Liquid Crystal-Based Enclosed Coplanar Waveguide Phase Shifter for 54–66 GHz Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bias Voltage-Dependent Impedance Matching

2.2. Tuning Range Ratio and Insertion Loss Analysis

2.3. PCB-to-Connectors Interface Design by Time Domain Reflectometry

3. Experiment and Results

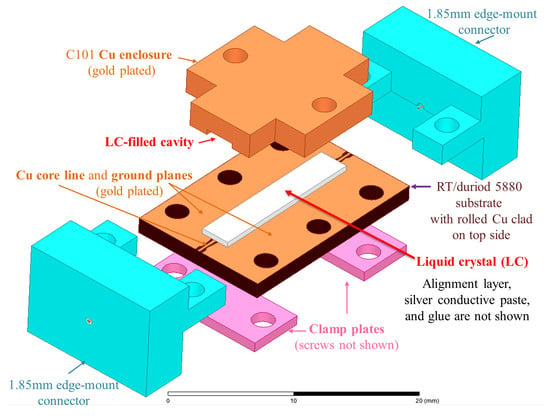

3.1. Device Fabrication

3.2. Measurement Results and Device Optimization

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thomas, N.; Carlos, C.; Adriana, B.F.; Edward, W.K.; Eldad, P.; Joerg, W. IEEE 802.11ad: directional 60 GHz communication for multi-Gigabit-per-second Wi-Fi [Invited Paper]. IEEE Commun. Mag. 2014, 52, 132–141. [Google Scholar]

- Jaime, L.; Nicholas, G.; Emre, M.K.; Patrick, A. Soli: Ubiquitous gesture sensing with millimetre wave radar. ACM Trans. Graph. 2016, 35, 142. [Google Scholar]

- Li, J.F.; Xu, H.; Chu, D.P. Design of liquid crystal based coplanar waveguide tunable phase shifter with no floating electrodes for 60–90 GHz applications. In Proceedings of the 2016 46th European Microwave Conference (EuMC), London, UK, 4–6 October 2016; pp. 1047–1050. [Google Scholar]

- Lim, K.C.; Margerum, J.D.; Lackner, A.M. Liquid crystal millimetre wave electronic phase shifter. Appl. Phys. Lett. 1993, 75, 1065–1067. [Google Scholar] [CrossRef]

- Garbovskiy, Y.; Zagorodnii, V.; Krivosik, P.; Lovejoy, J.; Camley, R.E.; Celinski1, Z.; Glushchenko, A.; Dziaduszek, J.; Dąbrowski, R. Liquid crystal phase shifters at millimetre wave frequencies. J. Appl. Phys. 2012, 111, 054504. [Google Scholar] [CrossRef]

- Martin, N.; Laurent, P.; Prigent, G.; Philippe, G.; Fabrice, H. Technological evolution and performances improvements of a tunable phase-shifter using liquid crystal. Microw. Opt. Technol. Lett. 2004, 43, 338–341. [Google Scholar] [CrossRef]

- Zografopoulos, D.C.; Ferraro, A.; Beccherelli, R. Liquid-crystal high-frequency microwave technology: Materials and Characterization. Adv. Mater. Technol. 2019, 4, 1800447. [Google Scholar] [CrossRef]

- Holger, M.; Matthias, J.; Roland, R.; Ersin, P.; Matthias, N.; Rolf, J. Microwave liquid crystal technology. Crystals 2018, 8, 355. [Google Scholar] [CrossRef] [Green Version]

- Santi, C.P.; Enrica, M.; Francesco, C.; Matteo, A.; Stefano, M. Surface wave dispersion for a tunable grounded liquid crystal substrate without and with metasurface on top. IEEE Trans. Antennas Propag. 2017, 65, 3540–3548. [Google Scholar]

- Pouria, Y.; Onur, H.K.; Bevan, B.; Christophe, F.; Rolf, J. Electrically Tuned Microwave Devices Using Liquid Crystal Technology. Int. J. Antenn. Propag. 2013, 2013, 824214. [Google Scholar] [CrossRef] [Green Version]

- Longzhu, C.; Huan, X.; Jinfeng, L.; Daping, C. High Figure-of-merit compact phase shifters based on liquid crystal material for 1–10 GHz applications. Jpn. J. Appl. Phys. 2017, 56, 011701. [Google Scholar] [CrossRef]

- Longzhu, C.; Huan, X.; Jinfeng, L.; Daping, C. High FoM liquid crystal based microstrip phase shifter for phased array antennas. In Proceedings of the 2016 International Symposium on Antennas and Propagation (ISAP), Okinawa, Japan, 24–28 October 2016; pp. 402–403. [Google Scholar]

- Muller, S.; Scheele, P.; Weil, C.; Wittek, M.; Hock, C.; Jakoby, R. Tunable passive phase shifter for microwave applications using highly anisotropic liquid crystals. In Proceedings of the IEEE MTT-S International Microwave Symposium Digest, Fort Worth, TX, USA, 6–11 June 2004; pp. 1153–1156. [Google Scholar]

- Mueller, S.; Penirschke, A.; Damm, C.; Scheele, P.; Wittek, M.; Weil, C.; Jakoby, R. Broad-band microwave characterization of liquid crystals using a temperature-controlled coaxial transmission line. IEEE Trans. Microw. Theory Tech. 2005, 53, 1937–1945. [Google Scholar] [CrossRef]

- Stefan, M.; Felix, G.; Patrick, S.; Michael, W.; Christian, H.; Rolf, J. Passive phase shifter for W-band applications using liquid crystals. In Proceedings of the 2006 European Microwave Conference (EuMC), Manchester, UK, 10–15 September 2006; pp. 306–309. [Google Scholar]

- Gaebler, A.; Goelden, F.; Manabe, A.; Goebel, M.; Mueller, S.; Jakoby, R. Investigation of high performance transmission line phase shifters based on liquid crystal. In Proceedings of the 2009 European Microwave Conference (EuMC), Rome, Italy, 29 September–1 October 2009; pp. 594–597. [Google Scholar]

- Jost, M.; Weickhmann, C.; Strunck, S.; Gäbler, A.; Fritzsch, C.; Karabey, O.H.; Jakoby, R. Liquid crystal based low-loss phase shifter for W-band frequencies. Electron. Lett. 2013, 49, 1460–1462. [Google Scholar] [CrossRef]

- Wang, K.D.; Wu, K. Liquid crystal enabled substrate integrated waveguide variable phase shifter for millimetre-wave application at 60GHz and beyond. In Proceedings of the 2015 IEEE MTT-S International Microwave Symposium, Phoenix, AZ, USA, 17–22 May 2015; pp. 1–4. [Google Scholar]

- Bulja, S.; Mirshekar-Syahkal, D.; Yazdanpanahi, M.; James, R.; Day, S.E.; Fernández, F.A. Liquid Crystal Based Phase Shifters in 60 GHz Band. In Proceedings of the 3rd European Wireless Technology Conference, Paris, France, 27–28 September 2010; pp. 37–40. [Google Scholar]

- Sahbani, F.; Tentillier, N.; Legrand, C.; Karine, B. Coplanar liquid crystal reconfigurable phase-shifters. Mol. Cryst. Liq. Cryst. 2011, 542, 726. [Google Scholar] [CrossRef]

- Kamei, T.; Moritake, H.; Utsumi, Y. Microwave and light-wave measurements for nematic-liquid-crystal-loaded phase shifter using coplanar waveguide with floating electrode. Jpn. J. Appl. Phys. 2010, 49, 01AF03. [Google Scholar] [CrossRef]

- Nose, T.; Yanase, T.; Yanagihara, S.; Honma, M. Transmission properties of the coplanar waveguide type liquid crystal cell. In Proceedings of the 2005 Joint 30th International Conference on Infrared and Millimetre Waves and 13th International Conference on Terahertz Electronics, Williamsburg, VA, USA, 19–23 September 2005; pp. 567–568. [Google Scholar]

- Nose, T.; Yanagihara, S.; Honma, M. Operational mode of millimetre-wave phase shifter using liquid crystal materials with coplanar waveguide. Jpn. J. Appl. Phys. 2007, 46, 1114–1117. [Google Scholar] [CrossRef]

- Goelden, F.; Gaebler, A.; Goebel, M.; Manabe, A.; Mueller, S.; Jakoby, R. Tunable liquid crystal phase shifter for microwave frequencies. Electron. Lett. 2009, 45, 686–687. [Google Scholar] [CrossRef]

- Ku, B.H.; Schmalenberg, P.; Inac, O.; Gurbuz, O.D.; Lee, J.S.; Shiozaki, K.; Rebeiz, G.M. A 77–81-GHz 16-element phased-array receiver with 50 beam scanning for advanced automotive radars. IEEE Trans. Microw. Theory Tech. 2014, 62, 2823–2832. [Google Scholar] [CrossRef]

- Kim, H.T.; Park, J.H.; Lee, S.; Kim, S.; Kim, J.M.; Kim, Y.K.; Kwon, Y. V-band 2-b and 4-b low-loss and low-voltage distributed MEMS digital phase shifter using metal-air-metal capacitors. IEEE Trans. Microw. Theory Tech. 2002, 50, 2918–2923. [Google Scholar]

- Carsten, F.; Flavio, G.; Onur, H.K.; Saygin, B.; Sabrina, C.; Rolf, J. Advanced characterisation of a W-band phase shifter based on liquid crystals and MEMS technology. Int. J. Microw. Wirel. Technol. 2012, 4, 379–386. [Google Scholar]

| Technology | Max. Phase Shift (ΔΦ) | Min. Insertion Loss (IL) | Figure-of-Merit |

|---|---|---|---|

| SiGe BiCMOS [25] | 180° | −5.9 dB | 31°/dB |

| 4-bit distributed MEMS [26] | 182° | −2.7 dB | 67°/dB |

| LC and MEMS [27] | 74° | −2.0 dB | 37°/dB |

| E7 LC-based substrate integrated waveguide with magnets bias [18] | 300° | −8.5 dB | 35°/dB |

| MDA-03-2844 LC-based ridged waveguide with magnets & electric bias [15] | 325° | −4.6 dB | 70°/dB |

| MDA-05-1132 LC-based ridged waveguide with dual-frequency electric bias [15] | 193° | −11 dB | 17.5°/dB |

| W-1825 LC-based inverted microstrip with coplanar access, electric bias [5] | 180° | −10 dB | 8°/dB |

| GT3-24002 LC-based enclosed CPW (ECPW) with 0–10V bias (this work) | 180° | −4.0 dB | 45°/dB |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Chu, D. Liquid Crystal-Based Enclosed Coplanar Waveguide Phase Shifter for 54–66 GHz Applications. Crystals 2019, 9, 650. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst9120650

Li J, Chu D. Liquid Crystal-Based Enclosed Coplanar Waveguide Phase Shifter for 54–66 GHz Applications. Crystals. 2019; 9(12):650. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst9120650

Chicago/Turabian StyleLi, Jinfeng, and Daping Chu. 2019. "Liquid Crystal-Based Enclosed Coplanar Waveguide Phase Shifter for 54–66 GHz Applications" Crystals 9, no. 12: 650. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst9120650