A Review on Properties and Application of Bio-Based Poly(Butylene Succinate)

Abstract

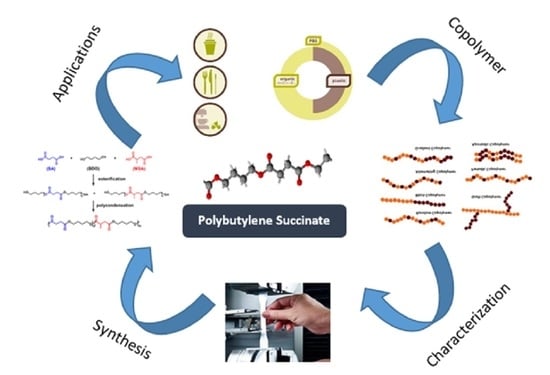

:1. Introduction

2. Poly(Butylene Succinate)

2.1. Structure

2.2. Synthesis

2.3. Copolymers

2.4. Treatments of Poly(Butylene Succinate)

3. Poly(Butylene Succinate)-Based Composites

3.1. Physical Properties

3.2. Mechanical Properties

3.3. Thermal Properties

4. Poly(Butylene Succinate)-Based Hybrid Composites

4.1. Physical Properties

4.2. Mechanical Properties

4.3. Thermal Properties

5. PBS-Based Nanocomposites

Biodegradability of PBS Composites

6. Applications

6.1. Biomedical

6.2. Food Packaging

6.3. Mulch Film

6.4. Tableware

7. Techno Economic Challenges of PBS

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chidambarampadmavathy, K.; Karthikeyan, O.P.; Heimann, K. Sustainable bio-plastic production through landfill methane recycling. Renew. Sustain. Energy Rev. 2017, 71, 555–562. [Google Scholar] [CrossRef]

- Gourmelon, G. Global plastic production rises, recycling lags—New worldwatch Institute analysis explores trends in global plastic consumption and recycling. Worldwatch Inst. 2015, 22, 91–95. [Google Scholar]

- Mazhandu, Z.S.; Muzenda, E.; Mamvura, T.A.; Belaid, M. Integrated and Consolidated Review of Plastic Waste Management and Bio-Based Biodegradable Plastics: Challenges and Opportunities. Sustainability 2020, 12, 8360. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, Y.; Wang, D.; Yan, M.; Zhang, J.; Zhang, P.; Chen, C. Current technologies for plastic waste treatment: A review. J. Clean. Prod. 2020, 282, 124523. [Google Scholar] [CrossRef]

- Saratale, R.G.; Cho, S.K.; Saratale, G.D.; Kadam, A.A.; Ghodake, G.S.; Kumar, M.; Shin, H.S. A comprehensive overview and recent advances on polyhydroxyalkanoates (PHA) production using various organic waste streams. Bioresour. Technol. 2021, 325, 124685. [Google Scholar] [CrossRef] [PubMed]

- Sohn, Y.J.; Kim, H.T.; Baritugo, K.A.; Jo, S.Y.; Song, H.M.; Park, S.Y.; Park, S.J. Recent advances in sustainable plastic upcycling and biopolymers. Biotechnol. J. 2020, 15, 1900489. [Google Scholar] [CrossRef]

- Negrin, M.; Macerata, E.; Consolati, G.; Quasso, F.; Genovese, L.; Soccio, M.; Giola, M.; Lotti, N.; Munari, A.; Mariani, M. Gamma radiation effects on random copolymers based on poly(butylene succinate) for packaging applications. Radiat. Phys. Chem. 2018, 142, 34–43. [Google Scholar] [CrossRef]

- Calabia, B.P.; Ninomiya, F.; Yagi, H.; Oishi, A.; Taguchi, K.; Kunioka, M.; Funabashi, M. Biodegradable poly(butylene succinate) composites reinforced by cotton fiber with silane coupling agent. Polymers 2013, 5, 128–141. [Google Scholar] [CrossRef] [Green Version]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Biodegradable compatibilized polymer blends for packaging applications: A literature review. J. Appl. Polym. Sci. 2018, 135, 45726. [Google Scholar] [CrossRef] [Green Version]

- Zeng, J.B.; Li, Y.D.; Zhu, Q.Y.; Yang, K.K.; Wang, X.L.; Wang, Y.Z. A novel biodegradable multiblock poly(ester urethane) containing poly(L-lactic acid) and poly(butylene succinate) blocks. Polymer 2009, 50, 1178–1186. [Google Scholar] [CrossRef]

- Saratale, R.G.; Cho, S.K.; Ghodake, G.S.; Shin, H.S.; Saratale, G.D.; Park, Y.; Kim, D.S. Utilization of noxious weed water hyacinth biomass as a potential feedstock for biopolymers production: A novel approach. Polymers 2020, 12, 1704. [Google Scholar] [CrossRef]

- Thurber, H.; Curtzwiler, G.W. Suitability of poly(butylene succinate) as a coating for paperboard convenience food packaging. Int. J. Biobased Plast. 2020, 2, 1–12. [Google Scholar] [CrossRef]

- Rudnik, E. Compostable Polymer Materials; Newne: Warsaw, Poland, 2019; p. 410. [Google Scholar]

- Aeschelmann, F.; Carus, M. Bio-based building blocks and polymers in the world. Capacities, production and applications: Status quo and trends towards 2020. Ind. Biotechnol. 2015, 11, 154–159. [Google Scholar] [CrossRef]

- Briassoulis, D.; Giannoulis, A. Evaluation of the functionality of bio-based plastic mulching films. Polym. Test. 2018, 67, 99–109. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Jiménez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.; Chiralt, A.; Torre, L. Production and characterization of PLA_PBS biodegradable blends reinforced with cellulose nanocrystals extracted from hemp fibres. Ind. Crop. Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, C.; Chu, P.K.; Lv, F.; Zhang, C.; Ji, J.; Zhang, R.; Wang, H. Mechanical and thermal properties of basalt fiber reinforced poly(butylene succinate) composites. Mater. Chem. Phys. 2012, 133, 845–849. [Google Scholar] [CrossRef]

- Kurokawa, N.; Kimura, S.; Hotta, A. Mechanical properties of poly(butylene succinate) composites with aligned cellulose-acetate nanofibers. J. Appl. Polym. Sci. 2018, 135, 45429. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.; Asim, M.; Saba, N. Natural fiber reinforced polylactic acid composites: A review. Polym. Compos. 2019, 40, 446–463. [Google Scholar] [CrossRef]

- Murariu, M.; Dubois, P. PLA composites: From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef] [PubMed]

- Liminana, P.; Garcia-Sanoguera, D.; Quiles-Carrillo, L.; Balart, R.; Montanes, N. Development and characterization of environmentally friendly composites from poly(butylene succinate)(PBS) and almond shell flour with different compatibilizers. Compos. Part B Eng. 2018, 144, 153–162. [Google Scholar] [CrossRef]

- Pan, P.; Inoue, Y. Polymorphism and isomorphism in biodegradable polyesters. Prog. Polym. Sci. 2009, 34, 605–640. [Google Scholar] [CrossRef]

- Shih, Y.-F.; Chen, L.; Jeng, R. Preparation and properties of biodegradable PBS/multi-walled carbon nanotube nanocomposites. Polymer 2008, 49, 4602–4611. [Google Scholar] [CrossRef]

- Liu, L.; Yu, J.; Cheng, L.; Qu, W. Mechanical properties of poly(butylene succinate)(PBS) biocomposites reinforced with surface modified jute fibre. Compos. Part A Appl. Sci. Manuf. 2009, 40, 669–674. [Google Scholar] [CrossRef]

- Ayu, R.; Khalina, A.; Harmaen, A.; Zaman, K.; Jawaid, M.; Lee, C. Effect of Modified Tapioca Starch on Mechanical, Thermal, and Morphological Properties of PBS Blends for Food Packaging. Polymers 2018, 10, 1187. [Google Scholar] [CrossRef] [Green Version]

- Harada, M.; Ohya, T.; Iida, K.; Hayashi, H.; Hirano, K.; Fukuda, H. Increased impact strength of biodegradable poly(lactic acid)/poly(butylene succinate) blend composites by using isocyanate as a reactive processing agent. J. Appl. Polym. Sci. 2007, 106, 1813–1820. [Google Scholar] [CrossRef]

- Cheung, H.-Y.; Ho, M.-P.; Lau, K.-T.; Cardona, F.; Hui, D. Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Compos. Part B Eng. 2009, 40, 655–663. [Google Scholar] [CrossRef]

- Ojijo, V.; Sinha Ray, S.; Sadiku, R. Role of specific interfacial area in controlling properties of immiscible blends of biodegradable polylactide and poly [(butylene succinate)-co-adipate]. ACS Appl. Mater. Interfaces 2012, 4, 6690–6701. [Google Scholar] [CrossRef] [PubMed]

- Bautista, M.; de Ilarduya, A.M.; Alla, A.; Vives, M.; Morató, J.; Muñoz-Guerra, S. Cationic poly(butylene succinate) copolyesters. Eur. Polym. J. 2016, 75, 329–342. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Guo, B.-H. Microbial succinic acid, its polymer poly(butylene succinate), and applications. In Plastics from Bacteria; Springer: Berlin/Heidelberg, Germany, 2010; pp. 347–388. [Google Scholar]

- Bi, S.; Tan, B.; Soule, J.L.; Sobkowicz, M.J. Enzymatic degradation of poly(butylene succinate-co-hexamethylene succinate). Polym. Degrad. Stab. 2018, 155, 9–14. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L.; Androsch, R.; Righetti, M.C. Low-temperature crystallization of poly(butylene succinate). Eur. Polym. J. 2017, 94, 384–391. [Google Scholar] [CrossRef]

- AL-Oqla, F.M.; Omari, M.A. Sustainable biocomposites: Challenges, potential and barriers for development. In Green Biocomposites; Springer: Berlin/Heidelberg, Germany, 2017; pp. 13–29. [Google Scholar]

- Gigli, M.; Fabbri, M.; Lotti, N.; Gamberini, R.; Rimini, B.; Munari, A. Poly(butylene succinate)-based polyesters for biomedical applications: A review. Eur. Polym. J. 2016, 75, 431–460. [Google Scholar] [CrossRef]

- De Moraes Crizel, T.; Costa, T.M.H.; de Oliveira Rios, A.; Flôres, S.H. Valorization of food-grade industrial waste in the obtaining active biodegradable films for packaging. Ind. Crop. Prod. 2016, 87, 218–228. [Google Scholar] [CrossRef]

- Someya, Y.; Nakazato, T.; Teramoto, N.; Shibata, M. Thermal and mechanical properties of poly(butylene succinate) nanocomposites with various organo-modified montmorillonites. J. Appl. Polym. Sci. 2004, 91, 1463–1475. [Google Scholar] [CrossRef]

- Ayu, R.S.; Khalina, A.; Harmaen, A.S.; Zaman, K.; Isma, T.; Liu, Q.; Lee, C.H. Characterization study of empty fruit bunch (EFB) fibers reinforcement in poly(Butylene) succinate (PBS)/starch/glycerol composite sheet. Polymers 2020, 12, 1571. [Google Scholar] [CrossRef] [PubMed]

- Ren, X. Biodegradable plastics: A solution or a challenge. J. Clean. Prod. 2003, 11, 27–40. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.; Ugwu, C.; Aiba, S. Biodegradability of plastics. Int. J. Mol. Sci. 2009, 10, 3722–3742. [Google Scholar] [CrossRef]

- Uesaka, T.; Nakane, K.; Maeda, S.; Ogihara, T.; Ogata, N. Structure and physical properties of poly(butylene succinate)/cellulose acetate blends. Polymer 2000, 41, 8449–8454. [Google Scholar] [CrossRef]

- Li, Y.-D.; Zeng, J.-B.; Wang, X.-L.; Yang, K.-K.; Wang, Y.-Z. Structure and properties of soy protein/poly(butylene succinate) blends with improved compatibility. Biomacromolecules 2008, 9, 3157–3164. [Google Scholar] [CrossRef]

- Kanemura, C.; Nakashima, S.; Hotta, A. Mechanical properties and chemical structures of biodegradable poly(butylene-succinate) for material reprocessing. Polym. Degrad. Stab. 2012, 97, 972–980. [Google Scholar] [CrossRef]

- Yu, L.; Ke, S.; Zhang, Y.; Shen, B.; Zhang, A.; Huang, H. Dielectric relaxations of high-k poly(butylene succinate) based all-organic nanocomposite films for capacitor applications. J. Mater. Res. 2011, 26, 2493–2502. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Guo, B.H. Poly(butylene succinate) and its copolymers: Research, development and industrialization. Biotechnol. J. 2010, 5, 1149–1163. [Google Scholar] [CrossRef]

- Αδαμοπούλου, Ε. Poly(Butylene Succinate): A Promising Biopolymer. Master’s Thesis, University of Piraeus School of Chemical Engineering Athens, Pireas, Greece, 2013. [Google Scholar]

- Delhomme, C.; Dirk, W.-B.; Fritz, E.K. Succinic acid from renewable resources as a C4 building-block chemical:a review of the catalytic possibilities in aqueous media. Green Chem. 2009, 11, 13–26. [Google Scholar] [CrossRef]

- Kasmi, N.; Majdoub, M.; Papageorgiou, Z.G.; Biki, D.N. Synthesis and crystallization of new fully renewable resources-based copolyesters: Poly(1,4-cyclohexanedimethanol-co-isosorbide 2,5-furandicarboxylate). Polym. Degrad. Stab. 2018, 1152, 177–190. [Google Scholar] [CrossRef]

- Nikolic, M.S.; Djonlagic, J. Synthesis and characterization of biodegradable poly(butylene succinate-co-butylene adipate) s. Polym. Degrad. Stab. 2001, 74, 263–270. [Google Scholar] [CrossRef]

- Jiang, Y.; Loos, K. Enzymatic synthesis of biobased polyesters and polyamides. Polymers 2016, 8, 243. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Azim, H.; Dekhterman, A.; Jiang, Z.; Gross, R.A. Candida a ntarctica Lipase B-Catalyzed Synthesis of Poly(butylene succinate): Shorter Chain Building Blocks Also Work. Biomacromolecules 2006, 7, 3093–3097. [Google Scholar] [CrossRef] [PubMed]

- Velmathi, S.; Nagahata, R.; Sugiyama, J.i.; Takeuchi, K. A Rapid Eco-Friendly Synthesis of Poly(butylene succinate) by a Direct Polyesterification under Microwave Irradiation. Macromol. Rapid Commun. 2005, 26, 1163–1167. [Google Scholar] [CrossRef]

- Zeng, Z.; Wang, S.; Yang, S. Synthesis and characterization of PbS nanocrystallites in random copolymer ionomers. Chem. Mater. 1999, 11, 3365–3369. [Google Scholar] [CrossRef]

- Papageorgiou, G.Z.; Bikiaris, D.N. Synthesis, cocrystallization, and enzymatic degradation of novel poly(butylene-co-propylene succinate) copolymers. Biomacromolecules 2007, 8, 2437–2449. [Google Scholar] [CrossRef]

- Tserki, V.; Matzinos, P.; Pavlidou, E.; Vachliotis, D.; Panayiotou, C. Biodegradable aliphatic polyesters. Part I. Properties and biodegradation of poly(butylene succinate-co-butylene adipate). Polym. Degrad. Stab. 2006, 91, 367–376. [Google Scholar] [CrossRef]

- Díaz, A.; Franco, L.; Puiggalí, J. Study on the crystallization of poly(butylene azelate-co-butylene succinate) copolymers. Thermochim. Acta 2014, 575, 45–54. [Google Scholar] [CrossRef]

- Park, S.S.; Chae, S.H.; Im, S.S. Transesterification and crystallization behavior of poly(butylene succinate)/poly(butylene terephthalate) block copolymers. J. Polym. Sci. Part A Polym. Chem. 1998, 36, 147–156. [Google Scholar] [CrossRef]

- Kim, M.-N.; Kim, K.-H.; Jin, H.-J.; Park, J.-K.; Yoon, J.-S. Biodegradability of ethyl and n-octyl branched poly(ethylene adipate) and poly(butylene succinate). Eur. Polym. J. 2001, 37, 1843–1847. [Google Scholar] [CrossRef]

- Fabbri, M.; Gigli, M.; Costa, M.; Govoni, M.; Seri, P.; Lotti, N.; Giordano, E.; Munari, A.; Gamberini, R.; Rimini, B. The effect of plasma surface modification on the biodegradation rate and biocompatibility of a poly(butylene succinate)-based copolymer. Polym. Degrad. Stab. 2015, 121, 271–279. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Biodegradable Poly(butylene succinate) and Poly(butylene adipate-co-terephthalate) Blends: Reactive Extrusion and Performance Evaluation. J. Polym. Environ. 2014, 22, 336–349. [Google Scholar] [CrossRef]

- Wang, H.; Ji, J.; Zhang, W.; Zhang, Y.; Jiang, J.; Wu, Z.; Pu, S.; Chu, P.K. Biocompatibility and bioactivity of plasma-treated biodegradable poly(butylene succinate). Acta Biomater. 2009, 5, 279–287. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Xu, M.; Wu, Z.; Zhang, W.; Ji, J.; Chu, P.K. Biodegradable poly(butylene succinate) modified by gas plasmas and their in vitro functions as bone implants. Acs Appl. Mater. Interfaces 2012, 4, 4380–4386. [Google Scholar] [CrossRef]

- Hirotsu, T.; Tsujisaka, T.; Masuda, T.; Nakayama, K. Plasma surface treatments and biodegradation of poly(butylene succinate) sheets. J. Appl. Polym. Sci. 2000, 78, 1121–1129. [Google Scholar] [CrossRef]

- Grace, J.M.; Gerenser, L.J. Plasma treatment of polymers. J. Dispers. Sci. Technol. 2003, 24, 305–341. [Google Scholar] [CrossRef]

- Zhao, H.-P.; Zhu, J.-T.; Fu, Z.-Y.; Feng, X.-Q.; Shao, Y.; Ma, R.-T. Plasma surface graft of acrylic acid and biodegradation of poly(butylene succinate) films. Thin Solid Film. 2008, 516, 5659–5663. [Google Scholar] [CrossRef]

- Mizuno, S.; Maeda, T.; Kanemura, C.; Hotta, A. Biodegradability, reprocessability, and mechanical properties of polybutylene succinate (PBS) photografted by hydrophilic or hydrophobic membranes. Polym. Degrad. Stab. 2015, 117, 58–65. [Google Scholar] [CrossRef]

- Gan, Z.; Abe, H.; Kurokawa, H.; Doi, Y. Solid-state microstructures, thermal properties, and crystallization of biodegradable poly(butylene succinate)(PBS) and its copolyesters. Biomacromolecules 2001, 2, 605–613. [Google Scholar] [CrossRef] [PubMed]

- Gigli, M.; Negroni, A.; Zanaroli, G.; Lotti, N.; Fava, F.; Munari, A. Environmentally friendly PBS-based copolyesters containing PEG-like subunit: Effect of block length on solid-state properties and enzymatic degradation. React. Funct. Polym. 2013, 73, 764–771. [Google Scholar] [CrossRef]

- Lee, S.-H.; Wang, S. Biodegradable polymers/bamboo fiber biocomposite with bio-based coupling agent. Compos. Part A Appl. Sci. Manuf. 2006, 37, 80–91. [Google Scholar] [CrossRef]

- Domínguez-Robles, J.; Larrañeta, E.; Fong, M.L.; Niamh, K.; Martin, N.K.; Irwin, N.J.; Mutjé, P.; Tarrés, Q.; Delgado-Aguilar, M. Lignin/poly(butylene succinate) composites with antioxidant and antibacterial properties for potential biomedical applications. Int. J. Biol. Macromol. 2020, 145, 92–99. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.S.; Yang, H.S.; Kim, H.J. Biodegradability and mechanical properties of agro-flour–filled polybutylene succinate biocomposites. J. Appl. Polym. Sci. 2005, 97, 1513–1521. [Google Scholar] [CrossRef]

- Phua, Y.; Chow, W.; Ishak, Z.M. The hydrolytic effect of moisture and hygrothermal aging on poly(butylene succinate)/organo-montmorillonite nanocomposites. Polym. Degrad. Stab. 2011, 96, 1194–1203. [Google Scholar] [CrossRef]

- Nam, T.H.; Ogihara, S.; Nakatani, H.; Kobayashi, S.; Song, J.I. Mechanical and thermal properties and water absorption of jute fiber reinforced poly(butylene succinate) biodegradable composites. Adv. Compos. Mater. 2012, 21, 241–258. [Google Scholar] [CrossRef]

- Frollini, E.; Bartolucci, N.; Sisti, L.; Celli, A. Poly(butylene succinate) reinforced with different lignocellulosic fibers. Ind. Crop. Prod. 2013, 45, 160–169. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.a.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Signori, F.; Pelagaggi, M.; Bronco, S.; Righetti, M.C. Amorphous/crystal and polymer/filler interphases in biocomposites from poly(butylene succinate). Thermochim. Acta 2012, 543, 74–81. [Google Scholar] [CrossRef]

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. J. Polym. Process. Inst. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Luo, X.; Li, J.; Feng, J.; Yang, T.; Lin, X. Mechanical and thermal performance of distillers grains filled poly(butylene succinate) composites. Mater. Des. 2014, 57, 195–200. [Google Scholar] [CrossRef]

- Thirmizir, M.A.; Ishak, Z.M.; Taib, R.M.; Sudin, R.; Leong, Y. Mechanical, water absorption and dimensional stability studies of kenaf bast fibre-filled poly(butylene succinate) composites. Polym. Plast. Technol. Eng. 2011, 50, 339–348. [Google Scholar] [CrossRef]

- Wu, C.-S.; Liao, H.-T.; Jhang, J.-J. Palm fibre-reinforced hybrid composites of poly(butylene succinate): Characterisation and assessment of mechanical and thermal properties. Polym. Bull. 2013, 70, 3443–3462. [Google Scholar] [CrossRef]

- Gigli, M.; Lotti, N.; Gazzano, M.; Finelli, L.; Munari, A. Macromolecular design of novel sulfur-containing copolyesters with promising mechanical properties. J. Appl. Polym. Sci. 2012, 126, 686–696. [Google Scholar] [CrossRef]

- Bhatia, A.; Gupta, R.; Bhattacharya, S.; Choi, H. Compatibility of biodegradable poly(lactic acid)(PLA) and poly(butylene succinate)(PBS) blends for packaging application. Korea-Aust. Rheol. J. 2007, 19, 125–131. [Google Scholar]

- Tallawi, M.; Rai, R.; R-Gleixner, M.; Roerick, O.; Weyand, M.; Roether, J.; Schubert, D.; Kozlowska, A.; Fray, M.E.; Merle, B. Poly(glycerol sebacate)\Poly(butylene succinate-dilinoleate) Blends as Candidate Materials for Cardiac Tissue Engineering. Macromol. Symp. 2013, 334, 57–67. [Google Scholar] [CrossRef]

- Frollini, E.; Bartolucci, N.; Sisti, L.; Celli, A. Biocomposites based on poly(butylene succinate) and curaua: Mechanical and morphological properties. Polym. Test. 2015, 45, 168–173. [Google Scholar] [CrossRef]

- Nam, T.H.; Ogihara, S.; Tung, N.H.; Kobayashi, S. Effect of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly(butylene succinate) biodegradable composites. Compos. Part B Eng. 2011, 42, 1648–1656. [Google Scholar] [CrossRef]

- Liang, Z.; Pan, P.; Zhu, B.; Dong, T.; Inoue, Y. Mechanical and thermal properties of poly(butylene succinate)/plant fiber biodegradable composite. J. Appl. Polym. Sci. 2010, 115, 3559–3567. [Google Scholar] [CrossRef]

- Pinho, E.D.; Martins, A.; Araújo, J.; Reis, R.; Neves, N. Degradable particulate composite reinforced with nanofibres for biomedical applications. Acta Biomater. 2009, 5, 1104–1114. [Google Scholar] [CrossRef] [Green Version]

- Zhou, M.; Fan, M.; Zhao, Y.; Jin, T.; Fu, Q. Effect of stretching on the mechanical properties in melt-spun poly(butylene succinate)/microfibrillated cellulose (MFC) nanocomposites. Carbohydr. Polym. 2016, 140, 383–392. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Injection molded sustainable biocomposites from poly(butylene succinate) bioplastic and perennial grass. Acs Sustain. Chem. Eng. 2015, 3, 2767–2776. [Google Scholar] [CrossRef]

- Correlo, V.M.; Boesel, L.F.; Bhattacharya, M.; Mano, J.F.; Neves, N.M.; Reis, R.L. Hydroxyapatite reinforced chitosan and polyester blends for biomedical applications. Macromol. Mater. Eng. 2005, 290, 1157–1165. [Google Scholar] [CrossRef] [Green Version]

- Cho, K.; Lee, J.; Kwon, K. Hydrolytic degradation behavior of poly(butylene succinate) s with different crystalline morphologies. J. Appl. Polym. Sci. 2001, 79, 1025–1033. [Google Scholar] [CrossRef]

- Yoo, E.; Im, S. Melting behavior of poly(butylene succinate) during heating scan by DSC. J. Polym. Sci. Part B Polym. Phys. 1999, 37, 1357–1366. [Google Scholar] [CrossRef]

- Shih, Y.F.; Lee, W.C.; Jeng, R.J.; Huang, C.M. Water bamboo husk-reinforced poly(butylene succinate) biodegradable composites. J. Appl. Polym. Sci. 2006, 99, 188–199. [Google Scholar] [CrossRef]

- Chen, R.-Y.; Zou, W.; Zhang, H.-C.; Zhang, G.-Z.; Yang, Z.-T.; Jin, G.; Qu, J.-P. Thermal behavior, dynamic mechanical properties and rheological properties of poly(butylene succinate) composites filled with nanometer calcium carbonate. Polym. Test. 2015, 42, 160–167. [Google Scholar] [CrossRef]

- Thwe, M.M.; Liao, K. Durability of bamboo-glass fiber reinforced polymer matrix hybrid composites. Compos. Sci. Technol. 2003, 63, 375–387. [Google Scholar] [CrossRef]

- Thwe, M.M.; Liao, K. Effects of environmental aging on the mechanical properties of bamboo–glass fiber reinforced polymer matrix hybrid composites. Compos. Part A Appl. Sci. Manuf. 2002, 33, 43–52. [Google Scholar] [CrossRef]

- Jacob, M.; Thomas, S.; Varughese, K.T. Mechanical properties of sisal/oil palm hybrid fiber reinforced natural rubber composites. Compos. Sci. Technol. 2004, 64, 955–965. [Google Scholar] [CrossRef]

- Gcwabaza, T.; Ray, S.S.; Focke, W.W.; Maity, A. Morphology and properties of nanostructured materials based on polypropylene/poly(butylene succinate) blend and organoclay. Eur. Polym. J. 2009, 45, 353–367. [Google Scholar] [CrossRef]

- Hwang, S.Y.; Yoo, E.S.; Im, S.S. Effects of TS-1 zeolite structures on physical properties and enzymatic degradation of poly(butylene succinate)(PBS)/TS-1 zeolite hybrid composites. Polymer 2011, 52, 965–975. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Bandyopadhyay, J.; Bousmina, M. Effect of Organoclay on the Morphology and Properties of Poly(propylene)/Poly [(butylene succinate)-co-adipate] Blends. Macromol. Mater. Eng. 2007, 292, 729–747. [Google Scholar] [CrossRef]

- Athijayamani, A.; Thiruchitrambalam, M.; Natarajan, U.; Pazhanivel, B. Effect of moisture absorption on the mechanical properties of randomly oriented natural fibers/polyester hybrid composite. Mater. Sci. Eng. A 2009, 517, 344–353. [Google Scholar] [CrossRef]

- Dan-mallam, Y.; Abdullah, M.Z.; Yusoff, P.S.M.M. Mechanical properties of recycled kenaf/polyethylene terephthalate (PET) fiber reinforced polyoxymethylene (POM) hybrid composite. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Yang, H.-S.; Kim, H.-J.; Park, H.-J.; Lee, B.-J.; Hwang, T.-S. Water absorption behavior and mechanical properties of lignocellulosic filler–polyolefin bio-composites. Compos. Struct. 2006, 72, 429–437. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Chen, G.-X.; Yoon, J.-S. Thermal stability of poly(L-lactide)/poly(butylene succinate)/clay nanocomposites. Polym. Degrad. Stab. 2005, 88, 206–212. [Google Scholar] [CrossRef]

- Shih, Y.-F.; Chang, W.-C.; Liu, W.-C.; Lee, C.-C.; Kuan, C.-S.; Yu, Y.-H. Pineapple leaf/recycled disposable chopstick hybrid fiber-reinforced biodegradable composites. J. Taiwan Inst. Chem. Eng. 2014, 45, 2039–2046. [Google Scholar] [CrossRef]

- Zaki Abdullah, M.; Dan-mallam, Y.; Yusoff, M.; Melor, P.S. Effect of environmental degradation on mechanical properties of kenaf/polyethylene terephthalate fiber reinforced polyoxymethylene hybrid composite. Adv. Mater. Sci. Eng. 2013, 2013. [Google Scholar] [CrossRef] [Green Version]

- Khalil, H.A.; Hanida, S.; Kang, C.; Fuaad, N.N. Agro-hybrid composite: The effects on mechanical and physical properties of oil palm fiber (EFB)/glass hybrid reinforced polyester composites. J. Reinf. Plast. Compos. 2007, 26, 203–218. [Google Scholar] [CrossRef]

- Sahoo, S.; Misra, M.; Mohanty, A.K. Biocomposites from switchgrass and lignin hybrid and poly(butylene succinate) bioplastic: Studies on reactive compatibilization and performance evaluation. Macromol. Mater. Eng. 2014, 299, 178–189. [Google Scholar] [CrossRef]

- Wu, C.-S. Renewable resource-based composites of recycled natural fibers and maleated polylactide bioplastic: Characterization and biodegradability. Polym. Degrad. Stab. 2009, 94, 1076–1084. [Google Scholar] [CrossRef]

- Dorez, G.; Ferry, L.; Sonnier, R.; Taguet, A.; Lopez-Cuesta, J.-M. Effect of cellulose, hemicellulose and lignin contents on pyrolysis and combustion of natural fibers. J. Anal. Appl. Pyrolysis 2014, 107, 323–331. [Google Scholar] [CrossRef]

- Song, L.; Qiu, Z. Crystallization behavior and thermal property of biodegradable poly(butylene succinate)/functional multi-walled carbon nanotubes nanocomposite. Polym. Degrad. Stab. 2009, 94, 632–637. [Google Scholar] [CrossRef]

- Ray, S.S.; Bandyopadhyay, J.; Bousmina, M. Thermal and thermomechanical properties of poly [(butylene succinate)-co-adipate] nanocomposite. Polym. Degrad. Stab. 2007, 92, 802–812. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Okamoto, K.; Okamoto, M. Structure− property relationship in biodegradable poly(butylene succinate)/layered silicate nanocomposites. Macromolecules 2003, 36, 2355–2367. [Google Scholar] [CrossRef]

- Okamoto, K.; Sinha Ray, S.; Okamoto, M. New poly(butylene succinate)/layered silicate nanocomposites. II. Effect of organically modified layered silicates on structure, properties, melt rheology, and biodegradability. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 3160–3172. [Google Scholar] [CrossRef]

- Ray, S.S.; Vaudreuil, S.; Maazouz, A.; Bousmina, M. Dispersion of multi-walled carbon nanotubes in biodegradable poly(butylene succinate) matrix. J. Nanosci. Nanotechnol. 2006, 6, 2191–2195. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.X.; Kim, E.S.; Yoon, J.S. Poly(butylene succinate)/twice functionalized organoclay nanocomposites: Preparation, characterization, and properties. J. Appl. Polym. Sci. 2005, 98, 1727–1732. [Google Scholar] [CrossRef]

- Phua, Y.; Chow, W.; Mohd Ishak, Z. Reactive processing of maleic anhydride-grafted poly(butylene succinate) and the compatibilizing effect on poly(butylene succinate) nanocomposites. Express Polym. Lett. 2013, 7, 340–354. [Google Scholar] [CrossRef]

- Tezuka, Y.; Ishii, N.; Kasuya, K.-i.; Mitomo, H. Degradation of poly(ethylene succinate) by mesophilic bacteria. Polym. Degrad. Stab. 2004, 84, 115–121. [Google Scholar] [CrossRef]

- Nishide, H.; Toyota, K.; Kimura, M. Effects of soil temperature and anaerobiosis on degradation of biodegradable plastics in soil and their degrading microorganisms. Soil Sci. Plant Nutr. 1999, 45, 963–972. [Google Scholar] [CrossRef]

- Kitakuni, E.; Yoshikawa, K.; Nakano, K.; Sasuga, J.; Nobiki, M.; Naoi, H.; Yokota, Y.; Ishioka, R.; Yakabe, Y. Biodegradation of poly(tetramethylene succinate-cotetramethylene abdicate) and poly(tetramethylene succinate) through water-soluble products. Environ. Toxicol. Chem. 2001, 20, 941–946. [Google Scholar] [CrossRef]

- Chrissafis, K.; Paraskevopoulos, K.; Bikiaris, D. Thermal degradation mechanism of poly(ethylene succinate) and poly(butylene succinate): Comparative study. Thermochim. Acta 2005, 435, 142–150. [Google Scholar] [CrossRef]

- Chen, G.G.-Q. Plastics from Bacteria: Natural Functions and Applications; Springer: Berlin/Heidelberg, Germany, 2009; Volume 14. [Google Scholar]

- Jamaluddin, N.; Razaina, M.; Ishak, Z.M. Mechanical and morphology behaviours of polybutylene (succinate)/thermoplastic polyurethaneblend. Procedia Chem. 2016, 19, 426–432. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Yu, J.; Cheng, L.; Yang, X. Biodegradability of poly(butylene succinate)(PBS) composite reinforced with jute fibre. Polym. Degrad. Stab. 2009, 94, 90–94. [Google Scholar] [CrossRef]

- Kim, H.-S.; Kim, H.-J.; Lee, J.-W.; Choi, I.-G. Biodegradability of bio-flour filled biodegradable poly(butylene succinate) bio-composites in natural and compost soil. Polym. Degrad. Stab. 2006, 91, 1117–1127. [Google Scholar] [CrossRef]

- Teramoto, N.; Urata, K.; Ozawa, K.; Shibata, M. Biodegradation of aliphatic polyester composites reinforced by abaca fiber. Polym. Degrad. Stab. 2004, 86, 401–409. [Google Scholar] [CrossRef]

- Phua, Y.; Lau, N.; Sudesh, K.; Chow, W.; Ishak, Z.M. Biodegradability studies of poly(butylene succinate)/organo-montmorillonite nanocomposites under controlled compost soil conditions: Effects of clay loading and compatibiliser. Polym. Degrad. Stab. 2012, 97, 1345–1354. [Google Scholar] [CrossRef]

- Shibata, M.; Oyamada, S.; Kobayashi, S.i.; Yaginuma, D. Mechanical properties and biodegradability of green composites based on biodegradable polyesters and lyocell fabric. J. Appl. Polym. Sci. 2004, 92, 3857–3863. [Google Scholar] [CrossRef]

- Anankaphong, H.; Pentrakoon, D.; Junkasem, J. Effect of rubberwood content on biodegradability of poly(butylene succinate) biocomposites. Int. J. Polym. Sci. 2015, 2015. [Google Scholar] [CrossRef] [Green Version]

- Ramos, M.; Jiménez, A.; Peltzer, M.; Garrigós, M.C. Development of novel nano-biocomposite antioxidant films based on poly(lactic acid) and thymol for active packaging. Food Chem. 2014, 162, 149–155. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, H.; Chang, J.; Cao, A.; Wang, J. In vitro evaluation of biodegradable poly(butylene succinate) as a novel biomaterial. Macromol. Biosci. 2005, 5, 433–440. [Google Scholar] [CrossRef]

- Causa, F.; Netti, P.; Ambrosio, L.; Ciapetti, G.; Baldini, N.; Pagani, S.; Martini, D.; Giunti, A. Poly-ϵ-caprolactone/hydroxyapatite composites for bone regeneration: In vitro characterization and human osteoblast response. J. Biomed. Mater. Res. Part A Off. J. Soc. Biomater. Jpn. Soc. Biomater. Aust. Soc. Biomater. Korean Soc. Biomater. 2006, 76, 151–162. [Google Scholar]

- Grigoriadou, I.; Nianias, N.; Hoppe, A.; Terzopoulou, Z.; Bikiaris, D.; Will, J.; Hum, J.; Roether, J.; Detsch, R.; Boccaccini, A. Evaluation of silica-nanotubes and strontium hydroxyapatite nanorods as appropriate nanoadditives for poly(butylene succinate) biodegradable polyester for biomedical applications. Compos. Part B Eng. 2014, 60, 49–59. [Google Scholar] [CrossRef]

- Coutinho, D.F.; Pashkuleva, I.H.; Alves, C.M.; Marques, A.P.; Neves, N.M.; Reis, R.L. The effect of chitosan on the in vitro biological performance of chitosan− poly(butylene succinate) blends. Biomacromolecules 2008, 9, 1139–1145. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, H.; Ji, J.; Zhang, W.; Wang, W.; Zhang, Y.; Wu, Z.; Zhang, Y.; Chu, P.K. Rat calvaria osteoblast behavior and antibacterial properties of O2 and N2 plasma-implanted biodegradable poly(butylene succinate). Acta Biomater. 2010, 6, 154–159. [Google Scholar] [CrossRef]

- Hariraksapitak, P.; Suwantong, O.; Pavasant, P.; Supaphol, P. Effectual drug-releasing porous scaffolds from 1, 6-diisocyanatohexane-extended poly(1, 4-butylene succinate) for bone tissue regeneration. Polymer 2008, 49, 2678–2685. [Google Scholar] [CrossRef]

- Siracusa, V.; Lotti, N.; Munari, A.; Dalla Rosa, M. Poly(butylene succinate) and poly(butylene succinate-co-adipate) for food packaging applications: Gas barrier properties after stressed treatments. Polym. Degrad. Stab. 2015, 119, 35–45. [Google Scholar] [CrossRef]

- Xie, L.; Xu, H.; Niu, B.; Ji, X.; Chen, J.; Li, Z.-M.; Hsiao, B.S.; Zhong, G.-J. Unprecedented access to strong and ductile poly(lactic acid) by introducing in situ nanofibrillar poly(butylene succinate) for green packaging. Biomacromolecules 2014, 15, 4054–4064. [Google Scholar] [CrossRef]

- Hassan, E.; Wei, Y.; Jiao, H.; Muhuo, Y. Dynamic mechanical properties and thermal stability of poly(lactic acid) and poly(butylene succinate) blends composites. J. Fiber Bioeng. Inform. 2013, 6, 85–94. [Google Scholar]

- Van den Broek, L.A.; Knoop, R.J.; Kappen, F.H.; Boeriu, C.G. Chitosan films and blends for packaging material. Carbohydr. Polym. 2015, 116, 237–242. [Google Scholar] [CrossRef]

- Quintavalla, S.; Vicini, L. Antimicrobial food packaging in meat industry. Meat Sci. 2002, 62, 373–380. [Google Scholar] [CrossRef]

- Siracusa, V.; Rocculi, P.; Romani, S.; Dalla Rosa, M. Biodegradable polymers for food packaging: A review. Trends Food Sci. Technol. 2008, 19, 634–643. [Google Scholar] [CrossRef]

- Sorrentino, A.; Gorrasi, G.; Vittoria, V. Potential perspectives of bio-nanocomposites for food packaging applications. Trends Food Sci. Technol. 2007, 18, 84–95. [Google Scholar] [CrossRef]

- Jian, J.; Xiangbin, Z.; Xianbo, H. An overview on synthesis, properties and applications of poly(butylene-adipate-co-terephthalate)–PBAT. Adv. Ind. Eng. Polym. Res. 2020, 3, 19–26. [Google Scholar] [CrossRef]

- Kasirajan, S.; Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: A review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar] [CrossRef]

- Brodhagen, M.; Peyron, M.; Miles, C.; Inglis, D.A. Biodegradable plastic agricultural mulches and key features of microbial degradation. Appl. Microbiol. Biotechnol. 2015, 99, 1039–1056. [Google Scholar] [CrossRef]

- Koitabashi, M.; Noguchi, M.T.; Sameshima-Yamashita, Y.; Hiradate, S.; Suzuki, K.; Yoshida, S.; Kitamoto, H.K. Degradation of biodegradable plastic mulch films in soil environment by phylloplane fungi isolated from gramineous plants. AMB Express 2012, 2, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Hongsriphan, N.; Pinpueng, A. Properties of agricultural films prepared from biodegradable poly(butylene succinate) adding natural sorbent and fertilizer. J. Polym. Environ. 2019, 27, 434–443. [Google Scholar] [CrossRef]

- Yamamoto-Tamura, K.; Hoshino, Y.T.; Tsuboi, S.; Huang, C.; Kishimoto-Mo, A.W.; Sameshima-Yamashita, Y.; Kitamoto, H. Fungal community dynamics during degradation of poly(butylene succinate-co-adipate) film in two cultivated soils in Japan. Biosci. Biotechnol. Biochem. 2020, 84, 1077–1087. [Google Scholar] [CrossRef] [PubMed]

- Rydz, J.; Sikorska, W.; Kyulavska, M.; Christova, D. Polyester-based (bio) degradable polymers as environmentally friendly materials for sustainable development. Int. J. Mol. Sci. 2015, 16, 564–596. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, Y.; Lin, S. A feasibility study on the transformation and sustainable development of “disposable tableware” in Taiwan night market. In International Conference on Human-Computer Interaction; Springer: Cham, Switzerland, 2019; pp. 370–381. [Google Scholar]

- Pavlovskay, N.E.; Gorkova, I.V.; Gagarina, I.N.; Gavrilova, A.Y. Creation of new polymer composite bioplastics to produce disposable tableware based on starch. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 422. [Google Scholar]

- Pan, W.; Bai, Z.; Su, T.; Wang, Z. Enzymatic degradation of poly(butylene succinate) with different molecular weights by cutinase. Int. J. Biol. Macromol. 2018, 111, 1040–1046. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, M.S.; Sani, N.; Adamu, M.; Abubakar, M.K. Biodegradable polymers for sustainable environmental and economic development. MOJ Biorg. Org. Chem. 2018, 2, 192–194. [Google Scholar]

- Folino, A.; Karageorgiou, A.; Calabrò, P.S.; Komilis, D. Biodegradation of wasted bioplastics in natural and industrial environments: A review. Sustainability 2020, 12, 6030. [Google Scholar] [CrossRef]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and its blends with poly(butylene succinate)(PBS): A brief review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef] [Green Version]

| PBS Grade | Company | MFI | Density (g/cm3) | Tg (°C) | Tm (°C) | Tensile Strength (MPa) | Tensile Modulus (MPa) | Reference |

|---|---|---|---|---|---|---|---|---|

| Molecular Weight 80,000 | Anqing Hexing chemical co.ltd | - | 1.24 | −44.3 | 109 | 27 | - | [35] |

| Bionelle 1020 MD | Showa Denko (Tokyo, Japan) | 20–34 g/10 min (at 140 °C and 2.16 kg) | 1.23 | 59.7 | 114.1 | - | 643 | [36] |

| Bionelle 1020 MD | Showa Highpolymer (Tokyo, Japan) | 25 g/10 min at (190 °C, 2.16 kg) | 1.26 | −32 | 115 | 33.7 | 707 | [37] |

| FZ91PM | PTT Public Company Limited in Thailand. | 5 g/10 min at (190 °C, 2.16 kg) | 1.26 | 78 | 115 | 20 | 450 | [17] |

| Bionelle | HKH National Engineering Research Centre of Plastic | 5 g/10 min at 150 °C, 2 kg | 1.26 | −32 | 114 | 32 | 30 | [38] |

| Copolymer + PBS | Properties | References |

|---|---|---|

| Hexamethylene |

| [30] |

| Ethylene |

| [58] |

| 1,6-hexanediamine |

| [59] |

| Thiodiglycolate |

| [59] |

| Thiodiethylene succinate |

| [7] |

| Terephthalate |

| [60] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rafiqah, S.A.; Khalina, A.; Harmaen, A.S.; Tawakkal, I.A.; Zaman, K.; Asim, M.; Nurrazi, M.N.; Lee, C.H. A Review on Properties and Application of Bio-Based Poly(Butylene Succinate). Polymers 2021, 13, 1436. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13091436

Rafiqah SA, Khalina A, Harmaen AS, Tawakkal IA, Zaman K, Asim M, Nurrazi MN, Lee CH. A Review on Properties and Application of Bio-Based Poly(Butylene Succinate). Polymers. 2021; 13(9):1436. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13091436

Chicago/Turabian StyleRafiqah, S. Ayu, Abdan Khalina, Ahmad Saffian Harmaen, Intan Amin Tawakkal, Khairul Zaman, M. Asim, M.N. Nurrazi, and Ching Hao Lee. 2021. "A Review on Properties and Application of Bio-Based Poly(Butylene Succinate)" Polymers 13, no. 9: 1436. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13091436