Increasing Sustainability of Growing Media Constituents and Stand-Alone Substrates in Soilless Culture Systems

Abstract

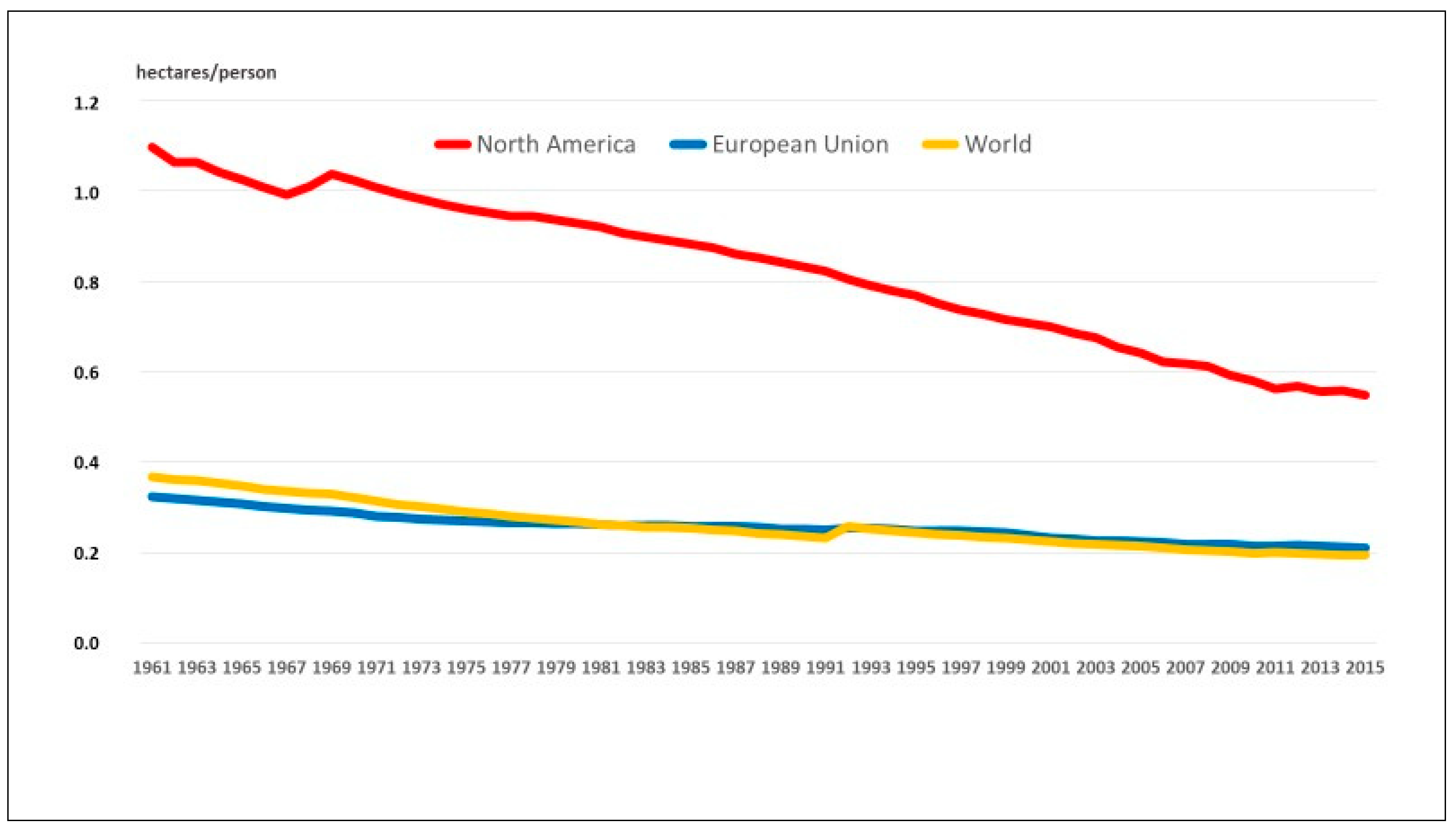

:1. Introduction

2. Results and Discussion

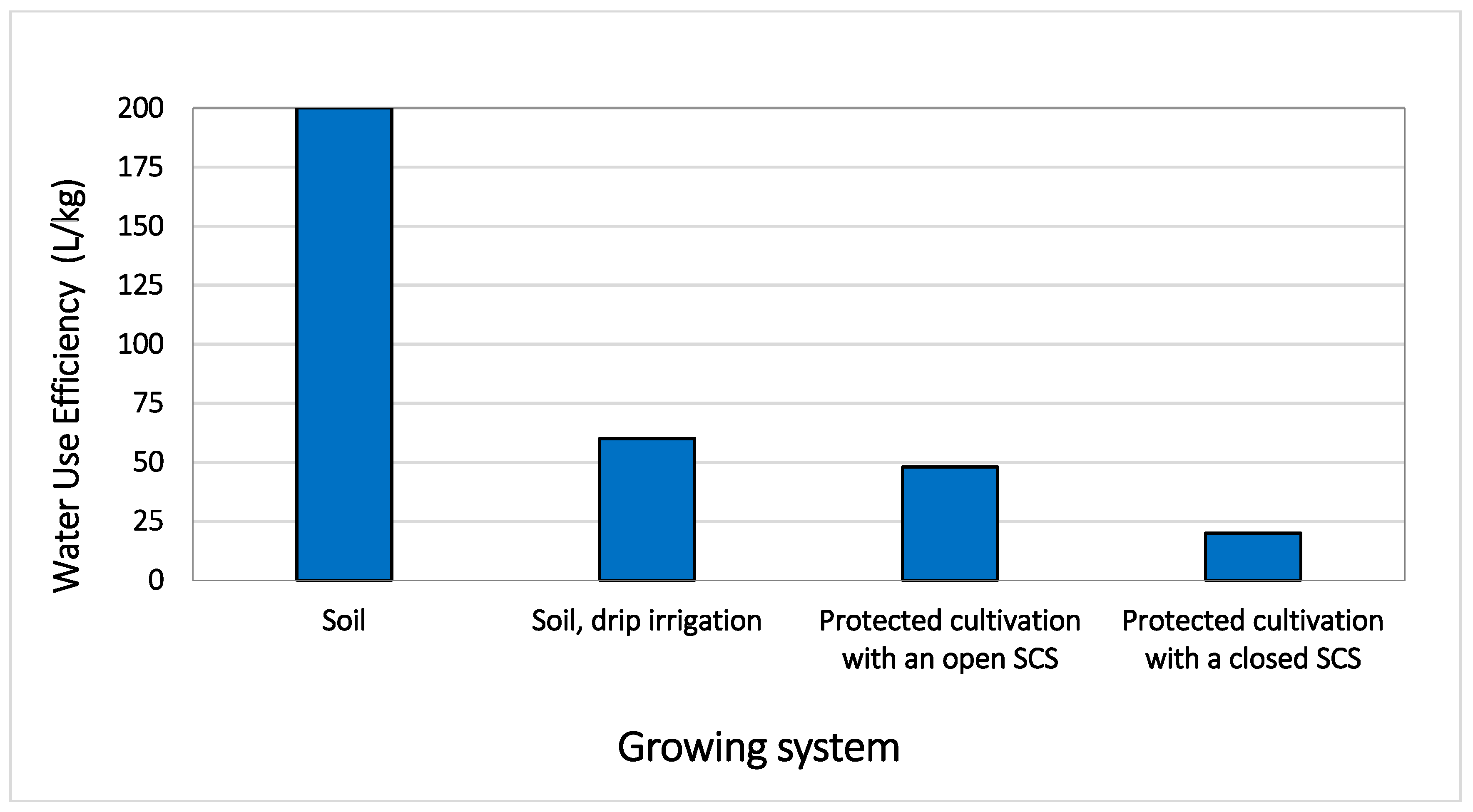

2.1. Soilless Culture and Growing Media: Pros and Cons

2.2. Organic Materials Other than Peat Used as Growing Media Constituents

2.2.1. Compost, as a Bioresource and Growing Media Constituent

2.2.2. Coir, a Growing Media Constituent and Stand-Alone Substrate

2.2.3. Bark and Wood-Based Materials as Bioresources, Growing Media Constituents, and Stand-Alone Substrates

2.2.4. Biochar and Hydrothermal Carbonization Products as Bioresources and Growing Media Constituents

2.2.5. Other Organic Materials as Bioresources and Growing Media Constituents

2.3. Growing Medium Choice

2.3.1. Production Systems

2.3.1.1. Nursery Production

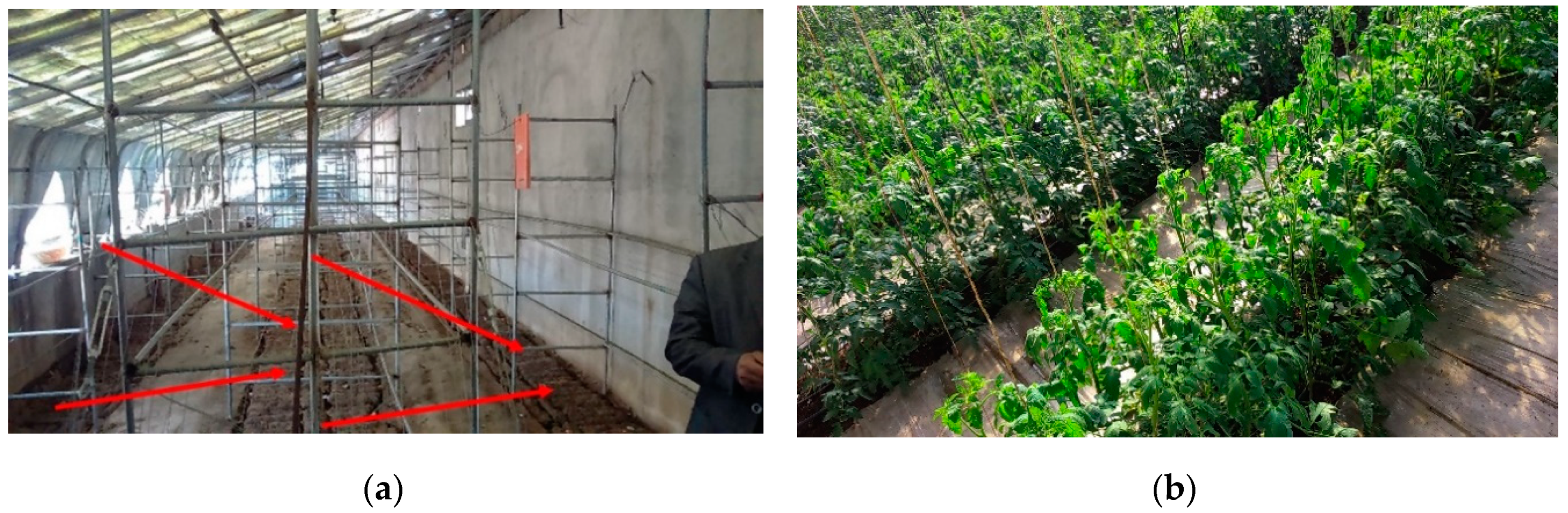

2.3.1.2. Greenhouse Vegetable Production

2.3.1.3. Greenhouse Ornamental Production

2.3.2. Transportation Distances

2.4. Disposal Concerns and Waste Management

2.5. Other Factors Having an Impact on Sustainability

3. Conclusions

Acknowledgments

Conflicts of Interest

References

- UN. Available online: https://esa.un.org/unpd/wpp (accessed on 27 July 2018).

- World Bank Group. International Development, Poverty, & Sustainability. Available online: www.worldbank.org (accessed on 7 June 2018).

- Eigenbrod, C.; Gruda, N. Urban vegetable for food security in cities. A review. Agron. Sustain. Dev. 2015, 35, 483–498. [Google Scholar] [CrossRef]

- Abukari, M.K.; Tok, M.E. Protected cultivation as adaptive response in climate change policy: The case of smallholders in northern Ghana. J. Emerg. Trends Econ. Manag. Sci. 2016, 7, 307–321. [Google Scholar]

- Olesen, J.E.; Bindi, M. Consequences of climate change for European agricultural productivity, land use and policy. Eur. J. Agron. 2002, 16, 239–262. [Google Scholar] [CrossRef]

- Bisbis, M.B.; Gruda, N.; Blanke, M. Potential impacts of climate change on vegetable production and product quality—A review. J. Clean. Prod. 2018, 170, 1602–1620. [Google Scholar] [CrossRef]

- Gruda, N.; Bisbis, M.B.; Tanny, J. Impacts of protected vegetable cultivation on climate change and adaptation strategies for cleaner production—A review. J. Clean. Prod. 2019, 225, 324–339. [Google Scholar] [CrossRef]

- Gruda, N.; Bisbis, M.B.; Tanny, J. Influence of climate change on protected cultivation: Impacts and sustainable adaptation strategies—A review. J. Clean. Prod. 2019, 225, 481–495. [Google Scholar] [CrossRef]

- Raviv, M. Can compost improve sustainability of plant production in growing media? Acta Hortic. 2017, 1168, 119–133. [Google Scholar] [CrossRef]

- Gruda, N.; Gianquinto, G.; Tüzel, Y.; Savvas, D. Soilless Culture. In Encyclopedia of Soil Sciences, 3rd ed.; Lal, R., Ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2016; pp. 533–537. [Google Scholar]

- Di Lorenzo, R.; Pisciotta, A.; Santamaria, P.; Scariot, V. From soil to soil-less in horticulture: Quality and typicity. Ital. J. Agron. 2013, 8, 30. [Google Scholar] [CrossRef]

- Peet, M.M.; Welles, G.W.H. Greenhouse tomato production. In Tomatoes—Crop Production Science in Horticulture; Heuvelink, E., Ed.; CABI Publishing: Wallingford, UK; Cambridge, MA, USA, 2005; Volume 13, pp. 257–304. [Google Scholar]

- Gruda, N. Do soilless culture systems have an influence on product quality of vegetables? J. Appl. Bot. Food Qual. 2009, 82, 141–147. [Google Scholar]

- Gruda, N.; Caron, J.; Prasad, M.; Maher, M.J. Growing media. In Encyclopedia of Soil Sciences, 3rd ed.; Lal, R., Ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2016; pp. 1053–1058. [Google Scholar]

- Savvas, D.; Gianquinto, G.; Tüzel, Y.; Gruda, N. Soilless culture. In Good Agricultural Practices for Greenhouse Vegetable Crops–Principles for Mediterranean Climate Areas; Plant Production and Protection Paper 217; Baudoin, W., Ed.; FAO: Rome, Italy, 2013; pp. 303–354. [Google Scholar]

- Savvas, D.; Gruda, N. Application of soilless culture technologies in the modern greenhouse industry—A review. Eur. J. Hortic. Sci. 2018, 83, 280–293. [Google Scholar] [CrossRef]

- Blok, C.; Urrestarazu, M. Substrate Growing Developments in Europe 2010–2027. Available online: www.horticom.com (accessed on 12 June 2009).

- Nichols, M. Coir: Sustainable Growing Media. 2013. Available online: http://cocopeatcompany.com/report/1475602985.pdf (accessed on 7 June 2018).

- Bussell, W.T.; Mckennie, S. Rockwool in horticulture, and its importance and sustainable use in New Zealand. N. Z. J. Crop Hortic. Sci. 2004, 32, 29–37. [Google Scholar] [CrossRef]

- QUANTIS. Comparative Life Cycle Assessment of Horticultural Growing Media Based on Peat and Other Growing Media Constituents 2012. Available online: http://epagma.eu/evidence-based (accessed on 23 November 2018).

- Apodaca, L.E. Peat (advance release). In Minerals Yearbook 2016; U.S. Department of the Interior: Washington, DC, USA; U.S. Geological Survey: Reston, VA, USA, 2018. [Google Scholar]

- Carlile, W.R.; Cattivello, C.; Zaccheo, P. Organic growing media: Constituents and properties. Vadose Zone J. 2015, 14. [Google Scholar] [CrossRef]

- Gruda, N. Current and future perspective of growing media in Europe. Acta Hortic. 2012, 960, 37–43. [Google Scholar] [CrossRef]

- Barrett, G.E.; Alexander, P.D.; Robinson, J.S.; Bragg, N.C. Achieving environmentally sustainable growing media for soilless plant cultivation systems–A review. Sci. Hortic. 2016, 212, 220–234. [Google Scholar] [CrossRef]

- Kern, J.; Tammeorg, P.; Shanskiy, M.; Sakrabani, R.; Knicker, H.; Kammann, C.; Tuhkanen, E.-M.; Smidt, G.; Prasad, M.; Tiilikkala, K.; et al. Synergistic use of peat and charred material in growing media–an option to reduce the pressure on peatlands? J. Environ. Eng. Landsc. Manag. 2017, 25, 160–174. [Google Scholar] [CrossRef]

- Yu, Z.C.; Loisel, J.; Brosseau, D.P.; Beilman, D.W.; Hunt, S.J. Global peatland dynamics since the last glacial maximum. Geophys. Res. Lett. 2010, 37, L13402. [Google Scholar] [CrossRef]

- Weissert, L.F.; Disney, M. Carbon storage in peatlands: A case study on the Isle of Man. Geoderma 2013, 204, 111–119. [Google Scholar] [CrossRef]

- UNEP. Frontiers 2018/19 Emerging Issues of Environmental Concern; United Nations Environment Programme: Nairobi, Kenya, 2019. [Google Scholar]

- Bonn, A.; Reed, M.S.; Evans, C.D.; Joosten, H.; Bain, C.; Farmer, J.; Emmer, I.; Couwenberg, J.; Moxey, A.; Artz, R. Investing in nature: Developing ecosystem service markets for peatland restoration. Ecosyst. Serv. 2014, 9, 54–65. [Google Scholar] [CrossRef] [Green Version]

- Gruda, N. Sustainable peat alternative growing media. Acta Hortic. 2012, 927, 973–980. [Google Scholar] [CrossRef]

- Chemetova, C.; Fabião, A.; Gominho, J.; Ribeiroa, H. Range analysis of Eucalyptus globulus bark low-temperature hydrothermal treatment to produce a new component for growing media industry. Waste Manag. 2018, 79, 1–7. [Google Scholar] [CrossRef]

- Page, G.; Ridoutt, B.; Bellotti, B. Carbon and water footprint tradeoffs in fresh tomato production. J. Clean. Prod. 2012, 32, 219–226. [Google Scholar] [CrossRef]

- Bojacá, C.R.; Wyckhuys, K.A.G.; Schrevens, E. Life cycle assessment of Colombian greenhouse tomato production based on farmer-level survey data. J. Clean. Prod. 2014, 69, 26–33. [Google Scholar] [CrossRef]

- Dias, G.M.; Ayer, N.W.; Khosla, S.; Van Acker, R.; Young, S.B.; Whitney, S.; Hendricks, P. Life cycle perspectives on the sustainability of Ontario greenhouse tomato production: Benchmarking and improvement opportunities. J. Clean. Prod. 2017, 140, 831–839. [Google Scholar] [CrossRef]

- Antón, A.; Torrellas, M.; Montero, J.I.; Ruijs, M.; Vermeulen, P.; Stanghellini, C. Environmental impact assessment of Dutch tomato crop production in a Venlo glasshouse. Acta Hortic. 2012, 927, 781–791. [Google Scholar] [CrossRef]

- Theurl, M.C.; Hörtenhuber, S.J.; Lindenthal, T.; Palme, W. Unheated soil-grown winter vegetables in Austria: Greenhouse gas emissions and socio-economic factors of diffusion potential. J. Clean. Prod. 2017, 151, 134–144. [Google Scholar] [CrossRef] [Green Version]

- Gruda, N.; Savvas, D.; Colla, G.; Rouphael, Y. Impacts of genetic material and current technologies on product quality of selected greenhouse vegetables–A review. Eur. J. Hortic. Sci. 2018, 83, 319–328. [Google Scholar] [CrossRef]

- Fernández, J.A.; Orsini, F.; Baeza, E.; Oztekin, G.B.; Muñoz, P.; Contreras, J.; Montero, J.I. Current trends in protected cultivation in Mediterranean climates. Eur. J. Hortic. Sci. 2018, 83, 294–305. [Google Scholar] [CrossRef]

- Rouphael, Y.; Kyriacou, M.C. Enhancing quality of fresh vegetables through salinity eustress and biofortification applications facilitated by soilless cultivation. Front. Plant Sci. 2018, 9, 1254. [Google Scholar] [CrossRef]

- Gruda, N. Assessing the impact of environmental factors on the quality of greenhouse produce. In Achieving Sustainable Greenhouse Cultivation; Marcelis, L., Heuvelink, E., Eds.; Burleigh Dodds Science Publishing Limited: Cambridge, UK, 2019; ISBN 978-1-78676-280-1. [Google Scholar]

- Sabatino, L.; D’Anna, F.; D’Anna, F.; Iapichino, G.; Moncada, A.; D’Anna, E.; De Pasquale, C. Interactive effects of genotype and molybdenum supply on yield and overall fruit quality of tomato. Front. Plant Sci. 2019, 9, 1922. [Google Scholar] [CrossRef]

- Sabatino, L.; Ntatsi, G.; Iapichino, G.; D’Anna, F.; De Pasquale, C. Effect of selenium enrichment and type of application on yield, functional quality and mineral composition of curly endive grown in a hydroponic System. Agronomy 2019, 9, 207. [Google Scholar] [CrossRef]

- Mugnozza, G.S.; Russo, G.; De Lucia Zeller, B. LCA methodology application in flower protected cultivation. Acta Hortic. 2007, 761, 625–632. [Google Scholar] [CrossRef]

- Hashida, S.N.; Johkan, M.; Kitazaki, K.; Shoji, K.; Goto, F.; Yoshihara, T. Management of nitrogen fertilizer application, rather than functional gene abundance, governs nitrous oxide fluxes in hydroponics with rockwool. Plant Soil 2014, 374, 715–725. [Google Scholar] [CrossRef]

- Postel, S. Growing more food with less water. Sci. Am. 2001, 284, 46–51. [Google Scholar] [CrossRef]

- Martinez-Mate, M.A.; Martin-Gorriz, B.; Martínez-Alvarez, V.; Soto-García, M.; Maestre-Valero, J.F. Hydroponic system and desalinated seawater as an alternative farm-productive proposal in water scarcity areas: Energy and greenhouse gas emissions analysis of lettuce production in southeast Spain. J. Clean. Prod. 2018, 172, 1298–1310. [Google Scholar] [CrossRef]

- Stoessel, F.; Juraske, R.; Pfister, S.; Hellweg, S. Life cycle inventory and carbon and water food print of fruits and vegetables: Application to a Swiss retailer. Environ. Sci. Technol. 2012, 46, 3253–3262. [Google Scholar] [CrossRef]

- Antón, A.; Montero, J.I.; Muñoz, P.; Castells, F. LCA and tomato production in Mediterranean greenhouses. Gov. Ecol. 2005, 4, 102–112. [Google Scholar] [CrossRef]

- Cellura, M.; Longo, S.; Mistretta, M. Life Cycle Assessment (LCA) of protected crops: An Italian case study. J. Clean. Prod. 2012, 28, 56–62. [Google Scholar] [CrossRef]

- Martínez-Blanco, J.; Muñoz, P.; Anton, A.; Rieradevall, J. Assessment of tomato Mediterranean production in open-field and standard multi-tunnel greenhouse, with compost or mineral fertilizers, from an agricultural and environmental standpoint. J. Clean. Prod. 2011, 19, 985–997. [Google Scholar] [CrossRef]

- Torrellas, M.; Antón, A.; Ruijs, M.; García, N.; Stanghellini, C.; Montero, J.I. Environmental and economic assessment of protected crops in four European scenarios. J. Clean. Prod. 2012, 28, 45–55. [Google Scholar] [CrossRef]

- Webb, J.; Williams, A.G.; Hope, E.; Evans, D.; Moorhouse, E. Do foods imported into the UK have a greater environmental impact than the same foods produced within the UK? Int. J. Life Cycle Assess. 2013, 18, 1325–1343. [Google Scholar] [CrossRef]

- Payen, S.; Basset-Mens, C.; Perret, S. LCA of local and imported tomato: An energy and water trade-off. J. Clean. Prod. 2015, 87, 139–148. [Google Scholar] [CrossRef]

- FAO. 2017. Available online: http//faostat3.fao.org (accessed on 27 May 2019).

- Van Kooten, O.; Heuvelink, E.; Stanghellini, C. Nutrient supply in soilless culture: On-demand strategies. Acta Hortic. 2004, 659, 533–540. [Google Scholar] [CrossRef]

- Ntinas, G.K.; Neumair, M.; Tsadilas, C.D.; Meyer, J. Carbon footprint and cumulative energy demand of greenhouse and open-field tomato cultivation systems under Southern and Central European climatic conditions. J. Clean. Prod. 2017, 142, 3617–3626. [Google Scholar] [CrossRef]

- Neocleous, D.; Savvas, D. NaCl accumulation and macronutrient uptake by a melon crop in a closed hydroponic system in relation to water uptake. Agric. Water Manag. 2016, 165, 22–32. [Google Scholar] [CrossRef]

- Incrocci, L.; Massa, D.; Pardossi, A.; Bacci, L.; Battista, P.; Rapi, B.; Romani, M. A decision support system to optimise fertigation management in greenhouse crops. Acta Hortic. 2012, 927, 115–122. [Google Scholar] [CrossRef]

- Blok, C.; van Os, E.; Daoud, R.; Waked, L.; Hasan, A. Hydroponic Green Farming Initiative: Increasing Water Use Efficiency by Use of Hydroponic Cultivation Methods in Jordan; Report GTB 1447; Wageningen University & Research: Wageningen, The Netherlands; BU Greenhouse Horticulture: Wageningen, The Netherlands, 2017. [Google Scholar]

- Gruda, N.; Tanny, J. Protected crops. In Horticulture: Plants for People and Places; Dixon, G.R., Aldous, D.E., Eds.; Springer: Dordrecht, The Netherlands, 2014; Volume 1, pp. 327–405. [Google Scholar]

- Gruda, N.; Tanny, J. Protected crops–recent advances, innovative technologies and future challenges. Acta Hortic. 2015, 1107, 271–278. [Google Scholar] [CrossRef]

- Rodríguez-Delfín, A.; Gruda, N.; Eigenbrod, C.; Orsini, F.; Gianquinto, G. Soil based and simplified hydroponics rooftop gardens. In Rooftop Urban Agriculture; Orsini, F., Dubbeling, M., de Zeeuw, H., Gianquinto, G., Eds.; Springer International Publishing AG: Berlin/Heidelberg, Germany, 2017; pp. 61–81. ISBN 978-3-319-57719-7. [Google Scholar]

- Raviv, M.; Wallach, R.; Silber, A.; Bar-Tal, A. Substrates and their analysis. In Hydroponic Production of Vegetables and Ornamentals; Savvas, D., Passam, H., Eds.; Embrio publications: Athens, Greece, 2002; pp. 25–102. [Google Scholar]

- Abad, M.; Noguera, P.; Burés, S. National inventory of organic wastes for use as growing media for ornamental potted plant production: Case study in Spain. Bioresour. Technol. 2001, 77, 197–200. [Google Scholar] [CrossRef]

- Zulfiqar, F.; Allaire, S.E.; Akram, N.A.; Méndez, A.; Younis, A.; Peerzada, A.M.; Shaukat, N.; Wright, S.R. Challenges in organic component selection and biochar as an opportunity in potting substrates: A review. J. Plant Nutr. 2019, 24, 1–6. [Google Scholar] [CrossRef]

- Raviv, M. Production of high-quality composts for horticultural purposes: A mini-review. HortTechnology 2005, 15, 52–57. [Google Scholar] [CrossRef]

- Raviv, M.; Medina, S.; Krasnovsky, A.; Ziadna, H. Organic matter and nitrogen conservation in dairy manure composting for organic agriculture. Compost Sci. Util. 2004, 12, 6–10. [Google Scholar] [CrossRef]

- Santos, F.T.; Goufo, P.; Santos, C.; Botelho, D.; Fonseca, J.; Queirós, A.; Costa, M.S.; Trindade, H. Comparison of five agro-industrial waste-based composts as growing media for lettuce: Effect on yield, phenolic compounds and vitamin C. Food Chem. 2016, 209, 293–301. [Google Scholar] [CrossRef] [PubMed]

- Riaz, A.; Younis, A.; Ghani, I.; Tariq, U.; Ahsan, M. Agricultural waste as growing media component for the growth and flowering of Gerbera jamesonii cv. hybrid mix. Int. J. Recycl. Org. Waste Agric. 2015, 4, 197. [Google Scholar] [CrossRef]

- Mattei, P.; Pastorelli, R.; Rami, G.; Mocali, S.; Giagnoni, L.; Gonnelli, C.; Renella, G. Evaluation of dredged sediment co-composted with green waste as plant growing media assessed by eco-toxicological tests, plant growth and microbial community structure. J. Hazard. Mater. 2017, 333, 144–153. [Google Scholar] [CrossRef] [PubMed]

- Suo, L.N.; Sun, X.Y.; Li, S.Y. Use of organic agricultural wastes as growing media for the production of Anthurium andraeanum ‘Pink Lady’. J. Hortic. Sci. Biotechnol. 2011, 86, 366–370. [Google Scholar] [CrossRef]

- Cole, D.M.; Sibley, J.L.; Blythe, E.K.; Eakes, D.J.; Tilt, K.M. Effect of cotton gin compost on substrate properties and growth of azalea under differing irrigation regimes in a greenhouse setting. HortTechnology 2005, 15, 145–148. [Google Scholar] [CrossRef]

- Berecha, G.; Lemessa, F.; Wakjira, M. Exploring the suitability of coffee pulp compost as growth media substitute in greenhouse production. Int. J. Agric. Res. 2011, 6, 255–267. [Google Scholar] [CrossRef]

- El-Mahrouk, M.E.; Yaser Hassan Dewir, Y.H.; El-Hendawy, S. Utilization of Grape Fruit Waste-based Substrates for Seed Germination and Seedling Growth of Lemon Basil. HortTechnology 2017, 27, 523–529. [Google Scholar] [CrossRef] [Green Version]

- Grigatti, M.; Giorgioni, M.E.; Ciavatta, C. Compost-based growing media: Influence on growth and nutrient use of bedding plants. Bioresour. Technol. 2007, 98, 3526–3534. [Google Scholar] [CrossRef] [PubMed]

- Morales-Corts, M.R.; Gómez-Sánchez, M.A.; Pérez-Sánchez, R. Evaluation of green/pruning wastes compost and vermicompost, slumgum compost and their mixes as growing media for horticultural production. Sci. Hortic. 2014, 172, 155–160. [Google Scholar] [CrossRef]

- Aviani, I.; Laor, Y.; Medina, S.; Krassnovsky, A.; Raviv, M. Co-composting of solid and liquid olive mill wastes: Management aspects and the horticultural value of the resulting composts. Bioresour. Technol. 2010, 101, 6699–6706. [Google Scholar] [CrossRef] [PubMed]

- Castaldi, P.; Melis, P. Growth and Yield Characteristics and heavy metal content on tomatoes grown in different growing media. Commun. Soil Sci. Plant 2004, 35, 85–98. [Google Scholar] [CrossRef]

- Mininni, C.; Santamaria, P.; Abdelrahman, H.M.; Cocozza, C.; Miano, T.; Montesano, F.; Parente, A. Posidonia-based compost as a peat substitute for lettuce transplant production. HortScience 2012, 47, 1438–1444. [Google Scholar] [CrossRef]

- Mininni, C.; Bustamante, M.; Medina, E.; Montesano, F.; Paredes, C.; Pérez-Espinosa, A.; Moral, R.; Santamaria, P. Evaluation of posidonia seaweed-based compost as a substrate for melon and tomato seedling production. J. Hortic. Sci. Biotechnol. 2013, 88, 345–351. [Google Scholar] [CrossRef]

- Mininni, C.; Grassi, F.; Traversa, A.; Cocozza, C.; Parente, A.; Miano, T.; Santamaria, P. Posidonia oceanica (L.) based compost as substrate for potted basil production. J. Sci. Food Agric. 2015, 95, 2041–2046. [Google Scholar] [CrossRef] [PubMed]

- Montesano, F.; Gattullo, C.; Parente, A.; Terzano, R.; Renna, M. Cultivation of potted sea fennel, an emerging mediterranean halophyte, using a renewable seaweed-based material as a peat substitute. Agriculture 2018, 8, 96. [Google Scholar] [CrossRef]

- Benito, M.; Masaguer, A.; De Antonio, R.; Moliner, A. Use of pruning waste compost as a component in soilless growing media. Bioresour. Technol. 2005, 96, 597–603. [Google Scholar] [CrossRef] [PubMed]

- Ostos, J.C.; López-Garrido, R.; Murillo, J.M.; López, R. Substitution of peat for municipal solid waste- and sewage sludge-based composts in nursery growing media: Effects on growth and nutrition of the native shrub Pistacia lentiscus L. Bioresour. Technol. 2008, 99, 1793–1800. [Google Scholar] [CrossRef]

- Hernández-Apaolaza, L.; Gascó, AM.; Gascó, JM.; Guerrero, F. Reuse of waste materials as growing media for ornamental plants. Bioresour. Technol. 2005, 96, 125–131. [Google Scholar] [CrossRef]

- Diaz-Perez, M.; Camacho-Ferre, F. Effect of composts in substrates on the growth of tomato transplants. HortTechnology 2010, 20, 361–367. [Google Scholar] [CrossRef]

- Massa, D.; Malorgio, F.; Lazzereschi, S.; Carmassi, G.; Prisa, D.; Burchi, G. Evaluation of two green composts for peat substitution in geranium (Pelargonium zonale L.) cultivation: Effect on plant growth, quality, nutrition, and photosynthesis. Sci. Hortic. 2018, 228, 213–221. [Google Scholar] [CrossRef]

- Maher, M.J.; Prasad, M. The effect of N source on the composting of green waste and its properties as a component of a peat growing medium. In Proceedings of the International Conference Orbit 2001 on Biological Processing of Waste; Spanish Waste Club: Seville, Spain, 2001; pp. 299–306. [Google Scholar]

- Paula, F.S.; Tatti, E.; Abram, F.; Wilson, J.; O’Flaherty, V. Stabilisation of spent mushroom substrate for application as a plant growth-promoting organic amendment. J. Environ. Manag. 2017, 196, 476–486. [Google Scholar] [CrossRef] [PubMed]

- Vandecasteele, B.; Debode, J.; Willekens, K. Recycling of P and K in circular horticulture through compost application in sustainable growing media for fertigated strawberry cultivation. Eur. J. Agron. 2018, 96, 131–145. [Google Scholar] [CrossRef] [Green Version]

- Gong, X.; Li, S.; Sun, X.; Wang, L.; Cai, L.; Zhang, J.; Wei, L. Green waste compost and vermicompost as peat substitutes in growing media for geranium (Pelargonium zonale L.) and calendula (Calendula officinalis L.). Sci. Hortic. 2018, 236, 186–191. [Google Scholar] [CrossRef]

- Garg, V.K.; Suthar, S.; Yadav, A. Management of food industry waste employing vermicomposting technology. Bioresour. Technol. 2012, 126, 437–443. [Google Scholar] [CrossRef] [PubMed]

- Lazcano, C.; Gómez-Brandón, M.; Domínguez, J. Comparison of the effectiveness of composting and vermicomposting for the biological stabilization of cattle manure. Chemosphere 2008, 72, 1013–1019. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.M.; Zhang, Y.M.; Lian, J.J.; Chao, J.Y.; Gao, Y.X.; Yang, F.; Zhang, L.Y. Impact of fly ash and phosphatic rock on metal stabilization and bioavailability during sewage sludge vermicomposting. Bioresour. Technol. 2013, 136, 281–287. [Google Scholar] [CrossRef]

- Robbins, J.A.; Evans, M.R. Growing media for container production in a greenhouse or nursery. Part I (Components and Mixes). Greenhouse and Nursery Series. 2011. Available online: https://https://www.uaex.edu/publications/PDF/FSA-6097.pdf (accessed on 8 November 2018).

- Gruda, N.; Qaryouti, M.M.; Leonardi, C. Growing media. In Good Agricultural Practices for Greenhouse Vegetable Crops–Principles for Mediterranean Climate Areas; Plant Production and Protection Paper 217; FAO: Rome, Italy, 2013; pp. 271–302. [Google Scholar]

- Prasad, M. Physical, chemical and biological properties of coir dust. Acta Hortic. 1997, 450, 21–30. [Google Scholar] [CrossRef]

- Noguera, P.; Abad, M.; Noguera, V.; Puchades, R.; Maquieira, A. Coconut coir waste, a new and viable ecologically-friendly peat substitute. Acta Hortic. 2000, 517, 279–286. [Google Scholar] [CrossRef]

- Gruda, N.; Schnitzler, W.H. The effect of water supply on bio-morphological and plant-physiological parameters of tomato transplants cultivated in wood fiber substrate. J. Appl. Bot. Food Qual. 2000, 74, 233–239. (In German) [Google Scholar]

- Gruda, N.; Schnitzler, W.H. The effect of water supply of seedlings, cultivated in different substrates and raising systems on the bio-morphological and plant-physiological parameters of lettuce. J. Appl. Bot. Food Qual. 2000, 74, 240–247. [Google Scholar]

- Gruda, N.; Schnitzler, W.H. Suitability of wood fiber substrates for production of vegetable transplants. I. Physical properties of wood fiber substrates. Sci. Hortic. 2004, 100, 309–322. [Google Scholar] [CrossRef]

- Jackson, B.E.; Wright, R.D.; Gruda, N. Container medium pH in a pine tree substrate amended with peat moss and dolomitic limestone affects plant growth. Hortscience 2009, 44, 1983–1987. [Google Scholar] [CrossRef]

- Prasad, M.; Chualáin, D.N. Relationship between particle size and air space of growing media. Acta Hortic. 2004, 648, 161–166. [Google Scholar] [CrossRef]

- Maher, M.J.; Thomson, D. Growth and Mn content of tomato (Lycopersicon esculentum) seedlings grown in Sitka spruce (Picea sitchensis (Bong.) Carr.) bark substrate. Sci. Hortic. 1991, 48, 223–231. [Google Scholar] [CrossRef]

- Gruda, N.; Rau, B.J.; Wright, R.D. Laboratory Bioassay and Greenhouse Evaluation of a Pine Tree Substrate Used as a Container Substrate. Eur. J. Hortic. Sci. 2009, 74, 73–78. [Google Scholar]

- Gruda, N.; Schnitzler, W.H. Suitability of wood fiber substrates for production of vegetable transplants II. The effect of wood fiber substrates and their volume weights on the growth of tomato transplants. Sci. Hortic. 2004, 100, 333–340. [Google Scholar] [CrossRef]

- Gruda, N.; Schnitzler, W.H. Wood fibers as a peat alternative substrate for vegetable production. Eur. J. Wood Wood Prod. 2006, 64, 347–350. [Google Scholar] [CrossRef]

- Jackson, B.E. Substrates on Trial. Nursery Management 10. 2018. Available online: www.nurserymag.com/article/wood-fiber-substrates-trials (accessed on 8 November 2018).

- Gruda, N. The effect of wood fiber mulch on water retention, soil temperature and growth of vegetable plants. J. Sustain. Agric. 2008, 32, 629–643. [Google Scholar] [CrossRef]

- Gruda, N. Weed suppression in vegetable crops using wood fibre mulch. Rep. Agric. 2007, 85, 329–334. (In German) [Google Scholar]

- Neumaier, D.; Lohr, D.; Voßeler, R.; Girmann, S.; Kolbinger, S.; Meinken, E. Hydrochars as peat substitute in growing media for organically grown potted herbs. Acta Hortic. 2017, 1168, 377–386. [Google Scholar] [CrossRef]

- Tsakaldimi, M. Kenaf (Hibiscus cannabinus L.) core and rice hulls as components of container media for growing Pinus halepensis M. seedlings. Bioresour. Technol. 2006, 97, 1631–1639. [Google Scholar] [CrossRef] [PubMed]

- Gómez, C.; Robbins, J. Pine bark substrates amended with parboiled rice hulls: Physical properties and growth of container-grown Spirea during long-term nursery production. HortScience 2011, 46, 784–790. [Google Scholar] [CrossRef]

- Bonaguro, J.E.; Coletto, L.; Zanin, G. Environmental and agronomic performance of fresh rice hulls used as growing medium component for Cyclamen persicum L. pot plants. J. Clean. Prod. 2017, 142, 2125–2132. [Google Scholar] [CrossRef]

- Urrestarazu, M.; Martínez, G.A.; del Carmen Salas, M. Almond shell waste: Possible local rockwool substitute in soilless crop culture. Sci. Hortic. 2005, 103, 453–460. [Google Scholar] [CrossRef]

- Arvanitoyannis, I.S.; Varzakas, T.H. Vegetable waste treatment: Comparison and critical presentation of methodologies. Crit. Rev. Food Sci. Nutr. 2008, 48, 205–247. [Google Scholar] [CrossRef]

- Valverde, M.; Madrid, R.; García, A.L.; del Amor, F.M.; Rincón, L.F. Use of almond shell and almond hull as substrates for sweet pepper cultivation. Effects of fruit yield and mineral content. Span. J. Agric. Res. 2013, 11, 164–172. [Google Scholar] [CrossRef]

- Özçelik, E.; Pekşen, A. Hazelnut husk as a substrate for the cultivation of shiitake mushroom (Lentinula edodes). Bioresour. Technol. 2007, 98, 2652–2658. [Google Scholar] [CrossRef]

- Dede, O.H.; Ozdemir, S. Development of nutrient-rich growing media with hazelnut husk and municipal sewage sludge. Environ. Technol. 2018, 39, 2223–2230. [Google Scholar] [CrossRef]

- Dede, O.H.; Dede, G.; Ozdemir, S.; Abad, M. Physicochemical characterization of hazelnut husk residues with different decomposition degrees for soilless growing media preparation. J. Plant Nutr. 2011, 34, 1973–1984. [Google Scholar] [CrossRef]

- Chrysargyris, A.; Stavrinides, M.; Moustakas, K.; Tzortzakis, N. Utilization of paper waste as growing media for potted ornamental plants. Clean Technol. Environ. Policy 2018. [Google Scholar] [CrossRef]

- Pouliot, R.; Hugron, S.; Rochefort, L. Sphagnum farming: A long-term study on producing peat moss biomass sustainably. Ecol. Eng. 2015, 74, 135–147. [Google Scholar] [CrossRef]

- Gaudig, G.; Fengler, F.; Krebs, M.; Prager, A.; Schulz, J.; Wichmann, S.; Joosten, H. Sphagnum farming in Germany–a review of progress. Mires Peat 2014, 13, 1–11. [Google Scholar]

- Kraska, T.; Kleinschmidt, B.; Weinand, J.; Pude, R. Cascading use of Miscanthus as growing substrate in soilless cultivation of vegetables (tomatoes, cucumbers) and subsequent direct combustion. Sci. Hortic. 2018, 235, 205–213. [Google Scholar] [CrossRef]

- Altland, J.E.; Krause, C. Use of switchgrass as a nursery container substrate. HortScience 2009, 44, 1861–1865. [Google Scholar] [CrossRef]

- Altland, J. Use of processed biofuel crops for nursery substrates. J. Environ. Hortic. 2010, 28, 129–134. [Google Scholar]

- Andreu-Rodriguez, J.; Medina, E.; Ferrandez-Garcia, M.T.; Ferrandez-Villena, M.; Ferrandez-Garcia, C.E.; Paredes, C.; Bustamante, M.A.; Moreno-Caselles, J. Agricultural and industrial valorization of Arundo donax L. Commun. Soil Sci. Plant Anal. 2013, 44, 598–609. [Google Scholar] [CrossRef]

- Kuisma, E.; Palonen, P.; Yli-Hallab, M. Reed canary grass straw as a substrate in soilless cultivation of strawberry. Sci. Hortic. 2014, 178, 217–223. [Google Scholar] [CrossRef]

- Köbbing, J.; Rehme, J.; Röse, D. Identify and evaluate emissions with a carbon footprint. Gemüse 2018, 5, 26–27. (In German) [Google Scholar]

- Martínez-Blanco, J.; Lazcano, C.; Christensen, T.H.; Muñoz, P.; Rieradevall, J.; Møller, J.; Antón, A.; Boldrin, A. Compost benefits for agriculture evaluated by life cycle assessment. A review. Agron. Sustain. Dev. 2013, 33, 721–732. [Google Scholar] [CrossRef] [Green Version]

- Alexander, P.D.; Bragg, N.C. Defining Sustainable Growing Media for Sustainable UK Horticulture. Acta Hortic. 2014, 1034, 219–225. [Google Scholar] [CrossRef]

- Knight, A. Towards Sustainable Growing Media. Chairman’s Report and Roadmap, Sustainable Growing Media Task Force; 2012. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/221019/pb13867-towards-sustainable-growing-media.pdf (accessed on 8 November 2018).

- Köbbing, J.; Rehme, J.; Röse, D. Ways to reduce the emissions: Klimabilanz für Gartenbaubetrieb und Pflanze, Teil 3. Gemüse 2018, 7, 20–21. (In German) [Google Scholar]

- Levesque, V.; Rochette, P.; Ziadi, N.; Dorais, M.; Antoun, H. Mitigation of CO2, CH4 and N2O from a fertigated horticultural growing medium amended with biochars and a compost. Appl. Soil Ecol. 2018, 126, 129–139. [Google Scholar] [CrossRef]

- Ilahi, W.F.F.; Ahmad, D. A study on the physical and hydraulic characteristics of cocopeat perlite mixture as a growing media in containerized plant production. Sains Malays. 2017, 46, 975–980. [Google Scholar] [CrossRef]

- Allaire, S.E.; Caron, J.; Menard, C.; Dorais, M. Potential replacements for rockwool as growing substrate for greenhouse tomato. Can. J. Soil Sci. 2005, 85, 67–74. [Google Scholar] [CrossRef]

- Cantliffe, D.J.; Shaw, N.L.; Saha, S.K.; Gruda, N. Greenhouse cooling for production of peppers under hot-humid summer conditions in a high-roof passively-ventilated greenhouse. Acta Hortic. 2007, 761, 41–48. [Google Scholar] [CrossRef]

- Rodriguez, J.C.; Cantliffe, D.J.; Shaw, N.L.; Karchi, Z. Soilless media and containers for greenhouse production of ‘Galia’ type muskmelon. HortScience 2006, 41, 1200–1205. [Google Scholar] [CrossRef]

- Shaw, N.L.; Cantliffe, D.J.; Funes, J.; Shine, C. Successful beit alpha cucumber production in the greenhouse using pine bark as an alternative soilless media. HortTechnology 2004, 14, 289–294. [Google Scholar] [CrossRef]

- Owen, J.S., Jr.; Warren, S.L.; Bilderback, T.E.; Cassel, D.K.; Albano, J.P. Physical properties of pine bark 938 substrate amended with industrial mineral aggregate. Acta Hortic. 2008, 779, 131–138. [Google Scholar] [CrossRef]

- Schnitzler, W.H.; Michalsky, F.; Gruda, N. Wood fibre substrate for cucumber in greenhouse cultivation. In Proceedings of the 9th International Congress on Soilless Culture, Saint Helier, Jersey, 12–19 April 1997; pp. 453–463. [Google Scholar]

- Depardieu, C.; Prémont, V.; Boily, C.; Caron, J. Sawdust and bark-based substrates for soilless strawberry production: Irrigation and electrical conductivity management. PLoS ONE 2016, 11, e0154104. [Google Scholar] [CrossRef]

- Gruda, N.; Tucher, S.V.; Schnitzler, W.H. N-immobilization of wood fiber substrates in the production of tomato transplants (Lycopersicon lycopersicum (L.) Karst. Ex. Farw.). J. Appl. Bot. Food Qual. 2000, 74, 32–37. (In German) [Google Scholar]

- Álvarez, J.M.; Pasian, C.; Lal, R.; López, R.; Díaz, M.J.; Fernández, M. Morpho-physiological plant quality when biochar and vermicompost are used as growing media replacement in urban horticulture. Urban. For. Urban Green. 2018, 34, 175–180. [Google Scholar] [CrossRef]

- Tian, Y.; Sun, X.; Li, S.; Wang, H.; Wang, L.; Cao, J.; Zhang, L. Biochar made from green waste as peat substitute in growth media for Calathea rotundifola cv. Fasciata. Sci. Hortic. 2012, 143, 15–18. [Google Scholar] [CrossRef]

- Conversa, G.; Bonasia, A.; Lazzizera, C.; Elia, A. Influence of biochar, mycorrhizal inoculation, and fertilizer rate on growth and flowering of Pelargonium (Pelargonium zonale L.) plants. Front. Plant Sci. 2015, 6, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Méndez, A.; Paz-Ferreiro, J.; Gil, E. The effect of paper sludge and biochar addition on brown peat and coir based growing media properties. Sci. Hortic. 2015, 193, 225–230. [Google Scholar] [CrossRef]

- Méndez, A.; Cárdenas-Aguiar, E.; Paz-Ferreiro, J.; Plaza, C.; Gascó, G. The effect of sewage sludge biochar on peat-based growing media. Biol. Agric. Hortic. 2017, 33, 40–51. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, K.R.; Yang, J.E.; Ok, Y.S.; Kim, W.; Kunhikrishnan, A.; Kim, K.-H. Amelioration of horticultural growing media properties through rice hull biochar incorporation. Waste Biomass Valorization 2017, 8, 483–492. [Google Scholar] [CrossRef]

- Emmel, M. Growing ornamental plants in Sphagnum biomass. Acta Hortic. 2008, 779, 173–178. [Google Scholar] [CrossRef]

- Jobin, P.; Caron, J.; Rochefort, L. Developing new potting mixes with Sphagnum fibers. Can. J. Soil Sci. 2014, 94, 585–593. [Google Scholar] [CrossRef]

- The ‘Reduce, Reuse, Recycle’ Waste Hierarchy. Available online: https://www.conserve-energy-future.com/reduce-reuse-recycle.php (accessed on 16 March 2019).

- Gruda, N.; Schnitzler, W.H. Alternative growing systems for head lettuce. Rep. Agric. 2006, 84, 469–484. [Google Scholar]

- Truffault, V.; Ristorto, M.; Brajeul, E.; Vercambre, G.; Gautier, H. To stop nitrogen overdose in soilless tomato crop: A way to promote fruit quality without affecting fruit yield. Agronomy 2019, 9, 80. [Google Scholar] [CrossRef]

- Stanghellini, C.; Montero, J.I. Resource use efficiency in protected cultivation: Towards the greenhouse with zero emissions. Acta Hortic. 2012, 927, 91–100. [Google Scholar] [CrossRef]

- Incrocci, L.; Pardossi, A.; Malorgio, F.; Maggini, R.; Campiotti, C.A. Cascade cropping systems for greenhouse soilless culture. Acta Hortic. 2003, 609, 297–300. [Google Scholar] [CrossRef]

- Muñoz, P.; Paranjpe, A.; Montero, J.I.; Antón, A. Cascade crops: An alternative solution for increasing sustainability of greenhouse tomato crops in Mediterranean zone. Acta Hortic. 2012, 927, 801–805. [Google Scholar] [CrossRef]

- Choi, B.; Lee, S.S.; Ok, Y.S. Effects of waste nutrient solution on growth of Chinese cabbage (Brassica campestris L.). Korean J. Environ. Agric. 2011, 30, 125–131. (In Korea) [Google Scholar] [CrossRef]

- Zhang, C.H.; Kang, H.M.; Kim, I.S. Effect of using waste nutrient solution fertigation on the musk melon and cucumber growth. J. Bioenviron. Control 2006, 15, 400–405. [Google Scholar]

- Kim, J.H.; Kim, T.J.; Kim, H.H.; Lee, H.D.; Lee, J.W.; Lee, C.H.; Paek, K.Y. Growth and development of ‘Gutbier V-10 Amy’ poinsettia (Euphorbia pulcherrima Willd.) as affected by application of waste nutrient solution. Korean J. Hortic. Sci. Technol. 2000, 18, 518–522. [Google Scholar]

- EU (The European Parliament and The Council of the European Communities). Directive (EU) 2018/851 the European Parliament and the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste. Off. J. Eur. Union 2018, L150, 109–140. [Google Scholar]

- Fonteno, W.C.; Cassel, D.K.; Larson, R.A. Physical properties of three container media and their effect on poinsettia growth. J. Am. Soc. Hortic. Sci. 1981, 106, 736–741. [Google Scholar]

- Gruda, N.; Schnitzler, W.H. Determination of volume weight and water content of wood fiber substrates with different methods. Agribiol. Res. 1999, 53, 163–170. [Google Scholar]

- Xing, J.; Gruda, N.; Xiong, J.; Liu, W. Influence of organic substrates on nutrient accumulation and proteome changes in tomato-roots. Sci. Hortic. 2019, 252, 192–200. [Google Scholar] [CrossRef]

- Diara, C.; Incrocci, L.; Pardossi, A.; Minuto, A. Reusing Greenhouse Growing Media. Acta Hortic. 2012, 927, 793–800. [Google Scholar] [CrossRef]

- Hanna, H.Y. Properly recycled perlite saves money, does nor reduce greenhouse tomato yield and can be re-used for many years. HortTechnology 2005, 15, 342–345. [Google Scholar] [CrossRef]

- Baum, C.; El-Tohamy, W.; Gruda, N. Increasing the productivity and product quality of vegetable crops using arbuscular mycorrhizal fungi: A review. Sci. Hortic. 2015, 187, 131–141. [Google Scholar] [CrossRef]

- Nambuthiri, S.; Fulcher, A.; Koeser, A.K.; Geneve, R.; Niu, G. Moving toward sustainability with alternative containers for greenhouse and nursery crop production: A review and research update. HortTechnology 2015, 25, 8–16. [Google Scholar] [CrossRef]

- Colla, G.; Nardi, S.; Cardarelli, M.; Ertani, A.; Lucini, L.; Canaguier, R.; Rouphael, Y. Protein hydrolysates as biostimulants in horticulture. Sci. Hortic. 2015, 196, 28–38. [Google Scholar] [CrossRef]

| Feedstock Waste | Use as Growing Medium for Plant Production | Reference(s) |

|---|---|---|

| Animal manures | Pot plant production, landscape nurseries, vegetables, and cut flowers production | [67] |

| Broccoli plants | Lettuce | [68] |

| Chestnut plants | Lettuce | [68] |

| Coconut coir dust | Gerbera | [69] |

| Dredged sediment co-composted with green waste | Ornamental plants | [70] |

| Corn cobs | Anthurium | [71] |

| Cotton gin | Azalea | [72] |

| Coffee pulp | Tomato seedling | [73] |

| Farm yard manure | Gerbera | [69] |

| Grape fruit with coir or vermiculite | Seedlings of lemon basil | [74] |

| Grapes | Lettuce | [68] |

| Green waste and sewage sludge | Ornamental bedding plant | [75] |

| Green/pruning; green/pruning wastes compost, vermicompost, and slumgum compost | Rosemary, Leyland cypress, lettuce, onion, petunia, and pansy | [76] |

| Olive mill 1, olive 2 | Melon, cress, and tomato plants 1; lettuces 2 | [77] 1, [68] 2 |

| Plant leaves | Gerbera | [69] |

| Posidonia residues | Tomato 1, lettuce seedlings 2, melon, and tomato seedlings 3, pot basil 4, pot sea fennel 5 | [78] 1,[79] 2,[80] 3,[81] 4,[82] 5 |

| Pruning wastes; pruning waste and municipal solid, or sewage sludge | Ryegrass and cypress 1, Pistacia (nursery) 2 | [83]1, [84]2 |

| Sewage sludge | Ornamental conifer plants | [84] |

| Slumgum compost | Rosemary, Leyland cypress, lettuce, onion, petunia, and pansy | [76] |

| Spent mushroom | Ryegrass and cypress | [85] |

| Urban solid wastes | Tomato transplant | [86] |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gruda, N.S. Increasing Sustainability of Growing Media Constituents and Stand-Alone Substrates in Soilless Culture Systems. Agronomy 2019, 9, 298. https://0-doi-org.brum.beds.ac.uk/10.3390/agronomy9060298

Gruda NS. Increasing Sustainability of Growing Media Constituents and Stand-Alone Substrates in Soilless Culture Systems. Agronomy. 2019; 9(6):298. https://0-doi-org.brum.beds.ac.uk/10.3390/agronomy9060298

Chicago/Turabian StyleGruda, Nazim S. 2019. "Increasing Sustainability of Growing Media Constituents and Stand-Alone Substrates in Soilless Culture Systems" Agronomy 9, no. 6: 298. https://0-doi-org.brum.beds.ac.uk/10.3390/agronomy9060298