Substrate Effects on the Electrical Properties in GaN-Based High Electron Mobility Transistors

Abstract

:1. Introduction

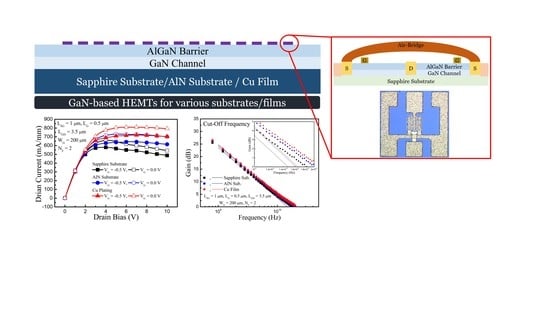

2. Device Fabrication

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kummer, V.; Lu, W.; Schwindt, R.; Kuliev, A.; Simin, G.; Yang, J.; Khan, M.A.; Adesida, I. AlGaN/GaN HEMTs on SiC with fT of over 120 GHz. IEEE Electron. Device Lett. 2002, 23, 455–457. [Google Scholar] [CrossRef]

- Palacios, T.; Chakraborty, A.; Rajan, S.; Poblenz, C.; Keller, S.; DenBaars, S.P.; Speck, J.S.; Mishra, U.K. High-power AlGaN/GaN HEMTs for Ka-band applications. IEEE Electron. Device Lett. 2005, 26, 781–783. [Google Scholar] [CrossRef] [Green Version]

- Ahn, S.; Kim, B.-J.; Lin, Y.-H.; Ren, F.; Pearton, S.J.; Yang, G.; Kim, J.; Kravchenoko, I.I. Effect of proton irradiation dose on InAlN/GaN metal-oxide semiconductor high electron mobility transistors with Al2O3 gate oxide. J. Vac. Sci. Technol. B 2016, 34, 051202. [Google Scholar] [CrossRef]

- Gao, Z.; Romero, M.F.; Redondo-Cubero, A.; Pampillon, M.A.; Andres, E.S.; Calle, F. Effect of Gd2O3 gate dielectric on Proton-Irradiated AlGaN/GaN HEMTs. IEEE Electron. Device Lett. 2017, 38, 611–614. [Google Scholar] [CrossRef]

- Chang, S.-J.; Kim, D.-S.; Kim, T.-W.; Lee, J.-H.; Bae, Y.; Jung, H.-W.; Kang, S.C.; Kim, H.; Noh, Y.-S.; Lee, S.-H.; et al. Comprehensive research of total ionizing dose effects in GaN-based MIS-HEMTs using extremely thin gate dielectric layer. Nanomaterials 2020, 10, 2175. [Google Scholar] [CrossRef]

- Chang, S.-J.; Cho, K.J.; Jung, H.-W.; Kim, J.-J.; Jang, Y.-J.; Bae, S.-B.; Kim, D.-S.; Bae, Y.; Yoon, H.S.; Ahn, H.-K.; et al. Improvement of proton radiation hardness using ALD-deposited Al2O3 gate insulator in GaN-based MIS-HEMTs. ECS J. Solid State Sci. Technol. 2019, 8, Q245–Q248. [Google Scholar] [CrossRef]

- Adesida, I.; Lu, W.; Kummar, V. AlGaN/GaN HFETs for low noise applications. In Proceedings of the 6th International Conference on Solid-State and Integrated Circuit Technology, Shanghai, China, 6 August 2001; pp. 1163–1168. [Google Scholar]

- Zhao, M.; Liu, X.; Zheng, Y.; Peng, M.; Ouyang, S.; Li, Y.; Wei, K. Thermal analysis of AlGaN/GaN high-electron-mobility transistors by infrared microscopy. Opt. Commun. 2013, 291, 104–109. [Google Scholar] [CrossRef]

- Karmalkar, S.; Mishra, U.K. Enhancement of breakdown voltage in AlGaN/GaN high electron mobility transistors using a filed plate. IEEE Trans. Electron. Devices 2001, 48, 1515–1521. [Google Scholar] [CrossRef]

- Kuzmik, J.; Javorka, R.; Alam, A.; Marso, M.; Jeuken, M.; Cordos, P. Determination of channel temperature in AlGaN/GaN HEMTs grown on sapphire and silicon substrate using DC characterization method. IEEE Trans. Electron. Devices 2002, 49, 1496–1498. [Google Scholar] [CrossRef]

- Arulkumaran, K.R.S.; Ng, G.I.; Sandupatra, A. Investigation of self-heating effect on DC and RF performances in AlGaN/GaN HEMTs on CVD-diamond. J. Electron. Devices Society 2019, 7, 1264–1269. [Google Scholar]

- Kuball, M.; Pomeroy, J.W.; Simms, R.; Riedel, G.J.; Ji, H.; Sarua, A.; Uren, M.J.; Martin, T. Thermal Properties and reliability of GaN microelectronics: Sub-micron spatial and nanosecond time resolution thermography. In Proceedings of the IEEE Compound Semiconductor Integrated Circuit Symposium, Portland, OR, USA, 14–17 October 2007; pp. 1–4. [Google Scholar]

- Hu, H.; Tang, B.; Wan, H.; Sun, H.; Zhou, S.; Dai, J.; Chen, C.; Liu, S.; Guo, L.J. Boosted ultraviolet electroluminescence of InGaN/AlGaN quantum structures grown on high-index contrast patterned sapphire with silica array. Nano Energy 2020, 69, 104427. [Google Scholar] [CrossRef]

- Ji, H.; Das, J.; Germain, M.; Kuball, M. Laser lift-off transfer of AlGaN/GaN HEMTs from sapphire onto Si: A thermal perspective. Solid-State Electron. 2009, 53, 526–529. [Google Scholar] [CrossRef]

- Liu, T.; Kong, Y.; Wu, L.; Guo, H.; Zhou, J.; Kong, C.; Chen, T. Chen 3-inch GaN-on-Diamond HEMTs with device-first transfer technology. IEEE Electron. Device Lett. 2017, 38, 1417–1420. [Google Scholar] [CrossRef]

- Hirama, K.; Taniyasu, Y.; Kasu, M. AlGaN/GaN high-electron mobility transistors with low thermal resistance grown on single-crystal diamond (111) substrates by metalorganic vapor-phase epitaxy. Appl. Phys. Lett. 2011, 98, 162112. [Google Scholar] [CrossRef]

- Gerrer, T.; Czap, H.; Maier, T.; Benkjelifa, F.; Muller, S.; Nobel, C.E.; Waltereit, P.; Quay, R.; Cimalla, V. 3 GHz RF measurements of AlGaN/GaN transistors transferred from silicon substrate onto single crystalline diamond. AIP Adv. 2019, 9, 125106. [Google Scholar] [CrossRef] [Green Version]

- Wong, W.S.; Sands, T.; Cheung, N.W.; Kneissl, M.; Bour, D.P.; Mei, P.; Romano, L.T.; Johnson, N.M. Fabrication of thin-film InGaN light-emitting diode membranes by laser lift-off. Appl. Phys. Lett. 1999, 75, 1360. [Google Scholar] [CrossRef]

- Wierer, J.J.; Steigerwald, D.A.; Krames, M.R.; O’shea, J.J.; Ludowise, M.J.; Christenson, G.; Shen, Y.-C.; Lowery, C.; Martin, P.S.; Subramanya, S.; et al. High power AlGaLiN filp-chip light-emitting diodes. Appl. Phys. Lett. 2001, 78, 3379. [Google Scholar] [CrossRef]

- Bao, K.; Kang, X.N.; Zhang, B.; Dai, T.; Sun, Y.J.; Fu, Q.; Lian, C.J.; Xiong, G.C.; Zhang, G.Y.; Chen, Y. Improvement of light extraction from GaN-based thin-film light-emitting diodes by patterning undoped GaN using modified laser lift-off. Appl. Phys. Lett. 2007, 92, 141104. [Google Scholar] [CrossRef]

- Lei, Y.; Wan, H.; Tang, B.; Lan, S.; Miao, J.; Wan, Z.; Liu, Y.; Zhou, S. Optical characterization of GaN-based vertical blue light-emitting diodes on p-type silicon substrate. Crystals 2020, 10, 621. [Google Scholar] [CrossRef]

- Zhao, M.; Tang, X.; Huo, W.; Han, L.; Deng, Z.; Jiang, Y.; Wang, W.; Chen, H.; Du, C.; Jia, H. Characteristics of AlGaN/GaN high electron mobility transistors on metallic substrate. Chin. Phys. B 2020, 29, 048104. [Google Scholar] [CrossRef]

- Wang, X.; Lo, C.-F.; Liu, L.; Cuervo, C.V.; Fan, R.; Pearton, S.J.; Bila, B.; Johns, M.R.; Zhou, L.; Smith, D.J.; et al. 193 nm excimer laser lift-off for AlGaN/GaN high electron mobility transistors. J. Vac. Sci. Technol. B 2012, 30, 061209. [Google Scholar] [CrossRef]

- Nigam, A.; Bhat, T.N.; Rajamani, S.; Dolmanan, S.B.; Tripathy, S.; Kumar, M. Effect of self-heating on electrical characteristics of AlGaN/GaN HEMT on (111) substrate. AIP Adv. 2017, 7, 085015. [Google Scholar] [CrossRef]

- Chang, S.-J.; Jung, H.-W.; Do, J.-W.; Cho, K.J.; Kim, J.-J.; Jang, Y.J.; Yoon, H.S.; Ahn, H.-K.; Min, B.-G.; Kim, H.; et al. Enhanced carrier transport properties in GaN-based metal-insulator semiconductor high electron mobility transistor with SiN/Al2O3 bi-layer passivation. ECS J. Solid State Sci. Technol. 2018, 7, N86–N89. [Google Scholar] [CrossRef]

- Chang, S.-J.; Kang, H.-S.; Lee, J.-H.; Yang, J.; Bhuiyan, M.; Jo, Y.-W.; Cui, S.; Lee, J.-H.; Ma, T.-P. Investigation of channel mobility in AlGaN/GaN high electron-mobility transistors. Jpn. J. Appl. Phys. 2016, 55, 044104. [Google Scholar] [CrossRef]

- Lee, J.-H.; Kim, J.-G.; Ju, J.-M.; Ahn, W.-H.; Kang, S.-H.; Lee, J.-H. AlInGaN/GaN double-channel FinFET with high on-current and negligible current collapse. Solid State Electron. 2020, 164, 107678. [Google Scholar] [CrossRef]

| Parameter | ID at VG = 0.0 V (mA/mm) | gm,max (mS/mm) | Max. µ (cm2/Vs) | RSH (Ω/sq) | fT (GHz) | fMAX (GHz) | |

|---|---|---|---|---|---|---|---|

| at VD = 4.0 V | at VD = 10.0 V | ||||||

| Sapphire Substrate | 658 | 542 | 220 | 1109 | 408 | 14.8 | 28.6 |

| AlN Substrate | 717 | 705 | 251 | 1189 | 393 | 16.3 | 31.1 |

| Cu Film | 776 | 795 | 271 | 1253 | 389 | 16.6 | 32.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, S.-J.; Cho, K.-J.; Lee, S.-Y.; Jeong, H.-H.; Lee, J.-H.; Jung, H.-W.; Bae, S.-B.; Choi, I.-G.; Kim, H.-C.; Ahn, H.-K.; et al. Substrate Effects on the Electrical Properties in GaN-Based High Electron Mobility Transistors. Crystals 2021, 11, 1414. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11111414

Chang S-J, Cho K-J, Lee S-Y, Jeong H-H, Lee J-H, Jung H-W, Bae S-B, Choi I-G, Kim H-C, Ahn H-K, et al. Substrate Effects on the Electrical Properties in GaN-Based High Electron Mobility Transistors. Crystals. 2021; 11(11):1414. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11111414

Chicago/Turabian StyleChang, Sung-Jae, Kyu-Jun Cho, Sang-Youl Lee, Hwan-Hee Jeong, Jae-Hoon Lee, Hyun-Wook Jung, Sung-Bum Bae, Il-Gyu Choi, Hae-Cheon Kim, Ho-Kyun Ahn, and et al. 2021. "Substrate Effects on the Electrical Properties in GaN-Based High Electron Mobility Transistors" Crystals 11, no. 11: 1414. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11111414