × 372.0 (1) | ||

| 2 × 401.5 (16) | 2 × 384.3 (2) | ||

| Al(1)–N | 2 × 173.7 (20) | 2 × 187.0 (6) | 4 × 182.5 (21) |

| 2 × 190.7 (19) | 2 × 189.8 (6) | ||

| Al(2)–N | 2 × 194.3 (11) | ||

| 2 × 207.8 (11) | |||

| Al(1)–Al(2) | 251.9 (14) | ||

| Angles | This Work, PXRD | This Work, scXRD | Jacobs et al. [18] |

| N(1)–Al(1)–N(1) | 101.0 (15)° | 97.471 (1)° | 2 × 103.9 (1)° |

| N(2)–Al(1)–N(2) | 105.1 (17)° | 99.833 (3)° | |

| N(1)–Al(1)–N(2) | 2 × 112.6 (15)° | 2 × 114.748 (2)° | 4 × 112.3 (8)° |

| 2 × 115.513 (2)° | |||

| N(1)–Al(2)–N(1) | 86.801 (1)° | ||

| N(2)–Al(2)–N(2) | 94.716 (2)° | ||

| N(1)–Al(2)–N(2) | 2 × 119.135 (2)° | ||

| 2 × 119.835 (2)° |

| Infrared/cm−1 | Raman/cm−1 | ||

|---|---|---|---|

| Tetragonal [18] | Monoclinic | Monoclinic | |

| Valence modes | |||

| νas(NH2−) | 3400 | 3400 | 3407 |

| 3330 | 3333 | 3334 | |

| νsym(NH2−) | 3255 | 3250 | |

| 3200 | 3190 | ||

| Deformation modes | |||

| δbend(HNH) | 1563 | 1544 | |

| 1545 | |||

| δ(N-H) | 1241 | ||

| Al–N lattice modes | |||

| 820 | 915 | ||

| 680 | 773 | ||

| 555 | 631 | 586 | |

| 523 | 608 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bäucker, C.; Niewa, R. A New Modification of Rb[Al(NH2)4] and Condensation in Solid State. Crystals 2020, 10, 1018. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10111018

Bäucker C, Niewa R. A New Modification of Rb[Al(NH2)4] and Condensation in Solid State. Crystals. 2020; 10(11):1018. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10111018

Chicago/Turabian StyleBäucker, Christian, and Rainer Niewa. 2020. "A New Modification of Rb[Al(NH2)4] and Condensation in Solid State" Crystals 10, no. 11: 1018. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10111018