Nematic Structures under Conical Anchoring at Various Director Tilt Angles Specified by Polymethacrylate Compositions

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Orientational Structures

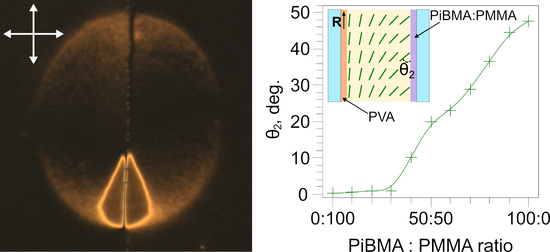

3.1.1. LC Cells Based on the Substrates with Rubbed PiBMA:PMMA Films

3.1.2. LC Cells Based on Substrates with Rubbed PVA Film and Non-Rubbed PiBMA:PMMA Film

3.2. An Electric Field Effect on the Orientational Structures

3.3. A Tilt Angle

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gennes, P.G.d.; Prost, J. The Physics of Liquid Crystals, 2nd ed.; The International Series of Monographs on Physics; Clarendon Press: Oxford, UK, 1998. [Google Scholar]

- Oswald, P.; Pieranski, P. Nematic and Cholesteric Liquid Crystals: Concepts and Physical Properties Illustrated by Experiments; The Liquid Crystals Book Series; Taylor & Francis: Boca Raton, FL, USA, 2005. [Google Scholar]

- Takatoh, K.; Hasegawa, M.; Koden, M.; Itoh, N.; Hasegawa, R.; Sakamoto, M. Alignment Technology and Applications of Liquid Crystal Devices; Liquid Crystals Book Series; CRC Press: Boca Raton, FL, USA, 2005; Volume 20054453. [Google Scholar] [CrossRef]

- Berreman, D.W.; Heffner, W.R. New bistable liquid-crystal twist cell. J. Appl. Phys. 1981, 52, 3032–3039. [Google Scholar] [CrossRef]

- Tseng, M.C.; Fan, F.; Lee, C.Y.; Murauski, A.; Chigrinov, V.; Kwok, H.S. Tunable lens by spatially varying liquid crystal pretilt angles. J. Appl. Phys. 2011, 109, 083109. [Google Scholar] [CrossRef] [Green Version]

- Jeng, S.C.; Hwang, S.J.; Horng, J.S.; Lin, K.R. Electrically switchable liquid crystal Fresnel lens using UV-modified alignment film. Opt. Express 2010, 18, 26325–26331. [Google Scholar] [CrossRef]

- Bezruchenko, V.S.; Muravsky, A.A.; Murauski, A.A.; Stankevich, A.I.; Mahilny, U.V. Gradient pretilt angle alignment materials with different photosensitivity for tunable polarization-independent self-aligned liquid crystal lens. J. Soc. Inf. Disp. 2021, 1–8. [Google Scholar] [CrossRef]

- Provenzano, C.; Pagliusi, P.; Cipparrone, G. Highly efficient liquid crystal based diffraction grating induced by polarization holograms at the aligning surfaces. Appl. Phys. Lett. 2006, 89, 121105. [Google Scholar] [CrossRef]

- Kim, J.; Na, J.H.; Lee, S.D. Fully continuous liquid crystal diffraction grating with alternating semi-circular alignment by imprinting. Opt. Express 2012, 20, 3034–3042. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.; Srivastava, A.; Xu, F.; Sun, J.T.; Lin, X.W.; Cui, H.Q.; Chigrinov, V.; Lu, Y.Q. Liquid crystal gratings based on alternate TN and PA photoalignment. Opt. Express 2012, 20, 5384–5391. [Google Scholar] [CrossRef] [PubMed]

- Tabiryan, N.V.; Roberts, D.E.; Liao, Z.; Hwang, J.Y.; Moran, M.; Ouskova, O.; Pshenichnyi, A.; Sigley, J.; Tabirian, A.; Vergara, R.; et al. Advances in Transparent Planar Optics: Enabling Large Aperture, Ultrathin Lenses. Adv. Opt. Mater. 2021, 9, 2001692. [Google Scholar] [CrossRef]

- Nys, I.; Stebryte, M.; Ussembayev, Y.Y.; Beeckman, J.; Neyts, K. Tilted chiral liquid crystal gratings for efficient large-angle diffraction. Adv. Opt. Mater. 2019, 7, 1901364. [Google Scholar] [CrossRef]

- Slussarenko, S.; Murauski, A.; Du, T.; Chigrinov, V.; Marrucci, L.; Santamato, E. Tunable liquid crystal q-plates with arbitrary topological charge. Opt. Express 2011, 19, 4085–4090. [Google Scholar] [CrossRef] [Green Version]

- Ma, L.L.; Li, S.S.; Li, W.S.; Ji, W.; Luo, B.; Zheng, Z.G.; Cai, Z.P.; Chigrinov, V.; Lu, Y.Q.; Hu, W.; et al. Rationally Designed Dynamic Superstructures Enabled by Photoaligning Cholesteric Liquid Crystals. Adv. Opt. Mater. 2015, 3, 1691–1696. [Google Scholar] [CrossRef]

- Ichimura, K. Photoalignment of Liquid-Crystal Systems. Chem. Rev. 2000, 100, 1847–1874. [Google Scholar] [CrossRef] [PubMed]

- Cognard, J. Alignment of Nematic Liquid Crystals and Their Mixtures; Number Suppl. 1 in Molecular Crystals and Liquid Crystals; Gordon and Breach Science Publishers: London, UK; New York, NY, USA, 1982. [Google Scholar]

- Lin, G.J.; Chen, T.J.; Lin, B.R.; Liao, H.I.; Chang, Y.; Wu, J.J.; Yang, Y.J. Effects of Pretilt Angle on Electro-Optical Properties of Optically Compensated Bend Liquid Crystal Devices With a Mixed Polyimide Alignment Layer. J. Disp. Technol. 2016, 12, 302–308. [Google Scholar] [CrossRef]

- Kang, H.; Kang, D. Polystyrene Blend Alignment Layers for High Pretilt Angle Control. Mol. Cryst. Liq. Cryst. 2016, 626, 207–214. [Google Scholar] [CrossRef]

- Wu, W.Y.; Wang, C.C.; Fuh, A.Y. Controlling pre-tilt angles of liquid crystal using mixed polyimide alignment layer. Opt. Express 2008, 16, 17131. [Google Scholar] [CrossRef] [PubMed]

- Ahn, H.J.; Kim, J.B.; Kim, K.C.; Hwang, B.H.; Kim, J.T.; Baik, H.K.; Park, J.S.; Kang, D. Liquid crystal pretilt angle control using adjustable wetting properties of alignment layers. Appl. Phys. Lett. 2007, 90, 253505. [Google Scholar] [CrossRef]

- Vaughn, K.E.; Sousa, M.; Kang, D.; Rosenblatt, C. Continuous control of liquid crystal pretilt angle from homeotropic to planar. Appl. Phys. Lett. 2007, 90, 194102. [Google Scholar] [CrossRef] [Green Version]

- Bezruchenko, V.S.; Muravsky, A.A.; Murauski, A.A.; Stankevich, A.I.; Mahilny, U.V. Tunable Liquid Crystal Lens Based on Pretilt Angle Gradient Alignment. Mol. Cryst. Liq. Cryst. 2016, 626, 222–228. [Google Scholar] [CrossRef]

- Lee, F.K.; Zhang, B.; Sheng, P.; Kwok, H.S.; Tsui, O.K.C. Continuous liquid crystal pretilt control through textured substrates. Appl. Phys. Lett. 2004, 85, 5556–5558. [Google Scholar] [CrossRef] [Green Version]

- Sinha, G.P.; Wen, B.; Rosenblatt, C. Large, continuously controllable nematic pretilt from vertical orientation. Appl. Phys. Lett. 2001, 79, 2543–2545. [Google Scholar] [CrossRef]

- Yoon, W.J.; Choi, Y.J.; Kang, D.G.; Kim, D.Y.; Park, M.; Lee, J.H.; Kang, S.W.; Lee, S.H.; Jeong, K.U. Construction of Polymer-Stabilized Automatic MultiDomain Vertical Molecular Alignment Layers with Pretilt Angles by Photopolymerizing Dendritic Monomers under Electric Fields. ACS Omega 2017, 2, 5942–5948. [Google Scholar] [CrossRef]

- Liu, B.Y.; Meng, C.H.; Chen, L.J. Role of Monomer Alkyl Chain Length in Pretilt Angle Control of Polymer-Stabilized Liquid Crystal Alignment System. J. Phys. Chem. C 2017, 121, 21037–21044. [Google Scholar] [CrossRef]

- Hsu, C.J.; Chen, B.L.; Huang, C.Y. Controlling liquid crystal pretilt angle with photocurable prepolymer and vertically aligned substrate. Opt. Express 2016, 24, 1463. [Google Scholar] [CrossRef] [PubMed]

- Ahn, D.; Jeong, Y.C.; Lee, S.; Lee, J.; Heo, Y.; Park, J.K. Control of liquid crystal pretilt angles by using organic/inorganic hybrid interpenetrating networks. Opt. Express 2009, 17, 16603. [Google Scholar] [CrossRef]

- Chen, T.J.; Chu, K.L. Pretilt angle control for single-cell-gap transflective liquid crystal cells. Appl. Phys. Lett. 2008, 92, 091102. [Google Scholar] [CrossRef]

- Dhara, S.; Kim, J.K.; Jeong, S.M.; Kogo, R.; Araoka, F.; Ishikawa, K.; Takezoe, H. Anchoring transitions of transversely polar liquid-crystal molecules on perfluoropolymer surfaces. Phys. Rev. E 2009, 79, 060701. [Google Scholar] [CrossRef] [Green Version]

- Faetti, S.; Palleschi, V. Nematic-isotropic interface of some members of the homologous series of 4-cyano-4′-(n-alkyl)biphenyl liquid crystals. Phys. Rev. A 1984, 30, 3241–3251. [Google Scholar] [CrossRef]

- Madhusudana, N.V.; Sumathy, K.R. Nematic droplets with a new structure. Mol. Cryst. Liq. Cryst. 1983, 92, 179–185. [Google Scholar] [CrossRef]

- Volovik, G.E.; Lavrentovich, O.D. Topological dynamics of defects: Boojums in nematic drops. JETP 1983, 58, 1159–1166. [Google Scholar]

- Tran, L.; Lavrentovich, M.O.; Durey, G.; Darmon, A.; Haase, M.F.; Li, N.; Lee, D.; Stebe, K.J.; Kamien, R.D.; Lopez-Leon, T. Change in stripes for cholesteric shells via anchoring in moderation. Phys. Rev. X 2017, 7, 041029. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Zhao, L.; Xu, A.; Wang, L.; Zhang, L.; Liu, S.; Liu, Y.; Li, H. Detecting enzymatic reactions in penicillinase via liquid crystal microdroplet-based pH sensor. Sens. Actuators B Chem. 2018, 258, 1090–1098. [Google Scholar] [CrossRef]

- Shvetsov, S.A.; Rudyak, V.Y.; Emelyanenko, A.V.; Boiko, N.I.; Zhang, Y.S.; Liu, J.H.; Khokhlov, A.R. Photoinduced orientational structures of nematic liquid crystal droplets in contact with polyimide coated surface. J. Mol. Liq. 2018, 267, 222–228. [Google Scholar] [CrossRef]

- Ramdane, O.O.; Auroy, P.; Forget, S.; Raspaud, E.; Martinot-Lagarde, P.; Dozov, I. Memory-Free Conic Anchoring of Liquid Crystals on a Solid Substrate. Phys. Rev. Lett. 2000, 84, 3871–3874. [Google Scholar] [CrossRef] [PubMed]

- Kumar, T.A.; Le, K.V.; Aya, S.; Kang, S.; Araoka, F.; Ishikawa, K.; Dhara, S.; Takezoe, H. Anchoring transition in a nematic liquid crystal doped with chiral agents. Phase Transit. 2012, 85, 888–899. [Google Scholar] [CrossRef]

- Krakhalev, M.N.; Prishchepa, O.O.; Sutormin, V.S.; Zyryanov, V.Y. Director configurations in nematic droplets with tilted surface anchoring. Liq. Cryst. 2017, 44, 355–363. [Google Scholar] [CrossRef] [Green Version]

- Krakhalev, M.N.; Bikbaev, R.G.; Sutormin, V.S.; Timofeev, I.V.; Zyryanov, V.Y. Nematic and cholesteric liquid crystal structures in cells with tangential-conical boundary conditions. Crystals 2019, 9, 249. [Google Scholar] [CrossRef] [Green Version]

- Biagio, R.; de Souza, R.; Evangelista, L.; Ribeiro de Almeida, R.; Zola, R. Spontaneous striped pattern formation in thin chiral nematic liquid crystal layers. J. Mol. Liq. 2018, 269, 703–711. [Google Scholar] [CrossRef]

- Zola, R.S.; Evangelista, L.R.; Yang, Y.C.; Yang, D.K. Surface induced phase separation and pattern formation at the isotropic interface in chiral nematic liquid crystals. Phys. Rev. Lett. 2013, 110, 057801. [Google Scholar] [CrossRef]

- Prishchepa, O.; Krakhalev, M.; Rudyak, V.; Sutormin, V.; Zyryanov, V. Electrically turning periodic structures in cholesteric layer with conical–planar boundary conditions. Sci. Rep. 2021, 11, 8409. [Google Scholar] [CrossRef]

- Krakhalev, M.N.; Prishchepa, O.O.; Sutormin, V.S.; Bikbaev, R.G.; Timofeev, I.V.; Zyryanov, V.Y. Electrically induced transformations of defects in cholesteric layer with tangential-conical boundary conditions. Sci. Rep. 2020, 10, 1–9. [Google Scholar]

- Sutormin, V.S.; Krakhalev, M.N.; Timofeev, I.V.; Bikbaev, R.G.; Prishchepa, O.O.; Zyryanov, V.Y. Cholesteric layers with tangential-conical surface anchoring for an electrically controlled polarization rotator. Opt. Mater. Express 2021, 11, 1527–1536. [Google Scholar] [CrossRef]

- Wang, S.Y.; Wu, H.M.; Yang, K.H. Simple and direct measurements of pretilt angles in hybrid-aligned nematic liquid-crystal cells. Appl. Opt. 2013, 52, 5106–5111. [Google Scholar] [CrossRef] [PubMed]

- Krakhalev, M.N.; Prishchepa, O.O.; Sutormin, V.S.; Zyryanov, V.Y. Polymer dispersed nematic liquid crystal films with conical boundary conditions for electrically controllable polarizers. Opt. Mater. 2019, 89, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Ji, Y.; Kelly, J.R.; West, J.L. A study of the surface anchoring at a polymer/liquid crystal interface in the neighbourhood of the glass transition. Liq. Cryst. 1993, 14, 1885–1893. [Google Scholar] [CrossRef]

- Gwag, J.S.; Kim, Y.K.; Lee, C.H.; Kim, J.H. Realization of multi-stable ground states in a nematic liquid crystal by surface and electric field modification. Sci. Rep. 2015, 5, 11368. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kostikov, D.A.; Krakhalev, M.N.; Prishchepa, O.O.; Zyryanov, V.Y. Nematic Structures under Conical Anchoring at Various Director Tilt Angles Specified by Polymethacrylate Compositions. Polymers 2021, 13, 2993. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13172993

Kostikov DA, Krakhalev MN, Prishchepa OO, Zyryanov VY. Nematic Structures under Conical Anchoring at Various Director Tilt Angles Specified by Polymethacrylate Compositions. Polymers. 2021; 13(17):2993. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13172993

Chicago/Turabian StyleKostikov, Denis A., Mikhail N. Krakhalev, Oxana O. Prishchepa, and Victor Ya. Zyryanov. 2021. "Nematic Structures under Conical Anchoring at Various Director Tilt Angles Specified by Polymethacrylate Compositions" Polymers 13, no. 17: 2993. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13172993