Microstructure and Mechanical Properties of Ti-6Al-4V Fabricated by Electron Beam Melting

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Processing Conditions

2.2. Sample Location and Preparation

2.3. Characterization Methodology

2.3.1. Microstructure and Porosity Characterization

2.3.2. Microhardness

2.3.3. Tensile Testing

3. Results and Discussion

3.1. Defects of Electron Beam Melting of Ti-6Al-4V Alloy

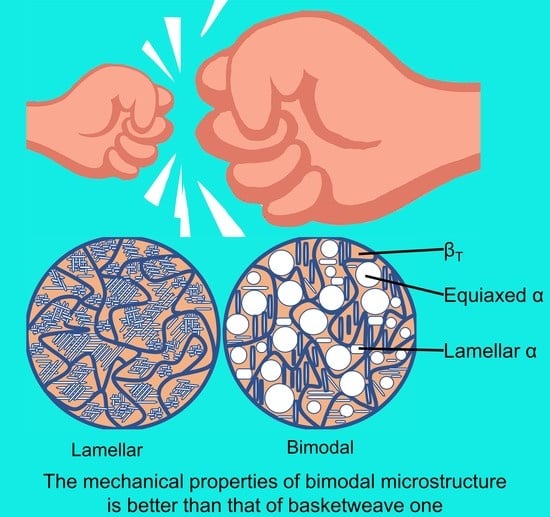

3.2. Microstructure and Relative Density of Ti-6Al-4V Alloy Produced by Electron Beam Melting

3.3. Mechanical Properties at Ambient Temperature of Ti-6Al-4V Produced by Electron Beam Melting

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sepe, R.; Franchitti, S.; Borrelli, R.; Di Caprio, F.; Armentani, E.; Caputo, F. Correlation between real geometry and tensile mechanical behaviour for Ti6Al4V electron beam melted thin specimens. Theor. Appl. Fract. Mech. 2020, 107, 102519. [Google Scholar] [CrossRef]

- Razavi, S.; Van Hooreweder, B.; Berto, F. Effect of build thickness and geometry on quasi-static and fatigue behavior of Ti-6Al-4V produced by Electron Beam Melting. Addit. Manuf. 2020, 36, 101426. [Google Scholar] [CrossRef]

- Guschlbauer, R.; Burkhardt, A.; Fu, Z.; Körner, C. Effect of the oxygen content of the powder on the selective electron beam melting of pure copper. Mater. Sci. Eng. A 2020, 779, 139106. [Google Scholar] [CrossRef]

- Murr, L.; Quinones, S.; Gaytan, S.; Lopez, M.; Rodela, A.; Martinez, E.; Hernandez, D.; Medina, F.; Wicker, R. Microstructure and mechanical behavior of Ti–6Al–4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2009, 2, 20–32. [Google Scholar] [CrossRef]

- Raghavan, S.; Nai, M.L.S.; Wang, P.; Sin, W.J.; Li, T.; Wei, J. Heat treatment of electron beam melted (EBM) Ti-6Al-4V: Microstructure to mechanical property correlations. Rapid Prototyp. J. 2018, 24, 774–783. [Google Scholar] [CrossRef]

- Neikter, M.; Åkerfeldt, P.; Pederson, R.; Antti, M.-L.; Sandell, V. Microstructural characterization and comparison of Ti-6Al-4V manufactured with different additive manufacturing processes. Mater. Charact. 2018, 143, 68–75. [Google Scholar] [CrossRef]

- Safdar, A.; Wei, L.Y.; Snis, A.; Lai, Z. Evaluation of microstructral development in electron beam melted Ti-6Al-4V. Mater. Charateriation 2012, 65, 8–15. [Google Scholar] [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The Origin of Microstructural Diversity, Texture, and Mechanical Properties in Electron Beam Melted Ti-6Al-4V. Met. Mater. Trans. A 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Dharmendra, C.; Alaghmandfard, R.; Hadadzadeh, A.; Amirkhiz, B.S.; Mohammadi, M. Influence of build orientation on small-scale properties of electron beam melted Ti-6Al-4V. Mater. Lett. 2020, 266, 126970. [Google Scholar] [CrossRef]

- Wang, P.; Goh, M.H.; Li, Q.; Nai, M.L.S.; Wei, J. Effect of defects and specimen size with rectangular cross-section on the tensile properties of additively manufactured components. Virtual Phys. Prototyp. 2020, 15, 251–264. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Toh, W.Q.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Revealing martensitic transformation and alpha/beta interface evolution in electron beam melting three-dimensional-printed Ti-6Al-4V. Sci. Rep. 2016, 6, 1–10. [Google Scholar]

- Lu, S.; Qian, M.; Tang, H.; Yan, M.; Wang, J.; StJohn, D. Massive transformation in Ti–6Al–4V additively manufactured by selective electron beam melting. Acta Mater. 2016, 104, 303–311. [Google Scholar] [CrossRef]

- Ghods, S.; Schultz, E.; Wisdom, C.; Schur, R.; Pahuja, R.; Montelione, A.; Arola, D.; Ramulu, M. Electron beam additive manufacturing of Ti6Al4V: Evolution of powder morphology and part microstructure with powder reuse. Materialia 2020, 9, 100631. [Google Scholar] [CrossRef]

- Bruno, J.; Rochman, A.; Cassar, G. Effect of Build Orientation of Electron Beam Melting on Microstructure and Mechanical Properties of Ti-6Al-4V. J. Mater. Eng. Perform. 2017, 26, 692–703. [Google Scholar] [CrossRef]

- Zhai, Y.; Galarraga, H.; Lados, D.A. Microstructure, static properties, and fatigue crack growth mechanisms in Ti-6Al-4V fabricated by additive manufacturing: LENS and EBM. Eng. Fail. Anal. 2016, 69, 3–14. [Google Scholar] [CrossRef]

- Murr, L.; Esquivel, E.; Quinones, S.; Gaytan, S.; Lopez, M.; Martinez, E.; Medina, F.; Hernandez, D.; Martinez, J.; Stafford, S.; et al. Microstructures and mechanical properties of electron beam-rapid manufactured Ti–6Al–4V biomedical prototypes compared to wrought Ti–6Al–4V. Mater. Charact. 2009, 60, 96–105. [Google Scholar] [CrossRef]

- Wysocki, B.; Maj, P.; Sitek, R.; Buhagiar, J.; Kurzydłowski, K.J.; Święszkowski, W. Laser and Electron Beam Additive Manufacturing Methods of Fabricating Titanium Bone Implants. Appl. Sci. 2017, 7, 657. [Google Scholar] [CrossRef]

- Chastand, V.; Quaegebeur, P.; Maia, W.; Charkaluk, E. Comparative study of fatigue properties of Ti-6Al-4V specimens built by electron beam melting (EBM) and selective laser melting (SLM). Mater. Charact. 2018, 143, 76–81. [Google Scholar] [CrossRef]

- Pirozzi, C.; Franchitti, S.; Borrelli, R.; Caiazzo, F.; Alfieri, V.; Argenio, P. Study on the Factors Affecting the Mechanical Behavior of Electron Beam Melted Ti6Al4V. J. Mater. Eng. Perform. 2017, 26, 4491–4499. [Google Scholar] [CrossRef]

- Hrabe, N.W.; Quinn, T.P. Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti–6Al–4V) fabricated using electron beam melting (EBM), Part 2: Energy input, orientation, and location. Mater. Sci. Eng. A 2013, 573, 271–277. [Google Scholar] [CrossRef]

- Wang, P.; Nai, M.L.S.; Sin, W.J.; Wei, J. Effect of Building Height on Microstructure and Mechanical Properties of Big-Sized Ti-6Al-4V Plate Fabricated by Electron Beam Melting. In Proceedings of the 4th International Conference on Material Science and Engineering Technology (ICMSET 2015), Singapore, 4 November 2015; Volume 30. [Google Scholar]

- Galarraga, H.; Warren, R.J.; Lados, D.A.; Dehoff, R.R.; Kirka, M.M.; Nandwana, P. Effects of heat treatments on microstructure and properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Mater. Sci. Eng. A 2017, 685, 417–428. [Google Scholar] [CrossRef] [Green Version]

- Hrabe, N.; Gnäupel-Herold, T.; Quinn, T. Fatigue properties of a titanium alloy (Ti–6Al–4V) fabricated via electron beam melting (EBM): Effects of internal defects and residual stress. Int. J. Fatigue 2017, 94, 202–210. [Google Scholar] [CrossRef] [Green Version]

- Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A. Microstructure and mechanical properties of Ti-6Al-4V produced by electron beam melting of pre-alloyed powders. Rapid Prototyp. J. 2009, 15, 171–178. [Google Scholar] [CrossRef]

- Edwards, P.; O’Conner, A.; Ramulu, M. Electron Beam Additive Manufacturing of Titanium Components: Properties and Performance. J. Manuf. Sci. Eng. 2013, 135, 061016. [Google Scholar] [CrossRef]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and Mechanical Properties of Ti6Al4V Parts Fabricated by Selective Laser Melting and Electron Beam Melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Leon, A.; Levy, G.K.; Ron, T.; Shirizly, A.; Aghion, E. The effect of hot isostatic pressure on the corrosion performance of Ti-6Al-4 V produced by an electron-beam melting additive manufacturing process. Addit. Manuf. 2020, 33, 101039. [Google Scholar] [CrossRef]

- Juechter, V.; Scharowsky, T.; Singer, R.; Körner, C. Processing window and evaporation phenomena for Ti–6Al–4V produced by selective electron beam melting. Acta Mater. 2014, 76, 252–258. [Google Scholar] [CrossRef] [Green Version]

- Everhart, W.; Dinardo, J.; Barr, C. The Effect of Scan Length on the Structure and Mechanical Properties of Electron Beam-Melted Ti-6Al-4V. Met. Mater. Trans. A 2016, 48, 697–705. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Starr, T.L.; Stucker, B. Analysis of defect generation in Ti–6Al–4V parts made using powder bed fusion additive manufacturing processes. Addit. Manuf. 2014, 1, 87–98. [Google Scholar] [CrossRef]

- Nandwana, P.; Peter, W.H.; Dehoff, R.R.; Lowe, L.E.; Kirka, M.M.; Medina, F.; Babu, S.S. Recyclability Study on Inconel 718 and Ti-6Al-4V Powders for Use in Electron Beam Melting. Met. Mater. Trans. A 2016, 47, 754–762. [Google Scholar] [CrossRef]

- Leung, C.L.A.; Marussi, S.; Towrie, M.; Atwood, R.C.; Withers, P.J.; Lee, P.D. The effect of powder oxidation on defect formation in laser additive manufacturing. Acta Mater. 2019, 166, 294–305. [Google Scholar] [CrossRef] [Green Version]

- Spierings, A.; Schneider, M.; Eggenberger, R. Comparison of density measurement techniques for additive manufactured metallic parts. Rapid Prototyp. J. 2011, 17, 380–386. [Google Scholar] [CrossRef]

- De Terris, T.; Andreau, O.; Peyre, P.; Adamski, F.; Koutiri, I.; Gorny, C.; Dupuy, C. Optimization and comparison of porosity rate measurement methods of Selective Laser Melted metallic parts. Addit. Manuf. 2019, 28, 802–813. [Google Scholar] [CrossRef]

- Galarraga, H.; Lados, D.A.; Dehoff, R.R.; Kirka, M.M.; Nandwana, P. Effects of the microstructure and porosity on properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Addit. Manuf. 2016, 10, 47–57. [Google Scholar] [CrossRef] [Green Version]

| Element | Ti | Al | V | Fe | C | N | O | H | Other Each |

|---|---|---|---|---|---|---|---|---|---|

| Standard values (wt.%) | Bal | 5.5–6.75 | 3.5–4.5 | ≤0.3 | ≤0.080 | ≤0.05 | ≤0.20 | 0.015 | ≤0.10 |

| Measured values (wt.%) | Bal | 6.20 | 4.23 | 0.069 | 0.022 | 0.01 | 0.088 | 0.0044 | ≤0.10 |

| Factors | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| Focus offset (mA) | 39 | 42 | 45 | 48 | 51 |

| Speed factor | 29 | 32 | 35 | 38 | 41 |

| Line offset (mm) | 0.16 | 0.19 | 0.22 | 0.25 | 0.28 |

| Sample | Focus Offset (mA) | Line Offset (mm) | Speed Factor | Relative Density (%) | UTS (MPa) | YS (MPa) | A (%) | Vickers Hardness (HV) |

|---|---|---|---|---|---|---|---|---|

| 1 | 39 | 0.25 | 35 | 98.49 | 966.3 | 753.8 | 15.5 | 312.3 |

| 2 | 42 | 0.25 | 35 | 98.55 | 970.0 | 774.2 | 15.7 | 315.8 |

| 3 | 45 | 0.25 | 35 | 98.63 | 982.6 | 782.6 | 15.6 | 326.2 |

| 4 | 48 | 0.25 | 35 | 98.19 | 990.1 | 816.0 | 16.6 | 310.4 |

| 5 | 51 | 0.25 | 35 | 97.24 | 994.7 | 825.8 | 16.2 | 306.5 |

| 6 | 48 | 0.25 | 29 | 98.06 | 981.6 | 747.7 | 15.9 | 318.6 |

| 7 | 48 | 0.25 | 32 | 98.45 | 971.3 | 739.2 | 15.9 | 329.1 |

| 8 | 48 | 0.25 | 35 | 98.69 | 980.8 | 831.1 | 16.1 | 323.4 |

| 9 | 48 | 0.25 | 38 | 97.97 | 991.4 | 762.4 | 12.0 | 316.7 |

| 10 | 48 | 0.25 | 41 | 97.28 | 987.1 | 763.9 | 12.7 | 333.3 |

| 11 | 48 | 0.16 | 35 | 97.97 | 999.7 | 666.4 | 11.5 | 317.0 |

| 12 | 48 | 0.19 | 35 | 98.40 | 984.8 | 708.4 | 13.8 | 322.6 |

| 13 | 48 | 0.22 | 35 | 98.44 | 983.4 | 687.8 | 15.7 | 330.2 |

| 14 | 48 | 0.25 | 35 | 98.33 | 989.3 | 693.8 | 16.9 | 321.2 |

| 15 | 48 | 0.28 | 35 | 98.28 | 1000.3 | 871.2 | 14.7 | 318.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ran, J.; Jiang, F.; Sun, X.; Chen, Z.; Tian, C.; Zhao, H. Microstructure and Mechanical Properties of Ti-6Al-4V Fabricated by Electron Beam Melting. Crystals 2020, 10, 972. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10110972

Ran J, Jiang F, Sun X, Chen Z, Tian C, Zhao H. Microstructure and Mechanical Properties of Ti-6Al-4V Fabricated by Electron Beam Melting. Crystals. 2020; 10(11):972. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10110972

Chicago/Turabian StyleRan, Jiangtao, Fengchun Jiang, Xiaojing Sun, Zhuo Chen, Cao Tian, and Hong Zhao. 2020. "Microstructure and Mechanical Properties of Ti-6Al-4V Fabricated by Electron Beam Melting" Crystals 10, no. 11: 972. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10110972