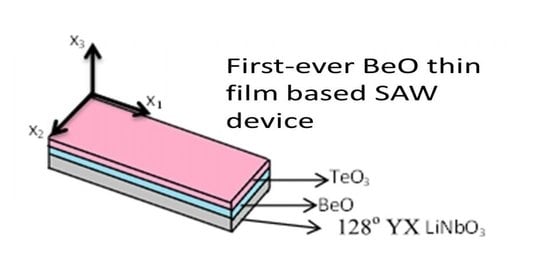

Enhanced Properties of SAW Device Based on Beryllium Oxide Thin Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Electromechanical Coupling Coefficient

2.2. Temperature Coefficient of Delay (TCD)

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Luo, J.T.; Quan, A.J.; Liang, G.X.; Zheng, Z.H.; Ramadan, S.; Fu, C.; Li, H.L.; Fu, Y.Q. Love-mode surface acoustic wave devices based on multilayers of TeO2/ ZnO(1 1 2 0)/Si(1 0 0) with high sensitivity and temperature stability. Ultrasonics 2017, 75, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Fan, L.; Zhang, S.; Ge, H.; Zhang, H. Theoretical investigation of acoustic wave devices based on different piezoelectric films deposited on silicon carbide. J. Appl. Phys. 2013, 114, 024504. [Google Scholar] [CrossRef]

- Naumenko, N.; Nicolay, P. AlN/Pt/LN structure for SAW sensors capable of operating at high temperature. Appl. Phys. Lett. 2017, 111, 073507. [Google Scholar] [CrossRef]

- Liang, J.; Yang, X.; Zheng, S.; Sun, C.; Zhang, M.; Zhang, H.; Zhang, D.; Pang, W. Modulation of acousto-electric current using a hybrid on-chip AlN SAW/GFET device. Appl. Phys. Lett. 2017, 110, 243504. [Google Scholar] [CrossRef]

- Gillinger, M.; Shaposhnikov, K.; Knobloch, T.; Schneider, M.; Kaltenbacher, M.; Schmid, U. Impact of layer and substrate properties on the surface acoustic wave velocity in scandium doped aluminum nitride based SAW devices on sapphire. Appl. Phys. Lett. 2016, 108, 231601. [Google Scholar] [CrossRef]

- Go, D.B.; Atashbar, M.Z.; Ramshani, Z.; Chang, H.-C. Surface acoustic wave devices for chemical sensing and microfluidics: A review and perspective. Anal. Methods 2017, 9, 4112–4134. [Google Scholar] [CrossRef]

- Delsing, P.; Cleland, A.N.; Schuetz, M.J.; Knörzer, J.; Giedke, G.; Cirac, J.I.; Srinivasan, K.; Wu, M.; Balram, K.C.; Bäuerle, C.; et al. The 2019 surface acoustic waves roadmap. J. Phys. D Appl. Phys. 2019, 52, 353001. [Google Scholar] [CrossRef]

- Campbell, C. Surface Acoustic Wave Devices for Mobile and Wireless Communications, Four-Volume Set; Academic Press: San Diego, CA, USA; Toronto, ON, Canada, 1998. [Google Scholar]

- Collins, H.; Hagon, P.J.; Pulliam, G.R. Evaluation of new single crystal piezoelectric materials for surface acoustic –wave applications. Ultrasonics 1970, 8, 218–226. [Google Scholar] [CrossRef]

- Lee, S.M.; Jang, Y.; Yum, J.H.; Larsen, E.S.; Lee, W.C.; Kim, S.K.; Bielawski, C.W.; Oh, J. Crystal Properties of atomic- layer deposited beryllium oxide on crystal and amorphous substrates. Semicond. Sci. Technol. 2019, 34, 115021. [Google Scholar] [CrossRef]

- Koh, D.; Yum, J.H.; Banerjee, S.K.; Hudnall, T.W.; Bielawski, C.; Lanford, W.A.; French, B.L.; French, M.; Henry, P.; Li, H.; et al. Investigation of atomic layer deposited beryllium oxide material properties for high K dielectric applications. J. Vac. Sci. Technol. B 2014, 32, 03D117. [Google Scholar] [CrossRef]

- Duman, S.; Sutlu, A.; Bagci, S.; Tutuncu, H.M.; Srivastava, G.P. Structural, elastic, electronic and phonon properties of zinc blende and wurtzite BeO. J. Appl. Phys. 2009, 105, 033719. [Google Scholar] [CrossRef]

- Farnell, G.W.; Adler, E.L. Elastic Wave Propagation in Thin Layers. In Physical Acoustics Principles and Methods; Mason, W.P., Thurston, R.N., Eds.; Academic Press: New York, NY, USA, 1972; Volume 9, pp. 35–127. [Google Scholar]

- Farnell, G.W.; Adler, E.L. Multilayer acoustic surface wave program. Proc. Inst. Electr. Eng. 1995, 122, 470–471. [Google Scholar]

- Nakahata, H.; Fujii, S.; Higaki, K.; Hachigo, A.; Kitabayashi, H.; Shikata, S.; Fujimori, N. Diamond-based surface acoustic wave devices. Semicond. Sci. Technol. 2003, 18, 96–104. [Google Scholar] [CrossRef]

- Zhou, C.; Yang, Y.; Zhan, J.; Ren, T.; Wang, X.; Tian, S. Surface acoustic wave characteristics based on c-axis (006) LiNbO3/diamond/silicon layered structure. Appl. Phys. Lett. 2011, 99, 022109. [Google Scholar] [CrossRef]

- Benetti, M.; Cannat’a, D.; Pietrantonio, F.D.; Verona, E. Growth of AlN piezoelectric film on diamond for high-frequency surface acoustic wave devices. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 1806. [Google Scholar] [CrossRef] [PubMed]

- Dewan, N.; Sreenivas, K.; Gupta, V. Temperature-Compensated Devices Using Thin TeO2 Layer with Negative TCD. IEEE Electron Device Letters 2006, 27, 752–754. [Google Scholar] [CrossRef]

- Cacho VD, D.; Siarkowski, A.L.; Morimoto, N.I.; Borges, B.V.; Kassab, L.R. Fabrication and Characterization of TeO2-ZnO Rib Waveguides. ECS Trans. 2010, 31, 225–229. [Google Scholar] [CrossRef]

- Dewan, N.; Sreenivas, K.; Gupta, V.; Katiyar, R.S. Growth of amorphous TeOx (2 ≤ x ≤ 3) thin film by radio frequency sputtering. J. Appl. Phys. 2007, 101, 084910. [Google Scholar] [CrossRef]

- Dewan, N.; Tomar, M.; Gupta, V.; Sreenivas, K. Temperature stable LiNbO3 surface acoustic wave device with diode sputtered amorphous TeO2 over-layer. Appl. Phys. Lett. 2005, 86, 223508. [Google Scholar] [CrossRef]

- Cline, C.F.; Dunegan, H.L.; Henderson, G.W. Elastic Constants of Hexagonal BeO, ZnS and CdSe. J. Appl. Phys. 1967, 38, 1944–1948. [Google Scholar] [CrossRef]

- Kovacs’s, G.; Anhorn, M.; Engan, H.E.; Visintini, G.; Ruppel, C.C.W. Improved material constants for LiNbO3 and LiTaO3. IEEE Symp. Ultrason. 1990, 1, 435–438. [Google Scholar]

- Sirota, N.N.; Kuzmina, A.M.; Orlova, N.S. Debye- Waller factors and Elastic constants for Beryllium oxide at temperature between 10 and 720 K. Cryst. Res. Technol. 1992, 27, 711–716. [Google Scholar] [CrossRef]

- Smith, R.T.; Welsh, F.S. Temperature Dependence of the Elastic, Piezoelectric, and Dielectric Constants of Lithium Tantalate and Lithium Niobate. J. Appl. Phys. 1971, 42, 2219–2230. [Google Scholar] [CrossRef]

- Soni, N.D. SAW propagation characteristics of TeO3/3C-SiC/LiNbO3 layered structure. Mater. Res. Express 2018, 5, 046309. [Google Scholar]

- Rana, L.; Gupta, V.; Soni, N.D.; Tomar, M. SAW field and acousto-optical interaction in ZnO/AlN/sapphire structure. In Proceedings of the 2016 Joint IEEE International Symposium on the Applications of Ferroelectrics, European Conference on Application of Polar Dielectrics, and Piezoelectric Force Microscopy Workshop (ISAF/ECAPD/PFM), Darmstadt, Germany, 21–25 August 2016. [Google Scholar]

- Shih, W.C.; Wang, T.L.; Hsu, L.L. Surface acoustic wave properties of aluminum oxide films on lithium Niobate. Thin Solid Film. 2010, 518, 7143–7146. [Google Scholar]

- Tomar, M.; Gupta, V.; Sreenivas, K.; Mansingh, A. Temperature stability of ZnO thin film SAW device on fused quartz. IEEE Trans. Device Mater. Reliab. 2005, 5, 494–500. [Google Scholar] [CrossRef]

- Gupta, V.; Tomar, M.; Sreenivas, K. Improved temperature stability of LiNbO3 surface acoustic wave devices with sputtered SiO2 over-layers. Ferroelectrics 2005, 329, 57–60. [Google Scholar] [CrossRef]

- Zhou, F.M.; Li, Z.; Fan, L.; Zhang, S.Y.; Shui, X.J.; Wasa, K. Effects of TeOx films on temperature coefficients of delay of Love type wave devices based on TeOx/ 36° YX—LiTaO3 structures. Vaccuum 2010, 84, 986–991. [Google Scholar] [CrossRef]

| Material Constants | Materials | Temperature Coefficients (°C−1) | ||||

|---|---|---|---|---|---|---|

| TeO3 [18] | BeO [12,22] | LiNbO3 [23] | TeO3 [18] | BeO [24] | LiNbO3 [25] | |

| Elastic Constants(1011 N/m2) | × 10−4 | |||||

| C11 | 0.14 | 4.606 | 1.98 | 0.06 | −2.63 | −1.74 |

| C33 | 4.916 | 2.279 | −1.34 | −1.53 | ||

| C66 | 1.670 | 0.728 | −1.98 | −1.43 | ||

| C44 | 0.265 | 1.477 | 0.5965 | 0.0646 | −0.95 | −2.04 |

| C12 | 1.265 | 0.5472 | −4.27 | −2.52 | ||

| C13 | 0.8848 | 0.6513 | −39.8 | −1.59 | ||

| C14 | 0.0788 | −2.14 | ||||

| Piezoelectric constant (C/m2) | ||||||

| e33 | 0.0364 | 1.77 | 8.87 | |||

| e31 | −0.0735 | 0.30 | 2.21 | |||

| e15 | 3.69 | 1.47 | ||||

| e22 | 2.42 | 0.79 | ||||

| Dielectric constant (10−11 F/m) | ||||||

| 23.7 | 3.06 | 45.6 | 1.6 | 3.23 | ||

| 3.13 | 26.3 | 6.27 | ||||

| Density (Kg/m3) | ||||||

| 4578 | 3010 | 4628 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soni, N.D.; Bhola, J. Enhanced Properties of SAW Device Based on Beryllium Oxide Thin Films. Crystals 2021, 11, 332. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11040332

Soni ND, Bhola J. Enhanced Properties of SAW Device Based on Beryllium Oxide Thin Films. Crystals. 2021; 11(4):332. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11040332

Chicago/Turabian StyleSoni, Namrata Dewan, and Jyoti Bhola. 2021. "Enhanced Properties of SAW Device Based on Beryllium Oxide Thin Films" Crystals 11, no. 4: 332. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11040332