Fabrication, Functionalization, and Application of Carbon Nanotube-Reinforced Polymer Composite: An Overview

Abstract

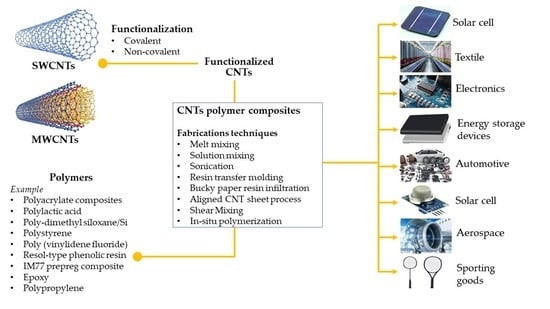

:1. Introduction

2. Synthetization of Carbon Nanotubes

3. Functionalization of Carbon Nanotubes

3.1. Covalent Functionalization

3.2. Non-Covalent Functionalization

4. Fabrication Technique Involved in Carbon Nanotube Polymer Composites

4.1. Melt Mixing

4.2. Solution Mixing

4.3. Sonication

4.4. Resin Transfer Molding

4.5. Bucky Paper Resin Infiltration

4.6. Aligned CNT Sheet Process

4.7. Shear Mixing

4.8. In-Situ Polymerization

5. Performance of Carbon Nanotube–Polymer Composites

5.1. CNT-Reinforced Polymer Composites on Mechanical Performance

5.2. CNT-Reinforced Polymer Composites on Thermal Performance

5.3. CNT-Reinforced Polymer Composites on Electrical Performance

5.3.1. Mechanism of Electrical Conductivity

5.3.2. Factors Affecting Electrical Conductivity of CNT-Reinforced Polymer Composites

Dispersion of CNTs

Filler Loading Amount

Structure of CNTs

Type of Polymers

- (a)

- Thermoplastic polymers: PP is known to be one of the highly favored thermoplastic polymers due to its high solubility in aqueous media and low cost. Being a thermoplastic commodity, PP has the advantage of recyclability with remarkable physical, thermal, and mechanical properties. PANI also has similar advantages and has been a subject of reinforced polymer research for many years [213,214,215]. Sobha et al. (2017) [196] successfully produced highly disperse functional MWCNTs (f-MWCNT) in thermoplastic polyurethane (TPU) composites based on PANI via an in-situ polymerization assisted by ultra-sonication. The well-dispersed and reduced aggregation of f-MWCNTs contribute to a very low percolation threshold at only 0.58 wt.%, hence exhibiting a significant conductivity of 28.6 Sm−1. The results showed promising applications, mostly as coating and electromagnetic interference shielding.

- (b)

- Thermoset polymers: As a conducting polymer, polypyrrole (PPy) has been widely used due to its superiority in optical and electrical properties. It possesses a high efficiency response towards visible light, a high carrier mobility, and an excellent thermal and chemical stability. Recently, by looking into these advantages, Saheeda and Jayaleksmi (2020) [216] successfully synthesized a nanocomposite of PPy and MWCNTs via liquid/liquid interfacial polymerization. In this study, they found that a strong interfacial interaction between the polymer and MWCNTs occurred. This led to the establishment of a high electrical conductivity of 8.05 × 102 Sm−1. Furthermore, the nanocomposite also possessed excellent nonlinear optical properties that suggested promise for its application in solar cells. Table 9 presents the properties of the electrical conductance of various CNTs and polymers, as well as their potential applications.

5.4. Environmental Concern and Health and Safety Issues of CNTs

5.4.1. Aspect Ratio

5.4.2. Length

5.4.3. Surface Area

5.4.4. Concentration

5.4.5. Cost

6. Applications and Potential Use of Carbon Nanotube-Reinforced Polymer Composites

6.1. Electronic Application

6.2. Aerospace Application

6.3. Automobile Application

6.4. Sensors

6.5. Sporting Goods

6.6. Wind Turbine Blades

6.7. Environmental Remediation

7. The Economic Analysis of CNT Production

8. Conclusions and Future Outlooks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- De, B.; Banerjee, S.; Verma, K.D.; Pal, T.; Manna, P.K.; Kar, K.K. Carbon nanotube as electrode materials for supercapacitors. In Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2020; Volume 302, pp. 229–243. [Google Scholar]

- Ahmadi, M.; Zabihi, O.; Masoomi, M.; Naebe, M. Synergistic effect of MWCNTs functionalization on interfacial and mechanical properties of multi-scale UHMWPE fibre reinforced epoxy composites. Compos. Sci. Technol. 2016, 134, 1–11. [Google Scholar] [CrossRef]

- Maruyama, B.; Alam, K. Carbon nanotubes and nanofibers in composite materials. SAMPE J. 2002, 38, 59–70. [Google Scholar]

- Collins, P.G.; Avouris, P. Nanotubes for Electronics–Scientific American; Nature Publishing Group: San Francisco, CA, USA, 2000. [Google Scholar]

- Song, H.J.; Zhang, Z.Z.; Men, X.H. Surface-modified carbon nanotubes and the effect of their addition on the tribological behavior of a polyurethane coating. Eur. Polym. J. 2007, 43, 4092–4102. [Google Scholar] [CrossRef]

- Morsi, M.A.; Rajeh, A.; Al-Muntaser, A.A. Reinforcement of the optical, thermal and electrical properties of PEO based on MWCNTs/Au hybrid fillers: Nanodielectric materials for organoelectronic devices. Compos. Part B Eng. 2019, 173. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, Z.; Pei, K.; Qian, X.; Jin, C.; Che, R. Dandelion-like carbon nanotube assembly embedded with closely separated Co nanoparticles for high-performance microwave absorption materials. Nanoscale 2020, 12, 10149–10157. [Google Scholar] [CrossRef]

- Mo, Z.; Yang, R.; Lu, D.; Yang, L.; Hu, Q.; Li, H.; Zhu, H.; Tang, Z.; Gui, X. Lightweight, three-dimensional carbon Nanotube@TiO 2 sponge with enhanced microwave absorption performance. Carbon N. Y. 2019, 144, 433–439. [Google Scholar] [CrossRef]

- Souto, L.F.C.; Soares, B.G. Polyaniline/carbon nanotube hybrids modified with ionic liquids as anticorrosive additive in epoxy coatings. Prog. Org. Coat. 2020, 143. [Google Scholar] [CrossRef]

- Hassan, A.G.; Yajid, M.A.M.; Saud, S.N.; Bakar, T.A.A.; Arshad, A.; Mazlan, N. Effects of varying electrodeposition voltages on surface morphology and corrosion behavior of multi-walled carbon nanotube coated on porous Ti-30 at.%-Ta shape memory alloys. Surf. Coat. Technol. 2020, 401. [Google Scholar] [CrossRef]

- Medupin, R.O.; Abubakre, O.K.; Abdulkareem, A.S.; Muriana, R.A.; Abdulrahman, A.S. Carbon Nanotube Reinforced Natural Rubber Nanocomposite for Anthropomorphic Prosthetic Foot Purpose. Sci. Rep. 2019, 9, 20146. [Google Scholar] [CrossRef] [PubMed]

- Zainol Abidin, M.S.; Herceg, T.; Greenhalgh, E.S.; Shaffer, M.; Bismarck, A. Enhanced fracture toughness of hierarchical carbon nanotube reinforced carbon fibre epoxy composites with engineered matrix microstructure. Compos. Sci. Technol. 2019, 170, 85–92. [Google Scholar] [CrossRef]

- Feng, D.; Xu, D.; Wang, Q.; Liu, P. Highly stretchable electromagnetic interference (EMI) shielding segregated polyurethane/carbon nanotube composites fabricated by microwave selective sintering. J. Mater. Chem. C 2019, 7, 7938–7946. [Google Scholar] [CrossRef]

- Zhou, E.; Xi, J.; Guo, Y.; Liu, Y.; Xu, Z.; Peng, L.; Gao, W.; Ying, J.; Chen, Z.; Gao, C. Synergistic effect of graphene and carbon nanotube for high-performance electromagnetic interference shielding films. Carbon N. Y. 2018, 133, 316–322. [Google Scholar] [CrossRef]

- Chen, M.; Jing, Q.S.; Sun, H.B.; Xu, J.Q.; Yuan, Z.Y.; Ren, J.T.; Ding, A.X.; Huang, Z.Y.; Dong, M.Y. Engineering the Core-Shell-Structured NCNTs-Ni2Si@Porous Si Composite with Robust Ni-Si Interfacial Bonding for High-Performance Li-Ion Batteries. Langmuir 2019, 35, 6321–6332. [Google Scholar] [CrossRef] [PubMed]

- Guo, F.; Kang, T.; Liu, Z.; Tong, B.; Guo, L.; Wang, Y.; Liu, C.; Chen, X.; Zhao, Y.; Shen, Y.; et al. Advanced Lithium Metal-Carbon Nanotube Composite Anode for High-Performance Lithium-Oxygen Batteries. Nano Lett. 2019, 19, 6377–6384. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Wang, G.C.; Yang, W.Q.; Yuan, Z.Y.; Qian, X.; Xu, J.Q.; Huang, Z.Y.; Ding, A.X. Enhanced Synergetic Catalytic Effect of Mo2C/NCNTs@Co Heterostructures in Dye-Sensitized Solar Cells: Fine-Tuned Energy Level Alignment and Efficient Charge Transfer Behavior. ACS Appl. Mater. Interfaces 2019, 11, 42156–42171. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Wang, G.C.; Shao, L.L.; Yuan, Z.Y.; Qian, X.; Jing, Q.S.; Huang, Z.Y.; Xu, D.L.; Yang, S.X. Strategic Design of Vacancy-Enriched Fe1- xS Nanoparticles Anchored on Fe3C-Encapsulated and N-Doped Carbon Nanotube Hybrids for High-Efficiency Triiodide Reduction in Dye-Sensitized Solar Cells. ACS Appl. Mater. Interfaces 2018, 10, 31208–31224. [Google Scholar] [CrossRef]

- Chen, M.; Zhao, G.; Shao, L.L.; Yuan, Z.Y.; Jing, Q.S.; Huang, K.J.; Huang, Z.Y.; Zhao, X.H.; Zou, G.D. Controlled Synthesis of Nickel Encapsulated into Nitrogen-Doped Carbon Nanotubes with Covalent Bonded Interfaces: The Structural and Electronic Modulation Strategy for an Efficient Electrocatalyst in Dye-Sensitized Solar Cells. Chem. Mater. 2017, 29, 9680–9694. [Google Scholar] [CrossRef]

- Chen, M.; Shao, L.L.; Lv, X.W.; Wang, G.C.; Yang, W.Q.; Yuan, Z.Y.; Qian, X.; Han, Y.Y.; Ding, A.X. In situ growth of Ni-encapsulated and N-doped carbon nanotubes on N-doped ordered mesoporous carbon for high-efficiency triiodide reduction in dye-sensitized solar cells. Chem. Eng. J. 2020, 390. [Google Scholar] [CrossRef]

- Janudin, N.; Abdullah, N.; Wan Yunus, W.M.Z.; Yasin, F.M.; Yaacob, M.H.; Mohamad Saidi, N.; Kasim, N.A.M. Effect of functionalized carbon nanotubes in the detection of benzene at room temperature. J. Nanotechnol. 2018, 2018. [Google Scholar] [CrossRef] [Green Version]

- Maity, D.; Rajavel, K.; Kumar, R.T.R. Polyvinyl alcohol wrapped multiwall carbon nanotube (MWCNTs) network on fabrics for wearable room temperature ethanol sensor. Sens. Actuators B Chem. 2018, 261, 297–306. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Harussani, M.M.; Siti Zulaikha, N.D.; Norhana, A.H.; Imran Syakir, M.; Norli, A. Composites based on conductive polymer with carbon nanotubes in DMMP gas sensors—An overview. Polimery 2021, 66, 85–97. [Google Scholar] [CrossRef]

- Mananghaya, M.; Yu, D.; Santos, G.N.; Rodulfo, E. Scandium and Titanium Containing Single-Walled Carbon Nanotubes for Hydrogen Storage: A Thermodynamic and First Principle Calculation. Sci. Rep. 2016, 6, 27370. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yahya, M.S.; Ismail, M. Improvement of hydrogen storage properties of MgH2 catalyzed by K2NbF7 and multiwall carbon nanotube. J. Phys. Chem. C 2018, 122, 11222–11233. [Google Scholar] [CrossRef]

- Park, S.; Gupta, A.P.; Yeo, S.J.; Jung, J.; Paik, S.H.; Mativenga, M.; Kim, S.H.; Shin, J.H.; Ahn, J.S.; Ryu, J. Carbon nanotube field emitters synthesized on metal alloy substrate by PECVD for customized compact field emission devices to be used in X-ray source applications. Nanomaterials 2018, 8, 378. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, Y.; Li, J.; Wu, Q.; Yi, C.; Wu, H.; Chen, Z.; Ou-Yang, W. Study of film thickness effect on carbon nanotube based field emission devices. J. Alloys Compd. 2020, 816. [Google Scholar] [CrossRef]

- Kumar, R.; Ansari, M.O.; Barakat, M.A. DBSA doped polyaniline/multi-walled carbon nanotubes composite for high efficiency removal of Cr(VI) from aqueous solution. Chem. Eng. J. 2013, 228, 748–755. [Google Scholar] [CrossRef]

- Xie, Y.; He, C.; Liu, L.; Mao, L.; Wang, K.; Huang, Q.; Liu, M.; Wan, Q.; Deng, F.; Huang, H.; et al. Carbon nanotube based polymer nanocomposites: Biomimic preparation and organic dye adsorption applications. RSC Adv. 2015, 5, 82503–82512. [Google Scholar] [CrossRef]

- Peng-ChengMa, A.; Siddiquia, N.; Gad, M.; Jang-Kyo, K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar]

- Singh, N.P.; Gupta, V.K.; Singh, A.P. Graphene and carbon nanotube reinforced epoxy nanocomposites: A review. Polymer (Guildf). 2019, 180, 121724. [Google Scholar] [CrossRef]

- Norizan, M.N.; Moklis, M.H.; Ngah Demon, S.Z.; Halim, N.A.; Samsuri, A.; Mohamad, I.S.; Knight, V.F.; Abdullah, N. Carbon nanotubes: Functionalisation and their application in chemical sensors. RSC Adv. 2020, 10, 43704–43732. [Google Scholar] [CrossRef]

- Bahun, G.J.; Wang, C.; Adronov, A. Solubilizing single-walled carbon nanotubes with pyrene-functionalized block copolymers. J. Polym. Sci. Part A Polym. Chem. 2006, 44, 1941–1951. [Google Scholar] [CrossRef]

- Khan, F.; Kausar, A.; Siddiq, M. A Review on Properties and Fabrication Techniques of Polymer/Carbon Nanotube Composites and Polymer Intercalated Buckypapers. Polym. Plast. Technol. Eng. 2015, 54, 1524–1539. [Google Scholar] [CrossRef]

- Manawi, Y.M.; Ihsanullah, S.A.; Al-Ansari, T.; Atieh, M.A. A review of carbon nanomaterials’ synthesis via the chemical vapor deposition (CVD) method. Materials 2018, 11, 822. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube-polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Chen, J.; Yan, L.; Song, W.; Xu, D. Interfacial characteristics of carbon nanotube-polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2018, 114, 149–169. [Google Scholar] [CrossRef]

- Jacobs, C.B.; Peairs, M.J.; Venton, B.J. Review: Carbon nanotube based electrochemical sensors for biomolecules. Anal. Chim. Acta 2010, 662, 105–127. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.L.; Stoddart, J.F. Noncovalent functionalization of single-walled carbon nanotubes. Acconut Chem. Res. 2009, 42, 1161–1171. [Google Scholar] [CrossRef]

- Konnola, R.; Joseph, K. Effect of side-wall functionalisation of multi-walled carbon nanotubes on the thermo-mechanical properties of epoxy composites. RSC Adv. 2016, 6, 23887–23899. [Google Scholar] [CrossRef]

- Maity, K.P.; Patra, A.; Prasad, V. Influence of the chemical functionalization of carbon nanotubes on low temperature ac conductivity with polyaniline composites. J. Phys. D. Appl. Phys. 2020, 53. [Google Scholar] [CrossRef]

- Quintero-Jaime, A.F.; Cazorla-Amorós, D.; Morallón, E. Electrochemical functionalization of single wall carbon nanotubes with phosphorus and nitrogen species. Electrochim. Acta 2020, 340. [Google Scholar] [CrossRef]

- Nakonechna, O.I.; Belyavina, N.N.; Dashevskyi, M.M.; Ivanenko, K.O.; Revo, S.L. Novel Ti2CuCx and Ti3Cu2Cx Carbides Obtained by Sintering of Products of Mechanochemical Synthesis of Ti, Cu and Carbon Nanotubes. Phys. Chem. Solid State 2019, 19, 179–185. [Google Scholar] [CrossRef] [Green Version]

- Garzia Trulli, M.; Sardella, E.; Palumbo, F.; Palazzo, G.; Giannossa, L.C.; Mangone, A.; Comparelli, R.; Musso, S.; Favia, P. Towards highly stable aqueous dispersions of multi-walled carbon nanotubes: The effect of oxygen plasma functionalization. J. Colloid Interface Sci. 2017, 491, 255–264. [Google Scholar] [CrossRef]

- Singh, B.; Lohan, S.; Sandhu, P.S.; Jain, A.; Mehta, S.K. Functionalized carbon nanotubes and their promising applications in therapeutics and diagnostics. Nanobiomater. Med. Imaging Appl. Nanobiomater. 2016, 455–478. [Google Scholar] [CrossRef]

- Ajori, S.; Ansari, R.; Darvizeh, M. Vibration characteristics of single- and double-walled carbon nanotubes functionalized with amide and amine groups. Phys. B Condens. Matter 2015, 462, 8–14. [Google Scholar] [CrossRef]

- Afrin, R.; Shah, N.A. Room temperature gas sensors based on carboxyl and thiol functionalized carbon nanotubes buckypapers. Diam. Relat. Mater. 2015, 60, 42–49. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Burghard, M. Chemically Functionalized Carbon Nanotubes. Small 2005, 1, 180–192. [Google Scholar] [CrossRef]

- Khan, M.U.; Gomes, V.G.; Altarawneh, I.S. Synthesizing polystyrene/carbon nanotube composites by emulsion polymerization with non-covalent and covalent functionalization. Carbon N. Y. 2010, 48, 2925–2933. [Google Scholar] [CrossRef]

- Liu, X.; Xu, F.; Zhang, K.; Wei, B.; Gao, Z.; Qiu, Y. Characterization of enhanced interfacial bonding between epoxy and plasma functionalized carbon nanotube films. Compos. Sci. Technol. 2017, 145, 114–121. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Li, Y.; Feng, Y.; Feng, W. Carbon-based functional nanomaterials: Preparation, properties and applications. Compos. Sci. Technol. 2019, 179, 10–40. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, S. Significant improvements in the mechanical properties of chitosan functionalized carbon nanotubes/epoxy composites. RSC Adv. 2016, 6, 26210–26215. [Google Scholar] [CrossRef]

- Fujigaya, T.; Nakashima, N. Non-covalent polymer wrapping of carbon nanotubes and the role of wrapped polymers as functional dispersants. Sci. Technol. Adv. Mater. 2015, 16. [Google Scholar] [CrossRef]

- Alemour, B.; Yaacob, M.H.; Lim, H.N.; Hassan, M.R. Review of electrical properties of graphene conductive composites. Int. J. Nanoelectron. Mater. 2018, 11, 371–398. [Google Scholar]

- Mallakpour, S.; Soltanian, S. Surface functionalization of carbon nanotubes: Fabrication and applications. RSC Adv. 2016, 6, 109916–109935. [Google Scholar] [CrossRef]

- Janudin, N.; Abdullah, N.; Yunus, W.M.Z.W.; Yasin, F.M.; Yaacob, M.H.; Kasim, N.; Shah, N.A.A.; Jamal, S.H.; Saidi, N.M.; Kasim, N.A.M. Carbon nanofibers functionalized with amide group for ammonia gas detection. AIP Conf. Proc. 2019, 2068. [Google Scholar] [CrossRef]

- Shamsuddin, S.A.; Derman, M.N.; Hashim, U.; Kashif, M.; Adam, T.; Halim, N.H.A.; Tahir, M.F.M. Nitric acid treated multi-walled carbon nanotubes optimized by Taguchi method. AIP Conf. Proc. 2016, 1756. [Google Scholar] [CrossRef]

- Gonzalez-Chi, P.I.; Rodríguez-Uicab, O.; Martin-Barrera, C.; Uribe-Calderon, J.; Canché-Escamilla, G.; Yazdani-Pedram, M.; May-Pat, A.; Avilés, F. Influence of aramid fiber treatment and carbon nanotubes on the interfacial strength of polypropylene hierarchical composites. Compos. Part. B Eng. 2017, 122, 16–22. [Google Scholar] [CrossRef]

- Zhang, T.; Xi, K.; Gu, M.; Jiang, Z.S. Phosphoryl choline-grafted water-soluble carbon nanotube. Chin. Chem. Lett. 2008, 19, 105–109. [Google Scholar] [CrossRef]

- Dyke, C.A.; Tour, J.M. Covalent functionalization of single-walled carbon nanotubes for materials applications. J. Phys. Chem. A 2004, 108, 11151–11159. [Google Scholar] [CrossRef]

- Jian, W.; Lau, D. Understanding the effect of functionalization in CNT-epoxy nanocomposite from molecular level. Compos. Sci. Technol. 2020, 191, 108076. [Google Scholar] [CrossRef]

- Zou, W.; Du, Z.J.; Liu, Y.X.; Yang, X.; Li, H.Q.; Zhang, C. Functionalization of MWNTs using polyacryloyl chloride and the properties of CNT-epoxy matrix nanocomposites. Compos. Sci. Technol. 2008, 68, 3259–3264. [Google Scholar] [CrossRef]

- Sydlik, S.A.; Lee, J.H.; Walish, J.J.; Thomas, E.L.; Swager, T.M. Epoxy functionalized multi-walled carbon nanotubes for improved adhesives. Carbon N. Y. 2013, 59, 109–120. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, J.; Gao, L.; Liu, T.; Zhong, W.; Sui, G.; Zheng, G.; Fang, W.; Yang, X. Dispersion stability of functionalized MWCNT in the epoxy-amine system and its effects on mechanical and interfacial properties of carbon fiber composites. Mater. Des. 2016, 94, 392–402. [Google Scholar] [CrossRef]

- Sapiai, N.; Jumahat, A.; Jawaid, M.; Khan, A. Effect of MWCNT surface functionalisation and distribution on compressive properties of kenaf and hybrid kenaf/glass fibres reinforced polymer composites. Polymers 2020, 12, 2522. [Google Scholar] [CrossRef] [PubMed]

- Vaisman, L.; Wagner, H.D.; Marom, G. The role of surfactants in dispersion of carbon nanotubes. Adv. Colloid Interface Sci. 2006, 128–130, 37–46. [Google Scholar] [CrossRef]

- Bilalis, P.; Katsigiannopoulos, D.; Avgeropoulos, A.; Sakellariou, G. Non-covalent functionalization of carbon nanotubes with polymers. RSC Adv. 2014, 4, 2911–2934. [Google Scholar] [CrossRef]

- Hertel, T.; Hagen, A.; Talalaev, V.; Arnold, K.; Hennrich, F.; Kappes, M.; Rosenthal, S.; McBride, J.; Ulbricht, H.; Flahaut, E. Spectroscopy of Single- and Double-Wall Carbon Nanotubes in Different Environments. Nano Lett. 2005, 5, 511–514. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Fernandes, R.M.F.; Regev, O.; Marques, E.F.; Furó, I. Dispersing Carbon Nanotubes in Water with Amphiphiles: Dispersant Adsorption, Kinetics, and Bundle Size Distribution as Defining Factors. J. Phys. Chem. C 2018, 122, 24386–24393. [Google Scholar] [CrossRef] [Green Version]

- Ghoreishi, S.M.; Behpour, M.; Mousavi, S.; Khoobi, A.; Ghoreishi, F.S. Simultaneous electrochemical determination of dopamine, ascorbic acid and uric acid in the presence of sodium dodecyl sulphate using a multi-walled carbon nanotube modified carbon paste electrode. RSC Adv. 2014, 4, 37979–37984. [Google Scholar] [CrossRef]

- Kharisov, B.I.; Kharissova, O.V.; Dimas, A.V. The dispersion, solubilization and stabilization in “solution” of single-walled carbon nanotubes. RSC Adv. 2016, 6, 68760–68787. [Google Scholar] [CrossRef]

- Zeng, X.; Yang, D.; Liu, H.; Zhou, N.; Wang, Y.; Zhou, W.; Xie, S.; Kataura, H. Detecting and Tuning the Interactions between Surfactants and Carbon Nanotubes for Their High-Efficiency Structure Separation. Adv. Mater. Interfaces 2018, 5. [Google Scholar] [CrossRef]

- Manilo, M.V.; Lebovka, N.; Barany, S. Combined effect of cetyltrimethylammonium bromide and laponite platelets on colloidal stability of carbon nanotubes in aqueous suspensions. J. Mol. Liq. 2017, 235, 104–110. [Google Scholar] [CrossRef]

- Park, M.; Park, J.; Lee, J.; Ju, S.Y. Scaling of binding affinities and cooperativities of surfactants on carbon nanotubes. Carbon N. Y. 2018, 139, 427–436. [Google Scholar] [CrossRef]

- Ishibashi, A.; Nakashima, N. Strong chemical structure dependence for individual dissolution of single-walled carbon nanotubes in aqueous micelles of biosurfactants. Bull. Chem. Soc. Jpn. 2006, 79, 357–359. [Google Scholar] [CrossRef]

- Chen, Y.; Wei, W.; Zhu, Y.; Luo, J.; Liu, X. Noncovalent functionalization of carbon nanotubes via co-deposition of tannic acid and polyethyleneimine for reinforcement and conductivity improvement in epoxy composite. Compos. Sci. Technol. 2019, 170, 25–33. [Google Scholar] [CrossRef]

- Du, A.-K.; Yang, K.-L.; Zhao, T.-H.; Wang, M.; Zeng, J.-B. Poly(sodium 4-styrenesulfonate) wrapped carbon nanotube with low percolation threshold in poly(ε-caprolactone) nanocomposites. Polym. Test. 2016, 51, 40–48. [Google Scholar] [CrossRef]

- Cha, J.; Jin, S.; Shim, J.H.; Park, C.S.; Ryu, H.J.; Hong, S.H. Functionalization of carbon nanotubes for fabrication of CNT/epoxy nanocomposites. Mater. Des. 2016, 95, 1–8. [Google Scholar] [CrossRef]

- Zhang, A.; Luan, J.; Zheng, Y.; Sun, L.; Tang, M. Effect of percolation on the electrical conductivity of amino molecules non-covalently coated multi-walled carbon nanotubes/epoxy composites. Appl. Surf. Sci. 2012, 258, 8492–8497. [Google Scholar] [CrossRef]

- Gupta, T.K.; Kumar, S. 4—Fabrication of Carbon Nanotube/Polymer Nanocomposites. In Carbon Nanotube-Reinforced Polymers; Rafie, R., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 61–81. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Li, Z.; Liu, M.; Kinloch, I.A.; Young, R.J. Mechanisms of mechanical reinforcement by graphene and carbon nanotubes in polymer nanocomposites. Nanoscale 2020, 12, 2228–2267. [Google Scholar] [CrossRef] [Green Version]

- Rane, A.V.; Kanny, K.; Abitha, V.K.; Thomas, S. Methods for Synthesis of Nanoparticles and Fabrication of Nanocomposites. Synth. Inorg. Nanomater. 2018, 121–139. [Google Scholar] [CrossRef]

- Venkataraman, A.; Amadi, E.V.; Chen, Y.; Papadopoulos, C. Carbon Nanotube Assembly and Integration for Applications. Nanoscale Res. Lett. 2019, 14, 220. [Google Scholar] [CrossRef]

- Yousfi, M.; Alix, S.; Lebeau, M.; Soulestin, J.; Lacrampe, M.F.; Krawczak, P. Evaluation of rheological properties of non-Newtonian fluids in micro rheology compounder: Experimental procedures for a reliable polymer melt viscosity measurement. Polym. Test. 2014, 40. [Google Scholar] [CrossRef]

- Balachandra, A.M.; Corporation, T.; Co, M.; Darsanasiri, N.; Corporation, M. Fabrication of Carbonnanotube/Polymer Nanocomposite Sheets and Its Mechanical Performance. Adv. Nanosci. Nanotechnol. 2018, 2. [Google Scholar] [CrossRef]

- Cheng, F.; Imin, P.; Maunders, C.; Botton, G.; Adronov, A. Soluble, discrete supramolecular complexes of single-walled carbon nanotubes with fluorene-based conjugated polymers. Macromolecules 2008, 41, 2304–2308. [Google Scholar] [CrossRef]

- Pei, X.; Hu, L.; Liu, W.; Hao, J. Synthesis of water-soluble carbon nanotubes via surface initiated redox polymerization and their tribological properties as water-based lubricant additive. Eur. Polym. J. 2008, 44, 2458–2464. [Google Scholar] [CrossRef]

- Kanoun, O.; Bouhamed, A.; Ramalingame, R.; Bautista-Quijano, J.R.; Rajendran, D.; Al-Hamry, A. Review review on conductive polymer/cnts nanocomposites based flexible and stretchable strain and pressure sensors. Sensors 2021, 21, 341. [Google Scholar] [CrossRef] [PubMed]

- Khan, W.; Sharma, R.; Saini, P. Carbon nanotube-based polymer composites: Synthesis, properties and applications. In Carbon Nanotubes Current Progress of their Polymer Composites; IntechOpen: London, UK, 2016. [Google Scholar] [CrossRef] [Green Version]

- Bryning, M.B.; Milkie, D.E.; Islam, M.F.; Kikkawa, J.M.; Yodh, A.G.; Bryning, M.B.; Milkie, D.E.; Islam, M.F.; Kikkawa, J.M.; Yodh, A.G. Thermal conductivity and interfacial resistance in single-wall carbon nanotube epoxy composites. Appl. Phys. Lett. 2005, 87, 161909. [Google Scholar] [CrossRef]

- Barrau, S.; Demont, P.; Perez, E.; Peigney, A.; Laurent, C.; Lacabanne, C. Effect of palmitic acid on the electrical conductivity of carbon nanotubes—Epoxy resin composites. Macromolecules 2003, 36, 9678–9680. [Google Scholar] [CrossRef] [Green Version]

- Islam, M.F.; Rojas, E.; Bergey, D.M.; Johnson, A.T.; Yodh, A.G. High weight fraction surfactant solubilization of single-wall carbon nanotubes in water. Nano Lett. 2003, 3, 269–273. [Google Scholar] [CrossRef]

- Arrigo, R.; Teresi, R.; Gambarotti, C.; Parisi, F.; Lazzara, G.; Dintcheva, N.T. Sonication-induced modification of carbon nanotubes: Effect on the rheological and thermo-oxidative behaviour of polymer-based nanocomposites. Materials 2018, 11, 383. [Google Scholar] [CrossRef] [Green Version]

- Sabet, S.M.; Mahfuz, H.; Hashemi, J.; Nezakat, M.; Szpunar, J.A. Effects of sonication energy on the dispersion of carbon nanotubes in a vinyl ester matrix and associated thermo-mechanical properties. J. Mater. Sci. 2015, 50, 4729–4740. [Google Scholar] [CrossRef]

- Korayem, A.H.; Barati, M.R.; Chen, S.J.; Simon, G.P.; Zhao, X.L.; Duan, W.H. Optimizing the degree of carbon nanotube dispersion in a solvent for producing reinforced epoxy matrices. Powder Technol. 2015, 284, 541–550. [Google Scholar] [CrossRef]

- Santos, A.C.M.Q.S.; Monticeli, F.M.; Ornaghi, H.; de Santos, L.F.P.; Cioffi, M.O.H. Porosity characterization and respective influence on short-beam strength of advanced composite processed by resin transfer molding and compression molding. Polym. Polym. Compos. 2020, 1–10. [Google Scholar] [CrossRef]

- Ali, M.A.; Umer, R.; Khan, K.A.; Samad, Y.A. Graphene coated smart fabrics for vartm process monitoring. ICCM Int. Conf. Compos. Mater. 2017. [Google Scholar]

- Cheng, Q.F.; Wang, J.P.; Wen, J.J.; Liu, C.H.; Jiang, K.L.; Li, Q.Q.; Fan, S.S. Carbon nanotube/epoxy composites fabricated by resin transfer molding. Carbon N. Y. 2010, 48, 260–266. [Google Scholar] [CrossRef]

- Trakakis, G.; Tomara, G.; Datsyuk, V.; Sygellou, L.; Bakolas, A.; Tasis, D.; Parthenios, J.; Krontiras, C.; Georga, S.; Galiotis, C.; et al. Mechanical, electrical, and thermal properties of carbon nanotube buckypapers/epoxy nanocomposites produced by oxidized and epoxidized nanotubes. Materials 2020, 13, 4308. [Google Scholar] [CrossRef] [PubMed]

- Teotia, S.; Singh, B.P.; Elizabeth, I.; Singh, V.N.; Ravikumar, R.; Singh, A.P.; Gopukumar, S.; Dhawan, S.K.; Srivastava, A.; Mathur, R.B. Multifunctional, robust, light-weight, free-standing MWCNT/phenolic composite paper as anodes for lithium ion batteries and EMI shielding material. RSC Adv. 2014, 4, 33168–33174. [Google Scholar] [CrossRef] [Green Version]

- Ogasawara, T.; Moon, S.Y.; Inoue, Y.; Shimamura, Y. Mechanical properties of aligned multi-walled carbon nanotube/epoxy composites processed using a hot-melt prepreg method. Compos. Sci. Technol. 2011, 71, 1826–1833. [Google Scholar] [CrossRef]

- Bradford, P.D.; Wang, X.; Zhao, H.; Maria, J.P.; Jia, Q.; Zhu, Y.T. A novel approach to fabricate high volume fraction nanocomposites with long aligned carbon nanotubes. Compos. Sci. Technol. 2010, 70, 1980–1985. [Google Scholar] [CrossRef]

- Jiang, Q.; Wang, X.; Zhu, Y.; Hui, D.; Qiu, Y. Mechanical, electrical and thermal properties of aligned carbon nanotube/polyimide composites. Compos. Part. B Eng. 2014, 56, 408–412. [Google Scholar] [CrossRef]

- Wang, X.; Yong, Z.Z.; Li, Q.W.; Bradford, P.D.; Liu, W.; Tucker, D.S.; Cai, W.; Wang, H.; Yuan, F.G.; Zhu, Y.T. Ultrastrong, stiff and multifunctional carbon nanotube composites. Mater. Res. Lett. 2013, 1, 19–25. [Google Scholar] [CrossRef] [Green Version]

- Nam, T.H.; Goto, K.; Yamaguchi, Y.; Premalal, E.V.A.; Shimamura, Y.; Inoue, Y.; Arikawa, S.; Yoneyama, S.; Ogihara, S. Improving mechanical properties of high volume fraction aligned multi-walled carbon nanotube/epoxy composites by stretching and pressing. Compos. Part. B Eng. 2016, 85, 15–23. [Google Scholar] [CrossRef] [Green Version]

- Nam, T.H.; Goto, K.; Oshima, K.; Premalal, E.V.A.; Shimamura, Y.; Inoue, Y.; Naito, K.; Ogihara, S. Mechanical property enhancement of aligned multi-walled carbon nanotube sheets and composites through press-drawing process. Adv. Compos. Mater. 2016, 25, 73–86. [Google Scholar] [CrossRef]

- Nam, T.H.; Goto, K.; Yamaguchi, Y.; Premalal, E.V.A.; Shimamura, Y.; Inoue, Y.; Naito, K.; Ogihara, S. Effects of CNT diameter on mechanical properties of aligned CNT sheets and composites. Compos. Part. A Appl. Sci. Manuf. 2015, 76, 289–298. [Google Scholar] [CrossRef] [Green Version]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nanosci. Technol. A Collect. Rev. Nat. J. 2009, 11–19. [Google Scholar] [CrossRef]

- Verma, D.; Goh, K.L. Functionalized graphene-based nanocomposites for energy applications. In Functionalized Graphene Nanocomposites and Their Derivatives: Synthesis, Processing and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 219–243. ISBN 9780128145531. [Google Scholar]

- Chatterjee, S.; Wang, J.W.; Kuo, W.S.; Tai, N.H.; Salzmann, C.; Li, W.L.; Hollertz, R.; Nüesch, F.A.; Chu, B.T.T. Mechanical reinforcement and thermal conductivity in expanded graphene nanoplatelets reinforced epoxy composites. Chem. Phys. Lett. 2012, 531, 6–10. [Google Scholar] [CrossRef]

- Kaminsky, W. Polyolefin-nanocomposites with special properties by in-situ polymerization. Front. Chem. Sci. Eng. 2018, 12, 555–563. [Google Scholar] [CrossRef]

- Yoo, H.J.; Jung, Y.C.; Sahoo, N.G.; Cho, J.W. Polyurethane-carbon nanotube nanocomposites prepared by in-situ polymerization with electroactive shape memory. J. Macromol. Sci. Part. B Phys. 2006, 45, 441–451. [Google Scholar] [CrossRef]

- Martin, D.J.; Osman, A.F.; Andriani, Y.; Edwards, G.A. Thermoplastic Polyurethane (TPU)-Based Polymer Nanocomposites. In Advances in Polymer Nanocomposites; Gao, F., Ed.; Woodhead Publishing Limited: Sawston, UK, 2012; ISBN 9781845699406. [Google Scholar]

- Xia, H.; Wang, Q.; Qiu, G. Polymer-encapsulated carbon nanotubes prepared through ultrasonically initiated in situ emulsion polymerization. Chem. Mater. 2003, 15, 3879–3886. [Google Scholar] [CrossRef]

- Ke, K.; Wang, Y.; Liu, X.Q.; Cao, J.; Luo, Y.; Yang, W.; Xie, B.H.; Yang, M.B. A comparison of melt and solution mixing on the dispersion of carbon nanotubes in a poly(vinylidene fluoride) matrix. Compos. Part. B Eng. 2012, 43, 1425–1432. [Google Scholar] [CrossRef]

- Wu, M.L.; Chen, Y.; Zhang, L.; Zhan, H.; Qiang, L.; Wang, J.N. High-performance carbon nanotube/polymer composite fiber from layer-by-layer deposition. ACS Appl. Mater. Interfaces 2016, 8, 8137–8144. [Google Scholar] [CrossRef] [PubMed]

- Al-Saleh, M.H.; Al-Anid, H.K.; Hussain, Y.A. CNT/ABS nanocomposites by solution processing: Proper dispersion and selective localization for low percolation threshold. Compos. Part. A Appl. Sci. Manuf. 2013, 46, 53–59. [Google Scholar] [CrossRef]

- Meitl, M.A.; Zhou, Y.; Gaur, A.; Jeon, S.; Usrey, M.L.; Strano, M.S.; Rogers, J.A. Solution casting and transfer printing single-walled carbon nanotube films. Nano Lett. 2004, 4, 1643–1647. [Google Scholar] [CrossRef]

- Du, J.H.; Bai, J.; Cheng, H.M. The present status and key problems of carbon nanotube based polymer composites. Express Polym. Lett. 2007, 1, 253–273. [Google Scholar] [CrossRef]

- Huang, Y.Y.; Terentjev, E.M. Dispersion of carbon nanotubes: Mixing, sonication, stabilization, and composite properties. Polymers 2012, 4, 275–295. [Google Scholar] [CrossRef] [Green Version]

- Montazeri, A.; Montazeri, N.; Pourshamsian, K.; Tcharkhtchi, A. The effect of sonication time and dispersing medium on the mechanical properties of multiwalled carbon nanotube (MWCNT)/epoxy composite. Int. J. Polym. Anal. Charact. 2011, 16, 465–476. [Google Scholar] [CrossRef]

- Byrne, M.T.; Guin’Ko, Y.K. Recent advances in research on carbon nanotube—Polymer composites. Adv. Mater. 2010, 22, 1672–1688. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Liang, Z.; Wang, B.; Zhang, C.; Kramer, L. Processing and property investigation of single-walled carbon nanotube (SWNT) buckypaper/epoxy resin matrix nanocomposites. Compos. Part. A Appl. Sci. Manuf. 2004, 35, 1225–1232. [Google Scholar] [CrossRef]

- Feng, Q.P.; Yang, J.P.; Fu, S.Y.; Mai, Y.W. Synthesis of carbon nanotube/epoxy composite films with a high nanotube loading by a mixed-curing-agent assisted layer-by-layer method and their electrical conductivity. Carbon N. Y. 2010, 48, 2057–2062. [Google Scholar] [CrossRef]

- Cheng, Q.; Bao, J.; Park, J.G.; Liang, Z.; Zhang, C.; Wang, B. High mechanical performance composite conductor: Multi-walled carbon nanotube sheet/bismaleimide nanocomposites. Adv. Funct. Mater. 2009, 19, 3219–3225. [Google Scholar] [CrossRef]

- Nam, T.H.; Goto, K.; Nakayama, H.; Oshima, K.; Premalal, V.; Shimamura, Y.; Inoue, Y.; Naito, K.; Kobayashi, S. Effects of stretching on mechanical properties of aligned multi-walled carbon nanotube/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2014, 64, 194–202. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Bradford, P.D.; Liu, W.; Zhao, H.; Inoue, Y.; Maria, J.P.; Li, Q.; Yuan, F.G.; Zhu, Y. Mechanical and electrical property improvement in CNT/Nylon composites through drawing and stretching. Compos. Sci. Technol. 2011, 71, 1677–1683. [Google Scholar] [CrossRef]

- Park, S.; Ruoff, R.S. Chemical methods for the production of graphenes. Nat. Nanotechnol. 2009, 4, 217–224. [Google Scholar] [CrossRef]

- Kim, S.; Fornasiero, F.; Park, H.G.; In, J.B.; Meshot, E.; Giraldo, G.; Stadermann, M.; Fireman, M.; Shan, J.; Grigoropoulos, C.P.; et al. Fabrication of flexible, aligned carbon nanotube/polymer composite membranes by in-situ polymerization. J. Membr. Sci. 2014, 460, 91–98. [Google Scholar] [CrossRef]

- Cho, B.G.; Lee, J.E.; Hwang, S.H.; Han, J.H.; Chae, H.G.; Park, Y. Bin Enhancement in mechanical properties of polyamide 66-carbon fiber composites containing graphene oxide-carbon nanotube hybrid nanofillers synthesized through in situ interfacial polymerization. Compos. Part. A Appl. Sci. Manuf. 2020, 135, 105938. [Google Scholar] [CrossRef]

- Park, D.W.; Shim, S. A review on thermal conductivity of polymer composites using carbon-based fillers: Carbon nanotubes and carbon fibers. Carbon Lett. 2010, 11, 347–356. [Google Scholar]

- Zhang, J.; Zou, H.; Qing, Q.; Yang, Y.; Li, Q.; Liu, Z.; Guo, X.; Du, Z. Effect of chemical oxidation on the structure of single-walled carbon nanotubes. J. Phys. Chem. B 2003, 107, 3712–3718. [Google Scholar] [CrossRef]

- Lourie, O.; Wagner, H.D. Evaluation of Young’s modulus of carbon nanotubes by micro-Raman spectroscopy. J. Mater. Res. 1998, 13, 2418–2422. [Google Scholar] [CrossRef]

- Lau, K.T.; Gu, C.; Hui, D. A critical review on nanotube and nanotube/nanoclay related polymer composite materials. Compos. Part B Eng. 2006, 37, 425–436. [Google Scholar] [CrossRef]

- Wernik, J.M.; Meguid, S.A. On the mechanical characterization of carbon nanotube reinforced epoxy adhesives. Mater. Des. 2014, 59, 19–32. [Google Scholar] [CrossRef]

- Coleman, J.N.; Khan, U.; Blau, W.J.; Gun’ko, Y.K. Small but strong: A review of the mechanical properties of carbon nanotube–polymer composites. Carbon N. Y. 2006, 44, 1624–1652. [Google Scholar] [CrossRef]

- Zhu, H.W.; Xu, C.L.; Wu, D.H.; Wei, B.Q.; Vajtai, R.; Ajayan, P.M. Direct synthesis of long single-walled carbon nanotube strands. Science 2002, 296, 884–886. [Google Scholar] [CrossRef]

- Daniel, I.M.; Ishai, O.; Daniel, I.M.; Daniel, I. Engineering Mechanics of Composite Materials; Oxford University Press: Oxford, UK, 2006. [Google Scholar]

- Fredriksson, T. Carbon Nanotubes: A Theoretical Study of Young’s Modulus. Master’s Thesis, Karlstad University; Faculty of Health, Science and Technology, Karlstad, Sweden, 2014. [Google Scholar]

- Gardea, F.; Lagoudas, D.C. Characterization of electrical and thermal properties of carbon nanotube/epoxy composites. Compos. Part B Eng. 2014, 56, 611–620. [Google Scholar] [CrossRef]

- Sankar, N.; Reddy, M.N.; Prasad, R.K. Carbon nanotubes dispersed polymer nanocomposites: Mechanical, electrical, thermal properties and surface morphology. Bull. Mater. Sci. 2016, 39, 47–55. [Google Scholar] [CrossRef] [Green Version]

- Thostenson, E.T.; Li, C.; Chou, T.W. Nanocomposites in context. Compos. Sci. Technol. 2005, 65, 491–516. [Google Scholar] [CrossRef]

- Hassan, M.A. Physicaland Thermal Properties of Fiber (S-Type)-Reinforced Compositearaldite Resin (GY 260). Al-Qadisiyah J. Eng. Sci. 2012, 5, 341–346. [Google Scholar]

- Marulanda, J.M. Carbon Nanotubes: Applications on Electron Devices. IntechOpen: London, UK, 2011. [Google Scholar]

- Mazumdar, S. Composites Manufacturing: Materials, Product, and Process Engineering; CRC Press: Boca Raton, FA, USA, 2001. [Google Scholar]

- Arash, B.; Wang, Q.; Varadan, V.K. Mechanical properties of carbon nanotube/polymer composites. Sci. Rep. 2014, 4, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Coleman, J.N.; Khan, U.; Gun’ko, Y.K. Mechanical reinforcement of polymers using carbon nanotubes. Adv. Mater. 2006, 18, 689–706. [Google Scholar] [CrossRef]

- Manchado, M.L.; Valentini, L.; Biagiotti, J.; Kenny, J.M. Thermal and mechanical properties of single-walled carbon nanotubes–polypropylene composites prepared by melt processing. Carbon N. Y. 2005, 43, 1499–1505. [Google Scholar] [CrossRef]

- Deep, A.; Singh, K.K.; Rawat, P.; Kumar, C.; Behera, R.P. Impact of hybrid reinforcement (nano-and macro-) over quasi-isotropic symmetrically designed GFRP composites on short beam strength properties. IOP Conf. Ser. Mater. Sci. Eng. 2018, 377, 012166. [Google Scholar] [CrossRef]

- Jia, Z.; Wang, Z.; Xu, C.; Liang, J.; Wei, B.; Wu, D.; Zhu, S. Study on poly (methyl methacrylate)/carbon nanotube composites. Mater. Sci. Eng. A 1999, 271, 395–400. [Google Scholar] [CrossRef]

- Yang, M.; Gao, Y.; Li, H.; Adronov, A. Functionalization of multiwalled carbon nanotubes with polyamide 6 by anionic ring-opening polymerization. Carbon N. Y. 2007, 45, 2327–2333. [Google Scholar] [CrossRef]

- Kearns, J.C.; Shambaugh, R.L. Polypropylene fibers reinforced with carbon nanotubes. J. Appl. Polym. Sci. 2002, 86, 2079–2084. [Google Scholar] [CrossRef]

- Siochi, E.J.; Working, D.C.; Park, C.; Lillehei, P.T.; Rouse, J.H.; Topping, C.C.; Bhattacharyya, A.R.; Kumar, S. Melt processing of SWCNT-polyimide nanocomposite fibers. Compos. Part B Eng. 2004, 35, 439–446. [Google Scholar] [CrossRef]

- Shi, D.; Lian, J.; He, P.; Wang, L.M.; Xiao, F.; Yang, L.; Schulz, M.J.; Mast, D.B. Plasma coating of carbon nanofibers for enhanced dispersion and interfacial bonding in polymer composites. Appl. Phys. Lett. 2003, 83, 5301–5303. [Google Scholar] [CrossRef] [Green Version]

- Lou, X.; Detrembleur, C.; Sciannamea, V.; Pagnoulle, C.; Jérôme, R. Grafting of alkoxyamine end-capped (co) polymers onto multi-walled carbon nanotubes. Polymer 2004, 45, 6097–6102. [Google Scholar] [CrossRef] [Green Version]

- Xie, L.; Xu, F.; Qiu, F.; Lu, H.; Yang, Y. Single-walled carbon nanotubes functionalized with high bonding density of polymer layers and enhanced mechanical properties of composites. Macromolecules 2007, 40, 3296–3305. [Google Scholar] [CrossRef]

- Hasanzadeh, M.; Mottaghitalab, V.; Ansari, R.; Moghadam, B.H.; Haghi, A.K. Issues in production of carbon nanotubes and related nanocomposites: A comprehensive review. Cell. Chem. Technol. 2015, 49, 237–257. [Google Scholar]

- Choi, E.Y.; Kim, J.Y.; Kim, C.K. Fabrication and properties of polycarbonate composites with polycarbonate grafted multi-walled carbon nanotubes by reactive extrusion. Polymer 2015, 60, 18–25. [Google Scholar] [CrossRef]

- Xiang, D.; Harkin-Jones, E.; Linton, D.; Martin, P. Structure, mechanical, and electrical properties of high-density polyethylene/multi-walled carbon nanotube composites processed by compression molding and blown film extrusion. J. Appl. Polym. Sci. 2015, 132, 1–12. [Google Scholar] [CrossRef]

- Verma, P.; Saini, P.; Choudhary, V. Designing of carbon nanotube/polymer composites using melt recirculation approach: Effect of aspect ratio on mechanical, electrical and EMI shielding response. Mater. Des. 2015, 88, 269–277. [Google Scholar] [CrossRef]

- Alam, J.; Khan, A.; Alam, M.; Mohan, R. Electroactive shape memory property of a Cu-decorated CNT dispersed PLA/ESO nanocomposite. Materials 2015, 8, 6391–6400. [Google Scholar] [CrossRef] [PubMed]

- Mei, H.; Xia, J.; Han, D.; Xiao, S.; Deng, J.; Cheng, L. Dramatic increase in electrical conductivity in epoxy composites with uni-directionally oriented laminae of carbon nanotubes. Chem. Eng. J. 2016, 304, 970–976. [Google Scholar] [CrossRef]

- Shamsi, R.; Mahyari, M.; Koosha, M. Synthesis of CNT-polyurethane nanocomposites using ester-based polyols with different molecular structure: Mechanical, thermal, and electrical properties. J. Appl. Polym. Sci. 2017, 134, 1–13. [Google Scholar] [CrossRef]

- Deplancke, T.; Lame, O.; Barrau, S.; Ravi, K.; Dalmas, F. Impact of carbon nanotube prelocalization on the ultra-low electrical percolation threshold and on the mechanical behavior of sintered UHMWPE-based nanocomposites. Polymer 2017, 111, 204–213. [Google Scholar] [CrossRef]

- Hajializadeh, S.; Barikani, M.; Bellah, S.M. Synthesis and characterization of multiwall carbon nanotube/waterborne polyurethane nanocomposites. Polym. Int. 2017, 66, 1074–1083. [Google Scholar] [CrossRef]

- Martinez-Rubi, Y.; Ashrafi, B.; Jakubinek, M.B.; Zou, S.; Laqua, K.; Barnes, M.; Simard, B. Fabrication of High Content Carbon Nanotube–Polyurethane Sheets with Tailorable Properties. ACS Appl. Mater. Interfaces 2017, 9, 30840–30849. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yakovlev, Y.V.; Gagolkina, Z.O.; Lobko, E.V.; Khalakhan, I.; Klepko, V.V. The effect of catalyst addition on the structure, electrical and mechanical properties of the cross-linked polyurethane/carbon nanotube composites. Compos. Sci. Technol. 2017, 144, 208–214. [Google Scholar] [CrossRef]

- Ibrahim, S.S.; Ayesh, A.S.; Abdel-Rahem, R.A. Investigation on the physical properties of multiwalled carbon nanotube–polystyrene nanocomposites treated with 2, 3-hydroxy-2-naphthoic acid. J. Thermoplast. Compos. Mater. 2017, 30, 1120–1135. [Google Scholar] [CrossRef]

- Kalakonda, P.; Banne, S. Thermomechanical properties of PMMA and modified SWCNT composites. Nanotechnol. Sci. Appl. 2017, 10, 45–52. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hawkins, S.A.; Yao, H.; Wang, H.; Sue, H.J. Tensile properties and electrical conductivity of epoxy composite thin films containing zinc oxide quantum dots and multi-walled carbon nanotubes. Carbon N. Y. 2017, 115, 18–27. [Google Scholar] [CrossRef]

- Wu, H.Y.; Jia, L.C.; Yan, D.X.; Gao, J.F.; Zhang, X.P.; Ren, P.G.; Li, Z.M. Simultaneously improved electromagnetic interference shielding and mechanical performance of segregated carbon nanotube/polypropylene composite via solid phase molding. Compos. Sci. Technol. 2018, 156, 87–94. [Google Scholar] [CrossRef]

- Behera, R.P.; Rawat, P.; Singh, K.K. Tensile behavior of three phased glass/epoxy laminate embedded with MWCNTs: An experimental approach. Mater. Today Proc. 2018, 5, 8176–8183. [Google Scholar] [CrossRef]

- Kumar, C.; Singh, K.K.; Rawat, P.; Deep, A.; Behera, R.P. Effect of loading rate on inter laminar shear strength (ILSS) of highly doped MWCNTs carbon/epoxy laminates. IOP Conf. Ser. Mater. Sci. Eng. 2018, 455, 012006. [Google Scholar] [CrossRef]

- Singh, K.K.; Rawat, P. Mechanical behavior of glass/epoxy composite laminate with varying amount of MWCNTs under different loadings. Mater. Res. Express 2018, 5, 055012. [Google Scholar] [CrossRef]

- Namasivayam, M.; Shapter, J. Factors affecting carbon nanotube fillers towards enhancement of thermal conductivity in polymer nanocomposites: A review. J. Compos. Mater. 2017, 51, 3657–3668. [Google Scholar] [CrossRef]

- Chen, J.; Liu, B.; Gao, X.; Xu, D. A review of the interfacial characteristics of polymer nanocomposites containing carbon nanotubes. RSC Adv. 2018, 8, 28048–28085. [Google Scholar] [CrossRef] [Green Version]

- Huang, C.; Qian, X.; Yang, R. Thermal conductivity of polymers and polymer nanocomposites. Mater. Sci. Eng. R Rep. 2018, 132, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Ginzburg, V.V.; Yang, J.; Yang, Y.; Liu, W.; Huang, Y.; Du, L.; Chen, B. Thermal conductivity of polymer-based composites: Fundamentals and applications. Prog. Polym. Sci. 2016, 59, 41–85. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, Q.; Mayo, A.; Ni, Z.; Yi, H.; Chen, Y.; Mu, R.; Bellan, L.M.; Li, D. Thermal conductivity of electrospun polyethylene nanofibers. Nanoscale 2015, 7, 16899–16908. [Google Scholar] [CrossRef]

- Smith, M.K.; Bougher, T.L.; Kalaitzidou, K.; Cola, B.A. Melt-processed P3HT and PE Polymer Nanofiber Thermal Conductivity. MRS Adv. 2017, 2, 3619–3626. [Google Scholar] [CrossRef]

- Lu, C.; Chiang, S.W.; Du, H.; Li, J.; Gan, L.; Zhang, X.; Chu, X.; Yao, Y.; Li, B.; Kang, F. Thermal conductivity of electrospinning chain-aligned polyethylene oxide (PEO). Polymer 2017, 115, 52–59. [Google Scholar] [CrossRef]

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Wang, G.; Wang, L.; Mark, L.H.; Shaayegan, V.; Wang, G.; Li, H.; Zhao, G.; Park, C.B. Ultralow-Threshold and Lightweight Biodegradable Porous PLA/MWCNT with Segregated Conductive Networks for High-Performance Thermal Insulation and Electromagnetic Interference Shielding Applications. ACS Appl. Mater. Interfaces 2018, 10, 1195–1203. [Google Scholar] [CrossRef]

- Ngo, I.L.; Jeon, S.; Byon, C. Thermal conductivity of transparent and flexible polymers containing fillers: A literature review. Int. J. Heat Mass Transf. 2016, 98, 219–226. [Google Scholar] [CrossRef]

- Gong, P.; Wang, G.; Tran, M.P.; Buahom, P.; Zhai, S.; Li, G.; Park, C.B. Advanced bimodal polystyrene/multi-walled carbon nanotube nanocomposite foams for thermal insulation. Carbon N. Y. 2017, 120, 1–10. [Google Scholar] [CrossRef]

- Guo, H.; Liu, J.; Wang, Q.; Liu, M.; Du, C.; Li, B.; Feng, L. High thermal conductive poly(vinylidene fluoride)-based composites with well-dispersed carbon nanotubes/graphene three-dimensional network structure via reduced interfacial thermal resistance. Compos. Sci. Technol. 2019, 181, 107713. [Google Scholar] [CrossRef]

- Kim, H.S.; Jang, J.U.; Yu, J.; Kim, S.Y. Thermal conductivity of polymer composites based on the length of multi-walled carbon nanotubes. Compos. Part B Eng. 2015, 79, 505–512. [Google Scholar] [CrossRef]

- Eslami, Z.; Yazdani, F.; Mirzapour, M.A. Thermal and mechanical properties of phenolic-based composites reinforced by carbon fibres and multiwall carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2015, 72, 22–31. [Google Scholar] [CrossRef]

- Jackson, E.M.; Laibinis, P.E.; Collins, W.E.; Ueda, A.; Wingard, C.D.; Penn, B. Development and thermal properties of carbon nanotube-polymer composites. Compos. Part B Eng. 2016, 89, 362–373. [Google Scholar] [CrossRef] [Green Version]

- Kamarian, S.; Bodaghi, M.; Isfahani, R.B.; Shakeri, M.; Yas, M.H. Influence of carbon nanotubes on thermal expansion coefficient and thermal buckling of polymer composite plates: Experimental and numerical investigations. Mech. Based Des. Struct. Mach. 2019, 42, 1–16. [Google Scholar] [CrossRef]

- Das, S.; Kumar, A.; Parida, K.; Choudhary, R.N.P.; Roy, A. Electrical and mechanical behavior of PMN-PT / CNT based polymer composite film for energy harvesting. Appl. Surf. Sci. 2018, 428, 356–363. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Deng, H.; Jing, Y.; Fu, Q. Enhanced thermal conductivity and electrical insulation properties of polymer composites via constructing Pglass/CNTs con fi ned hybrid fi llers. Compos. Part A Appl. Sci. Manuf. 2018, 115, 1–7. [Google Scholar] [CrossRef]

- Dydek, K.; Latko-durałek, P.; Boczkowska, A.; Sałaciński, M.; Kozera, R. Carbon Fiber Reinforced Polymers modified with thermoplastic nonwovens containing multi-walled carbon nanotubes. Compos. Sci. Technol. 2019, 173, 110–117. [Google Scholar] [CrossRef]

- Wang Y., W. G.J. Electrical Conductivity of Carbon Nanotube- and Graphene-Based Nanocomposites. In Micromechanics and Nanomechanics of Composite Solids; Springer: Cham, Switzerland, 2018; pp. 123–156. [Google Scholar]

- Sobha, A.P.; Sreekala, P.S.; Narayanankutty, S.K. Electrical, thermal, mechanical and electromagnetic interference shielding properties of PANI/FMWCNT/TPU composites. Prog. Org. Coat. 2017, 113, 168–174. [Google Scholar] [CrossRef]

- Gupta, P.; Rajput, M.; Singla, N.; Kumar, V.; Lahiri, D. Electric fi eld and current assisted alignment of CNT inside polymer matrix and its effects on electrical and mechanical properties. Polymer 2016, 89, 119–127. [Google Scholar] [CrossRef]

- Nguyen Thi, T.B.; Ata, S.; Morimoto, T.; Yamada, T.; Okazaki, T.; Hata, K. Tailoring the electrically conductive network of injection-molded polymer-carbon nanotube composite at low filler content. Mater. Today Proc. 2020, in press. [Google Scholar] [CrossRef]

- Haghgoo, M.; Ansari, R.; Hassanzadeh-Aghdam, M.K. Prediction of electrical conductivity of carbon fiber-carbon nanotube-reinforced polymer hybrid composites. Compos. Part B Eng. 2019, 167, 728–735. [Google Scholar] [CrossRef]

- Chen, J.; Han, J. Effect of hydroxylated carbon nanotubes on the thermal and electrical properties of derived epoxy composite materials. Results Phys. 2020, 18. [Google Scholar] [CrossRef]

- Matos, M.A.S.; Tagarielli, V.L.; Pinho, S.T. On the electrical conductivity of composites with a polymeric matrix and a non-uniform concentration of carbon nanotubes. Compos. Sci. Technol. 2020, 188. [Google Scholar] [CrossRef]

- Wang, S.; Huang, Y.; Chang, E.; Zhao, C.; Ameli, A.; Naguib, H.E.; Park, C.B. Evaluation and modeling of electrical conductivity in conductive polymer nanocomposite foams with multiwalled carbon nanotube networks. Chem. Eng. J. 2021, 411. [Google Scholar] [CrossRef]

- Mora, A.; Han, F.; Lubineau, G. Estimating and understanding the e ffi ciency of nanoparticles in enhancing the conductivity of carbon nanotube / polymer composites. Results Phys. 2018, 10, 81–90. [Google Scholar] [CrossRef]

- Doh, J.; Yang, Q.; Raghavan, N. Reliability-based robust design optimization of polymer nanocomposites to enhance percolated electrical conductivity considering correlated input variables using multivariate distributions. Polymer 2020, 186. [Google Scholar] [CrossRef]

- Weiya, Z.; Wenjun, M.A.; Zhiqiang, N.I.U.; Li, S.; Sishen, X.I.E. Freestanding single-walled carbon nanotube bundle networks: Fabrication, properties and composites. Chin. Sci. Bull. 2012, 57, 205–224. [Google Scholar] [CrossRef] [Green Version]

- Afiqah, N.; Radzuan, M.; Bakar, A.; Sahari, J. A review of electrical conductivity models for conductive polymer composite. Int. J. Hydrogen Energy 2016, 2. [Google Scholar] [CrossRef]

- Nabilah, A.; Yusuf, M.; Bakar, A.; Sahari, J. The effect of milled carbon fi bre fi ller on electrical conductivity in highly conductive polymer composites. Compos. Part B Eng. 2017, 110, 153–160. [Google Scholar]

- Xiaojuan, N.; Chao, H.; Ninghai, S.W.J.F.L. Monte Carlo simulations of electrical percolation in multicomponent thin films with nanofillers. Nanotechnology 2018, 29. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; Huang, X.; Hu, M.; Xue, H.; Li, R.K.Y. Electrically conductive polymer nano fi ber composite with an ultralow percolation threshold for chemical vapour sensing. Compos. Sci. Technol. 2018, 161, 135–142. [Google Scholar] [CrossRef]

- Zhai, W.; Zhao, S.; Wang, Y.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Segregated conductive polymer composite with synergistically electrical and mechanical properties. Compos. Part A 2018, 105, 68–77. [Google Scholar] [CrossRef]

- Yamamoto, T.; Kawaguchi, K. Synthesis and Electrical Properties of Composite Films Comprising Polymer Particles and Carbon Nanotubes. Colloid Interface Sci. Commun. 2017, 20, 5–8. [Google Scholar] [CrossRef]

- Xia, Q.; Mei, H.; Zhang, Z.; Liu, Y.; Liu, Y.; Leng, J. Fabrication of the silver modified carbon nanotube film/carbon fiber reinforced polymer composite for the lightning strike protection application. Compos. Part B Eng. 2020, 180. [Google Scholar] [CrossRef]

- Khan, T.; Irfan, M.S.; Ali, M.; Dong, Y.; Ramakrishna, S.; Umer, R. Insights to low electrical percolation thresholds of carbon-based polypropylene nanocomposites. Carbon 2021, 176, 602–631. [Google Scholar] [CrossRef]

- Imtiaz, S.; Siddiq, M.; Kausar, A.; Tul, S.; Ambreen, J.; Bibi, I. A Review Featuring Fabrication, Properties and Applications of Carbon Nanotubes ( CNTs ) Reinforced Polymer and Epoxy Nanocomposites. Chin. J. Polym. Sci. 2018, 36, 445–461. [Google Scholar] [CrossRef]

- Yuan, S.; Zheng, Y.; Chua, C.K.; Yan, Q.; Zhou, K. Electrical and thermal conductivities of MWCNT/polymer composites fabricated by selective laser sintering. Compos. Part A Appl. Sci. Manuf. 2018, 105. [Google Scholar] [CrossRef]

- Saheeda, P.; Jayaleksmi, S. Liquid/liquid interfacial polymerization as an effective synthesis approach for polypyrrole/MWCNTs nanocomposite with impressive nonlinear optical properties. Opt. Mater. 2020, 104. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Tang, M.; Zhou, L.; Li, J.; Fan, X.; Shi, X.; Qin, J. Synergistic effect of carbon nanotube and graphene nanoplates on the mechanical, electrical and electromagnetic interference shielding properties of polymer composites and polymer composite foams. Chem. Eng. J. 2018, 353, 381–393. [Google Scholar] [CrossRef]

- Burmistrov, I.; Gorshkov, N.; Ilinykh, I.; Muratov, D.; Kolesnikov, E.; Anshin, S. Improvement of carbon black based polymer composite electrical conductivity with additions of MWCNT. Compos. Sci. Technol. 2016, 129, 79–85. [Google Scholar] [CrossRef]

- Qu, S.; Yao, Q.; Wang, L.; Hua, J.; Chen, L. A novel hydrophilic pyridinium salt polymer/SWCNTs composite fi lm for high thermoelectric performance. Polymer 2018, 136, 149–156. [Google Scholar] [CrossRef]

- Avilés, F.; May-pat, A.; López-manchado, M.A.; Verdejo, R.; Bachmatiuk, A. A comparative study on the mechanical, electrical and piezoresistive properties of polymer composites using carbon nanostructures of di ff erent topology. Eur. Polym. J. 2018, 99, 394–402. [Google Scholar] [CrossRef]

- Francis, A.P.; Devasena, T. Toxicity of carbon nanotubes: A review. Toxicol. Ind. Health 2018, 34, 200–210. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.L.; Smith, B.A.; Ball, W.P.; Fairbrother, D.H. Assessing the colloidal properties of engineered nanoparticles in water: Case studies from fullerene C60 nanoparticles and carbon nanotubes. Environ. Chem. 2010, 7, 10–27. [Google Scholar] [CrossRef] [Green Version]

- Sousa, S.P.; Baptista, J.S.; Ribeiro, M. Polymer nano and submicro composites risk assessment. Int. J. Work. Cond. 2014, 7, 103–119. [Google Scholar]

- Chen, T.; Nie, H.; Gao, X.; Yang, J.; Pu, J. Epithelial–mesenchymal transition involved in pulmonary fibrosis induced by multi-walled carbon nanotubes via TGFbeta/ Smad signaling pathway. Toxicol. Lett. 2014, 226, 150–162. [Google Scholar] [CrossRef] [PubMed]

- Sohaebuddin, S.K.; Thevenot, P.T.; Baker, D.; Eaton, J.W.; Tang, L. Nanomaterial cytotoxicity is composition, size, and cell type dependent. Part Fibre Toxicol. 2010, 7. [Google Scholar] [CrossRef] [Green Version]

- Boyles, M.S.; Young, L.; Brown, D.M.; MacCalman, L.; Cowie, H.; Moisala, A.; Smail, F.; Smith, P.J.; Proudfoot, L.; Windle, A.H.; et al. Multi-walled carbon nanotube induced frustrated phagocytosis, cytotoxicity and pro-inflammatory conditions in macrophages are length dependent and greater than that of asbestos. Toxicol. Vitr. 2015, 29, 1513–1528. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.E.; Lim, H.T.; Minai-Tehrani, A.; Kwon, J.T.; Shin, J.Y.; Woo, C.G.; Choi, M.; Baek, J.; Jeong, D.H.; Ha, Y.C.; et al. Toxicity and clearance of intratracheally administered multiwalled carbon nanotubes from murine lung. J. Toxicol. Environ. Health Part A 2010, 73, 1530–1543. [Google Scholar] [CrossRef]

- Heister, E.; Brunner, E.W.; Dieckmann, G.R.; Jurewicz, I.; Dalton, A.B. Are carbon nanotubes a natural solution? Applications in biology and medicine. ACS Appl. Mater. Interfaces 2013, 5, 1870–1891. [Google Scholar] [CrossRef] [PubMed]

- Shvedova, A.A.; Kisin, E.R.; Murray, A.R.; Gorelik, O.; Arepalli, S.; Castranova, V.; Young, S.H.; Gao, F.; Tyurina, Y.Y.; Oury, T.D.; et al. Vitamin E deficiency enhances pulmonary inflammatory response and oxidative stress induced by single-walled carbon nanotubes in C57BL/6 mice. Toxicol. Appl. Pharmacol. 2007, 221, 339–348. [Google Scholar] [CrossRef] [Green Version]

- Facciolà, A.; Visalli, G.; La Maestra, S.; Ceccarelli, M.; D’Aleo, F.; Nunnari, G.; Pellicanò, G.F.; Di Pietro, A. Carbon nanotubes and central nervous system: Environmental risks, toxicological aspects and future perspectives. Environ. Toxicol. Pharmacol. 2019, 65, 23–30. [Google Scholar] [CrossRef]

- Fleury, D.; Bomfim, J.A.; Vignes, A.; Girard, C.; Metz, S.; Muñoz, F.; R’Mili, B.; Ustache, A.; Guiot, A.; Bouillard, J.X. Identification of the main exposure scenarios in the production of CNT-polymer nanocomposites by melt-moulding process. J. Clean. Prod. 2013, 53, 22–36. [Google Scholar] [CrossRef]

- Johari, A.N.; Ishak, M.R.; Leman, Z.; Yusoff, M.Z.M.; Asyraf, M.R.M. Creep behaviour monitoring of short-term duration for fiber-glass reinforced composite cross-arms with unsaturated polyester resin samples using conventional analysis. J. Mech. Eng. Sci. 2020, 14, 7361–7368. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Rafidah, M.; Ilyas, R.A.; Razman, M.R. Potential application of green composites for cross arm component in transmission tower: A brief review. Int. J. Polym. Sci. 2020. [Google Scholar] [CrossRef]

- Omran, A.A.B.; Mohammed, A.A.B.A.; Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M.; Koloor, S.S.R.; Petrů, M. Micro- and Nanocellulose in Polymer Composite Materials: A Review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef] [PubMed]

- Johari, A.N.; Ishak, M.R.; Leman, Z.; Yusoff, M.Z.M.; Asyraf, M.R.M. Influence of CaCO3 in pultruded glass fibre/unsaturated polyester composite on flexural creep behaviour using conventional and TTSP methods. Polimery 2020, 65, 46–54. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Razman, M.R. Integration of TRIZ, Morphological Chart and ANP method for development of FRP composite portable fire extinguisher. Polym. Compos. 2020, 41, 2917–2932. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A. Woods and composites cantilever beam: A comprehensive review of experimental and numerical creep methodologies. J. Mater. Res. Technol. 2020, 9, 6759–6776. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Shahroze, R.M.; Johari, A.N.; Rafidah, M.; Ilyas, R.A. Creep test rig for cantilever beam: Fundamentals, prospects and present views. J. Mech. Eng. Sci. 2020, 14, 6869–6887. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.; Atikah, M.; Asyraf, M.; Rafiqah, S.A.; Aisyah, H.; Nurazzi, N.M.; Norrrahim, M. Effect of hydrolysis time on the morphological, physical, chemical, and thermal behavior of sugar palm nanocrystalline cellulose (Arenga pinnata (Wurmb.) Merr). Text. Res. J. 2021, 91, 152–167. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Utilization of Bracing Arms as Additional Reinforcement in Pultruded Glass Fiber-Reinforced Polymer Composite Cross-Arms: Creep Experimental and Numerical Analyses. Polymers 2021, 13, 620. [Google Scholar] [CrossRef]

- Alsubari, S.; Zuhri, M.Y.M.; Sapuan, S.M.; Ishak, M.R.; Ilyas, R.A.; Asyraf, M.R.M. Potential of Natural Fiber Reinforced Polymer Composites in Sandwich Structures: A Review on Its Mechanical Properties. Polymers 2021, 13, 423. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Azrina, A.; Razman, M.R. Dynamic mechanical behaviour of kenaf cellulosic fibre biocomposites: A comprehensive review on chemical treatments. Cellulose 2021, 1–21. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Aisyah, H.A.; Rafiqah, S.A.; Sabaruddin, F.A.; Kamarudin, M.N.F.; Ilyas, R.A.; Sapuan, S.M. A Review on Natural Fiber Reinforced Polymer Composite for Bullet Proof and Ballistic Applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Sapuan, S.M.; Atiqah, A.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Nurazzi, N.M.; Atikah, M.S.N.; Ansari, M.N.M.; et al. Sugar palm (Arenga pinnata [Wurmb.] Merr) starch films containing sugar palm nanofibrillated cellulose as reinforcement: Water barrier properties. Polym. Compos. 2020, 41. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Asyraf, M.R.M.; Atikah, M.S.N.; Ibrahim, R.; Dele-Afolabia, T.T. Introduction to biofiller reinforced degradable polymer composites. In Biofiller Reinforced Biodegradable Polymer Composites; Sapuan, S.M., Jumaidin, R., Hanafi, I., Eds.; CRC Press: Boca Raton, FL, USA, 2020; pp. 1–23. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M.; Norrrahim, M.N.F.; Yasim-Anuar, T.A.T.; Kadier, A.; Kalil, M.S.; Atikah, M.S.N.; Ibrahim, R.; Asrofi, M.; Abral, H.; et al. Nanocellulose/starch biopolymer nanocomposites: Processing, manufacturing, and applications. In Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers; Al-Oqla, F.M., Sapuan, S.M., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 65–88. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Influence of Additional Bracing Arms as Reinforcement Members in Wooden Timber Cross-Arms on Their Long-Term Creep Responses and Properties. Appl. Sci. 2021, 11, 2061. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Chandrasekar, M. Fundamentals of creep, testing methods and development of test rig for the full-scale crossarm: A review. J. Teknol. 2019, 81, 155–164. [Google Scholar] [CrossRef] [Green Version]

- Amal, M.K.E.; Mahmoud, M.F. Carbon nanotube reinforced composites: Potential and current challenges. Mater. Des. 2007, 28, 2394–2401. [Google Scholar]

- Lau, A.K.T.; Hui, D. The revolutionary creation of new advanced materials—Carbon nanotube composites. Compos. Part B Eng. 2002, 33, 263–277. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Evaluation of Design and Simulation of Creep Test Rig for Full-Scale Crossarm Structure. Adv. Civ. Eng. 2020, 2020. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Conceptual design of multi-operation outdoor flexural creep test rig using hybrid concurrent engineering approach. J. Mater. Res. Technol. 2020, 9, 2357–2368. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Conceptual design of creep testing rig for full-scale cross arm using TRIZ-Morphological chart-analytic network process technique. J. Mater. Res. Technol. 2019, 8, 5647–5658. [Google Scholar] [CrossRef]

- Frackowiak, E.; Khomenko, V.; Jurewicz, K.; Lota, K.; Béguin, F. Supercapacitors based on conducting polymers/nanotubes composites. J. Power Sources 2006, 153, 413–418. [Google Scholar] [CrossRef]

- Dai, C.A.; Hsiao, C.C.; Weng, S.C.; Kao, A.C.; Liu, C.P.; Tsai, W.B.; Chen, W.S.; Liu, W.M.; Shih, W.P.; Ma, C.C. A membrane actuator based on an ionic polymer network and carbon nanotubes: The synergy of ionic transport and mechanical properties. Smart Mater. Struct. 2009, 18. [Google Scholar] [CrossRef]

- Jancar, J. Impact behavior of a short glass fiber reinforced thermoplastic polyurethane. Polym. Compos. 2000, 21, 369–376. [Google Scholar] [CrossRef]

- Meincke, O.; Kaempfer, D.; Weickmann, H.; Friedrich, C.; Vathauer, M.; Warth, H. Mechanical properties and electrical conductivity of carbon-nanotube filled polyamide-6 and its blends with acrylonitrile/butadiene/styrene. Polymer 2004, 45, 739–748. [Google Scholar] [CrossRef]

- Köhler, A.R.; Som, C.; Helland, A.; Gottschalk, F. Studying the potential release of carbon nanotubes throughout the application life cycle. J. Clean. Prod. 2008, 16, 927–937. [Google Scholar] [CrossRef]

- Kingston, C.; Zepp, R.; Andrady, A.; Boverhof, D.; Fehir, R.; Hawkins, D.; Roberts, J.; Sayre, P.; Shelton, B.; Sultan, Y.; et al. Release characteristics of selected carbon nanotube polymer composites. Carbon N. Y. 2014, 68, 33–57. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Thostenson, T.E.; Ren, Z.; Chou, T.W. Advances in the science and technology of carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef] [Green Version]

- Breuer, O.; Sundararaj, U. Big returns from small fibers: A review of polymer/carbon nanotube composites. Polym. Compos. 2004, 25, 630–645. [Google Scholar] [CrossRef]

- Connolly, T.; Smith, R.C.; Hernandez, Y.; Gun’ko, Y.; Coleman, J.C.; Carey, J.D. Carbon-nanotube-polymer nanocomposites for field-emission cathodes. Small 2009, 5, 826–831. [Google Scholar] [CrossRef] [Green Version]

- Li, S.Y.; Lee, C.Y.; Lin, P.; Tseng, T.Y. Gate-controlled ZnO nanowires for field-emission device application. J. Vac. Sci. Technol. B Microelectron. Nanomater. Struct. 2006, 24, 147. [Google Scholar] [CrossRef]

- Gupta, N.D.; Maity, S.; Chattopadhyay, K.K. Field emission enhancement of polypyrrole due to band bending induced tunnelling in polypyrrole-carbon nanotubes nanocomposite. J. Ind. Eng. Chem. 2014, 20, 3208–3213. [Google Scholar] [CrossRef]

- Sibiński, M.; Jakubowska, M.; Znajdek, K.; Słoma, M.; Guzowski, B. Carbon nanotube transparent conductive layers for solar cells applications. Opt. Appl. 2011, 41, 375–381. [Google Scholar]

- Joshi, M.; Chatterjee, U. Polymer nanocomposite: An advanced material for aerospace applications. Adv. Compos. Mater. Aerosp. Eng. 2016, 241–264. [Google Scholar]

- Kim, M.T.; Rhee, K.Y.; Lee, J.H.; Hui, D.; Lau, A.K.T. Property enhancement of a carbon fiber/epoxy composite by using carbon nanotubes. Compos. Part B Eng. 2011, 42, 1257–1261. [Google Scholar] [CrossRef]

- Bellucci, S.; Balasubramanian, C.; Micciulla, F.; Rinaldi, G. CNT composites for aerospace applications. J. Exp. Nanosci. 2007, 2, 193–206. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. Electromagnetic interference shielding mechanisms of CNT/polymer composites. Carbon N. Y. 2009, 47, 1738–1746. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Yun, J.; Kim, H.I.; Lee, Y.S. Effect of oxyfluorination on electromagnetic interference shielding of polypyrrole-coated multi-walled carbon nanotubes. J. Ind. Eng. Chem. 2012, 18, 392–398. [Google Scholar] [CrossRef]

- Zhang, D.; Villarreal, M.G.; Cabrera, E.; Benatar, A.; James Lee, L.; Castro, J.M. Performance study of ultrasonic assisted processing of CNT nanopaper/solventless epoxy composite. Compos. Part B Eng. 2019, 159, 327–335. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, M.S.; Norizan, M.N.; Norrrahim, M.N.F.; Ibrahim, R.; Atikah, M.S.N.; Huzaifah, M.R.M.; Radzi, A.M.; Izwan, S.; Azammi, A.M.N.; et al. Macro to nanoscale natural fiber composites for automotive components: Research, development, and application. In Biocomposite and Synthetic Composites for Automotive Applications; Sapuan, M.S., Ilyas, R.A., Eds.; Woodhead Publishing Series: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Inam, F.; Vo, T.; Jones, J.P.; Lee, X. Effect of carbon nanotube lengths on the mechanical properties of epoxy resin: An experimental study. J. Compos. Mater. 2013, 47, 2321–2330. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.J.; Kuiper, P.; de Wit, H. Recycling of composite materials. Chem. Eng. Process. Process. Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Njuguna, J.; Silva, F.; Sachse, S. Nanocomposites for vehicle structural applications. In Nanofibers Production, Properties and Functional Applications; Lin, T., Ed.; InTech: Rijeka, Crotia, 2011; pp. 401–434. [Google Scholar]

- Jin, M.; Feng, X.; Feng, L.; Sun, T.; Zhai, J.; Li, T.; Jiang, L. Superhydrophobic Aligned Polystyrene Nanotube Films with High Adhesive Force. Adv. Mater. 2005, 17, 1977–1981. [Google Scholar] [CrossRef]

- Lee, S.K.; Bai, B.C.; Im, J.S.; In, S.J.; Lee, Y.-S. Flame retardant epoxy complex produced by addition of montmorillonite and carbon nanotube. J. Ind. Eng. Chem. 2010, 16, 891–895. [Google Scholar] [CrossRef]

- Jia, X.; Wei, F. Advances in Production and Applications of Carbon Nanotubes. Top. Curr. Chem. 2017, 375, 18. [Google Scholar] [CrossRef] [PubMed]

- Kong, J.; Franklin, N.R.; Zhou, C.; Chapline, M.G.; Peng, S.; Cho, K.; Dai, H. Nanotube molecular wires as chemical sensors. Science 2000, 287, 622–625. [Google Scholar] [CrossRef]

- Sattari, S.; Reyhani, A.; Khanlari, M.R.; Khabazian, M.; Heydari, H. Synthesize of polyaniline–multi walled carbon nanotubes composite on the glass and silicon substrates and methane gas sensing behavior of them at room temperature. J. Ind. Eng. Chem. 2014, 20, 1761–1764. [Google Scholar] [CrossRef]

- Rajabi, Z.; Moghadassi, A.R.; Hosseini, S.M.; Mohammadi, M. Preparation and characterization of polyvinylchloride based mixed matrix membrane filled with multi walled carbon nano tubes for carbon dioxide separation. J. Ind. Eng. Chem. 2013, 19, 347–352. [Google Scholar] [CrossRef]

- Khan, A.; Khan, A.A.P.; Asiri, A.M.; Rub, M.A.; Azum, N.; Khan, S.B.; Marwani, H.M. Applied poly(2-methoxy aniline) Sn(II)silicate carbon nanotubes composite: Synthesis, characterization, structure–property relationships and applications. J. Ind. Eng. Chem. 2014, 20, 2301–2309. [Google Scholar] [CrossRef]

- Gomès, S.; Trannoy, N.; Grossel, P. DC thermal microscopy: Study of the thermal exchange between a probe and a sample. Meas. Sci. Technol. 1999, 10, 805–811. [Google Scholar] [CrossRef]

- Rafique, I.; Kausar, A.; Anwar, Z.; Muhammad, B. Exploration of Epoxy Resins, Hardening Systems, and Epoxy/Carbon Nanotube Composite Designed for High Performance Materials: A Review. Polym. Plast. Technol. Eng. 2016, 55, 312–333. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.-W. Processing-structure-multi-functional property relationship in carbon nanotube/epoxy composites. Carbon N. Y. 2006, 44, 3022–3029. [Google Scholar] [CrossRef]

- Johari, A.N.; Ishak, M.R.; Leman, Z.; Yusoff, M.Z.M.; Asyraf, M.R.M.; Ashraf, W.; Sharaf, H.K. Fabrication and cut-in speed enhancement of savonius vertical axis wind turbine (SVAWT) with hinged blade using fiberglass composites. In Proceedings of the Seminar Enau Kebangsaan, Bahau, Negeri Sembilan, Malaysia, 1 April 2019; pp. 978–983. [Google Scholar]

- Mishnaevsky, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for wind turbine blades: An overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef] [Green Version]

- Loos, M.R.; Schulte, K. Is it worth the effort to reinforce polymers with carbon nanotubes? Macromol. Theory Simul. 2011, 20, 350–362. [Google Scholar] [CrossRef]

- Böger, L.; Sumfleth, J.; Hedemann, H.; Schulte, K. Improvement of fatigue life by incorporation of nanoparticles in glass fibre reinforced epoxy. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1419–1424. [Google Scholar] [CrossRef]

- Ali, S.S.S.; Razman, M.R.; Awang, A. The estimation and relationship of domestic electricity consumption and appliances ownership in Malaysia’s intermediate city. Int. J. Energy Econ. Policy 2020, 10, 116–122. [Google Scholar] [CrossRef]

- Ali, S.S.S.; Razman, M.R.; Awang, A. The nexus of population, GDP growth, electricity generation, electricity consumption and carbon emissions output in Malaysia. Int. J. Energy Econ. Policy 2020, 10, 84–89. [Google Scholar] [CrossRef]

- Zainuddin, S.; Mascunra Amir, A.; Kibi, Y.R.; Khairil, M.; Zarina Syed Zakaria, S.; Rizal Razman, M. Social engineering model of natural resources management of Palu City. J. Eng. Appl. Sci. 2019, 14, 275–279. [Google Scholar] [CrossRef] [Green Version]

- Ali, M.E.; Das, R.; Maamor, A.; Hamid, S.B.A. Multifunctional carbon nanotubes (CNTs): A new dimension in environmental remediation. Adv. Mater. Res. 2014, 832, 328–332. [Google Scholar] [CrossRef]

- Agnihotri, S.; Mota, J.P.B.; Rostam-Abadi, M.; Rood, M.J. Structural characterization of single-walled carbon nanotube bundles by experiment and molecular simulation. Langmuir 2005, 21, 896–904. [Google Scholar] [CrossRef]

- Upadhyayula, V.K.K.; Deng, S.; Mitchell, M.C.; Smith, G.B. Application of carbon nanotube technology for removal of contaminants in drinking water: A review. Sci. Total Environ. 2009, 408, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Yan, H.; Yang, X.; Chen, J.; Yin, C.; Xiao, C.; Chen, H. Synergistic removal of aniline by carbon nanotubes and the enzymes of Delftia sp. XYJ6. J. Environ. Sci. 2011, 23, 1165–1170. [Google Scholar] [CrossRef]

- Zhai, R.; Zhang, B.; Wan, Y.; Li, C.; Wang, J.; Liu, J. Chitosan-halloysite hybrid-nanotubes: Horseradish peroxidase immobilization and applications in phenol removal. Chem. Eng. J. 2013, 214, 304–309. [Google Scholar] [CrossRef]

- Ihsanullah, A.A.; Al-Amer, A.M.; Laoui, T.; Al-Marri, M.J.; Nasser, M.S.; Khraisheh, M.; Atieh, M.A. Heavy metal removal from aqueous solution by advanced carbon nanotubes: Critical review of adsorption applications. Sep. Purif. Technol. 2016, 157, 141–161. [Google Scholar] [CrossRef]

- Carbon Nanotubes (CNT) Market by Type (Single, Multi Walled), Method (Chemical Vapor Deposition, Catalytic Chemical Vapor Deposition, High Pressure Carbon Monoxide), Application (Electronics, Chemical, Batteries, Energy, Medical)—Global Forecast to 2023. Available online: https://www.marketsandmarkets.com/Market-Reports/carbon-nanotubes-139.html (accessed on 21 March 2021).

- Da Luz, F.S.; Garcia Filho, F.D.C.; Del-Rio, M.T.G.; Nascimento, L.F.C.; Pinheiro, W.A.; Monteiro, S.N. Graphene-incorporated natural fiber polymer composites: A first overview. Polymers 2020, 12, 1601. [Google Scholar] [CrossRef] [PubMed]

| Technique | Advantages | Limitations |

|---|---|---|

| Arc discharge |

|

|

| Laser ablation |

|

|

| CVD |

|

|

| Technique | Advantages | Limitations | Reference |

|---|---|---|---|

| Melt mixing |

|

| [116,117] |

| Solution mixing |

|

| [37,86,118,119,120] |

| Sonication |

|

| [90,94,116,118,121,122] |

| Resin transfer molding |

|

| [99] |

| Bucky paper resin infiltration |

|

| [81,123,124,125] |

| Aligned CNT sheet processing |

|

| [102,107,126,127,128] |

| Shear Mixing |

|

| [32,90] |

| In-situ polymerization |

|

| [110,117,129,130,131] |

| Type of CNT | Young’s Modulus (TPa) | Tensile Strength (GPa) |

|---|---|---|

| SWCNT | 0.65–5.5 | 126 |

| MWCNT | 0.2–1.0 | >63 (300) |

| Stainless steel | 0.186–0.214 | 0.38–1.55 |

| Kevlar | 0.06–0.18 | 3.6–3.8 |

| Diamond | 1.22 | >60 (225) |

| Aluminum | 71 | 0.65 |

| Glass Fibers | 72 | 3 |

| Carbon Fibers | 300 | 3 |

| Silicon Carbide Fibers | 450 | 10 |

| Sample | Tensile Strength (MPa) | Elastic Modulus (GPa) | Thermal Conductivity (W/mK−1) | Electrical Conductivity (Scm−1) |

|---|---|---|---|---|

| Pristine polyimide | 227.70 | 4.04 | 0.027 | 10−16 |

| CNT/polyimide | 680 | 53.73 | 18.4 | 183.3 |

| Aspect Ratio of CNT (L/d) | Young’s Modulus (MPa) |

|---|---|

| 7.23 | 3.90 |

| 14.21 | 4.73 |

| 22.01 | 6.85 |

| ∞ | 46.73 |

| SWCNT Loading (wt.%) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Elongation (%) | Toughness (mJ/mm3) |

|---|---|---|---|---|

| 0 | 74 | 2.2 | 175 | 123 |

| 0.1 | 86 | 2.6 | 125 | 100 |

| 0.3 | 94 | 2.8 | 110 | 92 |

| 1.0 | 100 | 3.2 | 20 | 6 |

| Type of CNT | Filler Content (%) | Matrix | Fabrication Technique | Tensile Strength (MPa) | Tensile Modulus (GPa) | Reference |