Ultrasonic Welding of PBT-GF30 (70% Polybutylene Terephthalate + 30% Fiber Glass) and Expanded Polytetrafluoroethylene (e-PTFE)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Properties of PBT-GF30 Material

2.1.2. Properties of the e-PTFE Material

2.2. Methods

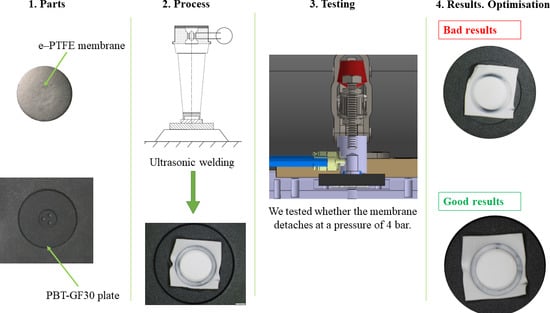

2.2.1. Realization of the Welded Joint with the Help of Ultrasound

- -

- In the first stage, there is perfect cleaning due to the phenomenon of acoustic cavitation, which occurs as a result of the propagation of ultrasonic waves;

- -

- In the second stage, the ultrasonic vibrations cause the development of heat on the surfaces in contact due to the existence of relative movement between them, with ultrasonic frequency. The heat resulting from the friction of contact surfaces causes most of materials to melt in a very short period of time;

- -

- In the third stage, connections appear between contact surfaces heated up to the plastic state temperature, allowing the realization of a welded joint with a good resistance.

2.2.2. Topography of the Surface Layer of the Plate-Type Part

2.2.3. Scanning Electron Microscopy (SEM) Analysis of the Membrane-Type Part and Welded Joint

2.2.4. Testing the Welded Joint from a Tightness Point of View

3. Results and Discussion

3.1. Results Obtained When Measuring the Surface Topography of the Plate-Type Part

- -

- In the first stage, ultrasonic oscillations cause the development of heat on contact micro-irregularities between the two surfaces. These micro-irregularities move relative to each other, with an ultrasonic frequency and a certain amplitude, resulting in a large amount of heat due to contact friction. Most thermoplastics start to melt in a very short time;

- -

- In the second stage, when heated up to the temperature of the plastic state, there are connections between the contact surfaces that allow a resistant joint to be obtained, after all the microneregularities have melted, creating a homogeneous area on the entire contact surface.

3.2. Results Obtained When Analyzing the Membrane-Type Part

3.3. Optimization of Ultrasonic Welding Process Parameters

4. Conclusions

- The amplitude of vibrations directly acts on the supplied energy and governs the local heating rate. However, in practice, there must be a correlation between the amplitude values and welding, time in order to prevent rapid flattening of the roughness of the parts, which causes a reduction in the overall efficiency of the ultrasonic welding process. The research initially started from a maximum amplitude of 40 μm, and an optimal value for the amplitude of 30 μm was finally obtained. Moreover, an optimal value of the welding time of 450 ms was established, although the research was initially performed with a welding time of 150 ms;

- Too much welding force results in a welded joint with reduced characteristics, as it causes a rapid change in the contact geometry between the surfaces of the energy parts before reaching a high temperature, and this negatively influences the performance of the welded joints. Therefore, an optimal value of the welding force of 70 N was determined, although the initial research was performed with a welding force of 120 N;

- A higher roughness for the plate-type fabric made of PBT-GF30 can positively influence the characteristics of the welded joint, but too high a roughness can cause the appearance of some porosities and thus may weaken the joint made, with negative effects on the pressure at which the two parts detach. On the contrary, a surface with a lower roughness can lead to progressive filling of the interface between parts with a lower porosity.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bhudolia, S.K.; Gohel, G.; Leong, K.F.; Barsotti, R.J., Jr. Investigation on Ultrasonic Welding Attributes of Novel Carbon/Elium® Composites. Materials 2020, 13, 1117. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Villegas, I.F.; Moser, L.; Yousefpour, A.; Mitschang, P.; Bersee, H.E. Process and performance evaluation of ultrasonic, induction and resistance welding of advanced thermoplastic composites. J. Thermoplast. Compos. Mater. 2013, 26, 1007–1024. [Google Scholar] [CrossRef]

- Brassard, D.; Dubé, M.; Tavares, J.R. Resistance welding of thermoplastic composites with a nanocomposite heating element. Compos. Part B Eng. 2019, 165, 779–784. [Google Scholar] [CrossRef]

- Stavrov, D.; Bersee, H.E.N. Resistance welding of thermoplastic composites—An overview. Compos. Part A Appl. Sci. Manuf. 2005, 36, 39–54. [Google Scholar] [CrossRef]

- Pappadà, S.; Salomi, A.; Montanaro, J.; Passaro, A.; Caruso, A.; Maffezzoli, A. Fabrication of a thermoplastic matrix composite stiffened panel by induction welding. Aerosp. Sci. Technol. 2015, 43, 314–320. [Google Scholar] [CrossRef]

- Raza, S.F. Ultrasonic Welding of Thermoplastics. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2015. [Google Scholar]

- Rashli, R.; Bakar, E.A.; Kamaruddin, S. Determination of ultrasonic welding optimal parameters for thermoplastic material of manufacturing products. Sci. Eng. 2013, 64, 19–24. [Google Scholar] [CrossRef] [Green Version]

- Yibo, S.; Yuqi, F.; Pengfei, H.; Xing, Z.; Xinhua, Y.; Guoxiong, W. Online visual monitoring and ultrasonic feedback detection in the ultrasonic precision bonding of polymers. Adv. Compos. Lett. 2020, 29. [Google Scholar] [CrossRef]

- Ülker, A.; Öztoprak, N.; Sayer, S. Optimization of welding parameters of hot plate welded PC/ABS blends by using the Taguchi experimental design method. J. Elastom. Plast. 2018, 50, 162–181. [Google Scholar] [CrossRef]

- Palardy, G.F.; Villegas, I. Smart ultrasonic welding of thermoplastic composites. In Proceedings of the American Society for Composites—31st Technical Conference on Composite Materials, Williamsburg, VA, USA, 19–22 September 2016. [Google Scholar]

- Raza, S.F.; Khan, S.A.; Mughal, M.P. Optimizing the weld factors affecting ultrasonic welding of thermoplastics. Int. J. Adv. Manuf. Technol. 2019, 103, 2053–2067. [Google Scholar] [CrossRef]

- Sackmann, J.; Burlage, K.; Gerhardy, C.; Memering, B.; Liao, S.; Schomburg, W.K. Review on ultrasonic fabrication of polymer micro devices. Ultrasonics 2014, 56, 189–200. [Google Scholar] [CrossRef]

- Costa, A.P.D.; Botelho, E.C.; Costa, M.L.; Narita, N.E.; Tarpani, J.R. A Review of Welding Technologies for Thermoplastic Composites in Aerospace Applications. J. Aerosp. Technol. Manag. 2012, 4, 255–265. [Google Scholar] [CrossRef] [Green Version]

- Wagner, G.; Balle, F.; Eifler, D. Ultrasonic Welding of Hybrid Joints. JOM 2012, 64, 401–406. [Google Scholar] [CrossRef]

- Gutnik, V.G.; Gorbach, N.V.; Dashkov, A.V. Some Characteristics of Ultrasonic Welding of Polymers. FIBER Chem. 2002, 34, 426–432. [Google Scholar] [CrossRef]

- Vendan, S.A.; Natesh, M.; Garg, A.; Gao, L. Confluence of Multidisciplinary Sciences for Polymer Joining; Ultrasonic Welding of Polymers; Springer: Singapore, 2019; pp. 73–101. [Google Scholar]

- Ganesh, M.; Praba Rajathi, R. Experimental study on ultrasonic welding of aluminum sheet to copper sheet. Int. J. Res. Eng. Technol. 2013, 2, 161–166. [Google Scholar]

- Amza, G.; Dobrotã, D.; Semenescu, A.; Iancului, I. Researches Concerning the Ultrasonic Energy’s Influence over the Resistance at Extraction of the Metallic Reinforcemention from the Rubber Matrix. Mater. Plast. 2008, 45, 377–380. [Google Scholar]

- Dobrota, D. Vulcanization of Rubber Conveyor Belts with Metallic Reinforcemention Using Ultrasounds. Procedia Eng. 2015, 100, 1160–1166. [Google Scholar] [CrossRef] [Green Version]

- Barbosa, L.C.M.; de Souza, S.D.B.; Botelho, E.C.; Cândido, G.M.; Rezende, M.C. Fractographic evaluation of welded joints of PPS/glass fiber thermoplastic composites. Eng. Fail. Anal. 2019, 102, 60–68. [Google Scholar] [CrossRef]

- Qiu, J.; Zhang, G.; Sakai, E.; Liu, W.; Zang, L. Thermal Welding by the Third Phase Between Polymers: A Review for Ultrasonic Weld Technology Developments. Polymers 2020, 12, 759. [Google Scholar] [CrossRef] [Green Version]

- Ulisses, H.R.; Inés, F.; Elisa, V. Ultrasonic Molding Technology: Recent Advances and Potential Applications in the Medical Industry. Polymers 2019, 11, 667. [Google Scholar]

- Showaib, E.A.; Elsheikh, A.H. Effect of surface preparation on the strength of vibration welded butt joint made from PBT composite. Polym. Test. 2020, 83, 106319. [Google Scholar] [CrossRef]

- Bappa, A. Laser transmission welding of polymers—A review on process fundamentals, material attributes, weldability, and welding techniques. J. Manuf. Process. 2020, 60, 227–246. [Google Scholar]

- Dimitrescu, A.; Nitoi, D.F.; Dobrota, D.; Apostolescu, Z. Researches and studies regarding brazed aluminium alloys microstructure used in aeronautic industry. Metalurgija 2015, 54, 583–586. [Google Scholar]

- Amza, G.; Dobrotǎ, D. Ultrasound effect on the mechanical properties of parts loaded by welding. Metalurgija 2013, 53, 83–86. [Google Scholar]

- Han, W.; Liu, J.; Chong, D.; Yan, J. Analysis of heat generation characteristics in ultrasonic welding of plastics under low amplitude conditions. J. Polym. Eng. 2015, 36, 4. [Google Scholar] [CrossRef]

- Ha Minh, D. Couplages thermo-mécaniques lors de la soudure par ultrasons. application aux thermoplastiques. Ph.D. Thesis, Ecole Nationale des Ponts et Chaussées, Marnravalle, France, 2009. [Google Scholar]

- Levy, A.; Le Corre, S.; Poitou, A. Ultrasonic welding of thermoplastic composites: A numerical analysis at the mesoscopic scale relating processing parameters, flow of polymer and quality of adhesion. Int. J. Mater. Form. 2014, 7, 39–51. [Google Scholar] [CrossRef]

| Density (g/cc) | Tensile Strength (GPa) | Poisson’s Ratio | Coefficient of Thermal Expansion (107 K−1) | Specific Heat (J/kg.K) | Thermal Conductivity (W/m.K) | Weighted Average Fiber Length (μm) |

|---|---|---|---|---|---|---|

| 2.57 | 2.01 | 0.23 | 5.1 × 10−6 | 805 | 1.35 | 327 |

| Parameter | Value |

|---|---|

| outer diameter sonotrode | 7.0 mm |

| inner diameter sonotrode | 5.6 mm |

| welding time | 0.15–0.45 s |

| hold time | 0.15 s |

| trigger force | 0.95 × welding force |

| welding force | 70–120 N |

| amplitude | 30–40 μm |

| Samples | Roughness Measurement Results, Ra (µm) | Height Differences Direction 1, µm | Height Differences Direction 2, µm |

|---|---|---|---|

| 1 | 2.32 | −0.05 | −0.83 |

| 2 | 2.48 | −0.15 | −0,.3 |

| 3 | 2.07 | −0.37 | −0.28 |

| 4 | 1.41 | 0.59 | 0.63 |

| 5 | 2.07 | 2.01 | 2.45 |

| 6 | 2.44 | 1.26 | 1.07 |

| 7 | 2.58 | −0.59 | −0.83 |

| 8 | 2.01 | −0.18 | 0.13 |

| 9 | 2.68 | −0.96 | −0.98 |

| 10 | 2.23 | −0.12 | −0.37 |

| Samples | Welding Force, N | Welding Time, ms | Amplitude, µm | Holding Time, ms | Energy Result, J | Membrane Detachment Pressure, bar |

|---|---|---|---|---|---|---|

| 1 | 87 | 150 | 40 | 150 | 20 | 0.87 |

| 2 | 87 | 150 | 40 | 150 | 21 | 0.91 |

| 3 | 100 | 150 | 40 | 150 | 20 | 0.85 |

| 4 | 100 | 150 | 40 | 150 | 20 | 0.78 |

| 5 | 110 | 150 | 40 | 150 | 22 | 0.86 |

| 6 | 110 | 150 | 40 | 150 | 22 | 0.89 |

| 7 | 120 | 150 | 40 | 150 | 24 | 0.94 |

| 8 | 120 | 150 | 40 | 150 | 23 | 0.84 |

| 9 | 120 | 150 | 40 | 150 | 24 | 0.98 |

| 10 | 120 | 150 | 40 | 150 | 24 | 0.88 |

| Qualifying | Element | Net Counts | Weight, % | Atom, % | Compound, % |

|---|---|---|---|---|---|

| Not adequate | C | 60,736 | 30.8 | 40.7 | 30.8 |

| O | 21,923 | 9.4 | 9.4 | 9.4 | |

| F | 195,570 | 59.7 | 49.9 | 59.7 | |

| Adequate | C | 48,162 | 26.7 | 36.1 | 26.7 |

| O | 18,019 | 7.3 | 7.4 | 7.3 | |

| F | 236,610 | 66.0 | 56.4 | 66.0 | |

| Reference | C | 48,354 | 26.1 | 35.5 | 26.1 |

| O | 18,435 | 7.1 | 7.3 | 7.1 | |

| F | 251,100 | 66.7 | 57.3 | 66.7 |

| Samples | Welding Force, N | Welding Time, ms | Amplitude, µm | Holding Time, ms | Energy Result, J | Membrane Detachment Pressure, bar |

|---|---|---|---|---|---|---|

| 1 | 85 | 350 | 34 | 150 | 50 | 4.2 |

| 2 | 90 | 300 | 36 | 150 | 39 | 2.9 |

| 3 | 85 | 350 | 36 | 150 | 57 | 5.1 |

| 4 | 80 | 450 | 28 | 150 | 50 | 4.3 |

| 5 | 80 | 450 | 26 | 150 | 39 | 2.3 |

| 6 | 85 | 450 | 28 | 150 | 41 | 4.4 |

| 7 | 75 | 450 | 28 | 150 | 48 | 4.5 |

| 8 | 75 | 450 | 28 | 150 | 48 | 4 |

| 9 | 75 | 450 | 28 | 150 | 48 | 4 |

| 10 | 75 | 450 | 28 | 150 | 47 | 4.3 |

| Parameters | p | F | Parameter_Beta |

|---|---|---|---|

| Welding force | 0.00000012 | 191.1677 | −0.713 |

| Welding time | 0.00000009 | 176.7996 | 0.879 |

| Amplitude | 0.00000007 | 212.7887 | 0.741 |

| Samples | Welding Force, N | Welding Time, ms | Amplitude, µm | Holding Time, ms | Energy Result, J | Membrane Detachment Pressure, bar |

|---|---|---|---|---|---|---|

| 1 | 70 | 450 | 30 | 150 | 34 | 4.4 |

| 2 | 70 | 450 | 30 | 150 | 33 | 4.1 |

| 3 | 70 | 450 | 30 | 150 | 35 | 4.5 |

| 4 | 70 | 450 | 30 | 150 | 31 | 4.1 |

| 5 | 70 | 450 | 30 | 150 | 33 | 4.2 |

| 6 | 70 | 450 | 30 | 150 | 31 | 4.2 |

| 7 | 70 | 450 | 30 | 150 | 32 | 4.3 |

| 8 | 70 | 450 | 30 | 150 | 34 | 4.2 |

| 9 | 70 | 450 | 30 | 150 | 31 | 4.1 |

| 10 | 70 | 450 | 30 | 150 | 33 | 4.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobrotă, D.; Lazăr, S.V. Ultrasonic Welding of PBT-GF30 (70% Polybutylene Terephthalate + 30% Fiber Glass) and Expanded Polytetrafluoroethylene (e-PTFE). Polymers 2021, 13, 298. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13020298

Dobrotă D, Lazăr SV. Ultrasonic Welding of PBT-GF30 (70% Polybutylene Terephthalate + 30% Fiber Glass) and Expanded Polytetrafluoroethylene (e-PTFE). Polymers. 2021; 13(2):298. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13020298

Chicago/Turabian StyleDobrotă, Dan, and Sergiu Viorel Lazăr. 2021. "Ultrasonic Welding of PBT-GF30 (70% Polybutylene Terephthalate + 30% Fiber Glass) and Expanded Polytetrafluoroethylene (e-PTFE)" Polymers 13, no. 2: 298. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13020298