Preparation and Electrochemical Properties of Porous Carbon Nanofiber Electrodes Derived from New Precursor Polymer: 6FDA-TFMB

Abstract

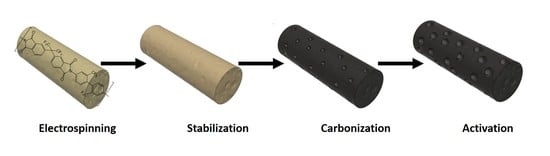

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Huang, J.; Sumpter, B.G.; Meunier, V.; Yushin, G.; Portet, C.; Gogotsi, Y. Curvature effects in carbon nanomaterials: Exohedral versus endohedral supercapacitors. J. Mater. Res. 2010, 25, 1525–1531. [Google Scholar] [CrossRef] [Green Version]

- Chen, T.; Dai, L. Carbon nanomaterials for high-performance supercapacitors. Mater. Today 2013, 16, 272–280. [Google Scholar] [CrossRef]

- Jung, K.-H.; Ferraris, J.P. Preparation of porous carbon nanofibers derived from PBI/PLLA for supercapacitor electrodes. Nanotechnology 2016, 27, 425708. [Google Scholar] [CrossRef]

- Lallave, M.; Bedia, J.; Ruiz-Rosas, R.; Rodríguez-Mirasol, J.; Cordero, T.; Otero, J.C.; Marquez, M.; Barrero, A.; Loscertales, I.G. Filled and hollow carbon nanofibers by coaxial electrospinning of alcell lignin without binder polymers. Adv. Mater. 2007, 19, 4292–4296. [Google Scholar] [CrossRef]

- Jazaeri, E.; Zhang, L.; Wang, X.; Tsuzuki, T. Fabrication of carbon nanofiber by pyrolysis of freeze-dried cellulose nanofiber. Cellulose 2011, 18, 1481–1485. [Google Scholar] [CrossRef]

- Geiszler, V.C.; Koros, W.J. Effects of polyimide pyrolysis conditions on carbon molecular sieve membrane properties. Ind. Eng. Chem. Res. 1996, 35, 2999–3003. [Google Scholar] [CrossRef]

- Park, H.B.; Kim, Y.K.; Lee, J.M.; Lee, S.Y.; Lee, Y.M. Relationship between chemical structure of aromatic polyimides and gas permeation properties of their carbon molecular sieve membranes. J. Membr. Sci. 2004, 229, 117–127. [Google Scholar] [CrossRef]

- Steel, K.M.; Koros, W.J. An investigation of the effects of pyrolysis parameters on gas separation properties of carbon materials. Carbon 2005, 43, 1843–1856. [Google Scholar] [CrossRef]

- Ma, X.; Swaidan, R.; Teng, B.; Tan, H.; Salinas, O.; Litwiller, E.; Han, Y.; Pinnau, I. Carbon molecular sieve gas separation membranes based on an intrinsically microporous polyimide precursor. Carbon 2013, 62, 88–96. [Google Scholar] [CrossRef]

- Seki, N.; Arai, T.; Suzuki, Y.; Kawakami, H. Novel polyimide-based electrospun carbon nanofibers prepared using ion-beam irradiation. Polymer 2012, 53, 2062–2067. [Google Scholar] [CrossRef]

- Al-Sayaghi, M.A.; Lewis, J.; Buelke, C.; Alshami, A.S. Structure-property-function connections underlying performance of polybenzoxazole membranes derived from BisAPAF polyimides. Polymer 2019, 182, 121825. [Google Scholar] [CrossRef]

- Inagaki, M.; Ohta, N.; Hishiyama, Y. Aromatic polyimides as carbon precursors. Carbon 2013, 61, 1–21. [Google Scholar] [CrossRef]

- Fu, S.; Sanders, E.S.; Kulkarni, S.S.; Wenz, G.B.; Koros, W.J. Temperature dependence of gas transport and sorption in carbon molecular sieve membranes derived from four 6FDA based polyimides: Entropic selectivity evaluation. Carbon 2015, 95, 995–1006. [Google Scholar] [CrossRef] [Green Version]

- Fu, S.; Sanders, E.S.; Kulkarni, S.S.; Koros, W.J. Carbon molecular sieve membrane structure–property relationships for four novel 6FDA based polyimide precursors. J. Membr. Sci. 2015, 487, 60–73. [Google Scholar] [CrossRef]

- Tong, H.; Hu, C.; Yang, S.; Ma, Y.; Guo, H.; Fan, L. Preparation of fluorinated polyimides with bulky structure and their gas separation performance correlated with microstructure. Polymer 2015, 69, 138–147. [Google Scholar] [CrossRef]

- Ohta, N.; Nishi, Y.; Morishita, T.; Tojo, T.; Inagaki, M. Preparation of microporous carbon films from fluorinated aromatic polyimides. Carbon 2008, 46, 1350–1357. [Google Scholar] [CrossRef]

- Jung, K.-H.; Panapitiya, N.; Ferraris, J.P. Electrochemical energy storage performance of carbon nanofiber electrodes derived from 6FDA-durene. Nanotechnology 2018, 29, 275701. [Google Scholar] [CrossRef]

- Bonso, J.S.; Kalaw, G.D.; Ferraris, J.P. High surface area carbon nanofibers derived from electrospun PIM-1 for energy storage applications. J. Mater. Chem. 2014, 2, 418–424. [Google Scholar] [CrossRef]

- Abeykoon, N.C.; Garcia, V.; Jayawickramage, R.A.; Perera, W.; Cure, J.; Chabal, Y.J.; Balkus, K.J.; Ferraris, J.P. Novel binder-free electrode materials for supercapacitors utilizing high surface area carbon nanofibers derived from immiscible polymer blends of PBI/6FDA-DAM: DABA. RSC Adv. 2017, 7, 20947–20959. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.W.; Kim, S.I.; Lee, B.; Choi, W.; Chae, B.; Kim, S.B.; Ree, M. Photoreactions and photoinduced molecular orientations of films of a photoreactive polyimide and their alignment of liquid crystals. Macromolecules 2003, 36, 6527–6536. [Google Scholar] [CrossRef]

- Lee, S.W.; Kim, S.I.; Lee, B.; Kim, H.C.; Chang, T.; Ree, M. A soluble photoreactive polyimide bearing the coumarin chromophore in the side group: Photoreaction, photoinduced molecular reorientation, and liquid-crystal alignability in thin films. Langmuir 2003, 19, 10381–10389. [Google Scholar] [CrossRef]

- Chen, L.-F.; Lu, Y.; Yu, L.; Lou, X.W.D. Designed formation of hollow particle-based nitrogen-doped carbon nanofibers for high-performance supercapacitors. Energy Environ. Sci. 2017, 10, 1777–1783. [Google Scholar] [CrossRef]

- Hatori, H.; Yamada, Y.; Shiraishi, M.; Yoshihara, M.; Kimura, T. The mechanism of polyimide pyrolysis in the early stage. Carbon 1996, 34, 201–208. [Google Scholar] [CrossRef]

- Feng, L.; Xie, N.; Zhong, J. Carbon nanofibers and their composites: A review of synthesizing, properties and applications. Materials 2014, 7, 3919–3945. [Google Scholar] [CrossRef] [PubMed]

- De, B.; Banerjee, S.; Verma, K.D.; Pal, T.; Manna, P.; Kar, K.K. Carbon Nanofiber as Electrode Materials for Supercapacitors. In Handbook of Nanocomposite Supercapacitor Materials II; Springer: Cham, Switzerland, 2020; pp. 179–200. [Google Scholar]

- Kondrat, S.; Perez, C.; Presser, V.; Gogotsi, Y.; Kornyshev, A. Effect of pore size and its dispersity on the energy storage in nanoporous supercapacitors. Energy Environ. Sci. 2012, 5, 6474–6479. [Google Scholar] [CrossRef]

- Yang, Y.; Centrone, A.; Chen, L.; Simeon, F.; Hatton, T.A.; Rutledge, G.C. Highly porous electrospun polyvinylidene fluoride (PVDF)-based carbon fiber. Carbon 2011, 49, 3395–3403. [Google Scholar] [CrossRef]

- Abeykoon, N.C.; Bonso, J.S.; Ferraris, J.P. Supercapacitor performance of carbon nanofiber electrodes derived from immiscible PAN/PMMA polymer blends. Rsc Adv. 2015, 5, 19865–19873. [Google Scholar] [CrossRef]

- Ando, S. Optical properties of fluorinated polyimides and their applications to optical components and waveguide circuits. J. Photopolym. Sci. Tech. 2004, 17, 219–232. [Google Scholar] [CrossRef] [Green Version]

- Chung, T.S.; Lin, W.H.; Vora, R.H. Gas transport properties of 6FDA-durene/1, 3-phenylenediamine (mPDA) copolyimides. J. Appl. Polym. Sci. 2001, 81, 3552–3564. [Google Scholar] [CrossRef]

- Chang, W.-M.; Wang, C.-C.; Chen, C.-Y. Fabrication of ultra-thin carbon nanofibers by centrifuged-electrospinning for application in high-rate supercapacitors. Electrochim. Acta 2019, 296, 268–275. [Google Scholar] [CrossRef]

- Pani, T.K.; Sahoo, B.B.; Sundaray, B. Carbon electrodes derived from polyacrylonitrile-polyethylene glycol blend for high-performance supercapcitor. Mater. Res. Express 2019, 6, 125077. [Google Scholar] [CrossRef]

- Dong, W.; Wang, Z.; Zhang, Q.; Ravi, M.; Yu, M.; Tan, Y.; Liu, Y.; Kong, L.; Kang, L.; Ran, F. Polymer/block copolymer blending system as the compatible precursor system for fabrication of mesoporous carbon nanofibers for supercapacitors. J. Power Sources 2019, 419, 137–147. [Google Scholar] [CrossRef]

- Kim, S.J.; Son, Y.J.; Jeon, B.; Han, Y.S.; Kim, Y.-J.; Jung, K.-H. Surface crosslinking of 6FDA-durene nanofibers for porous carbon nanofiber electrodes in electrochemical double layer capacitors. Nanotechnology 2020, 31, 215404. [Google Scholar] [CrossRef] [PubMed]

- Eskusson, J.; Jänes, A.; Kikas, A.; Matisen, L.; Lust, E. Physical and electrochemical characteristics of supercapacitors based on carbide derived carbon electrodes in aqueous electrolytes. J. Power Sources 2011, 196, 4109–4116. [Google Scholar] [CrossRef]

- Li, L.; Wu, Z.; Yuan, S.; Zhang, X.-B. Advances and challenges for flexible energy storage and conversion devices and systems. Energy Env. Sci. 2014, 7, 2101–2122. [Google Scholar] [CrossRef]

- Miao, F.; Shao, C.; Li, X.; Wang, K.; Liu, Y. Flexible solid-state supercapacitors based on freestanding nitrogen-doped porous carbon nanofibers derived from electrospun polyacrylonitrile@ polyaniline nanofibers. J. Mater. Chem. 2016, 4, 4180–4187. [Google Scholar] [CrossRef]

- Ma, X.; Kolla, P.; Zhao, Y.; Smirnova, A.L.; Fong, H. Electrospun lignin-derived carbon nanofiber mats surface-decorated with MnO2 nanowhiskers as binder-free supercapacitor electrodes with high performance. J. Power Sources 2016, 325, 541–548. [Google Scholar] [CrossRef]

- Wang, J.-G.; Yang, Y.; Huang, Z.-H.; Kang, F. A high-performance asymmetric supercapacitor based on carbon and carbon–MnO2 nanofiber electrodes. Carbon 2013, 61, 190–199. [Google Scholar] [CrossRef]

- Kim, J.-G.; Kim, H.-C.; Kim, N.D.; Khil, M.-S. N-doped hierarchical porous hollow carbon nanofibers based on PAN/PVP@ SAN structure for high performance super capacitor. Compos. Part B Eng. 2020, 107825. [Google Scholar] [CrossRef]

- Li, X.; Zhao, Y.; Bai, Y.; Zhao, X.; Wang, R.; Huang, Y.; Liang, Q.; Huang, Z. A non-woven network of porous nitrogen-doping carbon nanofibers as a binder-free electrode for supercapacitors. Electrochim. Acta 2017, 230, 445–453. [Google Scholar] [CrossRef]

| SSA 1 (m2 g−1) | TPV 2 (cm3 g−1) | Vmicro3 (cm3 g−1) | Vmeso4 (cm3 g−1) |

|---|---|---|---|

| 2210 | 1.055 | 0.757 | 0.298 |

| Precursor | 6FDA-TFMB | PAN |

|---|---|---|

| Specific capacitance (F g−1) at 10 mV s−1 | 292.3 | 210.7 |

| Energy density (Wh kg−1) at 0.5 A g−1 | 13.1 | 8.0 |

| Power density (kW kg−1) at 5 A g−1 | 1.7 | 1.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, B.; Ha, T.; Lee, D.Y.; Choi, M.-S.; Lee, S.W.; Jung, K.-H. Preparation and Electrochemical Properties of Porous Carbon Nanofiber Electrodes Derived from New Precursor Polymer: 6FDA-TFMB. Polymers 2020, 12, 1851. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12081851

Jeon B, Ha T, Lee DY, Choi M-S, Lee SW, Jung K-H. Preparation and Electrochemical Properties of Porous Carbon Nanofiber Electrodes Derived from New Precursor Polymer: 6FDA-TFMB. Polymers. 2020; 12(8):1851. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12081851

Chicago/Turabian StyleJeon, Byeongil, Taehwa Ha, Dong Yun Lee, Myung-Seok Choi, Seung Woo Lee, and Kyung-Hye Jung. 2020. "Preparation and Electrochemical Properties of Porous Carbon Nanofiber Electrodes Derived from New Precursor Polymer: 6FDA-TFMB" Polymers 12, no. 8: 1851. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12081851